PAW or Plasma arc welding (PAW) is where the joining of metals or coalescence takes place by heating with a constricted arc between the workpiece (transfer arc) and an electrode or the constricting nozzle and the electrode (non-transfer arc).

Narrow and deep welds can be made using this process at high welding speeds.

The way shielding occurs is related to the hot ionized gas that issues from the orifice. It can also be supplemented by another source of shielding gas. The shielding gas can be a mixture of gases or inert gas. Pressure can be used (or not used). You can also supply or not supply a filler metal.

The objective of the plasma arc welding process is to increase the energy level of the arc plasma in a controlled manner.

It is achieved by providing a special gas nozzle around a tungsten electrode operating on a DCEN power source.

The constricted plasma formed is concentrated and highly ionized.

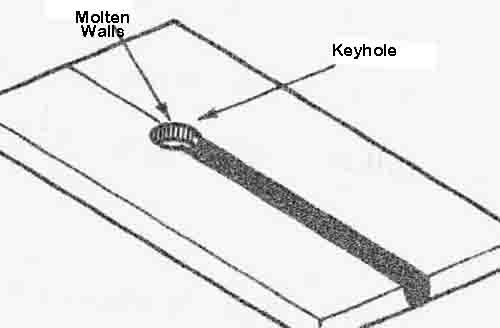

The process is detailed in the diagram below:

PAW Demonstration Video

Plasma Welding Equipment

Power Source

It is recommended that a constant current drooping characteristic power source that supplies DC welding current be used; that said ac/dc power can also be utilized.

Voltage should be an open circuit of 80 volts with a duty cycle of 60%. It is preferable that the power source have a built-in contactor and provisions for remote control current adjustment.

When welding very thin metals, it should have a minimum target amperage of 2 amps. A max. of 300 is workable for most plasma welding projects.

PAW Welding Torch

The welding torch for plasma arc welding is similar in appearance to a gas tungsten arc torch, but more complex.

All plasma torches are water cooled, even the lowest-current range torch. This is because the arc is contained inside a chamber in the torch where it generates considerable heat. If water flow is interrupted briefly, the nozzle may melt.

A cross section of a plasma welding arc torch head is shown by figure 10-36. During the non-transferred period, the arc will be struck between the nozzle or tip with the orifice and the tungsten electrode. Manual plasma arc torches are made in various sizes starting with 100 amps through 300 amperes. Automatic torches for machine operation are also available.

The torch utilizes the 2 percent thoriated tungsten electrode similar to that used for gas tungsten welding. Since the tungsten electrode is located inside the torch, it is almost impossible to contaminate it with base metal.

Control Console

A control console is required for plasma arc welding. The plasma arc torches are designed to connect to the control console rather than the power source. The console includes:

- A power source for the pilot arc

- A delay timing system for transferring from the pilot arc to the transferred arc

- Water and gas valves

- Separate flow meters for the plasma gas and the shielding gas.

The console is usually connected to the power source and may operate the contactor. It will also contain a high-frequency arc starting unit, a non-transferred pilot arc power supply, torch protection circuit, and an ammeter.

The high-frequency generator is used to initiate the pilot arc. Torch protective devices include water and plasma gas pressure switches which interlock with the contactor.

Wire Feeder

A wire feeder may be used for machine or automatic welding and must be the constant speed type. The wire feeder must have a speed adjustment covering the range of from 10 in. per minute (254 mm per minute) to 125 in. per minute (3.18 m per minute) feed speed.

Advantages

Advantages of plasma arc welding when compared to gas tungsten arc welding stem from the fact that PAW has a higher energy concentration. Its higher temperature, constricted cross-sectional area, and the velocity of the plasma jet create a higher heat content. The other advantage is based on the stiff columnar type of arc or form of the plasma, which doesn’t flare like the gas tungsten arc.

These two factors provide the following advantages:

- More Freedom During Manual Welds: The torch-to-work distance from the plasma arc is less critical than for gas tungsten arc welding. This is important for manual operation since it gives the welder more freedom to observe and control the weld.

- Keyhole Effect (complete single-pass penetration): High temperature and high heat concentration of the plasma allow for the keyhole effect, which provides complete penetration single pass welding of many joints. In this operation, the heat-affected zone and the form of the weld are more desirable. The heat-affected zone is smaller than with the gas tungsten arc, and the weld tends to have more parallel sides, which reduces angular distortion.

