Weld cracks are severe flaws that require rework or repair.

A welded joint experiences a dramatic reduction in strength as soon as the crack forms, hence the need to address them.

While weld cracks are alarming, there are many ways to prevent them. You can significantly reduce weld cracking if you understand how they form and take the necessary steps before, during, and after welding.

This article will teach you about hot and cold cracks, what causes them, and the crack prevention methods that work 99% of the time.

Why Do Welds Crack?

Welds crack when internal stresses exceed the strength of either the filler metal, the base metal, or both. There are two main types of welding cracks: hot and cold.

© weldguru.com – Image usage rights

These occur for various reasons, weakening the weld or the base metal beyond their limits.

For example, hydrogen can make the metal in the heat-affected zone (“HAZ”) more vulnerable.

Other factors, like improper weld geometry, stress concentration, low material ductility, and inadequate heat treatment, can also contribute to cracking.

Later in this article, we’ll discuss both and explain how they create fractures. You should also know that weld cracks are a weld discontinuity and a weld defect.

You can learn more about weld defects in our in-depth guide.

What Causes Stress?

In general, two sources of stress act on a welded joint:

- Physical loads

- Residual welding stresses

The latter is the more frequent cause of weld cracks. But stresses aren’t so black and white.

Residual stress may weaken the joint, while the applied load can be the straw that breaks the camel’s back—or, in a weld’s case, what causes a crack to appear.

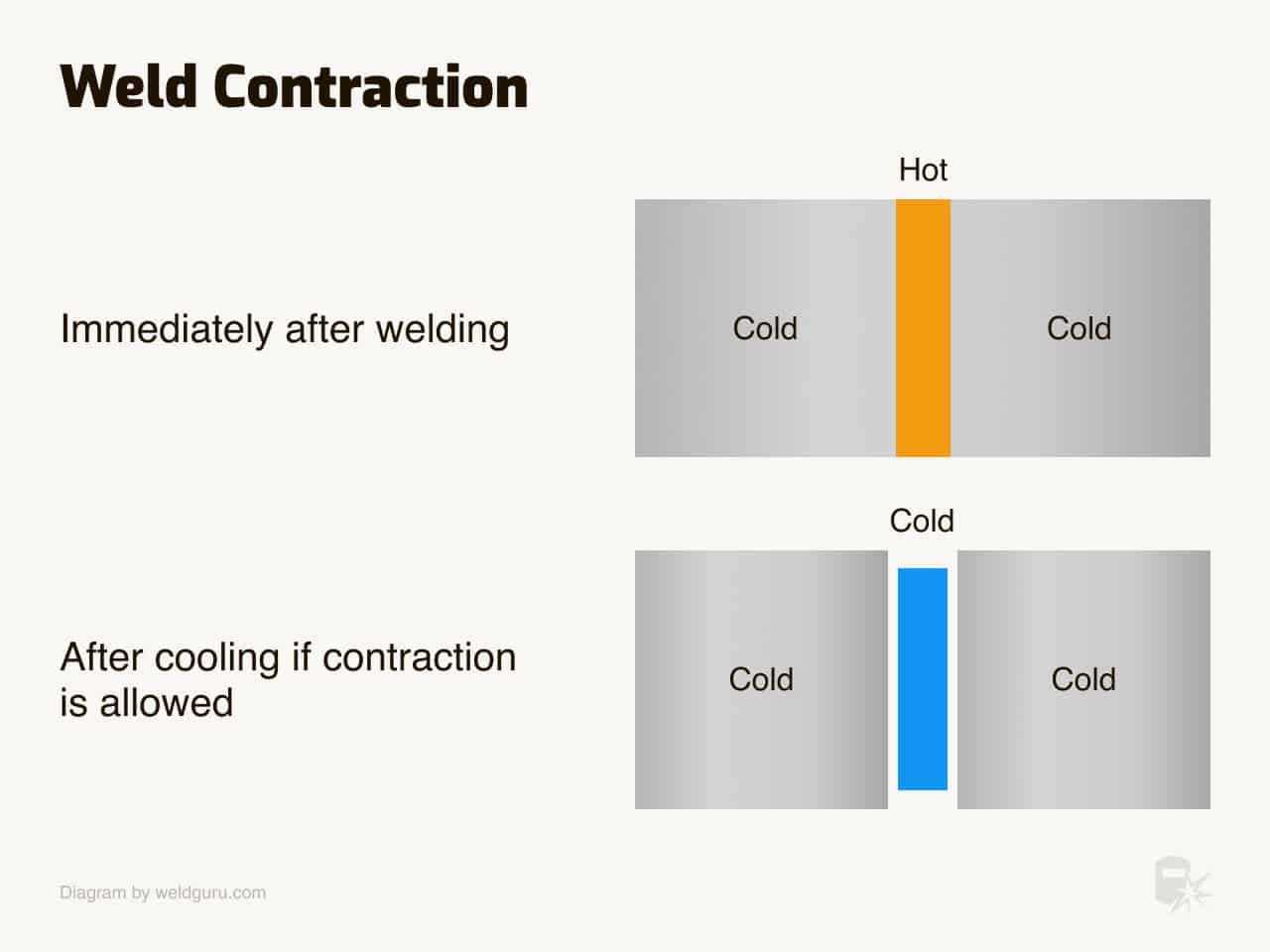

Residual stresses are internal in the weld joint and the HAZ. They form via the expansion and contraction of the metal during a weld. They expand when you heat the weld metal and the joint’s surface to the melting point.

