Summary

Friction welding is a solid state welding process which produces coalescence of materials by the heat obtained from mechanically-induced sliding motion between rubbing surfaces. The work parts are held together under pressure.

This process usually involves the rotating of one part against another to generate frictional heat at the junction. When a suitable high temperature has keen reached, rotational notion ceases. Additional pressure is applied and coalescence occurs.

There are two process variations:

- In the original process, one part is held stationary and the other part is rotated by a motor that maintains an essentially constant rotational speed. The two parts are brought in contact under pressure for a specified period of time with a specific pressure. Rotating power is disengaged from the rotating piece and the pressure is increased. When the rotating piece stops, the weld is completed. This process can be accurately controlled when speed, pressure, and time are closely regulated.

- The other variation is inertia welding. A flywheel is revolved by a motor until a preset speed is reached. It, in turn, rotates one of the pieces to be welded. The motor is disengaged from the flywheel and the other part to be welded is brought in contact under pressure with the rotating piece. During the predetermined time during which the rotational speed of the part is reduced, the flywheel is brought to an immediate stop. Additional pressure is provided to complete the weld.

Process

Both methods utilize frictional heat and produce welds of similar quality. Slightly better control is claimed with the original process. The two methods are similar, offer the same welding advantages, and are shown by figure 10-79 below.

There are three important factors involved:

- The rotational speed is related to the material to be welded and the diameter of the weld at the interface.

- The pressure between the two parts to be welded. Pressure changes during the weld sequence. At the start, the pressure is very low but is increased to create the frictional heat. When the rotation is stopped, the pressure is rapidly increased so forging takes place immediately before or after rotation is stopped.

- The welding time is related to the shape and the type of metal and the surface area. It is normally a matter of a few seconds. The actual operation of the machine is automatic. It is controlled by a sequence controller, which can be set according to the weld schedule established for the parts to be joined.

Normally, one of the parts to be welded is round in cross-section. This is not an absolute necessity. Visual inspection of weld quality can be based on the flash, which occurs around the outside perimeter of the weld. This flash will usually extend beyond the outside diameter of the parts and will curl around back toward the part but will have the joint extending beyond the outside diameter of the part.

If the flash sticks out relatively straight from the joint, it indicates that the welding time was too short, the pressure was too low, or the speed too high. These joints may crack.

If the flash curls too far back on the outside diameter, it indicates that the time was too long and the pressure was too high.

Between these extremes is the correct flash shape. The flash is normally removed after welding.

