Choosing the correct welding electrode, often called a rod or stick, is a challenging part of stick welding. Using the wrong electrode can lead to a bad weld and potential part rejection.

Inexperienced welders often make this mistake and suffer the consequences. They get confused by the numerous welding rods available and the many variables to consider.

However, it is possible to overcome this mistake by educating yourself on welding rods.

In this article, we’ll tackle this important topic and guide you on the most common rods, their classifications, their differences, and how to choose the correct rod for your job.

What Stick Weld Classifications Mean

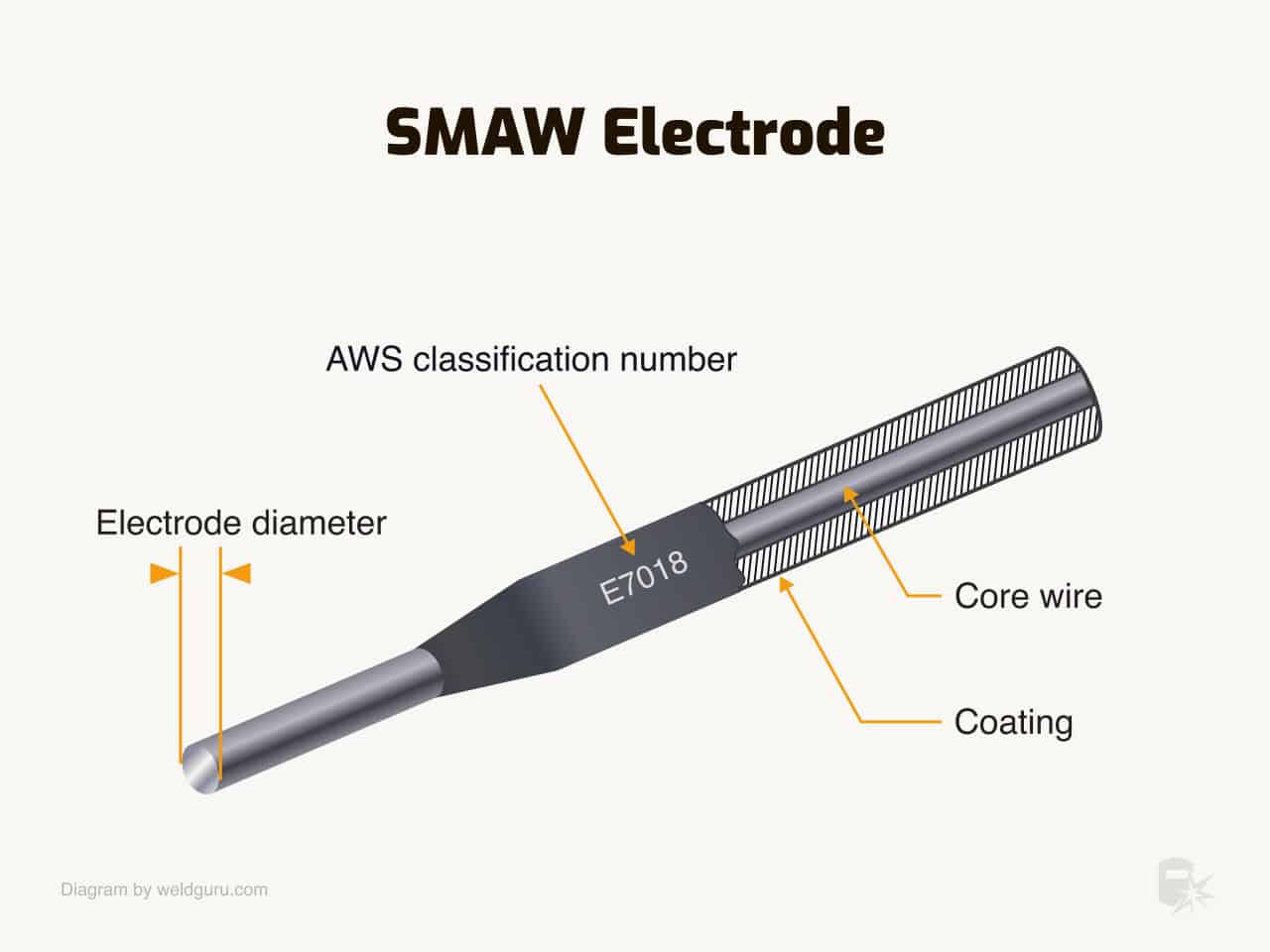

There is a wide variety of rods available to a welder, but in general, a stick electrode has a coated metal core.

