So, you want to weld titanium, but you’re unsure where to start. Titanium alloy isn’t the easiest material to weld as it acts like a mixture of stainless steel and aluminum.

If you haven’t welded both of those metals, this will be an extra challenge.

Titanium is as strong as stainless steel but much lighter than steel, like aluminum. It has the same corrosion resistance as stainless and aluminum with a similar oxide layer.

Most people want to weld titanium pipe for exhaust systems or bike frames.

If you’re ready for your next challenge and follow these tricks and tips, you’ll reach success a lot quicker.

What Is the Best Way To Weld Titanium?

The best way to weld titanium is using TIG (GTAW). This process is the best as it’s the most cost-effective and easiest way to get good results.

© weldguru.com – Image usage rights

With TIG, controlling the weld puddle and the heat-affected zone is much easier to protect the weld puddle from environmental contamination.

You can also use MIG welding (GMAW), but I wouldn’t recommend it as it can generate too much heat and spatter for titanium welds, leading to contamination.

Other processes used to weld titanium are electron beam welding, friction welding, or laser welding, which offer great control and produce high-quality welds with minimal contamination.

However, the welding equipment for these other processes is expensive, and you need some intense training. To give you some perspective, those are processes NASA uses for its projects, not quite intended for your DIYs.

Pre-Welding Preparation

When welding with TIG, the material, the tungsten, and the filler rod has to be clean to avoid contamination, or the contamination will transfer to the weld puddle, creating weld faults.

You have to weld stainless steel clean, aluminum even cleaner, and titanium has to be even cleaner than aluminum.

Handling & Cleaning Titanium

Titanium is easy to contaminate, and you must make every effort to clean the material and keep it clean throughout the welding process.

All tools and even your gloves should touch titanium only. Even touching the material with your bare hands can potentially contaminate the material.

All brushes should be stainless steel, and all grinding discs, deburring tools, and files needed for your project should be for titanium use only.

How To Clean the Surface

You’ll want to remove the oxide layer, as it melts much higher than the parent metal it’s protecting, just like you would with aluminum.

You can do this with a grinder or stainless steel wire brush. Ensure there’s no paint, oil, or anything else on the material that could cause contamination.

Credit: The Fabrication Series

Once that’s all removed, wear protective gloves, such as nitrile gloves, to apply an industrial cleaning agent, like acetone or methyl ethyl ketone, with a lint-free cloth, and wipe the complete welding zone.

You should go at least an inch on either side of the welding zone so nothing creeps into it to contaminate it.

Credit: Weld.com

Also, wipe down your tungsten and filler rod before welding to ensure everything is clean.

On longer breaks, you’ll want to protect your material with a thick cardboard or lint-free blanket to keep it free from contamination.

An important safety note: Dust created in the grinding and preparation of titanium can be volatile. I recommend a respirator and a well-ventilated area.

Shielding Gas Coverage

The recommended shielding gas for welding titanium is argon; you can also use an argon/helium mix.

Helium in any shielding gas increases deposition rates, as it increases your welding arc heat, and those are the situations where you should be using that mixture. The preferred mix is 75% argon and 25% helium.

Shielding gas coverage is important for your weld puddle and filler rod. Your filler rod should always be under the protection of the shielding gas when you’re welding titanium.

You should cut a half inch or so off your filler rod between welds, as environmental gases may have contaminated it.

When TIG welding, you should have a pre-flow of about 5 seconds before initiating an arc and a post-flow of 25 seconds. Your flow rate should be around 25psi with argon and around 28 or so with an argon/helium mix.

I recommend using a trailing shield, which you can sometimes buy at your local supplier. You can buy one online or make a custom one for your TIG gun.

This secondary shield gas protects what you’ve already welded as your weld cools like a post-flow gas.

© weldguru.com – Image usage rights

All this protects everything from nitrogen and oxygen from the air as titanium is reactive and prone to contamination.