But when the metal starts to cool, it contracts. So, the weld metal “pulls” on the adjacent metal in the HAZ, causing residual internal tension in the joint.

© weldguru.com – Image usage rights

Cracks occur if the weld or base metal isn’t strong enough to endure the resulting tensile forces. Cracks are the weld’s attempt to relieve the residual stress caused by heating and cooling.

But residual tension isn’t the only force acting on a joint. The welded element will have loads applied to it in everyday use.

For example, the welded joints of a staircase need to endure the load of people walking on it. However, some joints experience more complex loads. Vehicle body welds must resist vibration, tension, compression, flexing, and torsional forces.

Additionally, age and stress cycles are essential to consider. The joint may be able to endure a particular load once or twice. But what happens if you subject it to the same load tens of thousands of times?

The number of “cycles” a joint can resist is “fatigue strength” in material science. Welders must test elements like bicycle frames or airplane parts for hundreds or thousands of stress cycles to determine how long welded joints can last.

Hot Cracks – Causes and Types

Hot cracking happens during or immediately after welding at temperatures above 1000°F. You don’t need to wait to determine if your weld will hot crack.

The leading causes of hot cracking are stress concentration, a low melting point of elements in the weld puddle like sulfur, rapid cooling of the weld puddle, and low ductility of the welded material.

When these factors combine, they create weak grain boundaries, making the weld susceptible to cracking.

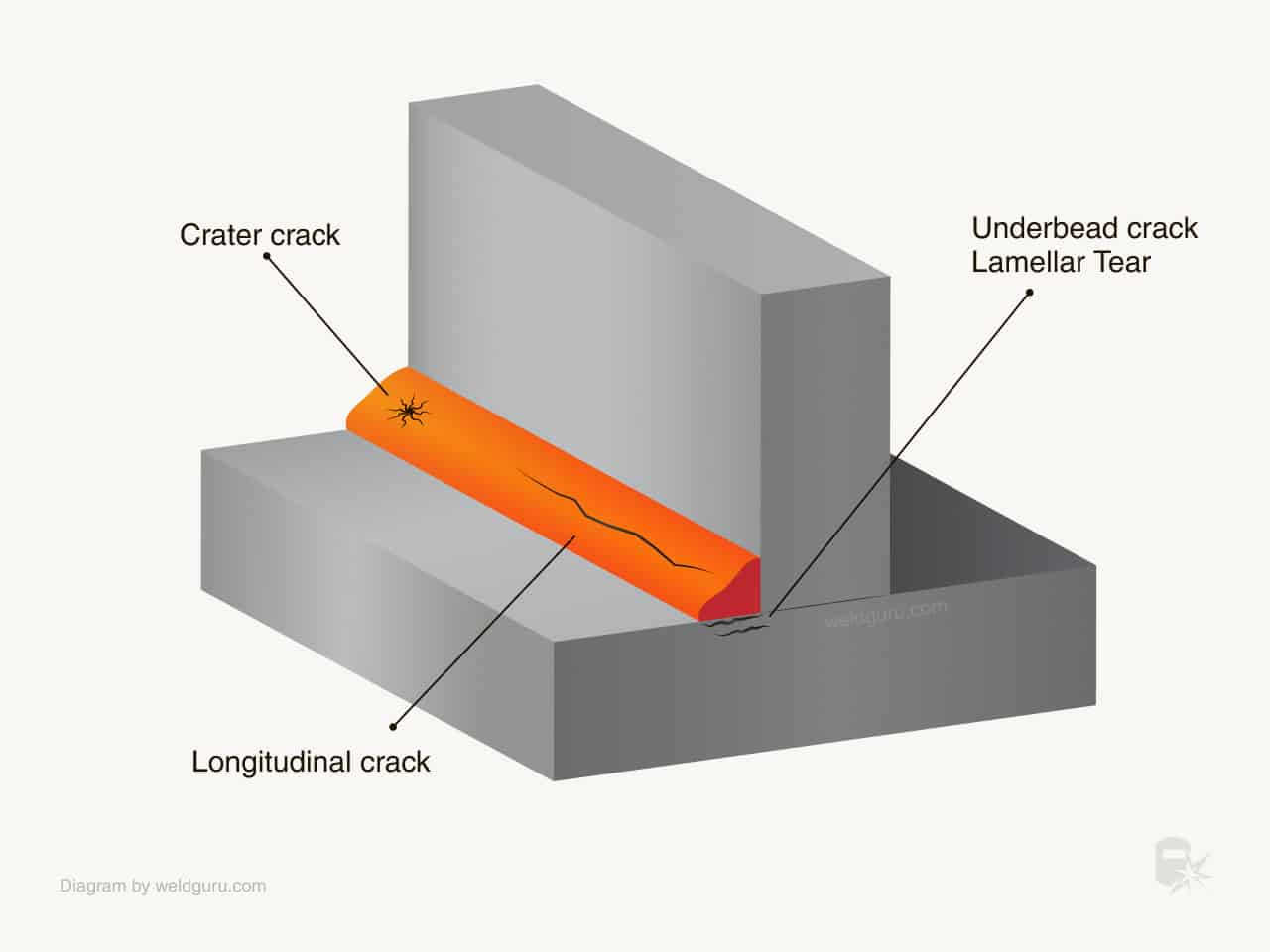

Hot cracks most commonly appear as longitudinal cracks, lamellar tears, and crater cracks.

