Welding cannot always be done in the most desirable position.

Welding is often done on structures in the position in which they are found and in the position the part will be used.

Often that may be on the ceiling, in the corner, or on the floor.

Techniques have been developed to allow welding in any position. Some welding processes have all-position capabilities, while others may be used in only one or two positions.

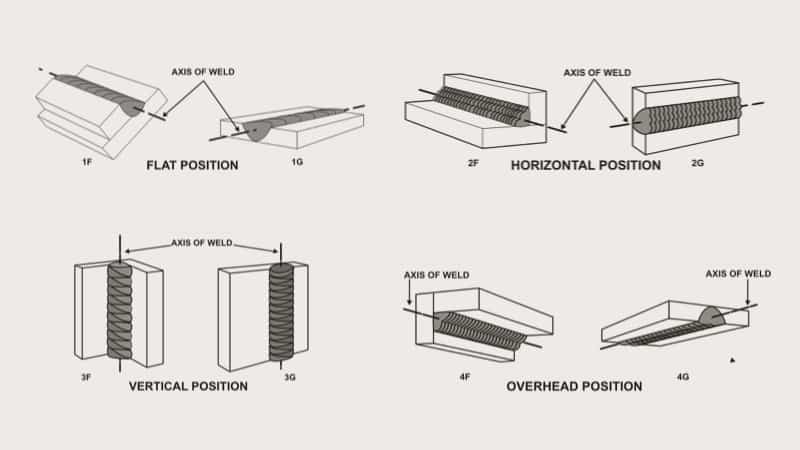

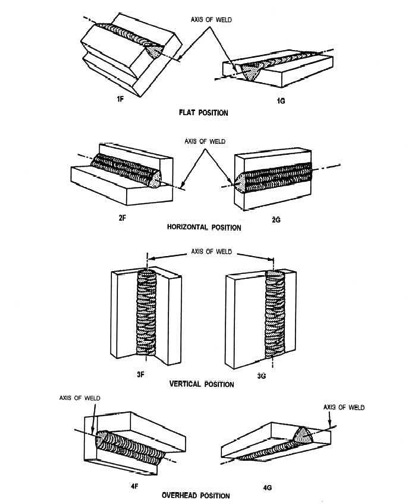

All welding can be classified according to the position of the workpiece or the position of the welded joint on the plates or sections being welded.

The American Welding Society has defined the four basic welding positions as shown below.

- Flat position

- Horizontal position

- Verticle position

- Overhead position

Any conversation around welding starts with a discussion on the welding position of the weld face.

A number is used to define the position, and an F for Fillet or G for groove refers to the type of weld.

An architect’s blueprints would indicate the welding symbol.

- 1 refers to a flat position – either 1F or 1G

- 2 refers to a horizontal position – either 2F or 2G

- 3 is a vertical position – either 3F or 3G

- 4 is an overhead position – either 4F or 4G

[welder101]

Flat Position (1G or 1F)

This type of welding is performed from the upper side of the joint. The face of the weld is approximately horizontal.

Flat welding is the preferred term; however, the same position is sometimes called downhand.

Note: The axis of a weld is a line through the length of the weld, perpendicular to the cross-section at its center of gravity.

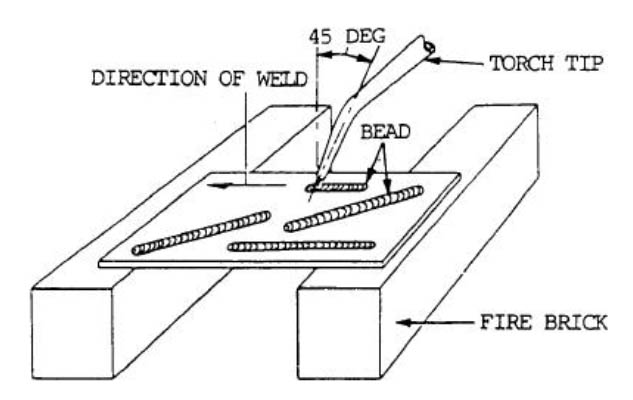

Flat Position Welding Procedures

To make good bead welds on a plate surface, the flare motion, tip angle, and position of the welding flame above the molten puddle should be carefully maintained.

The welding torch should be adjusted to give the proper type of flame for the particular metal being welded.

Narrow bead welds are made by raising and lowering the welding flare with a slight circular motion while progressing forward.

