Summary: Casting is a process by which a material is introduced into a mold while it is liquid, allowed to solidify in the shape inside the mold, and then removed producing a fabricated object, part, or casing.

Casting is often used for creating one or more copies of an original piece of sculptural (three-dimensional) artwork. It is also used extensively in the automobile manufacture industry, such as the casting of engine blocks or cylinder heads, or vacuum-forming of plastics and in the lost core process.

The process, particularly when performed with molten metals, is also called founding.

Casting may be used to form hot, liquid metals or meltable plastics (called thermoplastics), or various materials that cold set after mixing of components such as certain plastic resins (e.g. epoxy), water setting materials such as concrete or plaster, and materials that become liquid or paste when moist such as clay, which when dry enough to be rigid is removed from the mold, further dried, and fired in a kiln.

Substitution is always a factor in deciding whether other techniques should be used instead of casting. Alternatives include parts that can be stamped out on a punch press or deep-drawn, items that can be manufactured by extrusion or by cold-bending, and parts that can be made from highly active metals.

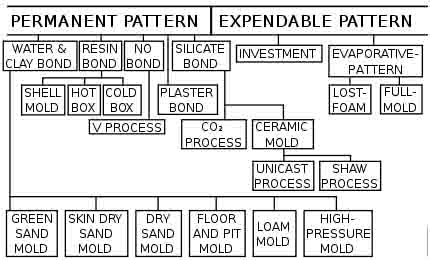

The metal casting process is subdivided into two distinct subgroups, non-expendable and expendable mold casting.

Expendable mold casting is a generic classification that includes sand, plastic, shell, and investment (lost-wax technique) moldings.

All of these involve the use of temporary and non-reusable molds, and need gravity to help force molten fluid into casting cavities. In this process the mold is used only once.

Expendable Mold Casting Processes Uses Non-reusable Temporary Metal Casting Molds

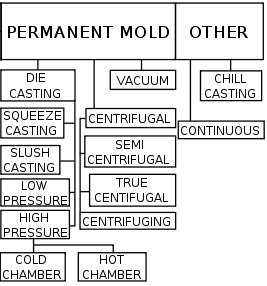

Non-expendable mold casting differs from expendable processes in that the mold need not be reformed after each production cycle. This technique includes at least four different methods: permanent, die, centrifugal, and continuous casting.

Many of the metal casting methods are described below.

Recent Metal Casting History

Modern mass production metal casting methods can produce thin but accurate molds—superficially resembling paper mache, such as is used in egg cartons, but that is refractory in nature—that are then supported by some means—such as dry sand surrounded by a box—during the casting process.

Due to the higher accuracy it is possible to make thinner and hence lighter castings—extra metal does not have to be present to allow for variations in the molds—these thin-mold casting methods have been used since the 1960s in the manufacture of cast-iron engine blocks and cylinder heads for automotive applications.

Various automotive mechanical components are now frequently made of aluminum, which for appropriately shaped components may be made either by sand casting or by die casting, the latter an accurate process that greatly reduces finishing and machining costs.

While the material and the processing setup is more expensive than the use of iron this is one of the most straightforward ways to reduce weight in a vehicle, important as a contributor to both fuel economy and acceleration performance.

Lost Foam Process

Starting in the early 1980s, some metal castings such as automotive engine blocks have been made using a sand casting technique conceptually similar to the lost wax process, known as the lost foam process.

In this process, the pattern is made of polystyrene foam, which the sand is packed around, leaving the foam in place. When the metal is poured into the mold, the heat of the metal vaporizes the foam a short distance away from the surface of the metal, leaving the molding cavity into which the metal flows.

The lost-foam process supports the sand much better than conventional sand casting, allowing greater flexibility in the design of the cast parts, with less need for machining to finish the casting.

This technique was developed for the clay mold casting of abstract art pieces and was first adopted for large quantity commercial production by the Saturn company.

Unfortunately, this process burns plastic in an uncontrolled way, producing a great deal of smoke.

Lost Foam Process Video Demonstration

Metal Casting At Home and Supplies

There are several kits available that will give hobbyists a head start in enjoying metal casting at home. A good place to start a search is Ebay which has multiple sellers offering kits and supplies.

