The two main categories of underwater welding techniques are:

- Wet underwater welding

- Dry underwater welding (also called Hyperbaric welding)

In wet underwater welding, shielded metal arc welding is commonly used, employing a waterproof electrode. Other processes that are used include flux-cored arc welding and friction welding.

In each of these cases, the welding power supply is connected to the welding equipment through cables and hoses.

The process is generally limited to low carbon equivalent steels, especially at greater depths, because of hydrogen-caused cracking.

In dry underwater welding, the weld is performed at the prevailing pressure in a chamber filled with a gas mixture sealed around the structure being welded.

For this process, gas tungsten arc welding is often used, and the resulting welds are generally of high integrity.

The applications of underwater welding are diverse – it is often used to repair and construct ships, offshore platforms, and pipelines. Steel is the most common material welded.

In terms of underwater cutting, oxygen-arc cutting with exothermic electrodes and steel tubular electrodes are also used.

Due to the danger and demands on the body, welders or cutters often work 1 month on and 3 months off.

This overview is not meant to be a reliable substitute for professional instruction and the manufacturer’s directions. This is for general information only.

Deep Underwater Welding

The definition of underwater welding usually refers to the wet welding technique where there is no mechanical barrier that separates the welding arc form the water.

For deep water welds and other applications where high strength is necessary, dry water welding is most commonly used. Research into using dry water welding at depths of up to 1000 m are ongoing.

In general, assuring the integrity of underwater welds can be difficult, especially wet underwater welds, because defects are difficult to detect.

For the structures being welded by wet underwater welding, inspection following welding may be more difficult than for welds deposited in air.

The best way to learn to weld underwater is as the U.S. Navy says, is practice, practice and practice.

Process

- Use a pre-job meeting to do a job safety analysis. Get the crew together at the beginning of the job to review the hazards and plan. (use the Job Safety Analysis – JSA format)

- Use an adequate size DC welding generator using straight polarity. Straight polarity is obtained by connecting the negative lug to the torch and the positive to the ground lead. Never use AC for burning or welding in the water. The electrical shock caused by AC current prevents voluntary relaxation of the muscles that control the hands. If electrocuted a diver may be unable to let go if his body or equipment accidentally enters the electrical circuit. If you use a rectifier machine, use a modern one that has up to date technology

- Divers should wear insulated gloves at all times when burning or welding.

- Attach the ground lead of the generator as close to the worksite as practical so that the diver is never between the electrode and the ground.

- Make sure there is a positive operating disconnect switch on the torch side of the current. When the diver is changing burning rods or doing anything other than burning, the disconnect switch must be in the open position (as shown). It is important that the opening and closing of the switch be directed by the diver. Each command should be confirmed by the diver using the terminology “make it hot,” or “make it cold.”

- Polarity can be checked by immersing the rod tip and ground clamp into a bucket of saltwater 2″ apart. Energize the rod by closing the safety knife switch. A stream of the bubble should rise from the rod tip. If not reverse the polarity and retest.

- After the diver enters the water, the first task is to clean a spot for the ground clamp. The spot should be in a position in front of the diver, as close as practical to the weld joint and should be scraped or wire brushed shiny clean. For diver safety, only C-type clamps should be used as grounding clamps for underwater cutting or welding operations. The clamp must be firmly secured to the workpiece and the cable should have

sufficient slack to prevent it from being pulled loose. The diver may elect to lightly tack weld the clamp in place when there is a possibility of it working loose. The ground should always be kept in the diver’s forward line of vision. - The diver should make a test weld to check the “heat” at working depth.

- When the electrode has been consumed to within 3″ of the torch, stop the cut and signal to “make it cold.” before attempting to change electrodes. Maintain the torch in the cutting position until the tender acknowledges “make it cold” or “switch off.”

- It is not safe to operate the welding torch without the flash arrestor in place.

- Never speed up the cutting by creating a fire or inferno deep inside the metal. Such a situation can lead to an explosion.

- Do not cut non-ferrous metals underwater since they do not oxidize and have to be melted. Cutting non-ferrous metals can result in an explosion.

- Ignition should not occur underwater when the oxygen pressure is low. This will result in the cable to burn inside itself, possible blowing holes through the cable, a situation that can result in injury.

- A diver risks electrical shock when welding or cutting when partially immersed in water.

- Acetylene is very unstable at pressures above 15 psi and is not used for underwater cutting.

- The hand should never be closer than 4″ from the electrode tip.

- The diving tender should always maintain a written record of the following in order to repeat what worked during the next welding or cutting session:

- The welding amperage as read from the tong meter.

- Both open and closed-circuit voltage as read from the voltmeter.

- Electrode diameter, type, manufacturer and waterproofing material.

- Electrical polarity.

- Length of welding cable.

- Depth of work site.

Welding & Burning Risks

Assuring the integrity of such underwater welds may be more difficult, and there is a risk that defects may remain undetected. The risks of underwater welding include the risk of electric shock to the welder.

To prevent this, the welding equipment ought to be properly insulated, and the voltage of the welding equipment should be controlled.

Underwater welders must also consider the safety issues that normal divers face; most notably, the risk of decompression sickness due to the increased pressure of inhaled breathing gases.

The Buildup of Gasses When Burning

Heat created by burning or torch can ignite trapped gases. Trapped gases need to be removed by venting or jetting gas.

In closed spaces small amounts of gas can get trapped and remain with the diver. Gas must be vented if it can be trapped. Drill vent holes to allow gas to escape to the surface.

The surface being drilled could also have unexpected gases and should be vented, such as a pipeline.

