Flux-core arc welding (FCAW) is a popular arc welding process that uses a constant voltage power supply and a flux-filled tubular wire as filler material.

The filler wire also acts as the electrode to start the arc and feeds into the weld puddle to form a weld bead.

Flux-core welding can be manual, semi-automatic, or automatic, and many industries use it.

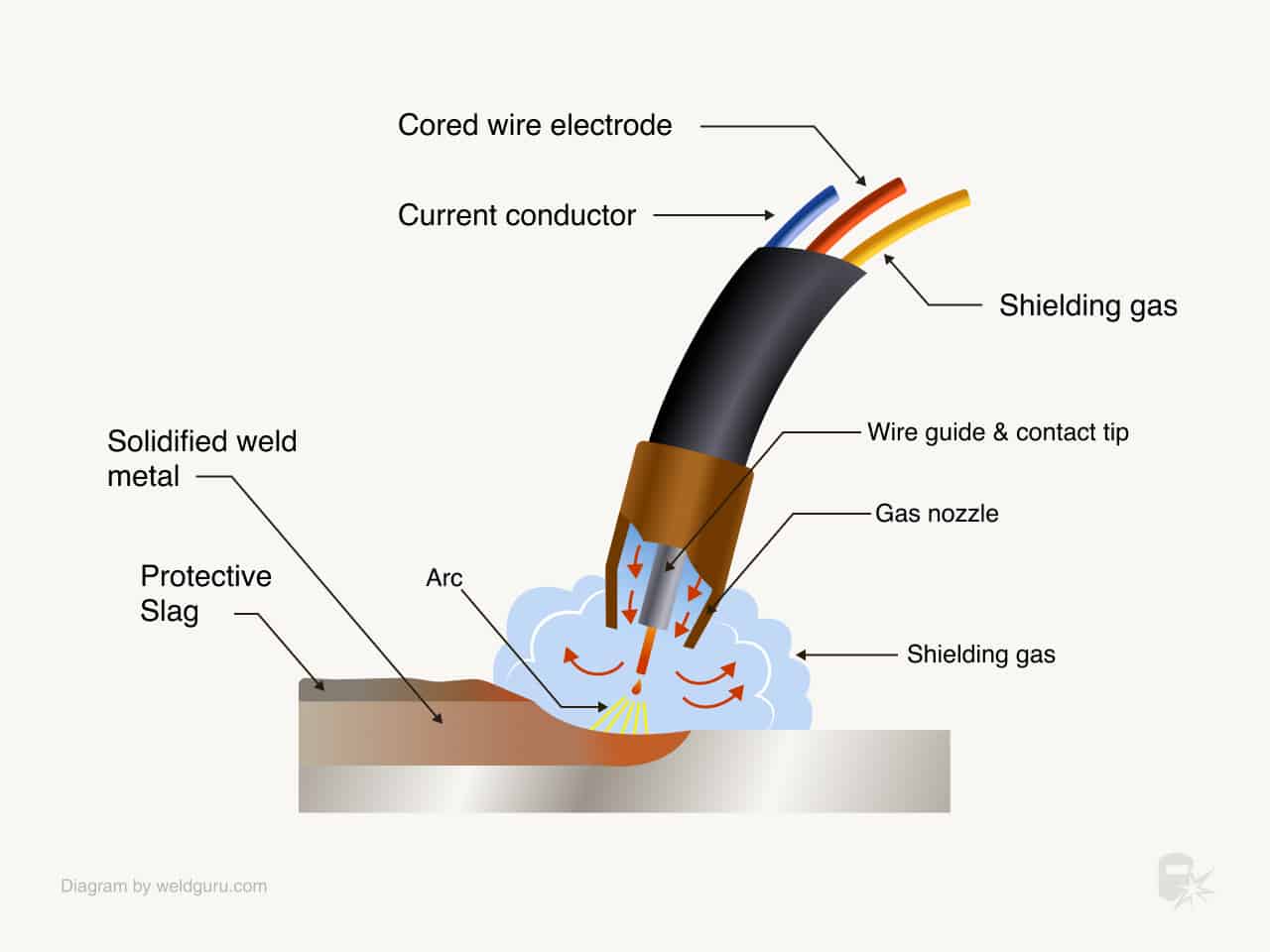

Key Components of Flux-Core Welding

© weldguru.com – Image usage rights

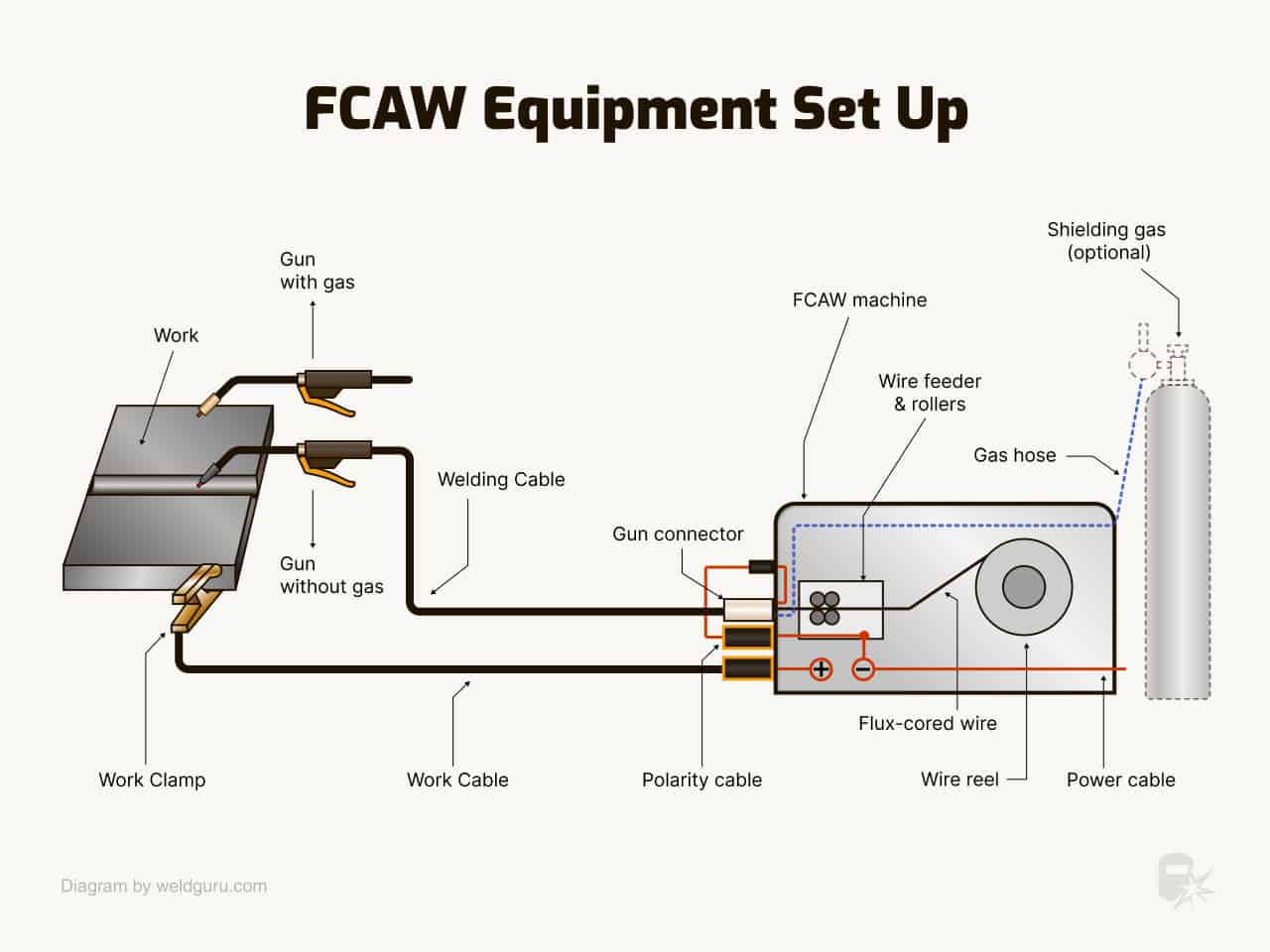

Flux-core welding requires a constant voltage power supply, wire feeder, welding gun, work lead (ground) clamp, and flux-core welding wire. Often, an external shielding gas provides further protection to the weld area.

The constant voltage power supply operates the welding gun. The gun transfers the electricity through a copper contact tip to the flux-core wire.

© weldguru.com – Image usage rights

While the power supply controls the voltage, the speed of the wire feeder determines the amperage for the welding circuit.

