This arc weld troubleshooting guide is easy to use. Simply find the problem in the table of contents on the left or match one of our many illustrations to the problem.

Conditions that often result in problems include:

- Use of low quality shielding gas with a moisture level that is too high. Moisture in the air can also cause problems.

- Equipment that isn’t clean

- Materials and filler rods that aren’t clean

- Uneven shielding gas flow

- Changes in welding parameters

- Surface contamination

- Gas coverage issues (insufficient gas flow causes electrode and part contamination)

- Grounding problems

- Changes in voltage due to use of other equipment in shop or incorrect voltage

- Overheating due to short between nozzle and electrode

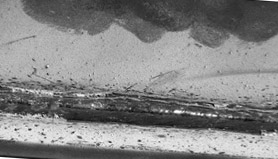

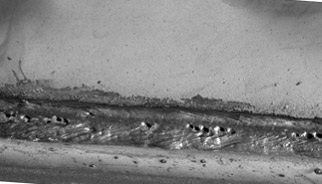

Ropey Weld Defect

Arc Weld Troubleshooting by Problem

Distortion

Why Distortion Occurs:

|

How to Fix It:

|

Step 1. Check for shrinkage of deposited metal.

- Properly clamp parts or tack weld parts to resist shrinkage.

- Preform or separate parts so as to allow for weld shrinkage.

- Peen the deposited metal while still hot.

Step 2. Check for uniform heating of parts.

- For heavy structures preheating is desirable.

- It is sometimes helpful before welding to perform removal of rolling or forming strains by stress relieving.

Step 3. Check the welding sequence.

- Study structure and develop a definite sequence of welding.

- Prevent excessive local heating by distributing welding.

Welding Stresses

Step 1. Check for excessive rigidity of joints.

- Slight movement of parts during welding will reduce welding stresses.

- Develop a welding procedure that permits all parts to be free to move as long as possible.

Step 2. Check the welding procedure.

- Use as few welding passes as practical.

- Use special intermittent or alternating welding sequence and back-step or skip procedures.

- Properly clamp parts adjacent to the joint. Use backup fixtures to cool parts rapidly.

Step 3. If no improper conditions exist, stresses could merely be those inherent in any weld, especially in heavy parts.

- Peen each deposit of weld metal.

- Stress relieve finished product at 1100 to 1250°F (593 to 677°C) 1 hour per 1.0 in. (25.4 cm) of thickness.

Warping of Thin Plates

Acetylene Weld Warping Troubleshooting

Warping Arc Weld Troubleshooting Suggestions

Why it Occurs:

|

Solutions:

|

Step 1. Check for shrinkage of deposited weld metal.

- Select electrode with high welding speed and moderate penetrating properties.

Step 2. Check for excessive local heating at the joint.

- Prevent excessive local heating of the plates adjacent to the weld by welding rapidly.

Step 3. Check for proper preparation of the joint.

- In the parts to be welded do not have excessive root opening in the joint between the parts to be welded.

- Hammer joint edges thinner than the rest of the plates before welding. This elongates the edges and the weld shrinkage causes them to pull back to the original shape.

Step 4. Check the welding procedure.

- Use special intermittent or alternating welding sequence and back-step or skip the procedure.

- Preheat material to achieve stress.

Step 5. Check the clamping of parts.

- Properly clamp parts adjacent to the joint. Use backup fixtures to cool parts rapidly.

Poor Weld Appearance

Acetylene Troubleshooting Poor Weld Appearance

Poor Weld Appearance Arc Weld Troubleshooting

Reasons for Poor Weld Appearance:

|

Solutions:

|

Step 1. Check the welding technique for proper current and electrode manipulation.

- Ensure the use of the proper welding technique for the electrode used.

- Do not use excessive welding current.

- Use a uniform weave or rate of travel at all times.

Step 2. Check characteristics of the type of electrode used.

- Use an electrode designed for the type of weld and base metal and the position in which the weld is to be made.

Step 3. Check welding position for which the electrode is designed.

- Do not make fillet welds with down-hand (flat position) electrodes unless the parts are positioned properly.

Step 4. Check for proper joint preparation.

- Prepare all joints properly.

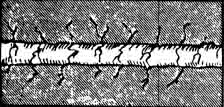

Cracked Welds

How to Troubleshoot Weld Stress Cracking

Cracked Arc Weld Troubleshooting

Why Cracked Welds Occur:

|

Solutions:

|

Step 1. Check for excessive joint rigidity.