Amazon has a more limited offering, but is worth a quick look.

Lost Wax Casting Process

The Lost Wax metal casting process is an ancient practice that is still in widespread use today. The process varies from foundry to foundry, but the steps which are usually used in casting small bronze sculptures in a modern bronze foundry are as follows:

- Sculpting: An artist creates an original artwork from wax, clay, or another material. Wax and oil-based clay are often preferred because these materials retain their softness.

- Mold Making: A mold is made of the original sculpture. Most molds are at least two pieces, and a shim with keys is placed between the two halves during construction so that the mould can be put back together accurately. Most moulds of small sculptures are made from plaster, but can also be made of fiberglass or other materials.To preserve the fine details on the original artwork’s surface, there is usually an inner mold made of latex or vinyl, which is supported by the plaster part of the mold. Usually, the original artwork is destroyed during the making and initial deconstruction of the plaster mold. This is because the originals are solid, and do not easily bend as the plaster mold is removed.Often long, thin pieces are cut off of the original and molded separately. Sometimes, especially in the case of large original (such as life-size) sculptures, many molds are needed to recreate the original sculpture.

- Wax: Once the plaster and latex mold is finished, molten wax is poured into it and swished around until an even coating, usually about 1/4 inches thick, covers the entire inner surface of the mold. This may be done in several layers.

- Removal of wax: This new, hollow wax copy of the original artwork is removed from the mold. The artist may reuse the mold to make more wax copies but wear and tear on the mold limit their number. For small bronze artworks, a common number of copies today is around 25.

- Chasing: Each hollow wax copy is then “chased”: a heated metal tool is used to rub out all the marks which show the “parting line” or “flashing” where the pieces of the mold came together. Wax pieces that were molded separately can be heated and attached; foundries often use “registration marks” to indicate exactly where they go.

- Spruing: Once the wax copy looks just like the original artwork, it is “sprued” with a treelike structure of wax that will eventually provide paths for molten bronze to flow. The carefully-planned spruing usually begins at the top with a wax “cup,” which is attached by wax cylinders to various points on the wax copy.

- Slurry: A “sprued” wax copy is dipped into a ceramic slurry, then into a mixture of powdered clay and sand. This is allowed to dry, and the process is repeated until a half-inch thick or thicker surface covers the entire piece. Only the inside of the cup is not coated, and the cup’s flat top serves as the base upon which the piece stands during this process.

- Burnout: The ceramic-coated piece is placed cup-down in a kiln, whose heat hardens the ceramic coatings into a shell, and the wax melts and runs out. The melted wax can be recovered and reused, although often it is simply combusted by the burnout process. Now all that remains of the original artwork is the negative space, formerly occupied by the wax, inside the hardened ceramic shell. The feeder and vent tubes and cup are now hollow, also.

- Testing: The ceramic shell is allowed to cool, then is tested to see if water will flow through the feeder and vent tubes as necessary. Cracks or leaks can be patched with thick ceramic paste. To test the thickness, holes can be drilled into the shell, then patched.

- Pouring: The shell is reheated in the kiln to harden the patches, then placed cup-upwards into a tub filled with sand. Bronze is melted in a crucible in a furnace, then poured carefully into the shell. If the shell were not hot, the temperature difference would shatter it. The bronze-filled shells are allowed to cool.

- Release: The shell is hammered or sand-blasted away, releasing the rough bronze. The spruing, which are also faithfully recreated in metal, are cut off, to be reused in another casting.

- Metal-chasing: Just as the wax copies were “chased,” the bronze copies are worked until the telltale signs of casting are removed, and the sculptures again look like the original artwork. Pits left by air bubbles in the molten bronze are filled, and the stubs of spruing filed down and polished.

- Patinating: The bronze is colored to the artist’s preference, using chemicals applied to heated or cooled metal. This coloring is called patina and is often green, black, white or brownish to simulate the surfaces of ancient bronze sculptures. (Ancient bronzes gained their patinas from oxidation and other effects of being on Earth for many years.) However, many artists prefer that their bronzes have brighter, paint-like colors.