Welding Variables

- Rotational Speed

- Heating pressure

- Forging pressure

- Time for heating

- Time for braking

- Time for forging

Types of Friction Welding

Spin Welding

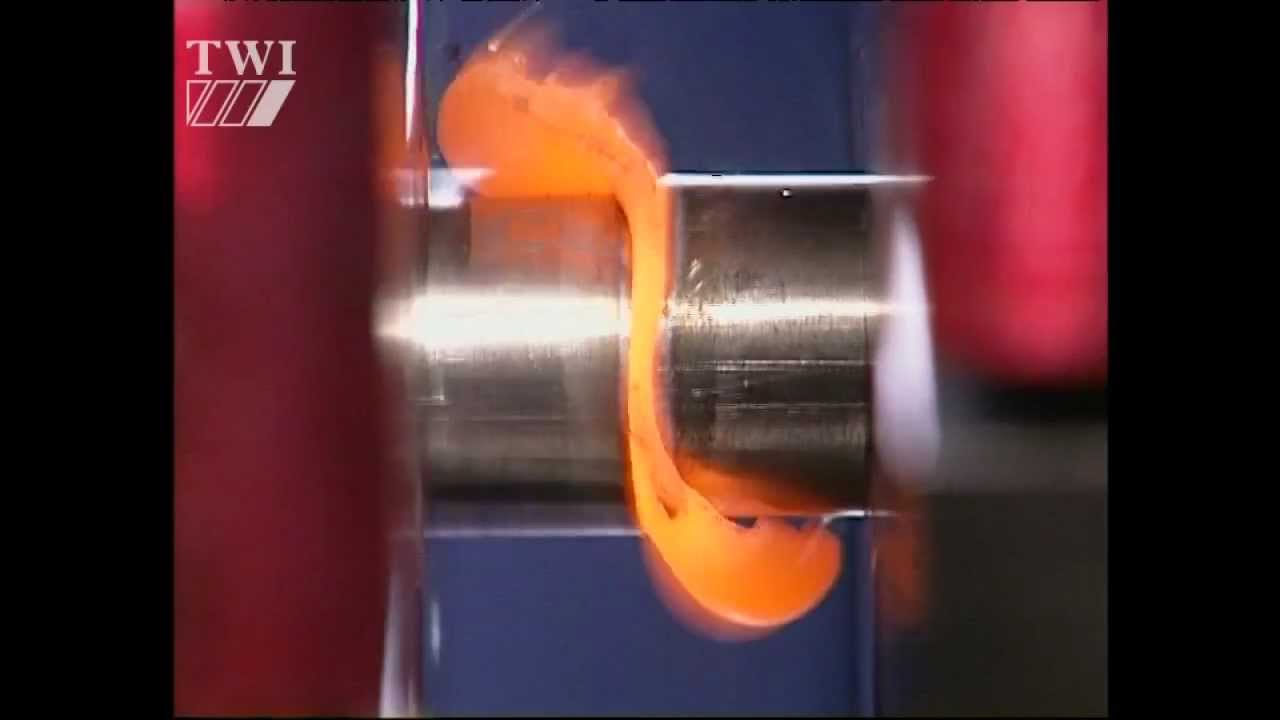

Spin Welding Video

Spin welding involves a rotating chuck along with a flywheel. After reaching the required speed the motor disengages with the flywheel.

Linear Friction Welding

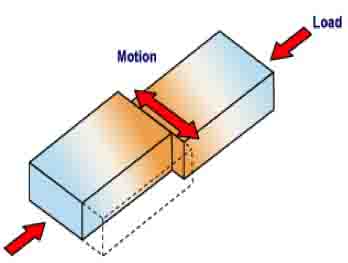

Linear Friction Welding Video

In linear friction welding, an oscillating chuck is used. It is applied to non-round shapes as compared to spin welding. The material welded has to have high shear strength.

In linear friction welding, an oscillating chuck is used. It is applied to non-round shapes as compared to spin welding. The material welded has to have high shear strength.

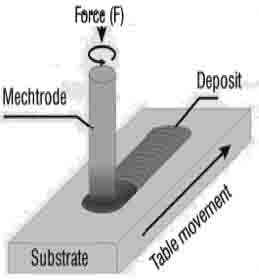

Friction Surfacing

Friction surfacing is a surface coating process. The coating material is Mechtrode, which is rotated under pressure over the substrate.

Friction Stir Welding

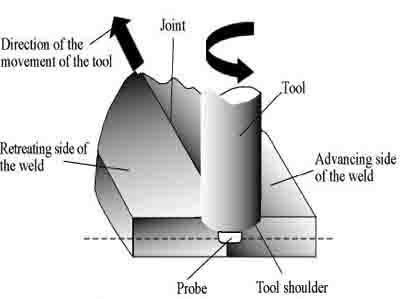

Friction stir welding is a cylindrical shouldered tool with a profiled probe. A pin or nib is used. Friction is created between the metal being worked, the nib and the shoulder.

Metals

There are a wide variety of metals that can be joined. The process can also be used to join different metals.

- Aluminum

- Brass

- Cast Iron

- Copper

- Lead

- Bronze

- Aluminum alloys

- Steel alloys

- Magnesium

- Magnesium Alloys

- Tungsten

- Vanadium

Advantages and Disadvantages of Friction Welding

Advantages:

- Can produce high-quality welds in short cycle time.

- No filler metal is required and flux is not used.

- The process is capable of welding most of the common metals. It can also be used to join many combinations of dissimilar metals. Friction welding requires a relatively expensive apparatus similar to a machine tool.

- Easy to operate equipment

- Not time-consuming

- Low levels of oxide films and surface impurities

- When compared to resistance butt welding creates better welds at a lower cost and higher speed, lower levels of electric current are required

- Small heat affected zone when comparing the process to conventional flash welding.

- When compared to flash butt welding, less shortening of the component.

- No need to use gas, filler metal or flux. No slag that can cause weld imperfections.

Disadvantages:

- Process limited to angular and flat butt welds.

- Only used for smaller parts.

- Complicated when used for tube welding.

- Hard to remove flash when working with high carbon steel.

- It requires a heavy rigid machine in order to create high thrust pressure.