© weldguru.com – Image usage rights

These cracks result from the tearing of the weld metal along partially fused grain boundaries of welds that haven’t fully solidified. While the weld metal is freezing, it also shrinks, causing these partially melted and weak grain boundaries to rupture.

They are generally longitudinal and occur in the center of the weld line (not always with perfect symmetry), but there are also other hot cracking configurations.

At the same time, the filler metal tries to shrink as it cools, and this shrinkage-induced stress easily fractures these partially fused grain boundaries.

Longitudinal Cracks

Longitudinal cracks occur during or immediately after welding and span the entire length of the weld.

© weldguru.com – Image usage rights

These cracks are most commonly associated with hot cracking and are most likely to appear in severely concave welds.

The next most likely candidates for these types of cracks are steel with high sulfur and low manganese content and steels with high carbon and phosphorus content.

Lamellar Tears

Lamellar tears occur in the parent material underneath the welded joint. It’s generally associated with transverse shrinkage strains, high sulfur content in steel, low base metal ductility, and the parallel fusion boundary between the weld metal and the workpiece.

Additionally, lamellar tearing happens only with rolled steel plates. So, if your work requires rolled steel, ask the manufacturer for a grade of steel with the lowest likelihood of lamellar tears.

The steel should have an “STRA” value above 20% to resist lamellar tears. This essentially means that the steel has low sulfur content.

Crater Cracks

Crater cracks most commonly form at the end of the weld but can quickly spread throughout the entire weld length, creating longitudinal cracks.

The most common reason for the formation of crater cracks is insufficient weld metal volume, in conjunction with other culprits for hot cracks we discussed earlier.

If the weld bead is too shallow at the end of your weld, there won’t be enough material to counter the internal stresses, and the crater cracks will form.

Cold Cracks – Causes and Types

Cold cracks can take minutes, hours, days, or weeks to appear and often require radiographic testing for detection.

The most common sources of hydrogen that lead to cold cracking are oil, grease, dirt, rust, paint and coatings, cleaning fluids, filler metal, and electrodes.