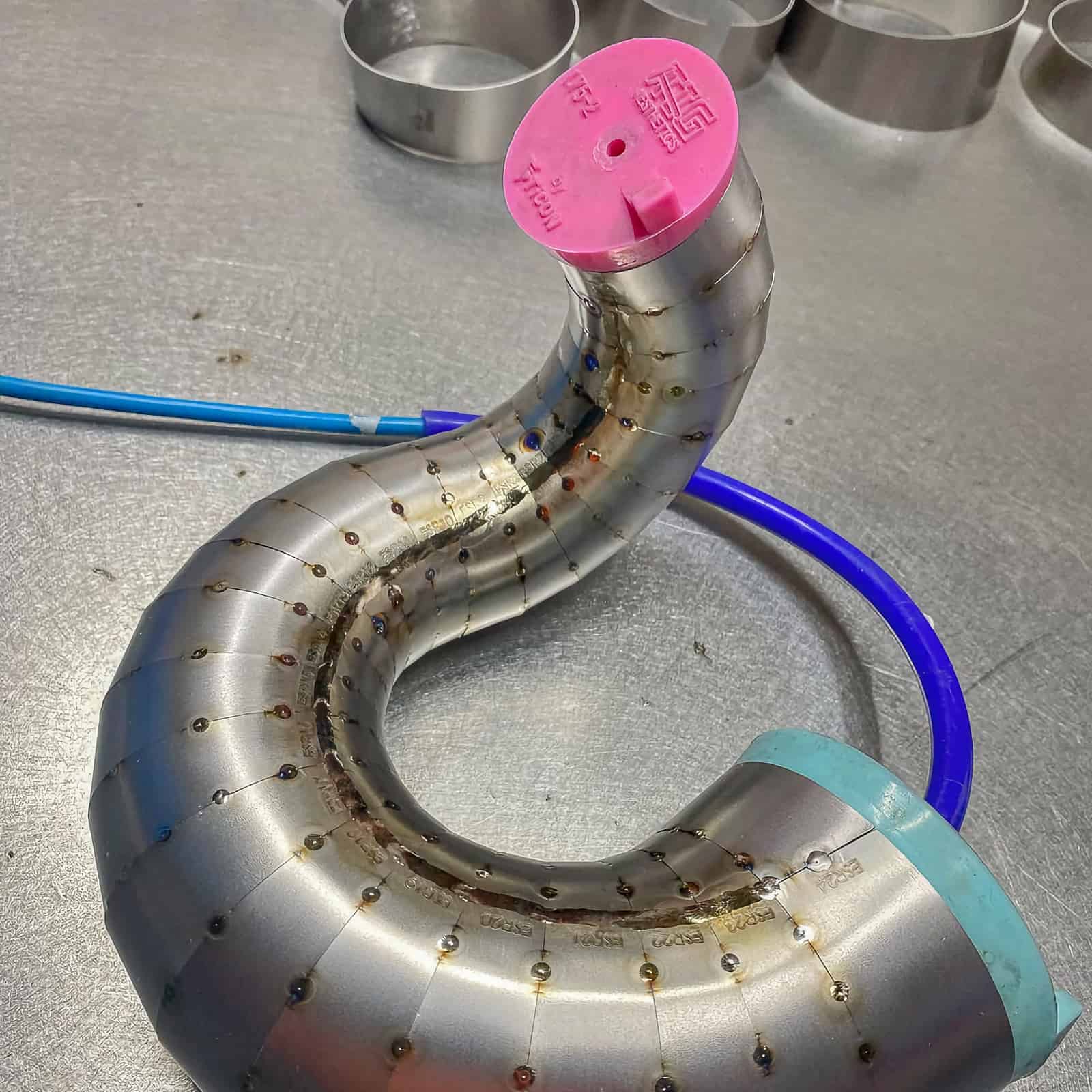

Purging the Underside

You should always purge the underside of titanium, just as you would when welding stainless steel.

I would use straight argon gas as it’ll be your cheapest inert gas.

© weldguru.com – Image usage rights

Make sure you have a good purge going. There should be absolutely no environmental gases left and only pure argon remaining.

You must do this as titanium is reactive with oxygen and nitrogen, the two main gases in the environment.

If you don’t do the purging or don’t do it correctly, you’ll get sugaring, the same as you would with stainless steel.

© weldguru.com – Image usage rights

When sugaring occurs, your weld will be much darker, appear uneven, lose its corrosion resistance, and be more prone to cracking. You’ll also see a white substance on your weld, similar to sugar.

At this point, you must do a cut-out, where you would cut out up to the edge of your heat-affected zone and start over.

