Struggling to figure out what size welding cable you need?

I get it—those charts and tables can be more perplexing than helpful if you don’t know how to read them.

In this article, we’ll navigate the key points, from deciphering cable and lead size charts to pinpointing the exact cable size that fits your specific needs using guidance from AWS F4.2:2020 handbook.

No more second-guessing or worrying about potential hazards from using the wrong size.

Quick Guide to Choosing the Right Cable Size

I know, you’re probably eager to get this sorted out—so let’s jump into the practical steps for picking the right welding cable size.

Note: If any of these steps don’t make full sense to you, then I encourage you to read the entire article to learn more in detail.

Step 1: Measure Your Welding Circuit Length

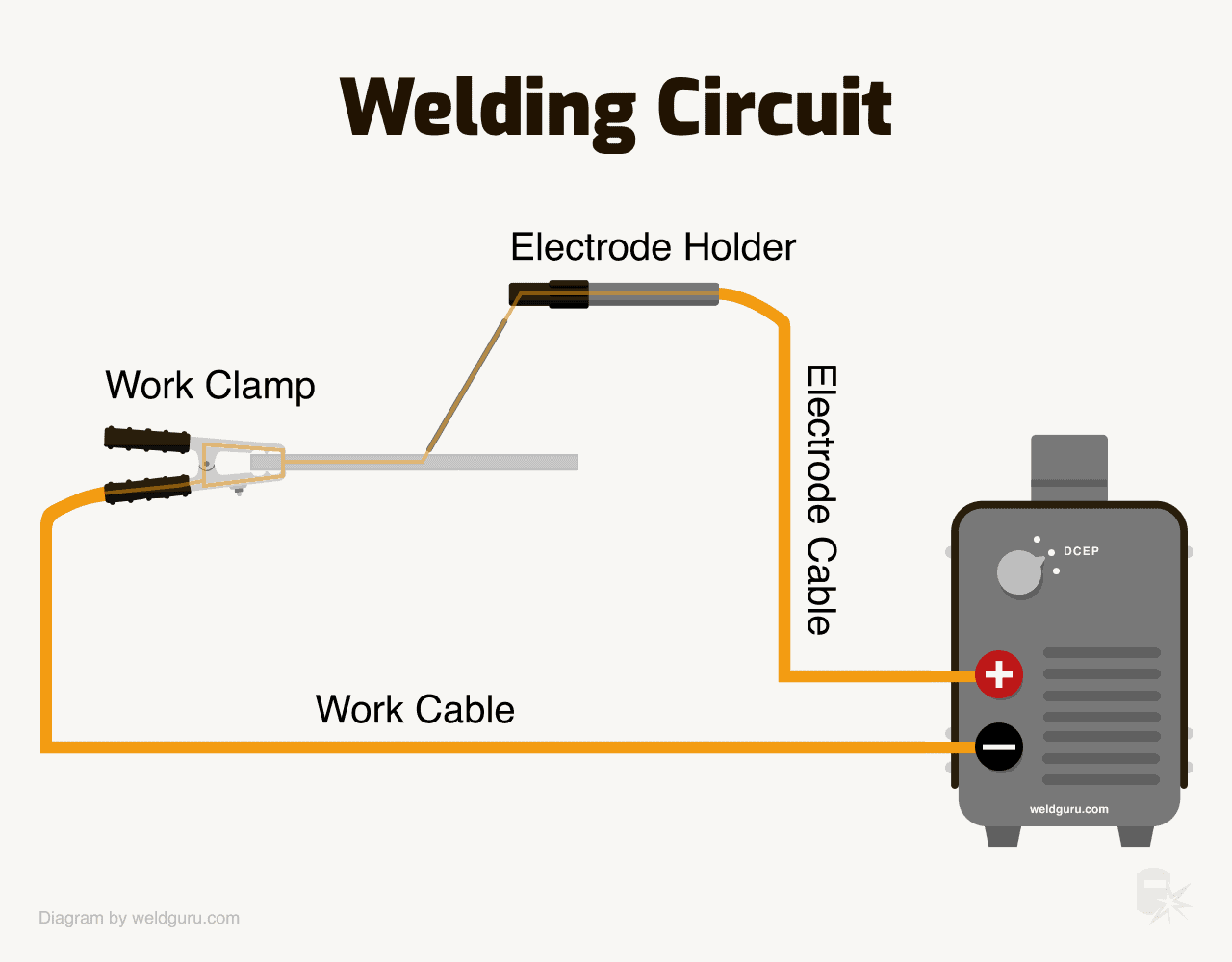

First, you need to measure the total length of your welding circuit. This includes the power source, electrode cable, work cable, and any other components in your setup.