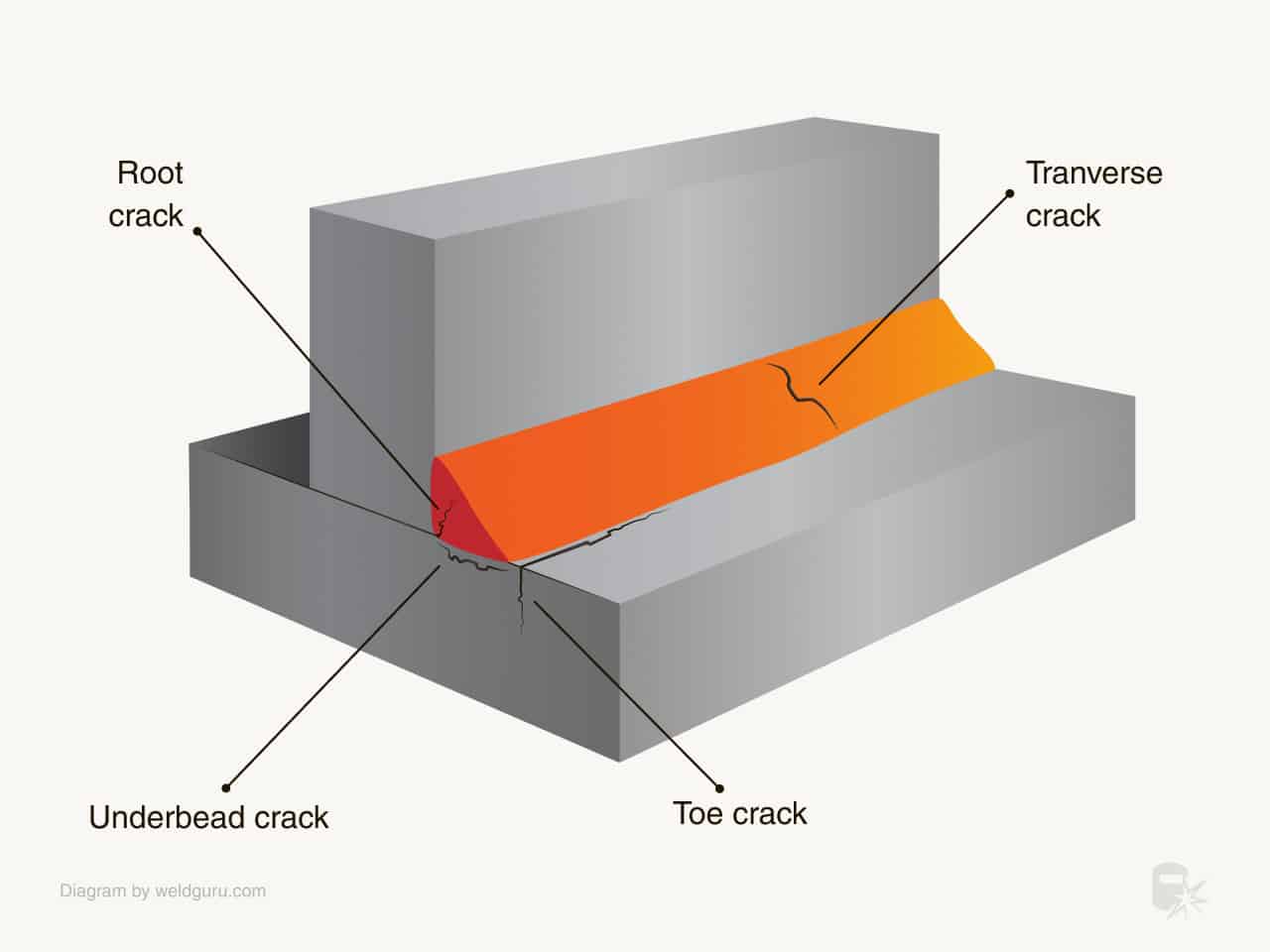

These cracks typically manifest as root, toe, transverse, and fusion-line cracks.

© weldguru.com – Image usage rights

Cold cracking is far more tricky than hot cracking because it doesn’t develop immediately and can remain hidden deep inside the weld and the HAZ (Heat Affected Zone).

The time-delayed nature of these cracks means that x-ray tests are usually performed weeks after welding.

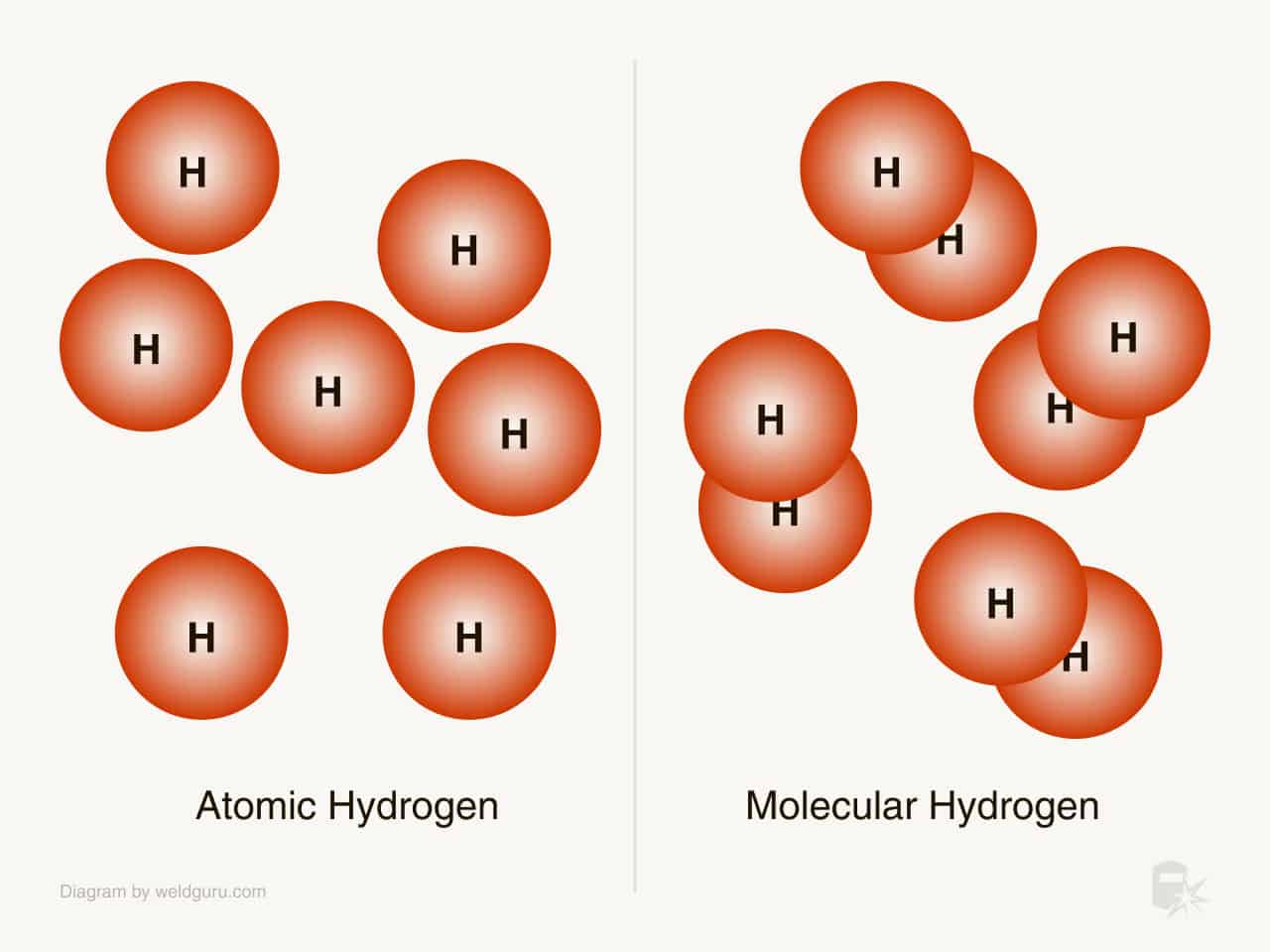

Cold cracks form due to hydrogen dissolving in the weld metal and diffusing into the HAZ.