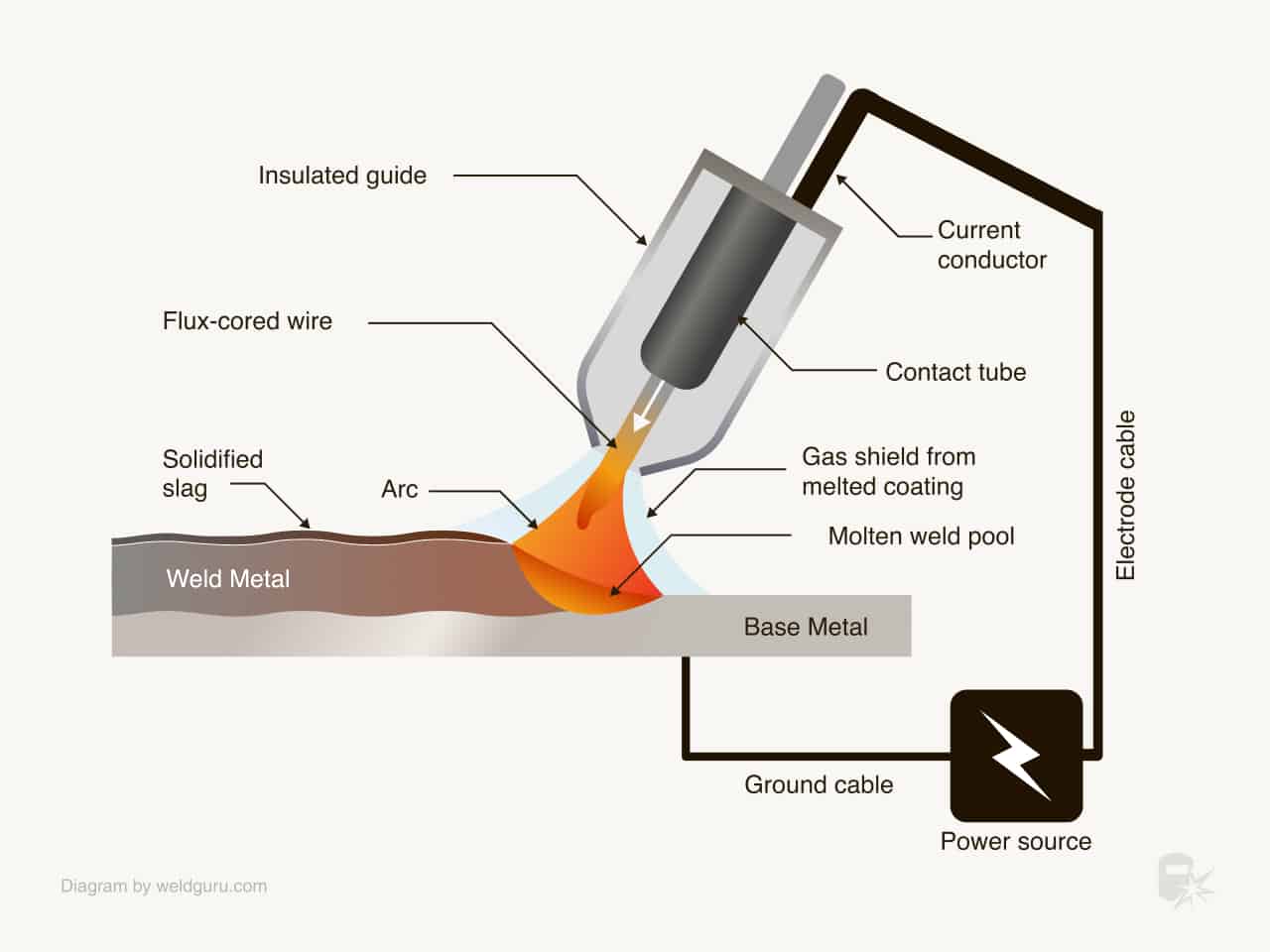

A wire feeder feeds the flux-core wire through the welding cable to the welding gun. When the wire contacts the base metal, a welding arc forms and remains as long as nothing breaks the welding circuit. The arc melts the base metals and the wire to form a weld puddle.

As the wire melts, the flux inside burns, providing a shielding gas to protect the weld from the atmosphere.

For gas-shielded wires, an external shielding gas and the flux inside the wire add to the gas shielding.

The Science Behind Flux-Core Welding: How It Works

Flux-core welding is like other wire-fed welding processes like GMAW and SAW but uniquely uses a special tubular wire filled with flux.