The speed of the tool can be controlled to keep temperatures at a safe level.

- Make sure all pipes have been purged with an inert non-flammable gas that will not combust.

- Make sure that when burning is done along with salvage work that a survey of the work site identifies any overhead hazards. Make sure any pipes that can twist or tear have been addressed.

- Another risk, generally limited to wet underwater welding, is the buildup of hydrogen and oxygen pockets in the weld, because these are potentially explosive. When using grinders or drills sufficient heat can ignite hydrocarbons causing an explosion. The material being burned might contain pockets that can trap burning gas. Gasses need to be properly vented. The solution is to slow down the drill bit to avoid generating the heat levels required to ignite any gas.

Wet Welding Demonstration Video

Mechanical Barriers and Mini-Habitats

Mechanical barriers, called Caissons and Cofferdams are used at the waters edge or in the splash zone of ships.

The structures keep the water from the work area, with the weld area in the atmosphere. The technique is limited by the depth of the weld and the size of the Cofferdam. Typical uses of mechanical welding barriers are to fix a ship’s hull or a harbor facility.

A mini-habitat is a small portable gas-filled enclosure. These are transparent plexiglass boxes that are placed over the joint by a diver. Water is then displaced by an inert gas.

Both of these methods allow for dry welds, which are better than wet welds because cooling rates are slower.

Underwater Welding Arcs

Underwater Welding Arc

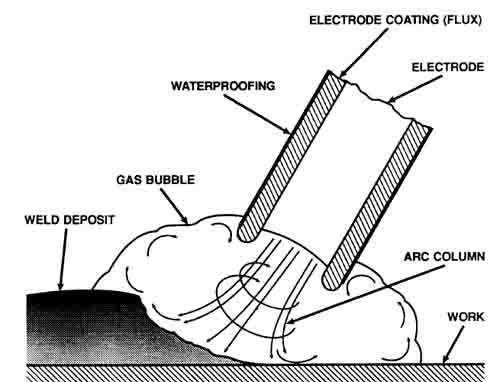

The welding arc does not behave underwater as it does on the surface and the activity of the gas bubble is particularly important to successful completion of the underwater weld.

When the arc is struck, the combustion of the electrode and the detachment of water creates a gas bubble or envelope As the pressure within the bubble increases, it is forced to leave the arc and meet with the surrounding water while another bubble forms to take its place. See example above.

Then, as this pressure head becomes greater than the capillary force, the bubble breaks down. Therefore, if the electrode is too far from the work, the weld will be destroyed as the gases explode and blow through. If the travel speed is too slow, the bubble will collapse around the weld and destroy the possibility of producing an effective weld.

Jobs and Careers

Career Path

- Visit a Doctor to get medically cleared for diving. This involves a physical examination to identify any disabilities. Annual exams are often required. Due to the physical demands of the profession, it is rare to find underwater welders over age 50.

- Apply and complete a commercial diving course (see schools below)

- Apply for a job at a commercial diving company that offers welding services

- Entry level jobs are referred to as being a “diver tender or apprentice diver.”

- The commercial diving company will work with you to obtain sufficient skill in wet and/or dry underwater welding in order to pass qualificaiton tests in accordance with ANSI/AWS D3.6, Specification for Underwater Welding.

- The time frame for moving from diver tender to qualified Underwater welder depends on the level of support and policies provided by the commercial diving company. For example, a shortage of personnel will accelerate the career path.

- If you already work as a commercial diver, the best path is to move to a firm that offers underwater welding services and training.

- If you are a certified “scuba diver,” then attend a commercial diving school to train on the safe use of commercial diving equipment.

- Many experience welder divers go on to other positions including:

– engineer

– instructor

– Welding Inspector

– consultants for under-water welding

Schools

Certified welders should also obtain certification from a commercial dive school. The AWS recommends that before attending any school visit a Doctor for a physical that gives the diver a clean bill of health before undergoing the expense.

To find a commercial diving school near you cal the Association of Diving Contractors in Houston, Texas (713) 893-8388.

Once commercial diver training is completed, then it is a best practice to apply for a job at a commercial diving company that offers welding services.

Required Skills

There are many skills required for a “jack of all trades” type of under water welder. Because it is rare to have all skills in one person, a commercial diving firm will use multiple people on a job.

These include:

- Diving

- Welding (oxyfuel)

- Underwater cutting (oxyfuel, abrasive jet, mechanical cutting equpment)

- Fitting and rigging

- Inspection and nondestructive testing (visual, magnetic particle, ultrasonics, radiography, eddy current)

- Drafting

- Under water photography and video

Certification

Underwater welders must have a commercial diver certification and must be a certified welder. Certifications can include:

- welding certificate

- diving certificate

- ASNT Level II or CSWIP ultrasonic certificate

- Riggers certificate

The AWS D3.6 standard has a more concise definition:

A “welder diver” is a certified welder who is also a commercial diver, capable of performing tasks associated with commercial sub sea work, weld setup and preparation, and who has the ability to weld in accordance with the AWS D3.6, Specification for Underwater Welding Specification for Underwater Welding (i.e., wet or dry), and other weld-related activities.

Required Skills:

- Commercial diving skills (diving physiology, safety, rigging, familiarity with underwater environment, communication)

- Welding setup

- Welding preparation skills

- Ability to certify a required underwater weld procedure

Welder divers must qualify as commercial divers as outlined below.

Salary

The annual salary for underwater welders ranges from $20,000 to $100,000+ per year.

Welders involved in demanding projects or underwater environments can command as much as $300,000 per year.

The salary is determined based on experience, diving method and depth.

Welders are often assigned on a per-project basis.