The oldest metal sculpture pieces are made out of copper alloys and bronze.

These metals offer the artist strength while also being malleable.

Other metals such as gold and silver are softer, enabling the artisan the ability to shape the metal with tools and by hammering. Related to the sculpting process is metal casting, where metals can be poured into a mold.

It is thought that metal casting as an ancient art dates back 6000 years with the first works made out of gold and copper.

Ancient civilizations such as the Egyptians carved deities and leaders in gold and other precious metals. They were also expert at “lost wax” casting which allowed small intricate shapes to be cast.

The Chinese used metal to honor symbols of importance such as tigers, religious figures and leaders.

The use of metal continued with the Greeks and Romans, who used bronze to make life-like statues and figurines.

Once the Roman empire fell the baton was passed to Charlemagne and the germanic tribes. This “father of Europe” rule during Medieval times. He oversaw the use of bronze and iron to commemorate his rule. Statues were also made of the Virgin Mary and Jesus.

During the Renaissance art was a front and center part of the culture. Statues were produced made out of copper and bronze that were either commissioned by the Catholic Church (statues of saints) or of leaders.

In modern times, such as metal sculpture found in the United States, are used to commemorate war heroes (solider on horse) as well as a place in the avant-garde art scene. Large metal sculptures are also a fixture in parks and prominent public spaces.

Kits and Sculpture Supplies

There are many metal sculpture kits available that are perfect for the hobbyist or artist just getting started. These can often be purchased for under $20 (U.S.) and are relatively easy to assemble

Metals Used in Sculpture

Bronze

Thought to be the first portrait medal of the Renaissance era. The revers image is the emperor on horseback. Produced out of cast bronze and other metals between 1438 and 1439.

Source: Wikipedia, Fasanelli, J. A., (1965) ‘Some Notes on Pisanello and the Council of Florence’, Master Drawings, vol.3, no.1 pp. 36–47

The introduction of bronze was significant to any civilization which encountered it. Metal sculpture, tools, weapons and armor made of bronze were harder and more durable than their stone and copper (“Chalcolithic”) predecessors. In early use, the natural impurity arsenic sometimes created a superior natural alloy; this is termed arsenical bronze.

While copper and tin can naturally co-occur, the two ores are rarely found together (although one ancient site in Thailand provides a counterexample). Serious bronze work has therefore always involved trade. (In fact, archaeologists suspect that a serious disruption of the tin trade precipitated the transition to the Iron Age.) For Europe, the major source for tin was Great Britain.

The earliest tin-alloy bronzes date to the late 4th millennium BC in Susa (Iran) and some ancient sites in Luristan (Iran) and Mesopotamia.

Bronze was stronger than the era’s iron; quality steels were not available until thousands of years later. But the Bronze Age gave way to the Iron Age, perhaps because the shipping of tin around the Mediterranean (or from Great Britain) became more limited during the major population migrations around 1200 – 1100 BC, which dramatically limited supplies and raised prices. Bronze was still used during the Iron Age, but for many purposes the weaker iron was found to be sufficiently strong. As iron working improved, iron became both cheaper and stronger, eclipsing bronze in Europe by the early to mid-Middle Ages.

Thomas Jefferson Memorial Sculpture Dome” by Jamieadams99 – Own work. Licensed under Creative Commons Attribution-Share Alike 3.0 via Wikimedia Commons

Properties

When steel is excluded from the discussion, bronze is superior to iron in nearly every application. While it develops a patina, it does not oxidize. It is considerably less brittle than iron and has a lower casting temperature. (Steel, of course, has wonderful properties that bronze cannot compete with.)

Copper-based alloys have lower melting points than steel and are more readily produced from their constituent metals. They are generally about 10 percent heavier than steel, although alloys using aluminium or silicon may be slightly less dense. Bronzes are softer and weaker than steel, and more elastic, though bronze springs are less stiff (and so store less energy) for the same bulk. Bronzes resist corrosion (especially seawater corrosion) and metal fatigue better than steel. Bronzes also conduct heat and electricity better than most steels. The cost of copper-base alloys is generally higher than that of steels but lower than that of nickel-base alloys.