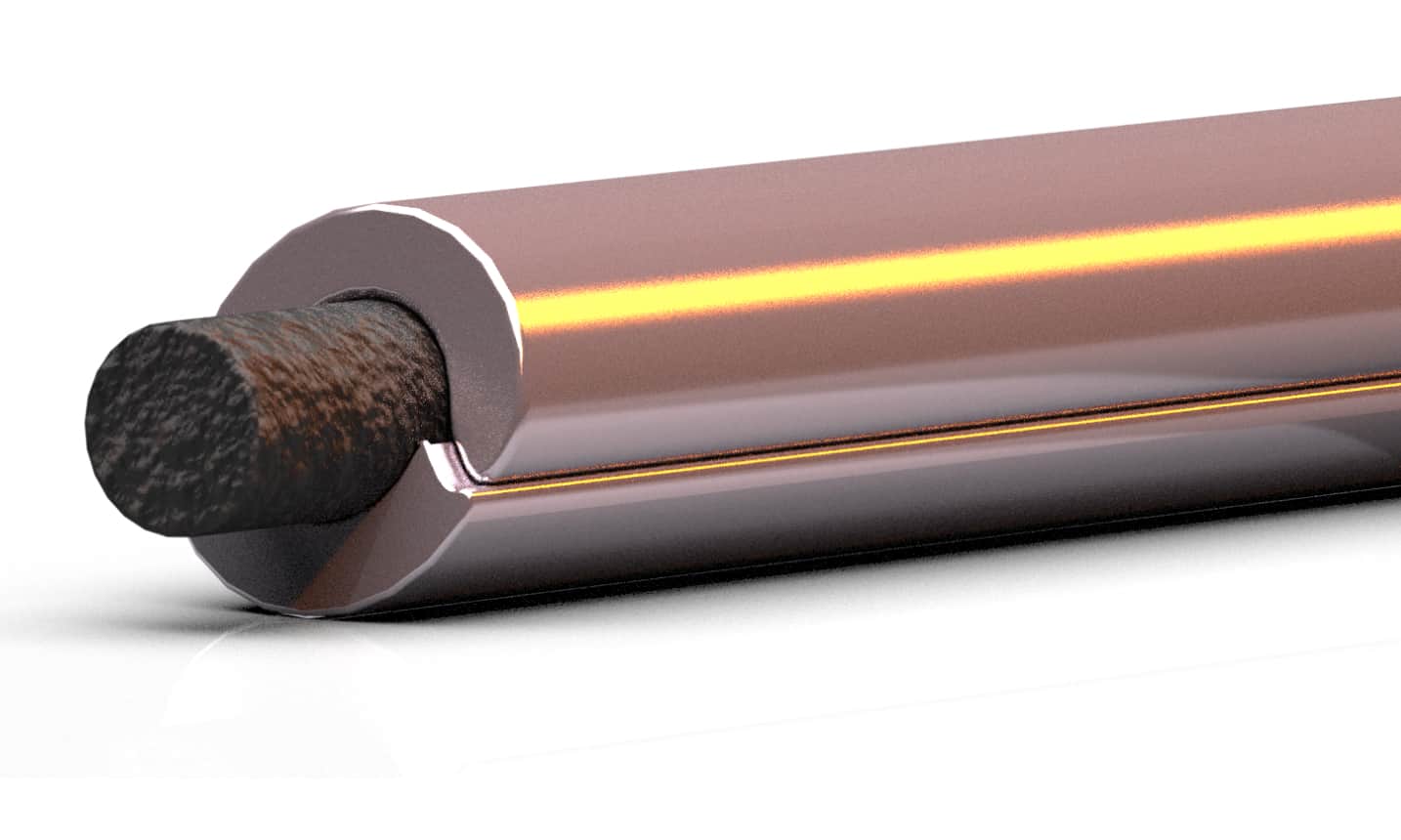

Understanding the Flux-Core Wire

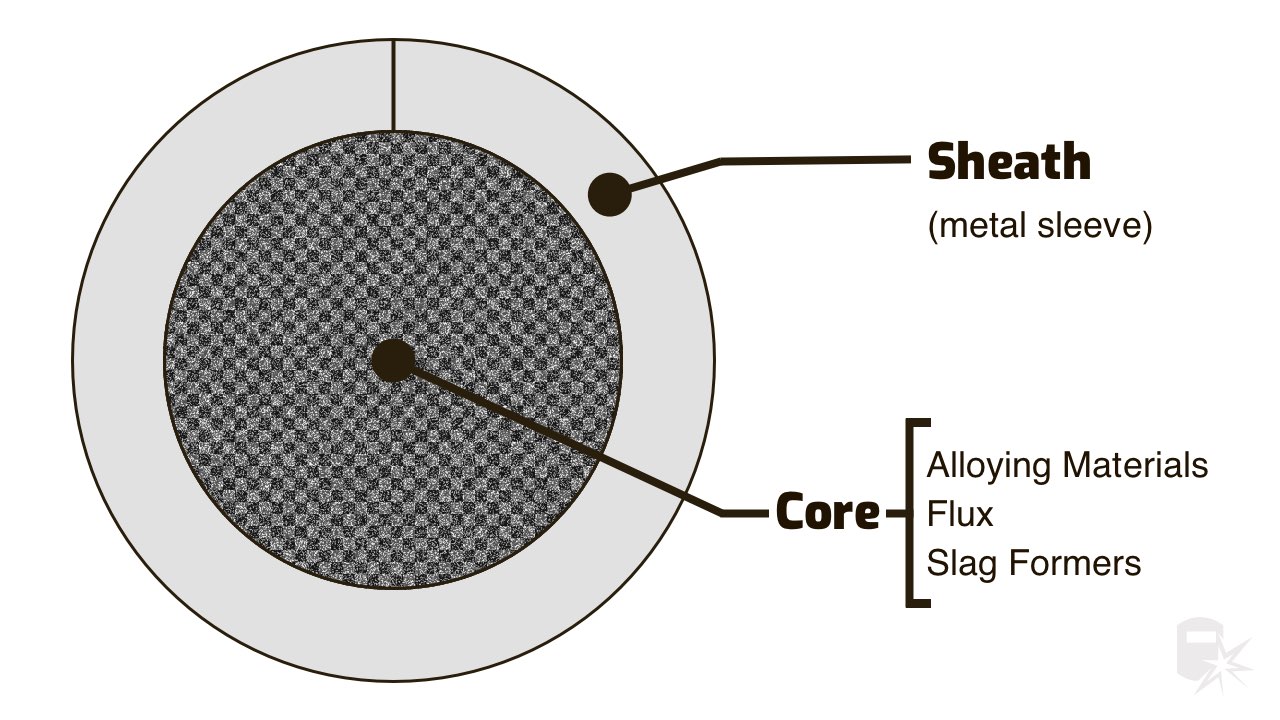

The wire used in flux core is the electrode and filler metal, like the wires used in GMAW. The major difference is that the hollow center contains flux.