However, they differ in the type of core metal and coating/flux types and are designed to provide different strengths and performance in various welding positions.

© weldguru.com – Image usage rights

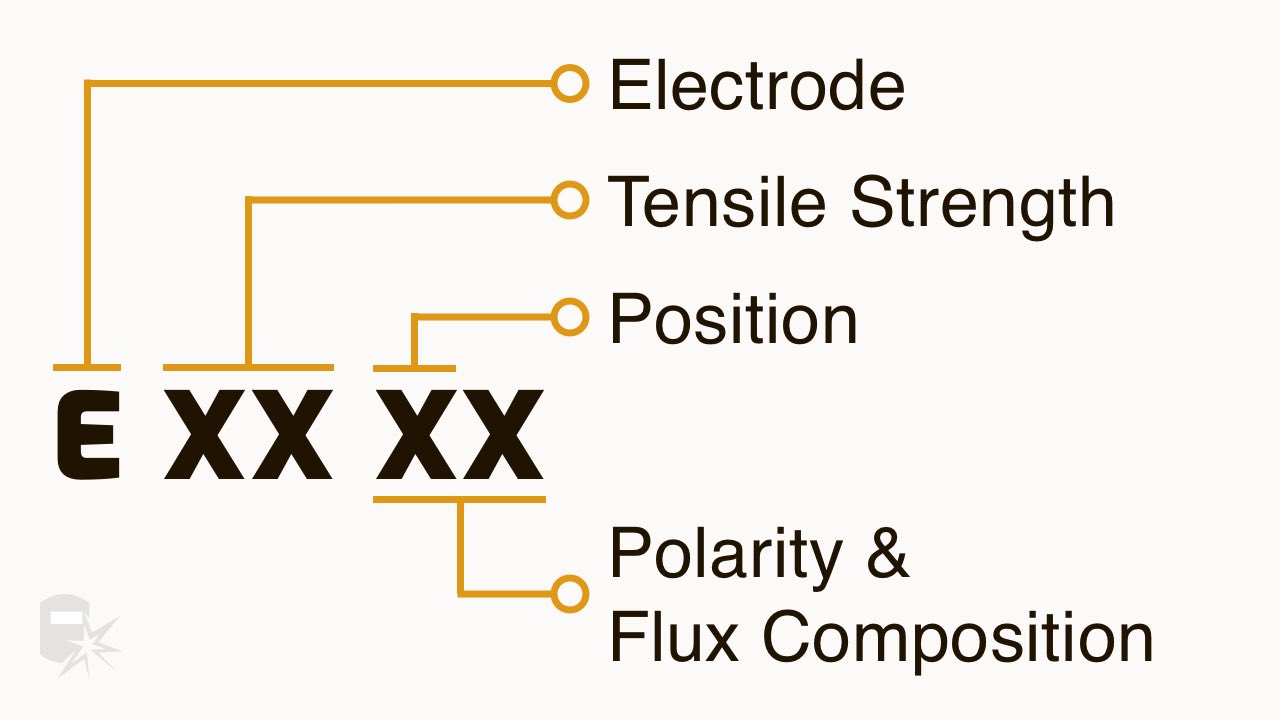

To help classify the electrodes, the American Welding Society (AWS) has developed the popular “E” code. You may have noticed it imprinted on your rods.

Each alphanumeric character in this code provides specific information about the electrode. A brief rundown is as follows:

- E – stands for “Electrode”.

- The first two digits – represent the resulting weld’s minimum tensile strength (in thousands of psi). For example, the E6010 electrode produces welds with at least 60,000 psi strength.

- The third digit – indicates the positions in which the rod can be used, and 1 is for all positions, 2 for flat and horizontal surfaces only, and 3 for flat positions only.

- The fourth (and the third) digit – specifies information like welding polarity, power supply (AC/DC), and flux composition.

You can learn more about the numbers on a welding rod here.

Types of Welding Electrodes

The code mentioned above is widely used for electrodes. However, you may frequently encounter other terms used to classify welding rods. A few of these terms are described below:

- Fast-Freeze Electrode: These electrodes solidify quickly after entering the weld pool. Due to this, they are preferred in jobs where a slow freezing rate can decrease the weld’s quality. For example, in overhead welding where there is a risk of molten metal falling down before solidifying due to gravity.

- Fast-Fill Electrode: These electrodes melt very quickly. This allows the weld pool to fill up the groove almost instantly, enabling the welder to use higher travel speeds. They also produce a wide, shallow seam.

- Fill-Freeze Electrode: These rods are a combination of both of the above electrodes. The electrode fills up the groove and freezes fairly quickly, but definitely not as fast as the above two. The joint has medium depth and width.