Copper and its alloys have a huge variety of uses that reflect their versatile physical, mechanical, and chemical properties. Some common examples are the high electrical conductivity of pure copper, the excellent deep-drawing qualities of cartridge case brass, the low-friction properties of bearing bronze, the resonant qualities of bell bronze, and the resistance to corrosion by sea water of several bronze alloys.

In the twentieth century, silicon was introduced as the primary alloying element, creating an alloy with wide application in industry and the major form used in contemporary statuary. Aluminium is also used for the structural metal Aluminium bronze.

Bronze is the most popular metal for top-quality bells and cymbals, and, more recently, saxophones. Bronze is also widely used for cast metal sculpture (see bronze sculpture). Common bronze alloys often have the unusual and very desirable property of expanding slightly just before they set, thus filling in the finest details of a mould.

Bronze also has very little metal-on-metal friction, which made it invaluable for the building of cannon where iron cannonballs would otherwise stick in the barrel. Bronze is still widely used today for springs, bearings, bushings and similar fittings, and is particularly common in the bearings of small electric motors. Phosphor bronze is particularly suited to precision-grade bearings and springs.

Bronze is typically 60% copper and 40% tin. Alpha bronze consists of the alpha solid solution of tin in copper. Alpha bronze alloys of 4-5% tin are used to make coins, springs, turbines and blades.

Commercial bronze (otherwise known as brass) is 90% copper and 10% zinc, and contains no tin. It is somewhat stronger than copper and it has equivalent ductility. It is used for screws and wires

Brass

Cyparissus’, copper and brass sculpture by Bumpei Akaji, 1968, Hawaii State Art Museum”. Via Wikipedia<

Brass is the term used for alloys of copper and zinc in a solid solution.

Typically it is more than 50% copper and from 5 to 20% zinc, in comparison to bronze which is principally an alloy of copper and tin.. Despite this distinction, some types of brasses are called bronzes.

Brass has a yellow color, somewhat similar to gold. Because of this, and its relative resistance to tarnishing, it is often used as a decoration.

Brass has been known to man since prehistoric times, long before zinc itself was discovered. It was produced by melting copper together with calamine, a zinc ore. During this process, the zinc is extracted from the calamine and instantly mixes with the copper. Pure zinc, on the other hand, is too reactive to be produced by ancient metalworking techniques.

Properties

The malleability and acoustic properties of brass have made it the metal of choice for brass musical instruments such as the tuba. Higher malleability than copper and zinc.

In some environments, brasses with higher content of zinc are prone to a selective leaching corrosion known as dezincification. In some territories, plumbing fittings designed to resist dezincification are embossed “CR” (corrosion resistant). A dezincified fitting has the pink appearance of pure copper and will easily crumble, being reduced to a weak sponge-like matrix. Brass is a versatile manufacturing material because of its hardness and workability.

Cast Iron

Kaslinskoe cast iron casting metal sculpture. “Radishchev Art Museum 10” by Eugene Alexandrovich Lanceray – Self-photographed. Licensed under Creative Commons Attribution-Share Alike 3.0 via Wikimedia Commons

Cast iron usually refers to grey cast iron, but can mean any of a group of iron-based alloys containing more than 2% carbon (alloys with less carbon are carbon steel by definition).

It is made by remelting pig iron, often along with substantial quantities of scrap iron and scrap steel, and taking various steps to remove undesirable contaminants such as phosphorus and sulfur, which weaken the material. Carbon and silicon content are reduced to the desired levels, which may be anywhere from 2% to 3.5% for carbon and 1% to 3% for silicon depending on the application. Other elements are then added to the melt before the final form is produced by casting.

The iron-carbon eutectic point lies at 1403 kelvins and 4.3 mass % carbon. Since cast iron has nearly this composition, its melting temperature of 1420 to 1470 K is about 300 K lower than the melting point of pure iron. Cast iron tends to be brittle, unless the name of the particular alloy suggests otherwise. The color of a fracture surface can be used to identify an alloy: carbide impurities allow cracks to pass straight through, resulting in a smooth, “white” surface, while graphite flakes deflect a passing crack and initiate countless new cracks as the material breaks, resulting in a rough surface that appears grey.