© weldguru.com – Image usage rights

Other wire-feed processes like GMAW don’t use flux but rely on external shielding gas. GMAW also uses the filler metal composition to add alloy elements to the weld metal, where the flux in FCAW wire contains these elements.

Related: FCAW vs. GMAW Differences Compared

Carbon steel, stainless steel, or alloy-steel, flux-core wires are in compositions to suit many base metals.

A thin strip of metal feeds through a machine to make flux-core wire, turning it into a “U” shape. Flux pours into the center of this profile before feeding into a series of dies. These dies turn the flux-filled U channel into a tubular wire of the correct diameter.

Filler metal makes up the outer shell of the wire, also known as a ‘sheath’, and the hollow center contains tightly-packed flux.

The metal shell of the wire serves three purposes: conducting electricity, providing filler metal, and protecting the flux from moisture or contamination.

The Role of Flux in Welding

Credit: Weldnotes.com

The flux at the core of the welding wire serves several purposes.

- It protects the weld – The most important job of the flux is protecting the weld. When burned, it produces a shielding gas that protects the weld area from atmospheric contamination. Some wires need an external shielding gas to give enough gas coverage for this protection.

- Adds alloys – The flux also adds alloys into the weld metal to improve certain aspects of the finished weld. Along with these alloys, flux has deoxidizers added to prevent the weld puddle from oxidizing.

- Slag protection – Another important job of the flux is the creation of a thin layer of slag over the weld. The slag protects the weld metal from the atmosphere as it cools it slowly and helps shape the weld.

- Stabilize the arc – The flux can stabilize and control the welding arc. A side effect of smoothing and stabilizing the welding arc is reducing the spatter.

The flux used in flux-core wire comes in many varieties. Some examples of types of flux are rutile, basic, cellulose, self-shielding, and metal core.

The type of flux used in the filler wire depends on the wire’s manufacturer, and two wires from different manufacturers could weld differently based on the flux used.

Understanding the Self-Shielding Process

Flux-core wire can be self-shielding or gas-shielding. The self-shielding wire does not need the addition of an external shielding gas to protect the weld area.

Instead, it uses the burning of the flux to produce the required gas shielding.

The arc melts the outer shell of the wire, exposing the flux inside. The arc’s heat burns the flux, creating a shield of inert gas around the weld puddle.

This process is like stick welding, but the flux is inside the electrode rather than on the outside.