Selecting the Right Filler Metal

For anything ⅛” or less, a filler rod isn’t necessary, but I still recommend it to avoid cracking and undercutting.

With thicker materials, as with welding any other materials with the TIG process, selecting the right filler metal is crucial.

You’ll want to match your consumable as closely as possible to the characteristics of your parent metal or better. Doing this avoids cracking, lack of fusion, undercut, and lack of penetration.

For example, Grade 1 is the purest type of titanium you can weld with an ErTi-2 (Grade 2) TIG welding rod. Grade 2 is stronger than Grade 1, so for this reason, it’s acceptable.

The characteristics and configuration of the joint will influence the size of the filler rod you choose but not the grade.

For example, for a vertical but weld, I would use a 3/32” filler as it’ll be easier to manipulate to get your desired outcome.

But on a flat lap or corner joint, I would use ⅛” and maybe even a 5/32” filler rod.

The Importance of Proper Joint Fit-Up

It’s very important to have proper joint fit-up because if you don’t, you’re setting yourself up for failure.

You want to ensure you take your time and properly set up your project to give you the best chance of success.

You should have no excessive gap on an open root to avoid burn-through and excessive reinforcement.

You want your lap, corner, and tee joints to be nice, tight, and square to avoid a lack of filler, undercut, and distortion.

Titanium is very prone to distortion, just like stainless steel.

5 Welding Tips for Titanium Welding

1. avoid contamination at all costs

The best welding tip for welding titanium is to avoid contamination at all costs.

Ensure your parent metal, tungsten, filler rod, and workspace are clean and stay clean to avoid any weld or material contamination.

2. keep your heat settings low

Make sure you keep your heat settings low as you would with stainless steel, as it’s very easy to overheat.

Too much heat will cause distortion and sugaring, making repairs time-consuming and costly.

It’s even a great idea to monitor your inter-heat temperatures with a heat gun or temperature stick on thicker materials to avoid overheating.

3. Get Good Gas Coverage

Use a proper gas pre-flow, flow rate, and post-flow to protect your weld before, during, and after initiating your welding arc.

You’ll also want to use a gas lens for the best gas coverage while welding.

4. Use A TIG Machine With The Right Features

Use a TIG welder with high-frequency start for arc initiation and pulse capabilities to finely control heat input.

These features make titanium welding much easier and reduce contamination risks from arc striking.

5. Keep a narrow heat setting

The correct amperage range for titanium is narrow, so constantly monitor your settings.

It’s easy to weld titanium too hot or too cold. Staying in the optimal range takes practice and vigilance.