The arc’s heat breaks down stable molecular hydrogen (H2) into unstable single atoms (H), which are later forced into HAZ grain boundaries.

© weldguru.com – Image usage rights

Over time, these hydrogen atoms reform into stable molecular hydrogen, leading to the formation of cold cracks.

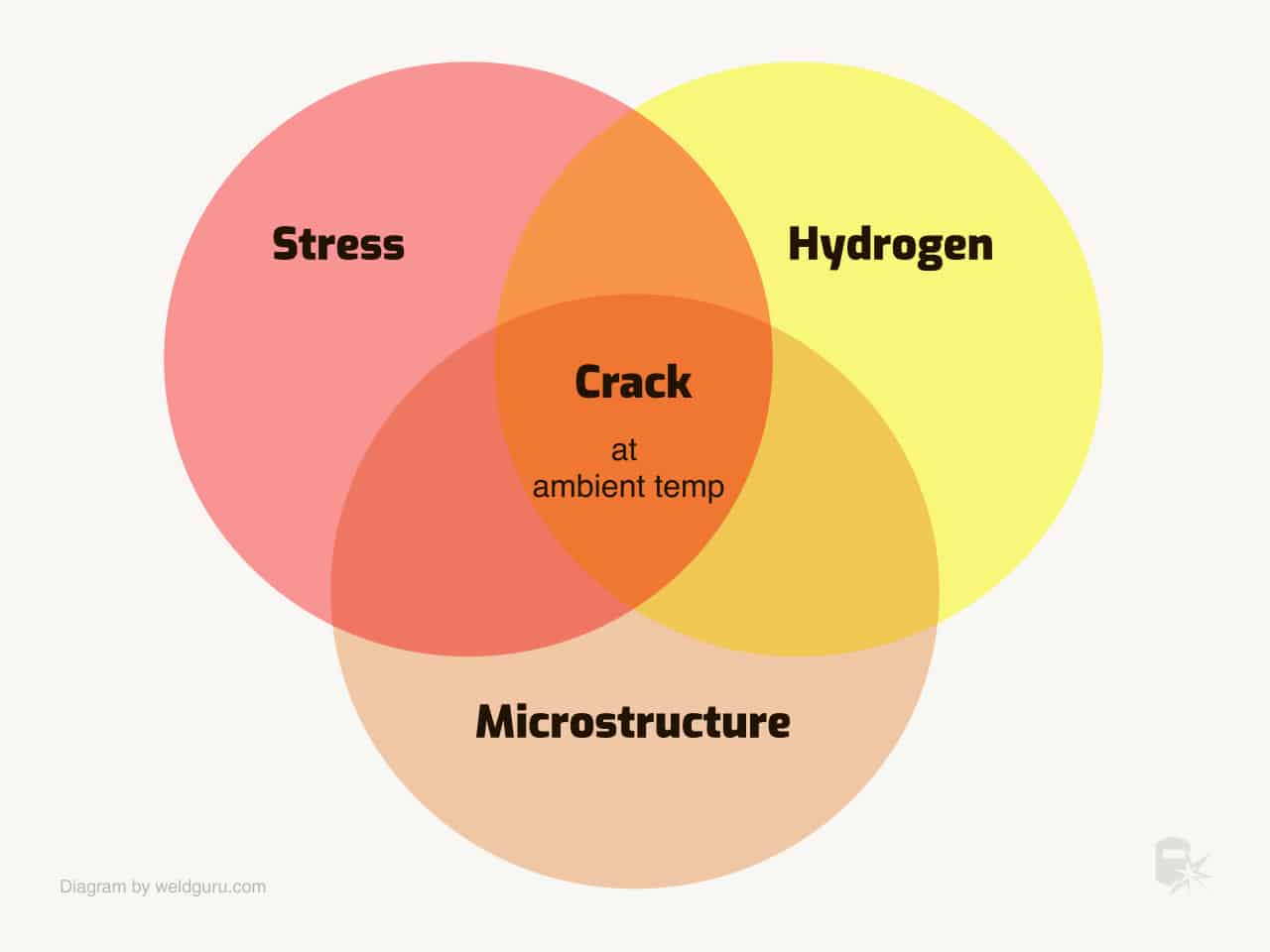

It’s essential to note that hydrogen itself doesn’t cause cracks; stress is the underlying culprit. High-strength steels are especially vulnerable, as hydrogen makes the metal more susceptible to cracking.

The prerequisites for cold cracking are stress concentration, a microstructure sensitive to hydrogen, and the presence of hydrogen.