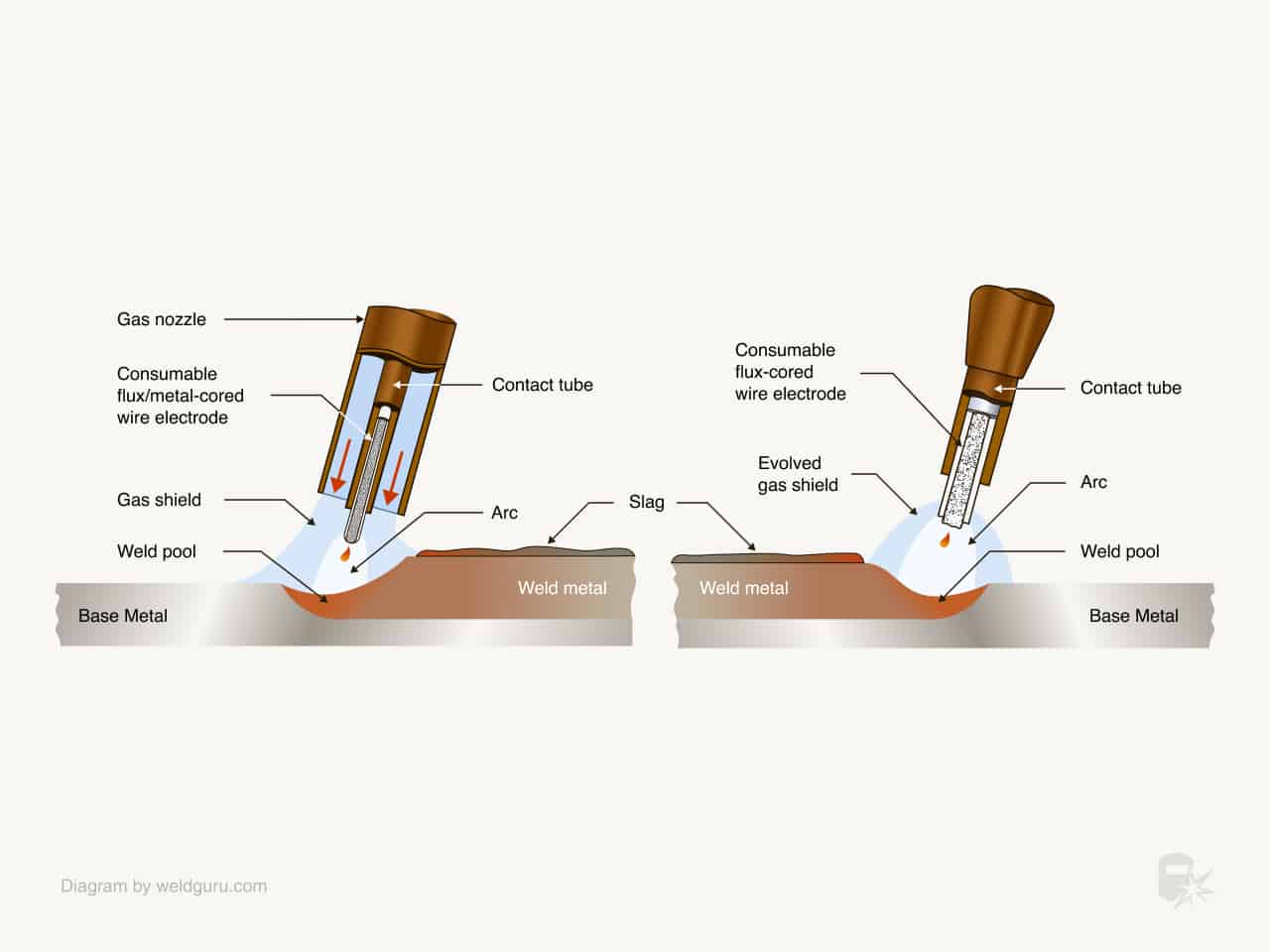

Different Types of Flux-Core Welding

© weldguru.com – Image usage rights

Flux-core welding has two sub-processes: self-shielding and gas-shielding. The primary difference between the two is using an external shielding gas.

Beyond this, each process also has specific applications.

