Welding overlap is a common yet easily preventable defect in welding. Understanding how to avoid overlap and other defects is crucial for achieving a high-quality weld.

Welding techniques have evolved primarily to minimize defects. The more carefully you execute these techniques, the better your weld will be.

This article takes an in-depth look at the causes of welding overlap and practical ways to prevent and fix it.

What is Welding Overlap?

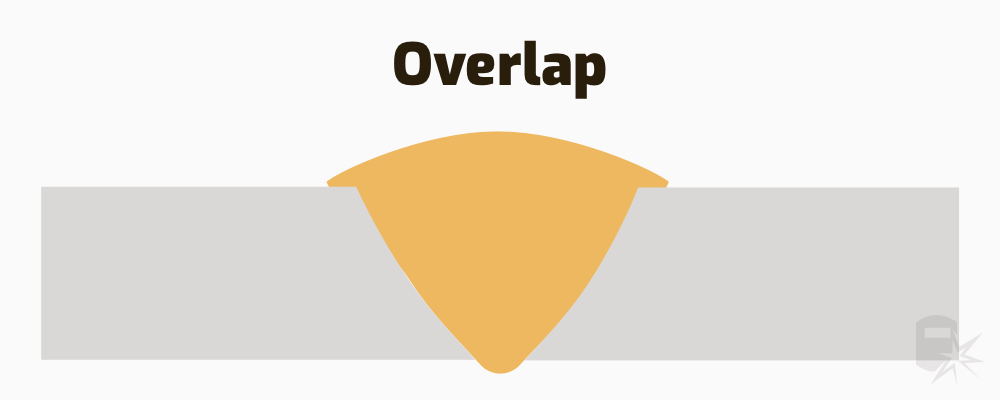

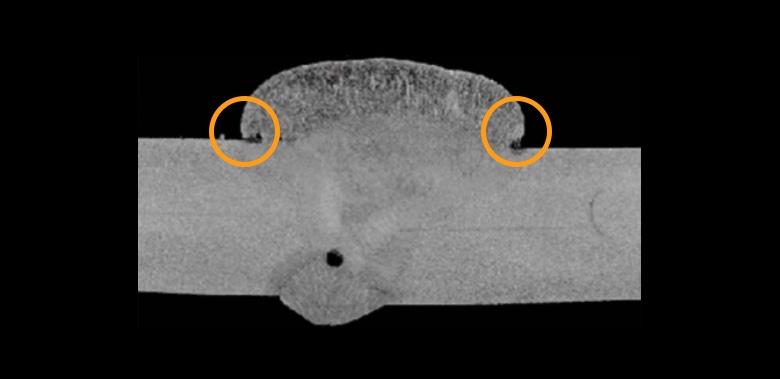

Welding overlap is extra filler material that protrudes beyond the weld toe or root. It occurs when additional filler metal is added to the weld pool but doesn’t properly mix with the base metal, causing it to flow outside the weldment.

Technically speaking, this overlap results from the surplus filler material spreading around the bead. This is in contrast to an ideal weld, where the base metals and filler metal melt and fuse into each other to create a solid joint.

To help visualize, think of an overflowing swimming pool. When surplus water exceeds a pool’s capacity, it flows out onto surfaces where it shouldn’t be.

Similarly, in welding overlap, the extra filler metal overflows, landing where it should not.

4 Main Causes of Overlap & How to Prevent it

© weldguru.com – Image usage rights

The four major causes of welding overlap are amperage settings, travel speed, electrode selection & usage, and welding technique.

Preventing overlap should be a priority for welders, as it impacts costs and aesthetics, although it has minimal effect on weld performance unlike other defects.

Let’s take a closer look at each one.

1. Amperage

Setting the amperage or current too high leads to excess filler material in the weld pool, causing it to flow out and solidify improperly.

To avoid this, check a settings chart to determine the optimal amperage settings for your specific job.

Once you’ve established a good starting point, perform test welds to fine-tune your settings. If overlap still occurs, lower the amperage incrementally until you achieve a clean weld.

2. Travel Speed

Low travel speed results in filler material accumulating in the weld pool, leading to overlap when the filler cannot properly fuse with the parent metal. The remedy is straightforward: Increase your travel speed if you notice overlapping.

Be cautious, though; too much speed can introduce other issues. The key is to find a balanced travel speed that prevents overlap while avoiding additional defects.

3. Electrode Selection & Usage

Choosing the wrong electrode size and angle can lead to welding overlap by affecting how much filler material is deposited.

To prevent this, correct electrode selection and proper angling are essential.

Electrode Angle

A wrong electrode angle leads to uneven filler deposition, causing more material to accumulate on one side of the weld bead, resulting overlap.

To fix this, adjust your electrode angle to ensure an even distribution of filler material across the weld.

Electrode Size

Using a large electrode introduces more filler material into the weld pool, increasing the risk of overlap.

If you suspect that electrode size is the issue, consult guides or experienced welders to select an appropriate size for your project

4. Welding Technique

Poor edge preparation, misaligned base metals, and lack of cleanliness can result in overlap. Addressing these issues is crucial for preventing this particular welding defect.

Start by thoroughly preparing your edges to be free of bumps or craters. Ensure proper alignment of the base metals before you begin welding. The cleaner and better-aligned your setup, the less likely you are to experience overlap.

How to Fix Welding Overlap

If you encounter overlap, it can be rectified by grinding off the excess material. Start by marking the boundaries where proper fusion occurs and carefully remove the overlap up to that point.

Welding defects are inevitable, even with the best practices. However, a bit of focused effort can make your weld look more professional and aesthetically pleasing.

Use caution during grinding to ensure you don’t damage the joint.

Conclusion

To minimize the risk of welding overlap, meticulous preparation and proper technique is key. Should overlap occur, it can usually be fixed by careful grinding.

Welding overlap, although common, is largely preventable through careful selection of electrode size, proper amperage settings, and a thorough understanding of welding techniques.

Feel free to comment below if you have further insights or think we missed something. Thanks for reading!