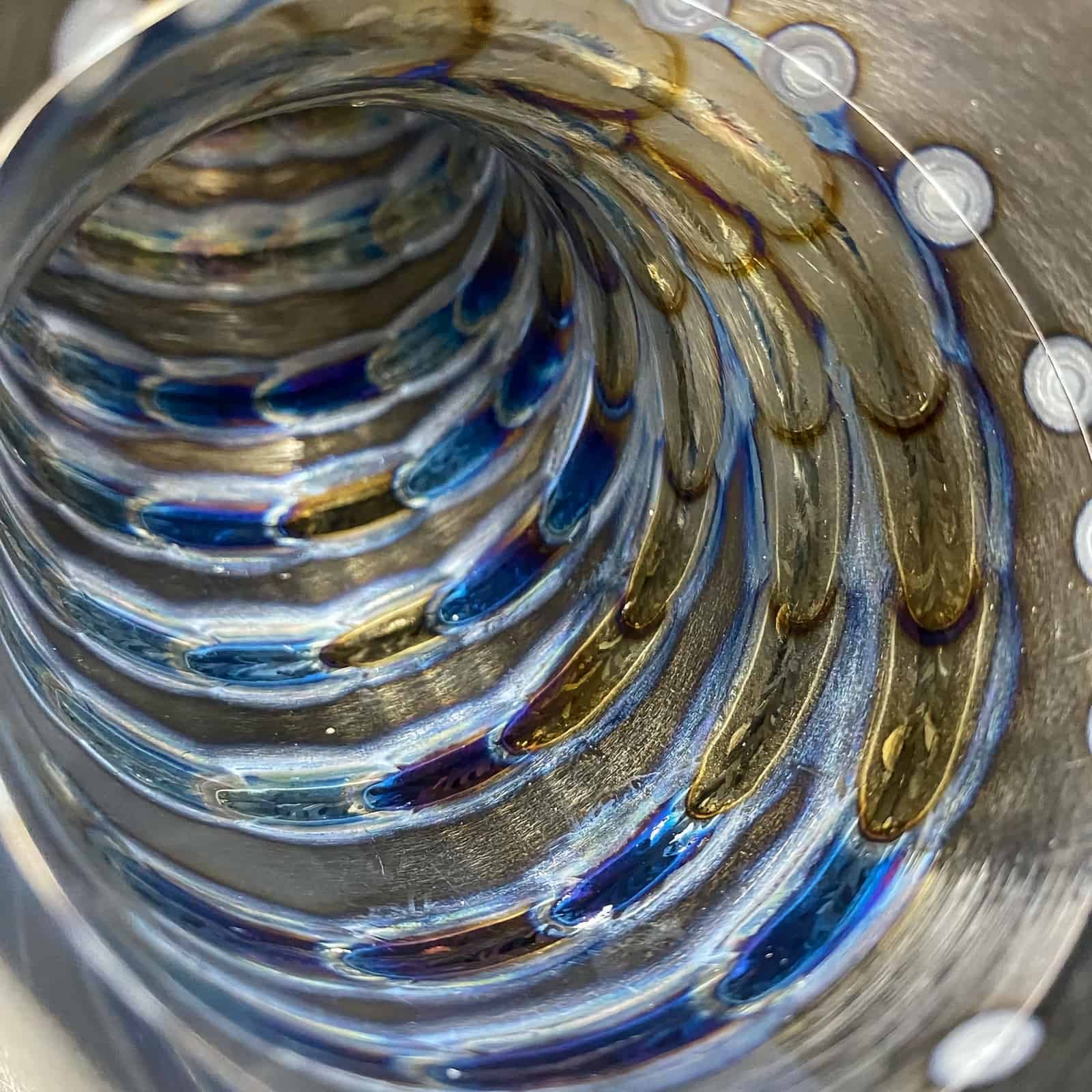

How To Detect Heavy Oxidation in Titanium

You can tell if you have a good or bad weld just by the color. Basically, the darker the color you get, the poorer your weld quality is, and this may result in a cut-out and do-over.

Ideally, you want your weld to look just like the titanium you’re welding: nice and shiny.

This result indicates no contamination and a nice and clean weld.

As contamination increases, the color changes from your nice silver finish to a light straw color, darker straw, dark blue, light blue, grey, and powdery white.

Up to a darker straw color is normally acceptable, depending on the application. Once you get to a dark and light blue, it can be acceptable, depending on the application.

But once you get to the grey and white powder, you’ve too much titanium oxide buildup and it’s automatically a failure. You must cut it out and start over.

| Weld Color | Inspection |

|---|---|

| Glossy silver | Acceptable |

| Light straw | Acceptable |

| Dark straw | Acceptable |

| Purple | Acceptable |

| Blue | Rejectable |

| Yellow | Rejectable |

| Gray | Rejectable |

| White | Rejectable |

To know for sure if your weld is acceptable, you can do a hardness test, and if you fall within the safe range, your weld will be fine.

Quick FAQs

Can You Weld Titanium to Aluminum?

You can weld them together, but it’s not recommended. It’s a complex and challenging process due to their significant differences in melting points, reactivity, and physical properties.

Doing this requires specialized techniques and careful consideration to achieve a successful and durable weld between titanium and aluminum.

Can You Weld Stainless Steel to Titanium?

You can do this, but I don’t recommend it. They have significant differences in melting points, thermal expansion rates, and reactivity, making welding them together very complex.

Can You MIG Weld Titanium?

The short answer is yes, but it’s not common or widely used. Titanium is highly reactive to oxygen and nitrogen, and with this welding process, it’s difficult to protect everything from contamination. You’ll also need expensive, specialized equipment and setup to make this possible.

Wrapping It Up

Even though welding titanium can be very difficult, if you follow these tips, it’ll definitely lower your learning curve and get you to success much quicker.

I would try aluminum and stainless steel welding first, as you’ll gain skills and knowledge from those two, which will help you greatly in welding titanium.

Again, good luck, have fun, and don’t quit until you get it right!