Patinas are generally less opaque than paint, which allows the luster of the metal to show through. After the patina is applied, a coating of wax is usually applied to protect the surface. Some patinas change color over time because of oxidation, and the wax layer slows this down somewhat.

Sculpture by:David Ascalon

The lost-wax metal casting process can also be used with any material that can burn, melt, or evaporate to leave a mold cavity. Some automobile manufacturers use a lost-foam technique to make engine blocks.

The model in this case is made of polystyrene foam, which is then placed into a casting flask, consisting of a cope and drag, which is then filled with casting sand.

The foam supports the sand, allowing shapes to be made which would not be possible if the process had to rely on the sand alone to hold its shape.

The metal is then poured in, and the heat of the metal vaporizes the foam as the metal enters the mold.

Sand Casting

Sand-casting is mainly used for casting flat, relief-like sculptures.

Aluminum is one material which is commonly used in sand-casting.

- The process starts with a tub filled with sand.

- The sand is wetted, and an object is pressed into the wet sand, or the sculptor uses his hands or tools to make the desired design in the sand, which is then dried.

- Molten aluminum is carefully poured into the depression and left to cool.

- Then the artist may choose to continue refining the object by “chasing” it or leave it with the roughened surface that is characteristic of sand-cast objects.

In manufacturing, sand casting is used to produce rough metal castings that are refined by one or more of these processes:

- Machining

- Machine grinding

- Rough grinding

- Plating

- Forging

- Polishing

- Shot peening

- Hammer peening

Sand castings not further worked by peening or polishing are readily recognized by the sand-like texture imparted by the mold.

As the accuracy of the casting is limited by imperfections in the mold making process there will be extra material to be removed by grinding or machining, more than is required by other more accurate metal casting processes.

Sand Casting Process Video

Patterns

From the design, provided by an engineer or designer, a craftsperson called a pattern maker produces a master of the object to be produced, often using wood.

As the metal to be cast will shrink somewhat between the time it first solidifies and the time it is cool the master must be made slightly larger than the finished product.

To simplify the making of the pattern the pattern maker will use an appropriately scaled oversize ruler—called a shrink rule—specific to the type of metal to be cast. Additional paths for the entrance of metal—the sprue —and the exiting of gas—the riser —are added to the pattern.

Molding and Box Materials

A multi-part molding box (known as a casting flask, sometimes referred to as the cope and drag) is prepared to receive the pattern.

Molding boxes are made in segments that may be latched to each other and to end closures.

For a simple object—flat on one side—the lower portion of the box, closed at the bottom, will be filled with prepared casting sand or green sand—a slightly moist mixture of sand and clay.

The sand is packed in through a vibratory process called ramming and, in this case, periodically screeded level. The surface of the sand may then be stabilized with a sizing compound. The pattern is placed on the sand and another molding box segment is added. Additional sand is rammed over and around the pattern.

Finally a cover is placed on the box and it is turned and unlatched, so that the halves of the mold may be parted and the pattern with its sprue and vent patterns removed.

Additional sizing may be added and any defects introduced by the removal of the pattern are corrected.

The box is closed again. This forms a “green” mold which must be dried to receive the hot metal.

If the mold is not sufficiently dried a steam explosion can occur that can throw molten metal about.

In some cases, the sand may be oiled instead of moistened, which makes possible casting without waiting for the sand to dry.

Sand may also be bonded by chemical binders, such as furane resins or amine-hardened resins.

Chills

If it is desired to have most of the—iron or steel—casting in a tough, ductile, state but with a few surfaces hard, it is possible to introduce, into the mold, metal plates—chills—where the metal is to be hardened.

The associated, local, rapid, cooling will form a finer-grained and harder metal at these locations. The inner diameter of an engine cylinder is made hard by a chilling core.

Cores

To produce cavities within the casting—such as for liquid cooling in engine blocks and cylinder heads —negative forms are used to produce cores.

Usually sand-molded, cores are inserted into the casting box after removal of the pattern.

Whenever possible, designs are made that avoid the use of cores, due to the additional set-up time and thus greater cost.

With a completed mold at the appropriate moisture content, the box containing the sand mold is then positioned for filling with molten metal—typically:

- Zinc

- Tin

- Lead

- Pot metal alloys

- Aluminum alloy

- Brass

- Bronze

- Steel

- Iron

After filling with liquid metal the box is set aside until the metal is sufficiently cool to be strong.

