When discussing anything with multiple components, you need to know the names of each part.

This also applies to welds.

There are multiple “parts” that every welder needs to know.

Parts of Weld Diagrams

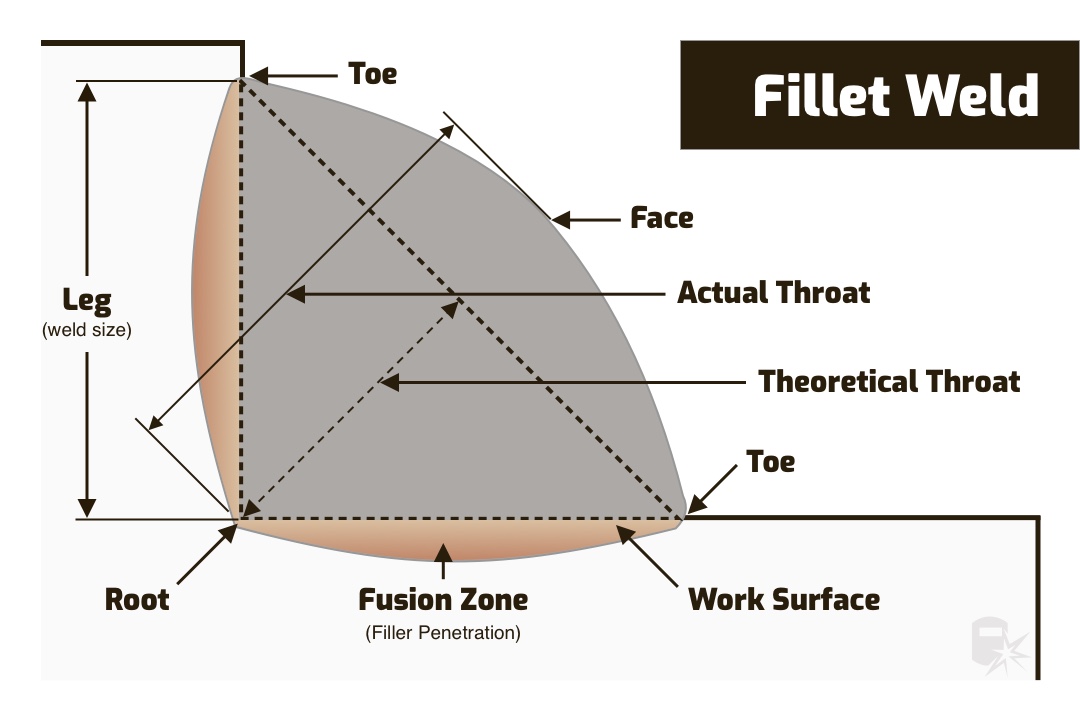

Parts of a Fillet Weld

A fillet weld joins two pieces of metal at an angle (60 to 120 degrees) or two lapped, flat ends.

The bead sits on the inside corner created by the base metal.

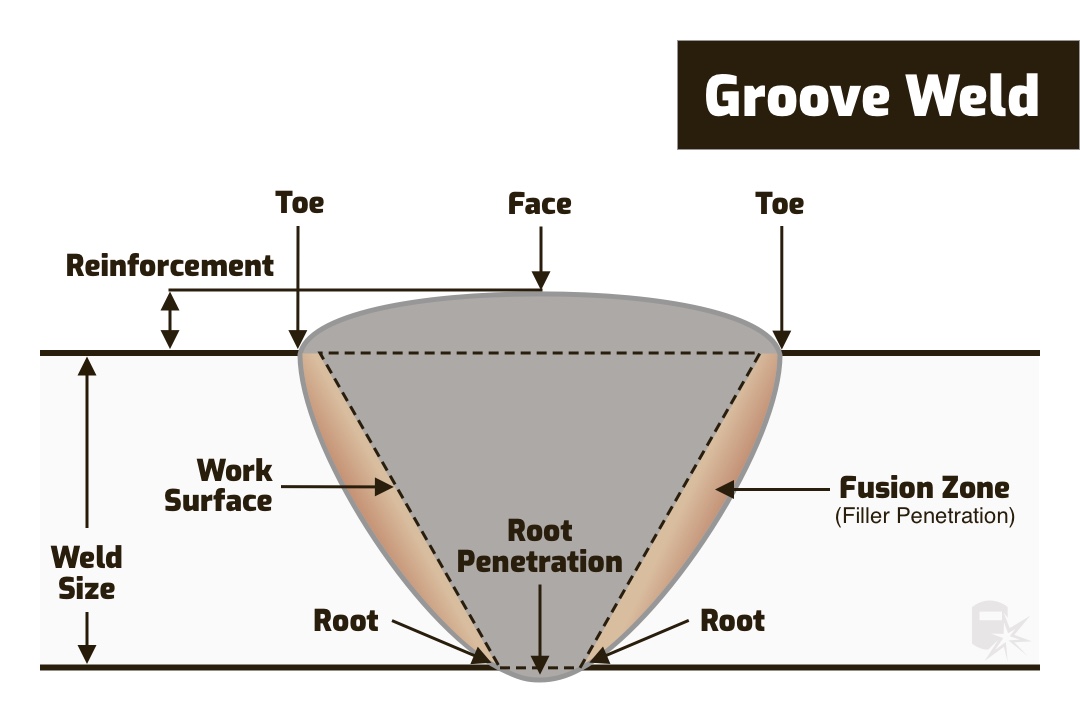

Parts of a Groove Weld

A groove weld is a bead placed into a groove made on the surface of the workpiece or the opening between two butted pieces.

Parts of Weld Explained

Weld Toe

The interface of the weld face and base metal.

Weld Face

The exposed weld surface on the side where the torch created the weld.

Weld Root

The interface of the weld and base metal at the “bottom” of the weld., opposite the face.

Weld Leg

The distance from the weld toe to the weld root.

Fusion Zone

The zone of base metal melted during the weld (as determined with a cross-section). Sometimes referred to as filler penetration.

Weld Reinforcement

Height of the portion of the weld above the base metal surface.

Fillet Weld Throat

The theoretical throat is the perpendicular distance of the weld from the hypotenuse of the largest right triangle that can be inscribed within the fillet weld cross-section (i.e., a line that connects the toe on each side of the root) to the root.

The actual throat is the distance from the root of a fillet weld to the center of its face.

What is The Size of The Weld?

Equal Leg Length Fillet Welds

For fillet welds with equal leg length, the size of the weld is designated by the leg length of the largest isosceles right triangle that can be scribed within the fillet weld cross-section.

Unequal Leg Length Fillet Welds

For unequal leg length, the size of the weld is designated by the largest leg length of the largest right triangle that can be inscribed within the fillet weld cross-section.

Groove Welds

The size of the weld is the depth of chamfering, plus the root penetration when specified.