Add up the lengths of the electrode and work cables to get your total circuit length.

© weldguru.com – Image usage rights

Step 2: Know Your Power Source Output

Next, you’ve got to know the maximum output of your welding power source. You’ll usually find this information in the machine’s name or operating manual.

It’s measured in amperage (amps), and examples include the “Idealarc® 250” (rated 250A output) or the Power Wave® S350 (350A rated output).

Step 3: Check the Duty Cycle

Look for the duty cycle rating of your welding power source. The duty cycle is expressed as a percentage and tells you how long your machine can operate at its maximum output within a ten-minute period without overheating.

Step 4: Use a Cable Size Chart

Now that you’ve got your measurements and ratings, it’s time to check a cable size chart like below.

Find your total circuit length and power source output on the chart to identify the recommended cable size:

| Current (amps) | Duty Cycle (%) | 0 to 50 ft. (AWG) | 51 to 100 ft. (AWG) | 101 to 150 ft. (AWG) | 151 to 200 ft. (AWG) |

|---|---|---|---|---|---|

| 125 | 30 | 6 | 5 | 4 | 3 |

| 150 | 40 | 6 | 5 | 3 | 2 |

| 180 | 30 | 6 | 5 | 3 | 2 |

| 200 | 60 | 4 | 4 | 3 | 2 |

| 250 | 60 | 3 | 3 | 2 | 1 |

| 300 | 60 | 2 | 2 | 1 | 1/0 |

| 350 | 60 | 1/0 | 1/0 | 1/0 | 2/0 |

| 400 | 100 | 1/0 | 1/0 | 1/0 | 2/0 |

| 500 | 60 | 2/0 | 2/0 | 2/0 | 3/0 |

Tip: Think About the Future

If you’re planning on upgrading your equipment or tackling bigger projects in the future, you might want to consider getting a slightly larger cable size. It might save you from having to buy new cables down the line.

Risks of Incorrect Cable Size

It’s important to get the cable size right. Choosing the wrong welding cable size can lead to:

- Overheating and Fire Hazards: Using a cable too small for your current can cause overheating and become a fire risk.

- Electrical Shock: Damaged insulation from overheating can expose you to electrical shocks.

- Inefficient Energy Use and Extra Costs: Oversized cables are more expensive but don’t perform better.

- Reduced Ampacity: Factors like length and temperature can lower a cable’s safe current-carrying capacity.

- Equipment Damage: The wrong cable size can lead to long-term damage to your welding equipment.

Remember, the right cable size is crucial not just for performance, but also for safety and cost-efficiency.

Understanding AWG and Metric Cable Sizes

Now that we’ve covered how to choose the right size and the risks of getting it wrong, let’s delve into how cable sizes are actually measured.

Trust me, this will make your life a lot easier when you’re looking at those charts or shopping for cables.

American Wire Gauge (AWG)