The sand is then removed revealing a rough casting that, in the case of iron or steel, may still be glowing red.

When casting with metals like iron or lead, which are significantly heavier than the casting sand, the casting flask is often covered with a heavy plate to prevent a problem known as floating the mold. Floating the mold occurs when the pressure of the metal pushes the sand above the mold cavity out of shape, causing the casting to fail.

After casting, the cores are broken up by rods or shot and removed from the casting. The metal from the sprue and risers is cut from the rough casting.

Various heat treatments may be applied to relieve stresses from the initial cooling and to add hardness—in the case of steel or iron, by quenching in water or oil.

The casting may be further strengthened by surface compression treatment—like shot peening —that adds resistance to tensile cracking and smooths the rough surface.

Design Requirements

The part to be made and its pattern must be designed to accommodate each stage of the process, as it must be possible to remove the pattern without disturbing the molding sand and to have proper locations to receive and position the cores. A slight taper, known as draft, must be used on surfaces perpendicular to the parting line, in order to be able to remove the pattern from the mold. This requirement also applies to cores, as they must be removed from the core box in which they are formed.

The sprue and risers must be arranged to allow a proper flow of metal and gasses within the mold in order to avoid an incomplete casting. Should a piece of core or mold become dislodged it may be embedded in the final casting, forming a sand pit, which may render the casting unusable.

Gas pockets can cause internal voids. These may be immediately visible or may only be revealed after extensive machining has been performed.

For critical applications, or where the cost of wasted effort is a factor, non-destructive testing methods may be applied before further work is performed.

Decorative Use of Patterns

Old wood-patterns, once used to make molds for casting machine parts, are sought out and collected by some for use as interior decorations.

Cuttlefish Casting

Cuttlefish casting using cuttlebone as a mold is a traditional casting method used by jewelers and silversmiths for small objects, especially in taking a copy from a metal original.

The fine grain of the calcium carbonate cuttlebone offers good definition, although it imparts a characteristic surface texture to the cast.

Plaster Casting

Plaster casting is similar to sand molding except that plaster is substituted for sand.

Plaster compound is actually composed of 70-80% gypsum and 20-30% strengthener and water.

Generally, the form takes less than a week to prepare, after which a production rate of 1-10 units/hr-mold is achieved with a capability to pour items as massive as 45 kg and as small as 30 g with very high surface resolution and fine tolerances.

Once used and cracked away, normal plaster cannot easily be recast. Plaster casting is normally used for nonferrous metals such as:

- copper-based alloys

- zinc

- aluminum

It cannot be used to cast ferrous material because sulfur in gypsum slowly reacts with iron.

Prior to mold preparation the pattern is sprayed with a thin film of parting compound to prevent the mold from sticking to the pattern.

The unit is shaken so plaster fills the small cavities around the pattern. The form is removed after the plaster sets.

Plaster casting represents a step up in sophistication and required skill.

The automatic functions easily are handed over to robots, yet the higher-precision pattern designs required demand even higher levels of direct human assistance.

Shell Molding

Shell molding is also similar to the sand molding metal casting process except that a mixture of sand and 3-6% resin holds the grains together.

Set-up and production of shell mold patterns takes weeks, after which an output of 5-50 pieces/hr-mold is attainable.

Aluminium and magnesium products average about 13.5 kg as a normal limit, but it is possible to cast items in the 45-90 kg range.

Shell mold walling varies from 3-10 mm thick, depending on the forming time of the resin.

There are a dozen different stages in shell mold metal casting processing that include:

- Initially preparing a metal-matched plate

- Mixing resin and sand

- Heating pattern, usually to between 505-550 K

- Inverting the pattern (the sand is at one end of a box and the pattern at the other, and the box is inverted for a time determined by the desired thickness of the mill)

- Curing shell and baking it

- Removing investment

- Inserting cores

- Repeating for other half

- Assembling mold

- Pouring mold

- Removing casting

- Cleaning and trimming.

The sand-resin mix can be recycled by burning off the resin at high temperatures.