© weldguru.com – Image usage rights

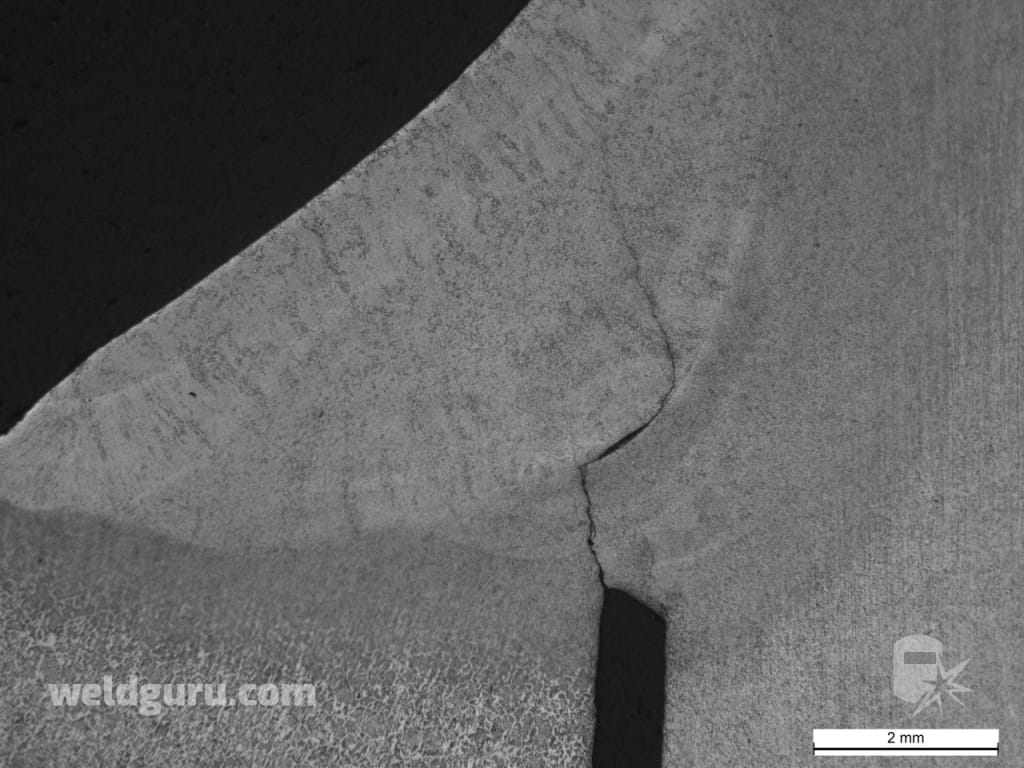

Toe Cracks

© weldguru.com – Image usage rights

Hydrogen cracking usually occurs at the weld toes because this is where the hydrogen diffuses and collects. Additionally, weld toes are a typical area where a stress riser can form.

Such an intense stress concentration coupled with hydrogen embrittlement creates the perfect conditions for toe cracking.

Root and Underbead Cracks

© weldguru.com – Image usage rights

Depending on the joint geometry, root or underbead cracks are also very common due to hydrogen embrittlement of steel.

That’s why cold cracking is sometimes referred to as underbead cracking.

Transverse Cracks

Transverse cracks often happen with high-strength steel. These cracks can even be seen using low magnification.

So, an x-ray inspection may not be necessary.

Fusion-line Cracks

Fusion-line cracks are not as prevalent as the three above, but if these cold cracks happen, they run parallel to the weld fusion zone.

11 Crack Prevention Tips

Now that we’ve explained why hot and cold cracking happens, let’s discuss practical tips to prevent both.

Many prevention methods apply to either of the two, so I’ll explain them.

Don’t worry. You can’t go wrong and cause cold cracking by preventing hot cracking and vice versa.

1. Choose the Correct Filler Material

Using the correct filler material is crucial for preventing cracking, especially if you are already experiencing fissures.

For high-strength steels or to reduce hydrogen-induced cracking, use low-hydrogen stick welding electrodes like E7018.

Welding mild steel is generally more forgiving, but materials like stainless steel and aluminum require a precise match between the filler metal and the metal being welded.

Make sure to keep filler rods, wires, and stick electrodes free from moisture to prevent hydrogen infusion.

2. Preheat The Metal

Preheating steel reduces the cooling stresses and allows hydrogen to escape the HAZ and joint.

Doing this reduces hydrogen migration and the formation of molecular bonds, which cause cracks.

Every steel type has different preheating requirements, so check the supplier’s specification sheet.

3. Slow the Cooling Rate

To further improve hydrogen diffusion and help it leave the weld metal, use heat blankets to slow the cooling rate of the metal and filler material.

You can also use welding ovens and induction heating equipment if necessary.

4. Avoid Welding High Sulfur Steel

High sulfur content steel is particularly susceptible to hot cracking because sulfur’s melting point is just 239°F.

As a result, it’s more liquid during the weld solidification and ends up in the centerline, where it easily cracks.