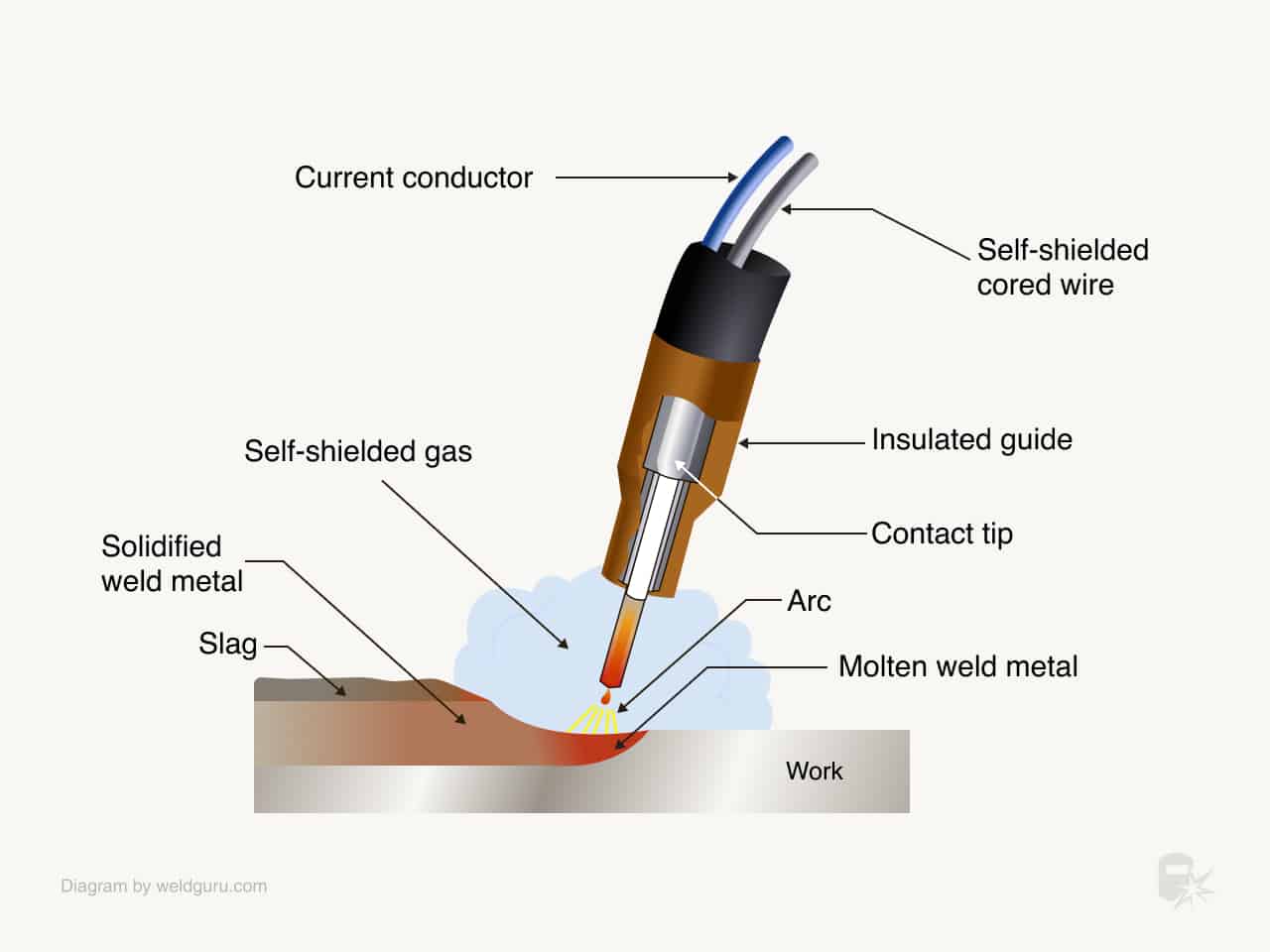

Self-Shielded Flux-Core Welding (FCAW-S)

© weldguru.com – Image usage rights

Self-shielding flux-core welding (FCAW-S) does not need an external inert shielding gas to protect the weld puddle. The flux in the center of the welding wire produces the shielding gas.

As the flux burns, it creates an envelope of shielding gas, protecting the weld puddle from atmospheric gases.

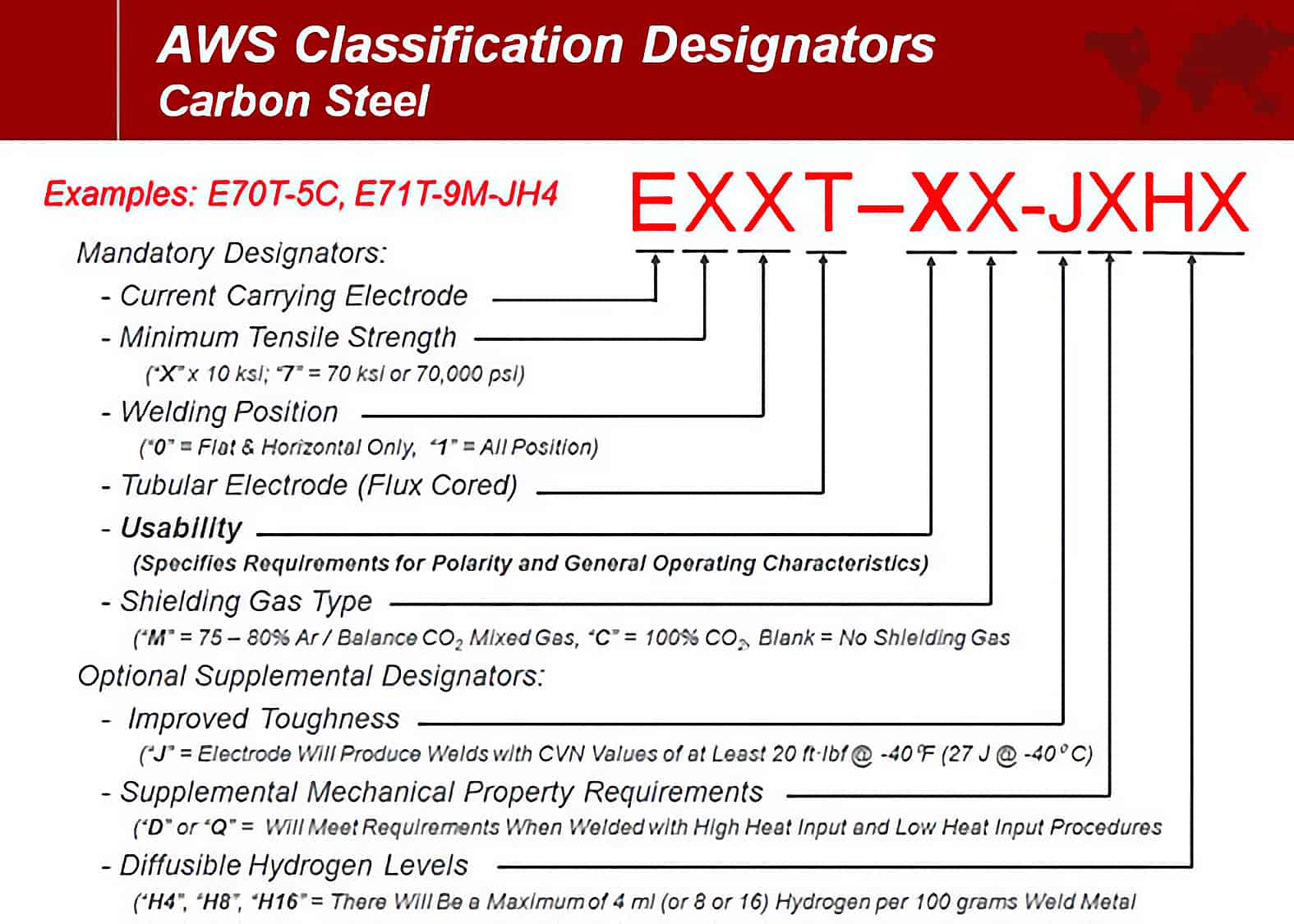

The AWS classification destinations for FCAW wire show whether a wire is self-shielding. The following numbers are for self-shielding wire:

- T-3

- T-4

- T-6

- T-7

- T-8

- T-10

- T-11

- T-13

- T-14

This process is ideal for outdoor applications because the shielding made by the flux is resistant to wind.