- Modify the welding procedure and redesign the structure in order to eliminate rigid joints.

Step 2. Are the welds too small relative to the size of the parts joined?

- Avoid using a small weld between heavy plates. Increase the weld size with additional filler metal.

Step 3. Review each stop of the welding procedure.

- Do not make welds in string beads. Deposit weld metal full size in short sections 8.0 to 10.0 in. (203.2 to 254.0 mm) long. (This is called block sequence.)

- The sequence of welding should be such as to leave ends free to move as long as possible.

- Preheating parts to be welded sometimes helps to reduce high contraction stresses caused by localized high temperature.

- Fill all craters at the end of the weld pass by moving the electrode back over the finished weld for a short distance equal to the length of the crater.

Step 4. Check for poor welds.

- Make sure welds are sound and the fusion is good. Be sure arc length and polarity are correct.

Step 5. Check for proper preparation of joints.

- Prepare joints with a uniform and proper root opening. In some cases, a root opening is essential. In other cases, a shrink or press fit may be required.

Undercut

Step 1. Check the welding current setting.

- Use a moderate welding sent and do not try to weld at too high a speed.

Step 2. Check for proper manipulation of the electrode.

- a. Do not use too large an electrode. If the puddle of molten metal becomes too large, undercut may result.

- b. Excessive width of weave will cause undercut and should not be used. A uniform weave, not over three times the electrode diameter, will aid greatly in preventing undercut in butt welds.

- c. If an electrode is held too near the vertical plate in making a horizontal fillet weld, undercut on the vertical plate will result.

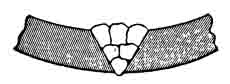

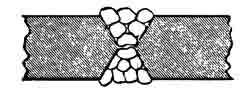

Incomplete Penetration

Troubleshooting Incomplete Weld Penetration

Example of Poor Penetration

Penetration Arc Weld Troubleshooting Suggestions

Why Incomplete Penetration Occurs:

|

Solutions:

|

Step 1. Check to see if the electrode is designed for the welding position being used.

- Electrodes should be used for welding in the position for which they were designed.

- Be sure to allow the proper root openings at the bottom of a weld.

- Use a backup bar if possible.

- Chip or cut out the back of the joint and deposit a bead of weld metal at this point.

Step 2. Check size of electrode used.

- Do not expect excessive penetration from an electrode.

- Use small diameter electrodes in a narrow welding groove.

Step 3. Check the welding current setting.

- Use sufficient welding current to obtain proper penetration. Do not weld too rapidly.

Step 4. Check the welding speed.

- Control the welding speed to penetrate to the bottom of the welded joint.

Porous Welds

Troubleshooting Arc Weld Porosity

Porous Arc Weld Troubleshooting

Why Porous Welds Occur:

|

Solutions:

|

Step 1. Check the electrode properties.

- Some electrodes inherently produce sounder welds than others. Be sure that proper electrodes are used.

Step 2. Check the current setting and welding procedure.

- A weld made of a series of string beads may contain small pinholes. Weaving will often eliminate this trouble.

Step 3. Check puddling time to see whether it is sufficient to allow the escape of entrapped gas.

- Puddling keeps the weld metal molten longer and often insures sounder welds.

Step 4. Check for dirty base metal.

- In some cases, the base metal may be at fault. Check this for segregations and impurities.

Brittle Welds

Step 1. Check the type of electrode used.

- Bare electrodes produce brittle welds. Shielded arc electrodes must be used if ductile welds are required.

Step 2. Check the welding current setting.

- Do not use excessive welding current, as this may cause coarse-grained structure and oxidized deposits.

Step 3. Check for high carbon or alloy base metal which has not been taken into consideration.

- a. A single pass weld may be more brittle than a multilayer weld because its micro-structure has not been refined by successive layers of weld metal.

- b. Welds may absorb alloy elements from the parent metal and become hard.

- c. Do not weld a metal unless the composition and characteristics are known.

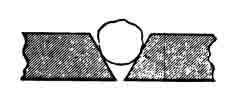

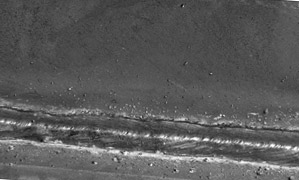

Poor Fusion Weld

Poor Fusion Weld

Poor Fusion Arc Weld Troubleshooting

Poor Fusion Weld Causes:

|

Solutions:

|

Step 1. Check diameter of electrode.