Now, let’s move on to the electrodes that you’ll commonly encounter.

E6010 Welding Electrode

| Feature | E6010 |

|---|---|

| Coating | High Cellulose Sodium |

| Position | All Positions |

| Current | DCEP |

| Penetration | Deep |

| Tensile Strength | 60,000 PSI |

The E6010 is one of the most common sticks used in industry. It is an all-position, DC-only rod. It is well-known for its deep penetration, which is why it is widely used for root pass welds.

Its deep penetration and fast-freeing cellulose flux make it a prime choice for stove pipe welding. Moreover, its performance is unaffected by rusty, unclean, or galvanized surfaces.

The E6010 bead is smooth and flat. The slag is light and paper-like, and mildly tricky to remove. However, you may see some spatter and the DC arc is difficult to control. The whip-and-pause technique is often suggested to control the weld pool temperature.

E6011 Welding Electrode

| Feature | E6011 |

|---|---|

| Coating | High Cellulose Sodium |

| Position | All Positions |

| Current | DCEP & AC |

| Penetration | Deep |

| Tensile Strength | 60,000 PSI |

The E6011 can be used in all positions. It has a cellulose flux coating that is slightly rich in potassium. Potassium helps stabilize the arc, allowing it to be used with both DC and AC power supplies.

Because of its AC capability, E6011 is often used in home welding setups. It is also used as an alternative to E6010.

It produces deep penetration joints. Plus, the arc can dig through surface contaminants like dirt, paint, and galvanized metals.

E6011 is also the preferred choice of learners as its AC arc is less intense and is easier to manage with an unsteady hand.

E6012 Welding Electrode

| Feature | E6012 |

|---|---|

| Coating | High Titania Sodium |

| Position | All Positions |

| Current | DCEN & AC |

| Penetration | Medium |

| Tensile Strength | 60,000 PSI |

The E6012 is an all-position stick that works with both AC/DC power supplies. It produces a moderate quality arc with decent deposition and penetration.

Its rutile flux coating makes it a fill-freeze electrode. The resulting filler material freezes and spreads quickly. For this reason, it works well in applications that require a balance between joint penetration and fill.

The arc is very stable and easily managed. Welders like it because of the smooth seam, and low spatter.

Because it supports low voltage and freezes quickly, it is also regularly used in high-speed, high-current applications.

E6013 Welding Electrode

| Feature | E6013 |

|---|---|

| Coating | High Titania Potassium |

| Position | All Positions |

| Current | DCEP, DCEN & AC |

| Penetration | Shallow |

| Tensile Strength | 60,000 PSI |

This rod is suitable for AC and DC power supplies and may be used in any position. It is coated with a rutile flux made up of titanium dioxide (“titania”) and potassium. Like E6012, this is also a fill-freeze flux.

This rod is suitable for mild-intensity jobs. It has a soft arc with shallow penetration that runs very smoothly. It also produces minimal spatter and an easy-to-remove slag. These characteristics make it a popular choice as a general-purpose rod.

However, it’s somewhat limited in its applications since its arc is not that powerful. Because of its performance characteristics, it is only applicable for use on clean sheet metal.

E7018 Welding Electrode

| Feature | E7018 |

|---|---|

| Coating | Low Hydrogen, Iron Powder |

| Position | All Positions |

| Current | DCEP & AC |

| Penetration | Shallow to Medium |

| Tensile Strength | 70,000 PSI |

E7018 is an all-position, low hydrogen electrode. It is suitable for both AC/DC supplies but is mainly used with a DC input.

It runs very quietly and smooth with low amounts of spatter. It is a fill-freeze rod with shallow-to-moderate penetration and medium fill. The arc is stable and easily controlled as well.

The inherent low hydrogen levels prevent cold cracking (also known as hydrogen cracking). Due to this, it is ideal to use with metals like structural and high-carbon steels.

Of note, the flux produces heavy slag that sticks to the metal. Therefore, some effort is required to remove it from the joint completely.

It is recommended to store E7018 rods in moisture-free environments and to oven-bake them before use to ensure the desired low levels of hydrogen.

E7024 Welding Electrode

| Feature | E7024 |

|---|---|

| Coating | Low Hydrogen, Iron Powder |

| Position | Flat & Horizontal |

| Current | DCEN & AC |

| Penetration | Shallow to Medium |

| Tensile Strength | 70,000 PSI |

The E7024 is a unique stick on our list. It is an AC/DC electrode that can only be used in flat and horizontal orientations. Significantly, its low hydrogen flux contains up to 50% iron powder content.