Dedicated self-shielding FCAW machines are often smaller, which a welder will carry around the job site. The portability of this process makes it ideal for situations that make access difficult.

The flux in self-shielding flux-core wire will form a slag layer on top of the weld. The slag protects the weld metal as it cools, protecting it from the atmosphere and shaping the weld bead.

Self-shielding flux core costs less than gas-shielded flux core and is a good choice for outdoor welding or areas with difficult access, as no gas cylinder is necessary.

Gas-Shielded Flux-Core Welding (FCAW-G)

© weldguru.com – Image usage rights

Gas-shielded flux core (FCAW-G) needs to use an external shielding gas because the flux at the center of the wire doesn’t provide enough shielding gas to protect the weld from atmospheric gases.

Gas-shielded flux-core must use a welding gun that allows gas to flow through a regulator and a shielding gas cylinder. A gas-shielded welding machine will also be less portable than a self-shielding machine and limited to indoor use.

The AWS classification destinations for FCAW wire also show if a wire is gas-shielded. The following numbers are for gas-shielded wire:

- T-1

- T-2

- T-5

- T-9

- T-12

The same classification will also show what shielding gas to use:

- M = 75-80% argon shielding gas mix

- C = 100% CO2

The welds produced by gas-shielded flux core are higher quality than self-sheilding welds. They have less splatter, more penetration, and are more visually appealing. The slag on gas-shielded flux core welds is also easier to remove.

A gas-shielded flux core wire often is the better choice when a weld needs to be very strong and look good.

What Is Flux-Core Arc Welding Typically Used For?

Flux-core arc welding is popular in many industries for various applications. Some industries will prefer self-shielding flux core, while others will use gas-shielding flux cores.

- Manufacturing/Fabrication: The high deposition rates, ease of use, and excellent penetration make flux core a great option for many types of fabrication. Flux core also produces welds that look smoother and nicer than welds produced through GMAW or SMAW.

- Construction: Self-shielding flux core is great in outdoor construction sites where the goal is to weld faster than SMAW. Gas-shielding flux core is inappropriate for outdoor construction sites because the wind greatly affects the external shielding gas.

- Shipyards: Shipyards will use FCAW in both gas-shielding and self-shielding, depending on factors like access. Since gas-shielded flux core produces high-quality welds with fast speeds, it’s an ideal process for the construction of ships. Self-shielding flux core is portable, so a welder can carry the flux core machine in areas with difficult access.

- DIY: Often, low-power, self-shielding flux core machines are suitcase-sized and need only 120 or 220 volts. This quality makes them ideal for DIYers. FCAW is easier to learn than SMAW, and the welds produced by self-shielding FCAW can be as strong as SMAW

- Heavy equipment and machinery: The production and maintenance of heavy equipment and machinery use gas-shielded FCAW often because the welds are of higher quality, look better, and are faster than SMAW or GMAW.

- Aerospace: The aerospace industry does not use FCAW in aircraft construction. For the production of the tooling used to build aircraft and their parts, gas-shielding FCAW is in wide use. The high deposition rates, good penetration, and smooth welds make FCAW a popular choice for the aerospace industry.

Advantages and Disadvantages of Flux-Core Arc Welding

As with most welding processes, FCAW has advantages and limitations to consider.

Benefits

Flux core has many advantages over other welding processes, and many industries and scenarios prefer it.

- FCAW has deeper penetration than SMAW or GMAW

- Deposition rates are higher than other processes

- Welds are of high quality and appropriate for many applications

- Good for welding thick materials

- Self-shielding FCAW is highly portable

- Easy to learn

- Appropriate for manual, semi-automatic, or automatic welding

Limitations

Although FCAW has many advantages, there are several disadvantages to consider.

- Creates significant amounts of hazardous smoke and fumes

- Gas-shielded FCAW isn’t good for outdoor environments or locations where there is a draft

- Slag needs removal after welding, increasing the post-weld cleaning costs

- The wire is more expensive than GMAW

- The equipment is more expensive than that of SMAW

- Does not weld thinner materials as well as other processes

Related read: Flux Core vs. Stick Welding

Wrapping it Up

Flux core welding is faster than SMAW and gives better results than GMAW, which is why it’s widely used across so many industries. With so many shops relying on FCAW and its ease of use and versatility, flux-core welding will continue to be widely used for decades to come.