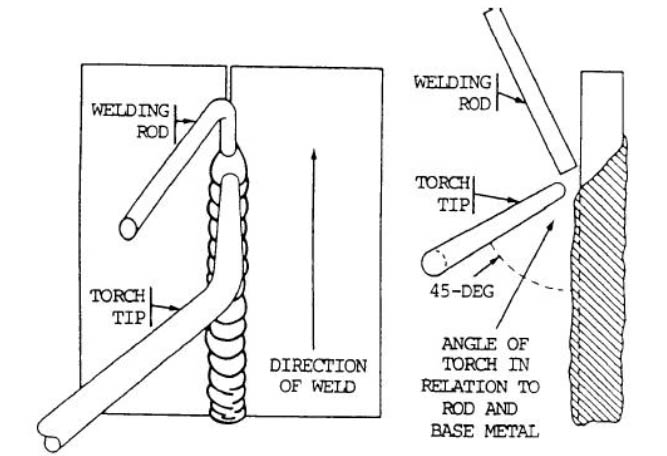

The tip should form an angle of approximately 45 degrees with the plate surface. The flame will be pointed in the welding direction.

To increase the depth of fusion, either increase the angle between the tip and the plate surface or decrease the welding speed.

The puddle size should not be too large because this will cause the flame to burn through the plate.

A properly made bead weld, without a filler rod, will be slightly below the upper surface of the plate. A bead weld with a filler rod shows a buildup on the surface.

Related read: Welding Beads: Types & Patterns

A small puddle should be formed on the surface when making a bead weld with a welding rod. The welding rod is inserted into the puddle, and the base plate and rod are melted together. The torch should be moved slightly from side to side to obtain good fusion. The size of the bead can be controlled by varying the speed of welding and the amount of metal deposited from the welding rod.

Several types of joints are used to make butt welds in the flat position.

Tack welds should be used to keep the plates aligned. The lighter sheets should be spaced to allow for weld metal contraction and thus prevent warpage.

The following table should be used for selecting the number of passes in butt welding steel plates:

| Plate thickness, in. | Number of passes |

|---|---|

| 1/8 to 1/4 | 1 |

| 1/4 to 5/8 | 2 |

| 5/8 to 7/8 | 3 |

| 7/8 to 1-1/8 | 4 |

The welding rod and torch tip position in making a flat position butt joint is shown in figure 11-13.

The motion of the flame should be controlled to melt the sidewalls of the plates and enough of the welding rod to produce a puddle of the desired size.

A molten puddle of a given size can be carried along the joint by oscillating the torch tip. This will ensure both complete penetration and sufficient filler metal to provide some reinforcement at the weld.

Care should be taken not to overheat the molten puddle. This will result in burning the metal, porosity, and low strength in the completed weld.

Horizontal Position (2F or 2G)

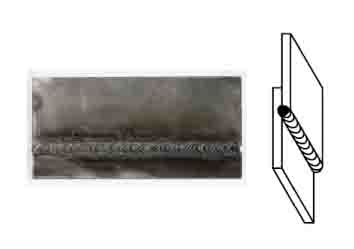

In horizontal welding, the weld axis is approximately horizontal, but the weld type dictates the complete definition.

For a fillet weld – welding is performed on the upper side of an approximately horizontal surface and against an approximately vertical surface.

For a groove weld – the face of the weld lies in an approximately vertical plane.

Butt welding – is a little more difficult to master than flat position. This is due to the tendency of molten metal to flow to the lower side of the joint. The heat from the torch rises to the upper side of the joint. The combination of these opposing factors makes it difficult to apply a uniform deposit to this joint.

Align the plates and tack weld at both ends. The torch should move with a slight oscillation up and down to distribute the heat equally to both sides of the joint, thereby holding the molten metal in a plastic state. This prevents excessive flow of the metal to the lower side of the joint and permits faster solidification of the weld metal. A joint in a horizontal position will require considerably more practice than the previous techniques. It is, however, important that the technique be mastered before passing on to other types of weld positions.

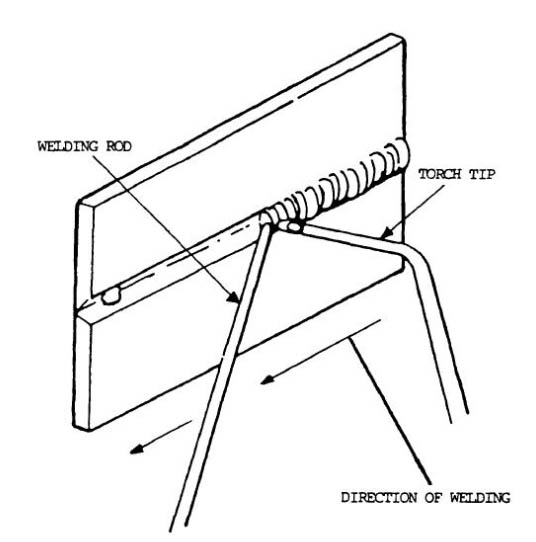

Vertical Position (3F or 3G)

In vertical position welding, the axis of the weld is approximately vertical.