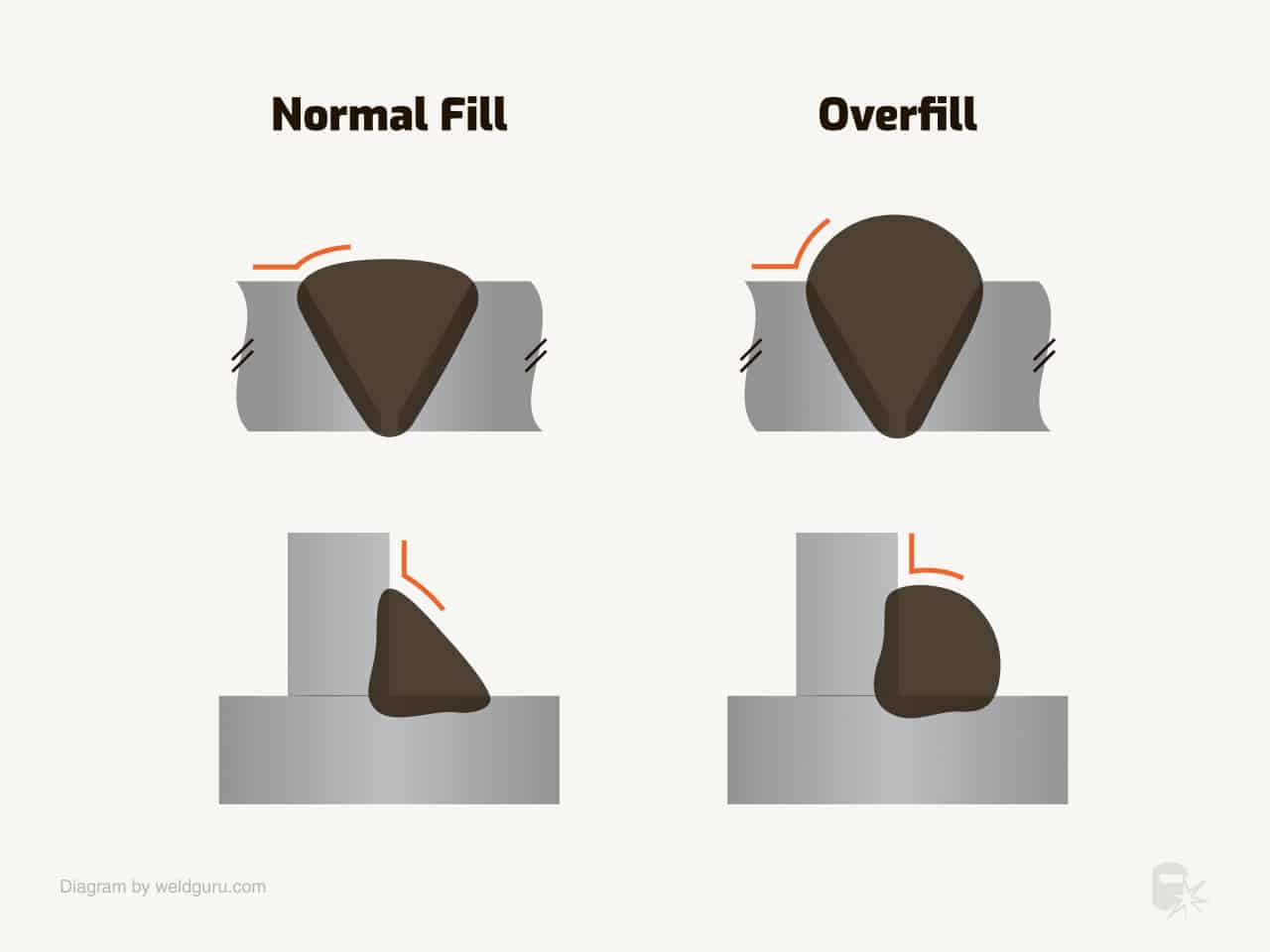

5. Avoid Extreme Concave or Convex-shaped Beads

Concave beads lack filler metal deposition and have insufficient material to withstand the residual stresses. This aspect can cause cracking.

However, highly convex-shaped beads aren’t a solution. Excessive weld reinforcement provides too much filler metal.

So, as this extreme volume of metal shrinks as the metal solidifies, the internal stresses are more substantial compared to “normal” welds.