Gray Cast Iron

Gray cast iron (also called Gray Iron or International Standard A48) is a type of cast iron, with the difference being that is has what is called a graphitic microstructure. As the name implies, it is named after its’ color, which it inherits from the graphite content.

Silicon is essential to making of grey cast iron as opposed to white cast iron. Silicon causes the carbon to rapidly come out of solution as graphite, leaving a matrix of relatively pure, soft iron. Weak bonding between planes of graphite lead to a high activation energy for growth in that direction, resulting in thin, round flakes. This structure has several useful properties such as good machinability.

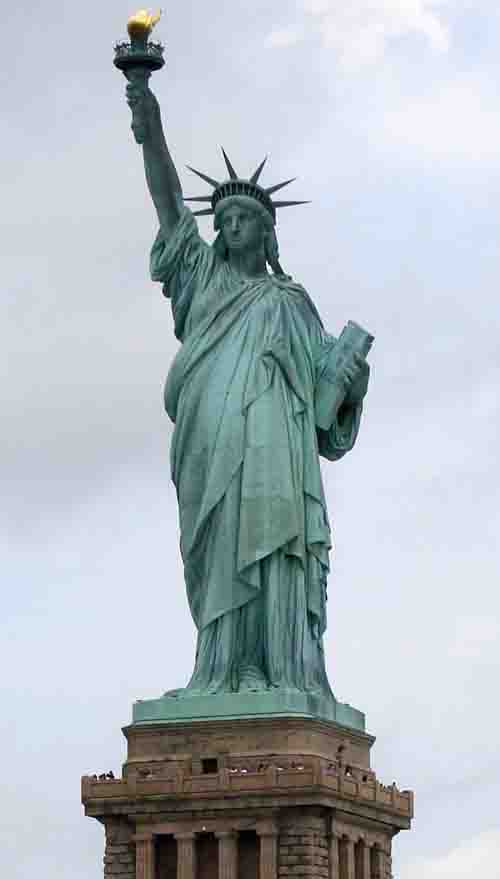

Copper

Statue of Liberty 7″ Clad in Copper Sheeting by Elcobbola – Own work. Licensed under Public domain via Wikimedia Commons

Copper is a chemical element in the periodic table that has the symbol Cu (L.: Cuprum) and atomic number 29.

It is a ductile metal with excellent electrical conductivity, and finds extensive use as a building material, as an electrical conductor, and as a component of various alloys.

Notable Characteristics

Copper is a reddish-colored metal, with a high electrical and thermal conductivity (among pure metals at room temperature, only silver has a higher electrical conductivity). Copper has its characteristic color because it reflects red and orange light and absorbs other frequencies in the visible spectrum, due to its band structure. Contrast this with the optical properties of silver, gold and aluminium.

Copper is insoluble in water (H2O) as well as isopropanol, or isopropyl alcohol.

There are two stable isotopes, 63Cu and 65Cu, along with a couple of dozen radioisotopes. The vast majority of radioisotopes have half lives on the order of minutes or less; the longest lived, 64Cu, has a half life of 12.7 hours, with two decay modes, leading to two separate products.

There are numerous alloys of copper—speculum metal is a copper/tin alloy, brass is a copper/zinc alloy, and bronze is a copper/tin alloy. Monel metal is a copper/nickel alloy, also called cupronickel.

British Museum Copper Bull” by BabelStone (Own work). Licensed under Creative Commons Zero, Public Domain Dedication via Wikimedia Commons

“Muisca raft Legend of El Dorado Offerings of gold” by Andrew Bertram – World66. Licensed under Creative Commons Attribution-Share Alike 1.0 via Wikimedia Commons

Gold is a chemical element in the periodic table that has the symbol Au (from the Latin aurum) and atomic number 79.