Investment Casting

Investment casting (lost-wax process) yields a finely detailed and accurate product, with excellent metallurgical properties.

Polystyrene foam is also used in investment casting.

After a variable lead time, usually weeks, 1–1000 pieces/hour-mold can be produced in the mass range 2.3–2.7 kg. Items up to 45 kg and as light as 30 g are possible for unit production.

The process starts by creating an injection die to the desired specifications. This die will be used to inject wax to create the patterns needed for investment casting. The patterns are attached to a central wax sprue, creating an assembly, or mold. The sprue contains the fill cup where the molten metal will be poured into the assembly.

The wax assembly is now dipped multiple times in a ceramic slurry, depending on the shell thickness desired. A layer of fine sand (usually zircon) is added on top of each ceramic layer. This process will be repeated until the desired shell is created.

After the shell is created to the specifications desired, the wax must be removed; this is normally achieved using an autoclave. This is where the name “lost-wax process” comes from. This leaves an impression of the desired castings, which will be filled with metal. Before being cast, however, the shells must be heated in a furnace so they do not break during the casting process.

Next, the desired metal is poured into the hot ceramic shell. The metal fills each part on the assembly, and the central sprue cavity and fill cup. The individual parts will be removed after the mold cools and the shell is removed. The shell is generally removed with water-blasting, although alternate methods can be used. What remains are the cast metal parts, but they are still attached to the sprue assembly. The individual parts are removed by cold-break (dipping in liquid nitrogen and breaking the parts off with hammer and chisel) or with large cutoff saws.

The last step is finishing. First the gate, or the place where the part was connected to the sprue, must be removed. The gate is ground off to part specifications. Parts are also inspected to make sure they were cast properly, and if not are either fixed or scrapped. Depending on the investment casting facility and specifications, more finishing work can be done on-site, sub-contracted, or not done at all.

Investment casting yields exceedingly fine quality products made of all types of metals. It has special applications in fabricating very high-temperature metals, especially those which cannot be cast in metal or plaster molds and those which are difficult to machine or work.

Permanent Mold Casting

Permanent mold casting (typically for non-ferrous metals) requires a set-up time on the order of weeks to prepare a steel tool, after which production rates of 5-50 pieces/hr-mold are achieved with an upper mass limit of 9 kg per iron alloy item (cf., up to 135 kg for many nonferrous metal parts) and a lower limit of about 0.1 kg.

Steel cavities are coated with refractory wash of acetylene soot before processing to allow easy removal of the workpiece and promote longer tool life.

Permanent molds have a life which varies depending on maintenance of after which they require refinishing or replacement.

Cast parts from a permanent mold generally show 20% increase in tensile strength and 30% increase in elongation as compared to the products of sand casting.

The only necessary input is the coating applied regularly. Typically, permanent mold casting is used in forming iron-, aluminum-, magnesium-, and copper-based alloys. The process is highly automated.

Metal Die-casting

In die-casting, molten metal casting is injected into a mold at high pressures.

Set-up time for dies is 1-2 hours, after which production rates of 20–200 pieces per hour-mold are normally obtained.

Maximum mass limits for magnesium, zinc, and aluminum parts are roughly 4.5 kg, 18 kg, and 45 kg, respectively (though larger machines do exist); the lower limit in all cases is about 30 g.

Die injection machines are generally large (up to 3 × 8 m) and operate at high pressures — 100 megapascals (1000 kgf/cm2) and higher, although aluminum usually is processed at lower pressure.

A well-designed unit produces over 500,000 castings during the production lifetime of a single mold. While the dies used in the process are quite expensive, if a very large number of castings can be produced, significant cost savings can be achieved when a component is manufactured by die casting.

The major production step is die construction, usually a steel alloy requiring a great deal of skill and fine tooling to prepare. Mostly non-ferrous materials are die-cast, such as aluminum, zinc, magnesium, and copper-based alloys.

This is the process used in the production of certain toys, notably that of model automobiles.

Centrifugal Casting

Centrifugal casting is both gravity- and pressure-independent since it creates its own force feed using a temporary sand mold held in a spinning chamber at up to 90 g (900 m/s²). Lead time varies with the application. Semi- and true-centrifugal processing permit 30-50 pieces/hr-mold to be produced, with a practical limit for batch processing of approximately 9000 kg total mass with a typical per-item limit of 2.3-4.5 kg.