© weldguru.com – Image usage rights

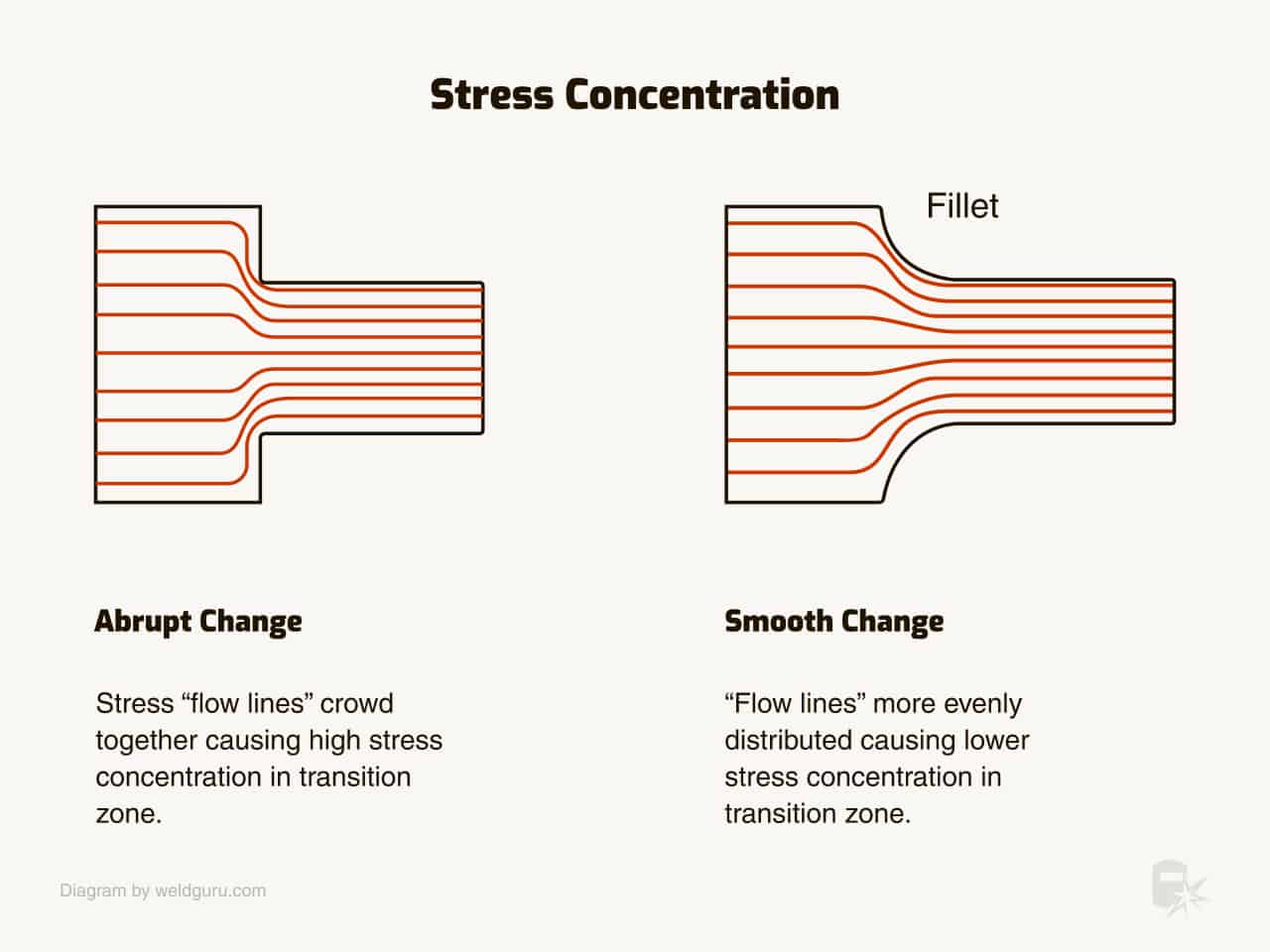

However, the problem occurs at the weld toes because excessively reinforced welds usually don’t transition smoothly into the surrounding metal.

This harsh transition acts as a stress concentration point (stress raiser) and causes cracking.

© weldguru.com – Image usage rights

6. Use Quality Materials

Using quality filler and parent materials is key to reducing the risk of weld cracking.

Issues like uneven distribution of additives, poor mixing, and rust from improper storage can all lead to cracking.

If the metal’s grain structure or chemical composition has changed due to previous mechanical or thermal treatment, this too can contribute to cracking.

Therefore, it’s crucial to be aware of the metal’s history and storage conditions.

7. Avoid High Travel Speed

Too high a travel speed reduces the weld throat and leads to concave welds.

Reduce the travel speed to fill the joint and achieve sufficient weld thickness.

8. Hydrogen and Ferrous Metals

Don’t use hydrogen in your shielding gas mixture when welding ferrous metals like carbon steel.

To improve penetration, use a helium gas mixture instead and avoid hydrogen as a shielding gas addition.

9. Use the correct Width to Depth Weld Ratio

Maintaining a width-to-depth ratio between 0.5 to 0.8 is crucial for preventing cracks, especially in materials prone to hot cracking.

An improper ratio can result in stresses that encourage the formation of cracks.

The bead shape dictates the metal’s solidification pattern and influences the resulting stresses.

Ratios outside the recommended 0.5 to 0.8 range are more likely to cause low melting point materials, like sulfur, to concentrate in the centerline, leading to cracks.

10. End a Weld Bead Properly

When ending the bead, ensure you fill the weld crater to its full cross-section (to match the rest of the weld) because insufficient filler metal deposition causes crater cracking.

11. Expansion and Contraction Stresses

Allowing room for the metal to expand and contract during welding and cooling is essential to prevent excessive internal stresses that can lead to cracking. Restraining the welded parts can have the opposite effect.

Don’t restrain the welded parts during the welding process and post-weld cooling. Instead, give the metal some space to naturally expand and contract, minimizing the risk of cracking due to internal stresses.

Wrapping It

If weld cracks appear, you must repair the joint. So, preventive measures are the key to avoiding costly rework. If you run a welding shop, weld cracks delay job completion and waste resources.

But, even hobby welders should understand the basics of weld crack prevention. A cracked joint is unreliable as this is the worst weld defect possible.

So, at the minimum, you should match the filler metal with the base material, clean the joint properly, preheat the metal, and use an adequate welding technique for the welding process.