When welding is done on a vertical surface, the molten metal tends to run downward and pile up.

The flow of metal can be controlled by pointing the flame upward at a 45-degree angle to the plate and holding the rod between the flame and the molten puddle (see above).

The manipulation of the torch and the filler rod keeps the metal from sagging or falling and ensures good penetration and fusion at the joint.

Both the torch and the welding rod should be oscillated to deposit a uniform bead. The welding rod should be held slightly above the centerline of the joint, and the welding flame should sweep the molten metal across the joint to distribute it evenly.

Butt joints welded in the vertical position should be prepared for welding in the same manner required for welding in the flat position.

[welder101]

Overhead Position (4F or 4G)

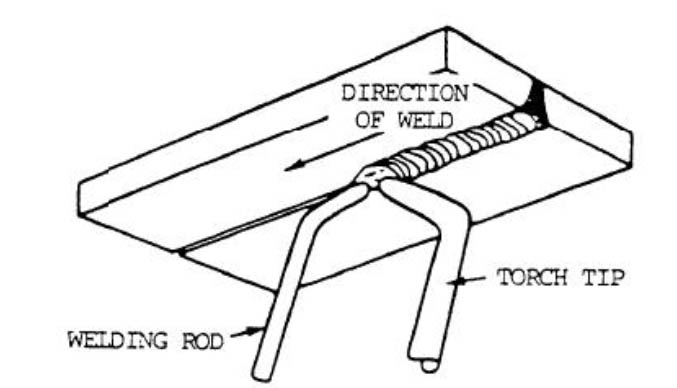

Overhead welding is performed from the underside of a joint.

In overhead welding, the metal deposited tends to drop or sag on the plate, causing the bead to have a high crown.

The molten puddle should be kept small to overcome this difficulty, and enough filler metal should be added to obtain good fusion with some reinforcement at the bead. If the puddle becomes too large, the flame should be removed for an instant to permit the weld metal to freeze.

When welding light sheets, the puddle size can be controlled by applying the heat equally to the base metal and filler rod.

The flame should be directed to melt both edges of the joint. Sufficient filler metal should be added to maintain an adequate puddle with enough reinforcement.

The welding flame should support the molten metal, and small welding avoids burning done from one distribute it along the joint.

Only a small puddle is required, so a rod should be used. Care should be taken to control the heat through the plates.

This is particularly important when welding is side only.

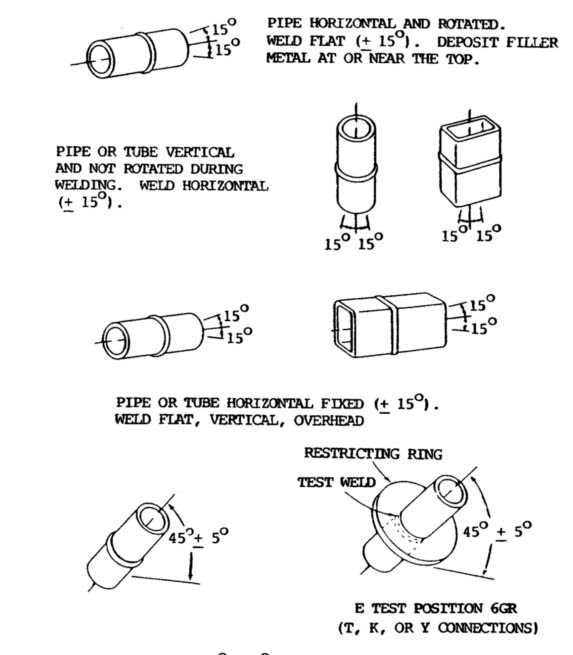

Positions for Pipe Welding

Pipe welds are made under many different requirements and in different welding situations. The job dictates the welding position.

In general, the position is fixed, but it can be rolled for flat-position work in some cases. Positions and procedures for welding pipe are outlined below.

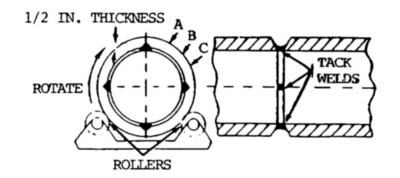

Horizontal Pipe Rolled Weld

Align the joint and tack weld or hold in position with steel bridge clamps with the pipe mounted on suitable rollers. Start welding at point C (figure below), progressing upward to point B. When point B is reached, rotate the pipe clockwise until the stopping point of the weld is at point C and again weld upward to point B. When the pipe is being rotated, the torch should be held between points B and C, and the pipe rotated past it.