- When welding in narrow groove joints use an electrode small enough to properly reach the bottom of the joint.

Step 2. Check the welding current setting.

- Use sufficient welding current to deposit the metal and penetrate into the plates.

- Heavier plates require higher current for a given electrode than light plates.

Step 3. Check the welding technique.

- Be sure the weave is wide enough to melt the sidewalls of the joint thoroughly.

Step 4. Check the joint preparation.

- The deposited metal should fuse with the base metal and not curl away from it or merely adhere to it.

Corrosion

Step 1. Check the type of electrode used.

- Bare electrodes produce welds that are less resistant to corrosion than the parent metal.

- Shield arc electrodes produce welds that are more resistant to corrosion than the parent metal.

- For the best corrosion resistance, use a filler rod whose composition is similar to that of the base metal.

Step 2. Check to see if the weld metal deposited is proper for the corrosive fluid or atmosphere to be encountered.

- Do not expect more from the weld than you do from the parent metal. On stainless steels, use electrodes that are equal to or better than the parent metal in corrosion resistance.

Step 3. Check on the metallurgical effect of the welding.

- When welding 18-8 austenitic stainless steel, be sure the analysis of the steel and welding procedure is correct, so that the welding does not cause carbide precipitations. Carbide precipitation is the rising of carbon to the surface of the weld zone. This condition can be corrected by annealing at 1900 to 2100°F (1038 to 1149°C) after welding. By doing this corrosion in the form of iron oxide, or rust, can be eliminated.

Step 4. Check for proper cleaning of the weld.

- Certain materials, such as aluminum, require careful cleaning of all slag after welding to prevent corrosion in service.

Brittle Joints

Step 1. Check for air hardening of the base metal.

- In medium carbon steel or certain alloy steals, the heat affected zone may be hard as a result of rapid cooling. Preheating at 300 to 500°F (149 to 260°C) should be resorted to before welding.

Step 2. Check the welding procedure.

- Multilayer welds will tend to anneal hard heat affected zones.

- Stress relieving at 1100 to 1250°F (593 to 677°C) after welding will generally reduce hard areas formed during welding.

Step 3. Check the type of electrode used.

- The use of austenitic electrodes will often be successful on special steels, but the heat-affected zone will generally contain an alloy which is hard.

Magnetic Blow

Step 1. Check for deflection of the arc from its normal path, particularly at the ends of joints and in corners.

- Make sure the ground is properly located on the work. Placing the ground in the direction of the arc deflection is often helpful.

- Separating the ground into two or more parts is helpful.

- Weld toward the direction in which the arc blows.

- Hold a short arc.

- Changing the angle of the electrode relative to the work may help to stabilize the arc.

- Magnetic blow is held to a minimum in alternating current welding.

Spatter

Weld Spatter Example

Step 1. Check the properties of the electrode used.

- Select the proper type of electrode.

Step 2. Check to see if the welding current is excessive for the type and diameter of electrode used.

- Use a short arc but do not use excessive welding current

Step 3. Check for spalls.

- Paint parts adjacent to welds with whitewash or other protective coating. This prevents spalls from welding to parts, and they can be easily removed.

- Coated electrodes produce larger spalls than bare electrodes.

Excessive Electrode Consumption

Arc Weld Troubleshoot Electrode Consumption

Causes of Unusual Electrode Consumption:

|

Solutions:

|

Electrode Contamination

Reasons for a Contaminated Electrode:

|

Solutions:

|

Workpiece Has Tungsten Contamination

Reasons for Tungsten Contamination:

|

Solutions:

|

Welding Voltage Problems

Welding Voltage Problems:

|

Solution:

|

Electrode Material

Problems with Electrode Material:

|

Solution:

|

Electrode Material Quality

Causes of Electrode Material Quality:

|

Solution:

|

Electrode Dimensions or Geometry

Arc Weld Troubleshooting Geometry or Electrode Dimensions

Causes of Problem:

|

Solution:

|

Welding Cables

Arc Weld Troubleshooting of Welding Cables

Problems with welding cables

|

Solution:

|

Difficulty Starting Arc

Arc Weld Troubleshooting when Welding Arc Will Not Start

Reasons for difficulty starting weld arc:

|

Solutions:

|

Arc Does Not Transfer

Arc Weld Troubleshooting When Arc Does Not Transfer

Reasons why arc does not transfer:

|

Solutions:

|