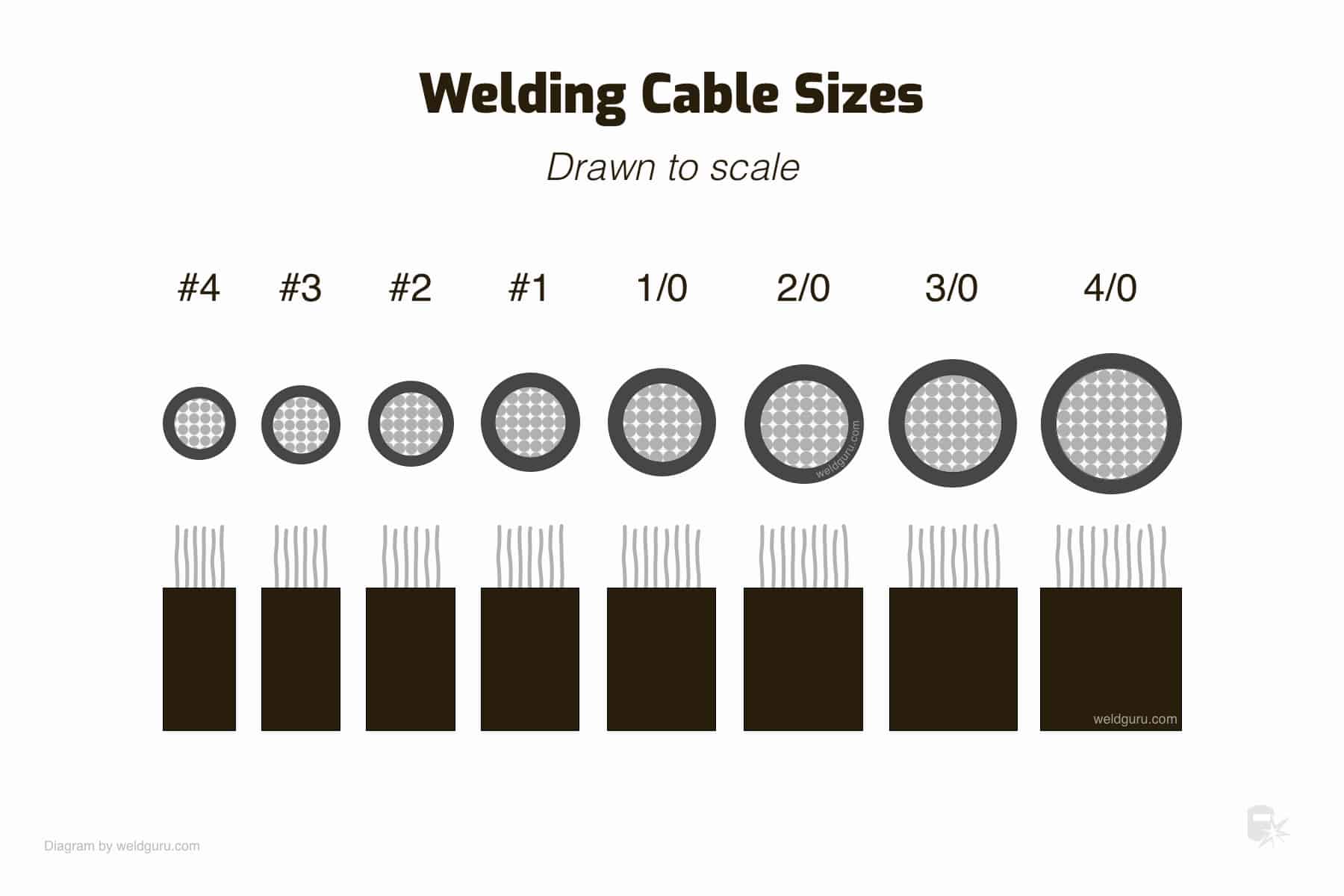

In the United States, we often use the American Wire Gauge (AWG) system to categorize cable sizes. The funny thing is, the smaller the AWG number, the larger the cable diameter.

So, for instance, a #4 AWG cable is actually larger than a #6 AWG cable. And to make it even more interesting, sizes larger than one are expressed as zeros, like 1/0 (pronounced “one aught”), 2/0, 3/0, and so on.

© weldguru.com – Image usage rights

Metric Cable Sizes

You might come across metric measurements if you’re looking at international options or specs.

In the metric system, the size is straightforwardly expressed in square millimeters (mm²), representing the cross-sectional area of the cable.

AWG vs. Metric: Making the Comparison

It’s possible to convert between AWG and metric sizes, but having a comparison chart can be a lifesaver in a hurry.

These charts typically show you the equivalent sizes in both systems:

| Cable Size (AWG) | Equivalent Size (mm²) | Standard Int’l Size (mm²) |

|---|---|---|

| 6 | 13.3 | 10 |

| 5 | 16.8 | 16 |

| 4 | 21.1 | 25 |

| 3 | 26.7 | 25 |

| 2 | 33.6 | 35 |

| 1 | 42.4 | 50 |

| 1/0 | 53.5 | 50 |

| 2/0 | 67.4 | 70 |

| 3/0 | 85.0 | 95 |

| 4/0 | 107.2 | 120 |

Quick Reference for Welders

In welding, cable sizes usually range between #4 and #4/0 in AWG or their metric equivalents.