The position of the torch at point A is similar to that for a vertical weld. As point B is approached, the weld assumes a nearly flat position, and the angles of application of the torch and rod are altered slightly to compensate for this change.

The weld should be stopped just before the root of the starting point so that a small opening remains. The starting point is then reheated so that the junction point area is at a uniform temperature. This will ensure a complete fusion of the advancing weld with the starting point.

If the sidewall of the pipe is more than 1/4 in. (0.64 cm) in thickness, a multi-pass weld should be made.

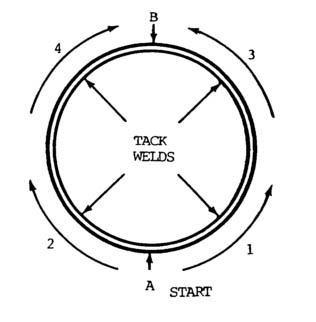

Horizontal Pipe Fixed Position Weld

After tack welding, the pipe is set up so that the tack welds are oriented approximately, as shown below. After welding has been started, the pipe must not be moved in any direction.

When welding in the horizontal fixed position, the pipe is welded in four steps as described below.

- Starting at the bottom or 6 o’clock position, weld upward to the 3 o’clock position.

- Starting back at the bottom, weld upward to the 9 o’clock position.

- Starting back at the 3 o’clock position, weld to the top.

- Starting back at the 9 o’clock position, weld upward to the top, overlapping the bead.

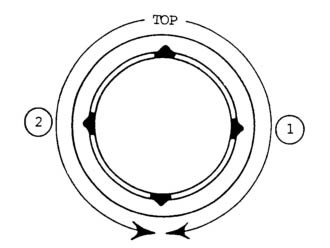

When welding downward, the weld is made in two stages. Start at the top (see below) and work down one side to the bottom, then return to the top and work down the other side to join with the previous weld at the bottom. The downward welding method is particularly effective with arc welding since the higher temperature of the electric arc makes it possible to use faster welding speeds. With arc welding, the speed is approximately three times that of the upward welding method.

Welding by the backhand method is used for joints in low carbon or low alloy steel piping that can be rolled or are in a horizontal position. One pass is used for wall thicknesses not exceeding 3/8 in. (0.95 cm), two passes for wall thicknesses 3/8 to 5/8 in. (0.95 to 1.59 cm), three passes for wall thicknesses 5/8 to 7/8 in. (1.59 to 2.22 cm), and four passes for wall thicknesses 7/8 to 1-1/8 in. (2.22 to 2.87 cm).

Vertical Pipe Fixed Position Weld

Pipe in this position, wherein the joint is horizontal, is most frequently welded by the backhand method. The weld is started at the tack and carried continuously around the pipe.

Multipass Arc Welding

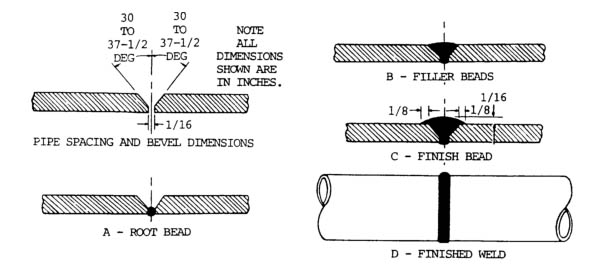

Root Beads

If a lineup clamp is used, the root bead (see below) is started at the bottom of the groove while the clamp is in position. When no backing ring is used, care should be taken to build up a slight bead on the inside of the pipe. If a backing ring is used, the root bead should be carefully fused to it. As much root bead as the bars of the lineup clamp will permit should be applied before the clamp is removed. Complete the bead after the clamp is removed.

Filler Beads

Care should be taken that the filler beads (see diagram view B above) are fused into the root bead to remove any undercut causal by the deposition of the root bead. One or more filler beads around the pipe usually will be required.

Finish Beads

The finish beads (see diagram view C above) are applied over the filler beads to complete the joint. Usually, this is a weave bead about 5/8 in. (1.59 cm) wide and approximately 1/16 in. (0.16 cm) above the outside surface of the pipe when complete. The finished weld is shown in view D above.

Aluminum Pipe Welding

For aluminum pipe, special joint details have been developed and are normally associated with combination-type procedures. A backing ring is not used in most cases. The rectangular backing ring is rarely used when fluids are transmitted through the piping system. It may be used for structural applications in which pipe and tubular members are used to transmit loads rather than materials.