This high iron content results in high deposition rates, producing a wide, convex seam. For this reason, it is used for plates at least ¼” thick like ship structures, bridges, structural steels for buildings. Also, the produced joint has high strength (even at low temperatures) and is compatible with high-carbon steels.

The slag it produces is heavy and must be carefully removed from all pockets and surfaces. Since it is a low hydrogen rod, it must also be kept in moisture-free storage like E7018.

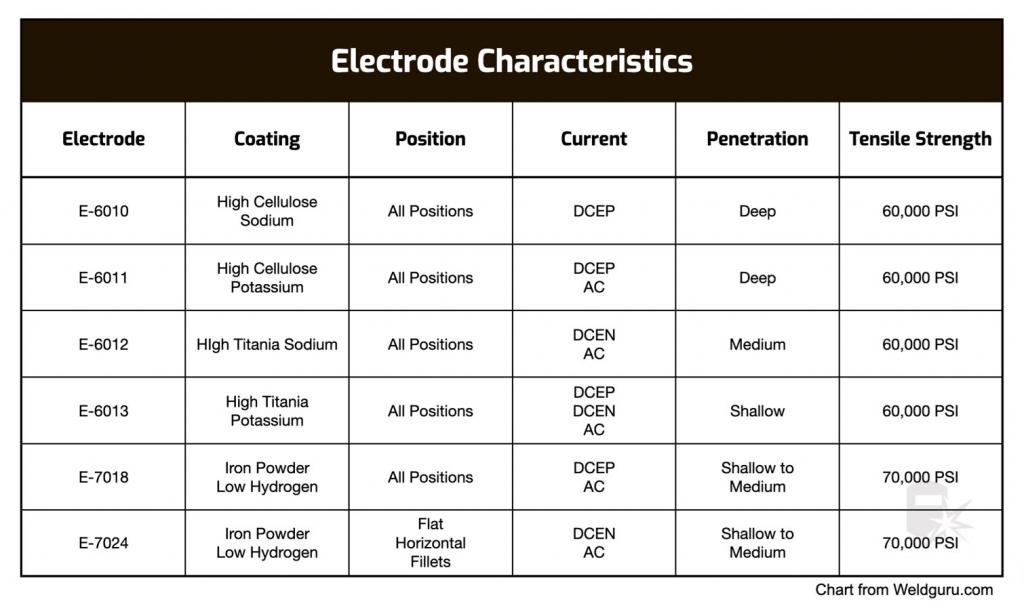

We understand that all this information might be a bit too much to absorb at first, but you will have no trouble recalling it once you gain some experience. So, for now, we have summarized the main points in the table above for the upcoming discussion.

New to stick welding? Check out these stick welding tips to improve your technique.

Quick FAQs

It can be difficult to choose the right stick for your job with so many options. This decision is easy when you know the key differences between the electrodes.

So, we directly compared some of the common electrodes.

6010 vs. 6011 Electrodes

The 6010 and 611 are similar electrodes and are often used interchangeably.

Their flux composition is different, which gives E6011 the additional ability to be used with AC. Due to this, the E6011 arc is also slightly less intense and easier to control when used with an AC power supply.

| Electrodes | 6010 | 6011 |

|---|---|---|

| Flux Coating | High CelluloseSodium | High CellulosePotassium |

| Tensile Strength | 60,000 psi | 60,000 psi |

| Welding Position | All Positions | All Positions |

| Welding Current | DC | AC/DC |

| Arc Characteristics | Tight, Erratic | Tight, Erratic |

| Penetration | Deep | Deep |

| Fill | Narrow | Narrow |

| Slag Type | Light, Flaky | Light, Flaky |

| Special Applications | Root Pass, Dirty/Oily/Painted Surfaces, Stove Pipe Welding | Root Pass, Dirty/Oily/Painted Surfaces, General Industrial |

6010 Vs. 7018 Electrodes

6010 and 7018 electrodes differ in joint strength, flux coating, and applications.

E7018 produces stronger joints, and it is compatible with high-carbon steels due to its low hydrogen content. Its slag is thicker and more difficult to remove than E6010. Both rods are widely used in the industry for their specific purposes.

| Electrodes | 6010 | 7018 |

|---|---|---|

| Flux Coating | High CelluloseSodium | 25% Iron PowderLow Hydrogen |

| Tensile Strength | 60,000 psi | 70,000 psi |

| Welding Position | All Positions | All Positions |

| Welding Current | DC | AC/DC (Usually DC) |

| Arc Characteristics | Tight, Erratic | Smooth |

| Penetration | Deep | Shallow to Medium |

| Fill | Narrow | Medium to Wide |

| Slag Type | Light, Flaky | Thick |

| Special Applications | Root Pass, Dirty/Oily/Painted Surfaces, Stove Pipe Welding | High-Carbon Steels, Low-Alloy/High-Strength Joints |

6011 vs. 6013 Electrodes

The E6011 and E6013 are comparable in tensile strength, welding positions, and current types.