Keep this range in mind when you’re looking for welding cables; it’ll help you narrow down your choices.

The Concept of Welding Cable “Ampacity”

Let’s get into a term you’ll often hear when dealing with welding cables: “ampacity.”

While it may sound like jargon, it’s a crucial concept that impacts your welding project’s safety and effectiveness.

What is Ampacity?

Ampacity stands for “amperage capacity,” and it’s the maximum amount of electrical current that a cable can safely conduct. Think of it as the cable’s “power limit.”

Factors Affecting Ampacity

- Length: Shorter cables can carry more current than longer ones of the same diameter.

- Ohm Rating: This is the resistance rating of the cable. Higher resistance means lower ampacity.

- Temperature Ratings: The insulation material of the cable often has temperature ratings like 75°C (167°F), 90°C (194°F), or 105°C (221°F). Exceeding these can lead to insulation melt.

- Ambient Temperature: Higher ambient temperatures can reduce the cable’s ability to dissipate heat, lowering its ampacity.

Why Ampacity Matters

Getting the ampacity right is crucial for two main reasons:

- Safety: As discussed in the risks section, an overloaded cable is a safety hazard.

- Performance: Incorrect ampacity can affect your welding performance and even damage your equipment over time.

Practical Tips

- Always check the ampacity ratings when selecting a cable.

- Make sure to factor in the length of your welding circuit.

- Consider the working environment’s temperature.

And there you go! You’re now familiar with the concept of ampacity and why it’s essential in selecting the right welding cable.

You’re not just picking a cable; you’re making an informed choice that ensures safety and optimal performance.

Extension Cables

Extension cables work similarly to welding cables. Essentially, you need a cable that can handle the welder’s input amperage and voltage for the desired extension cable length.

I wrote a complete guide on extension cables for welding here.

Where To Buy Cables

Many tool stores sell welding cables, but it’s easiest to get them on Amazon because of the wide selection. We link to commonly used cables below, but you should know that welding leads are sold either standalone or with an electrode holder, ground clamp, lugs, and DINSE plugs.

If you buy cables at the welding stores, you have the advantage of buying by the foot. But, if you buy on Amazon and similar online stores, you will usually get a fixed length. Still, it’s more convenient to get the cables online, and you can save the extra length for other needs.

A Complete Package – 100 ft.Tweco Leads

- 100 FT Welding Cable - Size 1/0 Gauge

- Tweco 300 Amp Ground Clamp

- Tweco 250 Amp Electrode Holder

- Tweco 2-MPC-1 Cable Connectors

- (2 ea) Tweco 2-AF Lugs

This 100 ft. welding cable comes with a high-quality 300A Tweco ground clamp and 250A electrode holder. It also includes DINSE plugs and standard Tweco 2-AF Lugs if your machine doesn’t use DINSE connectors. The cable is AWG 1/0 gauge (AWG zero, as discussed earlier).

Many people don’t need a 100 ft. welding circuit, but this cable is still a popular choice because you can trim it and save the rest for future needs. Your welding leads are bound to break at some point, so it’s good to have a spare cable for replacement.

100 ft. EWCS 2 AWG Cable – Made in the USA

- Sunlight Resistant

- Water Resistant

- Highly flexible 30 guage copper stranding

- Ships as a coil

- Specially packaged and printed by EWCS to assure quality

If you need a cable to weld using about 200-250A at 30-60% duty cycles, this AWG 2 cable from EWCS is a good choice. It has a 100% copper core and offers excellent insulation and conductivity. Plus, EWCS cables are made in the USA and they specialize in cable production.

But if you need more amperage, the same brand also offers a flexible, durable AWG 1/0 100 ft. cable.

Wrapping It

Welding cables must have an adequate diameter for your specific setup. The cable length, amperage, machine’s duty cycle, and the cable’s insulation rating dictate the necessary size.

The larger the diameter (e.g., the lower the AWG rating), the higher the amperage the cable can transport over longer distances and at a higher duty cycle.

If you are ever in doubt, it’s best to choose a cable one-size larger.

Cable ratings are not always 100% accurate, and they are usually rated at a 40 Celsius ambient temperature.

If you weld in an area with a higher temperature, you’ll need a slightly thicker cable. So, it’s always a good idea to go with a larger diameter, if your budget allows it.