A soft, shiny, yellow, dense, malleable, ductile (trivalent and univalent) transition metal, gold does not react with most chemicals but is attacked by chlorine, fluorine and aqua regia. The metal occurs as nuggets or grains in rocks and in alluvial deposits and is one of the coinage metals.

For millennia gold has been used as money, a store of value and in jewelry. Modern industrial uses include dentistry and electronics. Gold forms the basis for a monetary standard used by the International Monetary Fund (IMF) and the Bank for International Settlements (BIS). Its ISO currency code is XAU.

Notable Characteristics

Gold is a metallic element with a characteristic yellow color, but can also be black or ruby when finely divided, while colloidal solutions are intensely colored and often purple. These colors are the result of gold’s plasmon frequency lying in the visible range, which causes red and yellow light to be reflected, and blue light to be absorbed. Only silver colloids exhibit the same interactions with light, albeit at a shorter frequency, making silver colloids yellow in color.

Tin

Tin Man Metal Sculpture Made From Cookware such as Pots and Pans

Tin is a chemical element in the periodic table that has the symbol Sn (L. Stannum) and atomic number 50.

This silvery, malleable poor metal that is not easily oxidized in air and resists corrosion is found in many alloys and is used to coat other metals to prevent corrosion. Tin is obtained chiefly from the mineral cassiterite, where it occurs as an oxide.

Notable Characteristics

Tin is a malleable, ductile, highly crystalline, silvery-white metal whose crystal structure causes a strange screeching sound known as the “tin cry” when a bar of tin is bent (caused by crystals breaking). This metal resists corrosion from distilled sea and soft tap water, but can be attacked by strong acids, alkalis, and by acid salts. Tin acts as a catalyst when oxygen is in solution and helps accelerate chemical attack.

Tin forms the dioxide SnO2 when it is heated in the presence of air. SnO2, in turn, is feebly acidic and forms stannate (SnO3-2) salts with basic oxides. Tin can be highly polished and is used as a protective coat for other metals in order to prevent corrosion or other chemical action.

Because is it so malleable, it is a popular choice in metal structure.

Wrought Iron

“IITB Lawn” Metal Sculpture by Rohan Sethi, IIT Bombay – Personal communication. Licensed under Creative Commons Attribution-Share Alike 3.0 via Wikimedia Commons

Wrought iron is a very pure form of commercial iron, having a very small carbon content. It is tough, malleable, ductile and can be easily welded. However, it is too soft to make blades and swords. When formed into bars, it is known as “bar iron”.

Wrought iron has been used for thousands of years, and represents the “iron” that is referred to throughout history. In turn, it is also in the metal sculpture.

Wrought iron was originally produced by a variety of methods today known as a bloomery. Bloomeries used charcoal-heated smelters, typically in the form of small pots or ladles, into which the ore was poured and then covered with a thin layer of charcoal. Air was blown onto the charcoal after lighting it on fire. The heat produced would melt the ore. As the ore melted it would be reduced (ore is iron oxide, or rust), mixing with the charcoal to release carbon dioxide. This way little carbon entered the iron directly.

In a bloomery, the fire does not get hot enough to melt the iron completely, so you are left with a spongy mass containing iron and silicates from the ore; this is iron bloom from which the technique gets its name. The bloom was then mechanically worked to break off the masses of slag and impurities. This process gives rise to the name “wrought”, as the iron was pounded, twisted, and folded. As a result of this process, many strands of slag are mixed into the metal. These slag inclusions give it a “grain” like wood, and distinct look when etched. Also due to the slag, it has a fibrous look when broken or bent past its failure point.

Silver

“British Museum Asia 8” by Gryffindor – Own work. Licensed under Creative Commons Attribution-Share Alike 3.0 via Wikimedia Commons

Silver is a chemical element with the symbol Ag (from the traditional abbreviation for the Latin argentum). A soft white lustrous transition metal, it has the highest electrical and thermal conductivity of any metal and occurs in minerals and in free form.

This metal is used in metal sculpture, coins, jewelry, tableware, photography, and in mirrors.

Notable Characteristics

Silver is a very ductile and malleable (slightly harder than gold)