E6011 is more of a heavy-duty industrial rod better suited for deep joints. E6013 has a delicate arc that is better for clean sheet metal welds. Also, the E6011 requires a steady, skilled hand to get good results.

| Electrodes | 6011 | 6013 |

|---|---|---|

| Flux Coating | High Cellulose, Potassium | High Titania, Potassium |

| Tensile Strength | 60,000 psi | 60,000 psi |

| Welding Position | All Positions | All Positions |

| Welding Current | AC/DC | AC/DC |

| Arc Characteristics | Tight, Erratic | Smooth |

| Penetration | Deep | Shallow to Medium |

| Fill | Narrow | Medium |

| Slag Type | Light, Flaky | Light, Easy to Remove |

| Special Applications | Root Pass, Dirty/Oily/Painted Surfaces, General Industrial | Sheet Metal |

6011 vs. 7018 Electrodes

The 6011 and 7018 sticks have little in common. E7018 produces stronger joints and can handle high-carbon alloys, unlike the E6011 electrode. E7018 is a fill-freeze rod, so it has medium penetration and fill. The fast-freeze E6011 is well-known only for its deep penetration.

| Electrodes | 6011 | 7018 |

|---|---|---|

| Flux Coating | High Cellulose, Potassium | 25% Iron Powder, Low Hydrogen |

| Tensile Strength | 60,000 psi | 70,000 psi |

| Welding Position | All Positions | All Positions |

| Welding Current | AC/DC | AC/DC (Usually DC) |

| Arc Characteristics | Tight, Erratic | Smooth |

| Penetration | Deep | Shallow to Medium |

| Fill | Narrow | Medium to Wide |

| Slag Type | Light, Flaky | Thick |

| Special Applications | Root Pass, Dirty/Oily/Painted Surfaces, General Industrial | High-Carbon Steels, Low-Alloy/High-Strength Joints |

6013 vs. 7018 Electrodes

6013 and 7018 electrodes do not share many qualities.

E6013 has a rutile flux, while E7018 is a low hydrogen rod. The E6013 is used almost exclusively for thin sheets, while the E7018 can handle thicker workpieces, a wider range of materials, and has better strength.

| Electrodes | 6013 | 7018 |

|---|---|---|

| Flux Coating | High Titania, Potassium | 25% Iron Powder, Low Hydrogen |

| Tensile Strength | 60,000 psi | 70,000 psi |

| Welding Position | All Positions | All Positions |

| Welding Current | AC/DC | AC/DC (Usually DC) |

| Arc Characteristics | Smooth | Smooth |

| Penetration | Shallow to Medium | Shallow to Medium |

| Fill | Medium | Medium to Wide |

| Slag Type | Light, Easy to Remove | Thick |

| Special Applications | Sheet Metal | High-Carbon Steels, Low-Alloy/High-Strength Joints |

Selecting the Right Electrode

You can follow our step-by-step guide below to choose an electrode that fits your application.

Usually, the selection process goes like this:

- Strength: Check the required joint strength. For example, if you need 65,000 psi, you immediately eliminate E60XX rods and look for a suitable E70XX.

- Position: Your list of options further decreases when you filter out electrodes suitable only for your welding position.

- Size: The size of your welding rod will depend on the metal’s thickness. The rule of thumb is to choose an electrode a little smaller than the thickness of the base metal.

- Power Supply: Never use a rod that cannot run on your power supply!

- Joint Type: Consider factors such as penetration, joint access for slag removal, plate/sheet thickness, and surface cleanliness.

- Material: You will need a low hydrogen rod (E7018, E7024) if your base metal is at risk of hydrogen cracking.

This was just a sample selection guide. Every application is unique, and you must study it carefully before finalizing a rod.

Conclusion

We covered six common welding electrodes and outlined their main characteristics as well as the best applications for each. It is critical to have the right stick electrode for every job, which requires some know-how.

But with this basic knowledge, you will be able to find the right stick electrode for every job. It will take some time and practice to engrain this information into your memory, but it is not as hard as it sounds, and with some experience, it will become second nature for you.

We hope this was a fun, educational read. If you have any questions or feedback, let us know in the comments below.