Industrially, the centrifugal casting of railway wheels was an early application of the method developed by German industrial company Krupp and this capability enabled the rapid growth of the enterprise.

Small art pieces such as jewelry are often cast by this method using the lost-wax process, as the forces enable the rather viscous liquid metals to flow through very small passages and into fine details such as leaves and petals. This effect is similar to the benefits from vacuum casting, also applied to jewelry casting.

Continuous Casting

Continuous metal casting is a refinement of the casting process for the continuous, high-volume production of metal sections with a constant cross-section.

Molten metal is poured into an open-ended, water-cooled copper mold, which allows a ‘skin’ of solid metal to form over the still-liquid center.

The strand, as it is now called, is withdrawn from the mold and passed into a chamber of rollers and water sprays; the rollers support the thin skin of the strand while the sprays remove heat from the strand, gradually solidifying the strand from the outside in.

After solidification, predetermined lengths of the strand are cut off by either mechanical shears or traveling oxyacetylene torches and transferred to further forming processes, or to a stockpile. Cast sizes can range from strip (a few millimeters thick by about five meters wide) to billets (90 to 160 mm square) to slabs (1.25 m wide by 230 mm thick). Sometimes, the strand may undergo an initial hot rolling process before being cut.

Continuous casting provides a better quality product as it allows finer control over the casting process, along with the obvious advantages inherent in a continuous forming process. Continuously cast metals such as aluminum, copper and steel are continuously cast, with the largest tonnage poured being steel.

Cooling Rate

The rate at which a casting cools affects its microstructure, quality, and properties.

The products of sand casting and slurry-mold processes, often large with thick walls, generally cool slowly. This increases the metal’s grain size, creating a coarse microstructure that lowers the strength of the casting.

Coarse grains can allow elements of an alloy to separate, which also weakens the casting. But slower cooling keeps the casting metal liquid longer, which allows more gases and waste metal to escape, reducing the voids and inclusions that can weaken a casting.

Conversely, the products of die-casting and metal-mold processes generally cool more quickly, resulting in a fine microstructure with small grain and less alloy segregation but more trapped gases and inclusions.

On the other hand, according to the Pillings Bedworth Ratio, the strength of a material is inversely proportional to the square root of its grain size.

Provided de-gassing techniques are used during molten metal preparation, die-cast products may have superior strength when compared with equivalent sand castings.

Shrinkage

Like nearly all materials, metal is less dense as a liquid than a solid, and so a casting shrinks as it cools — mostly as it solidifies, but also as the temperature of the solid material drops. Compensation for this natural phenomena must be considered in two ways.

Volumetric Shrinkage

The shrinkage caused by solidification can leave cavities in a casting, weakening it.

Risers provide additional material to the casting as it solidifies. The riser (sometimes called a “feeder”) is designed to solidify later than the part of the casting to which it is attached. Thus the liquid metal in the riser will flow into the solidifying casting and feed it until the casting is completely solid. In the riser itself there will be a cavity showing the metal which was fed. Risers add cost because some of their material must be removed, by cutting away from the casting which will be shipped to the customer. They are often necessary to produce parts that are free of internal shrinkage voids.

Sometimes, to promote directional shrinkage. Chills must be used in the mold. A chill is any material which will conduct heat away from the casting more rapidly that the material used for molding. Thus if silica sand is used for molding, a chill may be made of copper, iron, aluminum, graphite, zircon sand, chromite or any other material with the ability to remove heat faster locally from the casting. All castings solidify with progressive solidification but in some designs a chill is used to control the rate and sequence of solidification of the casting.

Linear Shrinkage

Shrinkage after solidification can be dealt with by using an over-sized pattern designed for the relevant alloy. Pattern makers use special “shrink rulers” to make the patterns used by the foundry to make castings to the design size required. These rulers are 2 – 6 % oversize, depending on the material to be cast. Using such a ruler during pattern making will ensure an oversize pattern. Thus, the mold is larger also, and when the molten metal solidifies it will shrink and the casting will be the size required by the design.