In the keyhole mode, a penetrating hole is formed at the leading edge of the weld pool. The molten weld metal flows around the hole and solidifies behind the keyhole to form the weld bead. Therefore, keyhole welds are complete penetration welds with high depth to width ratios. This results in low weld distortion. With operating currents up to 300 amperes, this mode can be used to weld materials up to about 3/4 inch thick, and to weld titanium and aluminum alloys. - Faster Travel Speeds: The higher heat concentration and the plasma jet allow for higher travel speeds.

The plasma arc is more stable and is not as easily deflected to the closest point of base metal. Greater variation in joint alignment is possible with plasma arc welding. This is important when making root pass welds on pipe and other one-side weld joints. Plasma welding has deeper penetration capabilities and produces a narrower weld. This means that the depth-to-width ratio is more advantageous.

Disadvantages

- Orifice replacement necessary

- Expensive equipment

- More skill needed than for GTAW process

Major Uses

Some of the major uses of plasma arc are its application for the manufacture of tubing (stainless steel, titanium alloy). Higher production rates based on faster travel speeds result from plasma over gas tungsten arc welding. Tubing made of stainless steel, titanium, and other metals is being produced with the plasma process at higher production rates than previously with gas tungsten arc welding.

Most applications of plasma welding are in the low-current range, from 100 amperes or less. The plasma can be operated at extremely low currents to allow the welding of foil thickness material.

Plasma welding is also used for making small welds on weldments for instrument manufacturing and other small components made of thin metal. It is used for making butt joints of wall tubing.

This process is also used to do work similar to electron beam welding, but with a much lower equipment cost.

Welding Process

Plasma arc welding is normally applied as a manual welding process, but is also used in automatic and machine applications. Manual application is the most popular. Semiautomatic methods of application are not useful.

The normal methods of applying plasma arc welding are manual (MA), machine (ME), and automatic (AU).

Positions

The plasma welding process is an all-position welding process. Table 10-2 below shows the welding position capabilities.

Welding Positions Capabilities

| Welding Position | Rating |

|---|---|

| 1. Flat Horizontal Fillet | A |

| 2. Horizontal | A |

| 3. Vertical | A |

| 4. Overhead | A |

| 5. Pipe-fixed | A |

Metals

Types of Metals Welded

The plasma welding process is able to join practically all commercially available metals. It may not be the best selection or the most economical process for welding some metals. The plasma arc welding process will join all metals that the gas tungsten arc process will weld.

This is illustrated in table 10-3 below.

Base Metals Weldable By The Plasma Arc Process

| Base Metal | Weldability |

|---|---|

| Aluminums | Weldable |

| Bronzes | Possible, not popular |

| Copper | Weldable |

| Copper Nickel | Weldable |

| Cast, malleable, nodular | Possible, not popular |

| Wrought iron | Possible, not popular |

| Lead | Possible, not popular |

| Magnesium | Possible, not popular |

| Inconel | Weldable |

| Nickel | Weldable |

| Monel | Weldable |

| Precious metals | Weldable |

| Low carbon steel | Weldable |

| Low allow steel | Weldable |

| High & Medium Carbon | Weldable |

| Alloys Steel | Weldable |

| Stainless Steel | Weldable |

| Tool steels | Weldable |

| Titanium | Weldable |

| Tungsten | Weldable |

Metal Thickness

Regarding thickness ranges welded by the plasma process, the keyhole mode of operation can be used only where the plasma jet can penetrate the joint. In this mode, it can be used for welding material from 1/16 in. (1.6 mm) through 1/4 in. (12.0 mm). Thickness ranges vary with different metals. The melt-in mode is used to weld material as thin as 0.002 in. (0.050 mm) up through 1/8 in. (3.2 mm).

Using multi-pass techniques, unlimited thicknesses of metal can be welded. Note that the filler rod is used for making welds in thicker material. Refer to table 10-4 below for base metal thickness ranges.

Process Limitations

The major limitations of the plasma welding process have to do more with the equipment and apparatus.

- The torch is more delicate and complex than a gas tungsten arc torch. Even the lowest-rated torches must be water-cooled.

- The tip of the tungsten and the alignment of the orifice in the nozzle is extremely important and must be maintained within very close limits. The current level of the torch cannot be exceeded without damaging the tip.

- The water-cooling passages in the torch are relatively small and for this reason, water filters and deionized water are recommended for the lower current or smaller torches. The control console adds another piece of equipment to the system. This extra equipment makes the system more expensive and may require a higher level of maintenance.