All welding and thermal cutting operations carried on in confined spaces must be adequately ventilated to prevent the accumulation of toxic materials, combustible gases, or possible oxygen deficiency.

Monitoring instruments should be used to detect harmful atmospheres. Where it is impossible to provide adequate ventilation, air-supplied respirators or hose masks approved for this purpose must be used.

In these situations, lookouts must be used on the outside of the confined space to ensure the safety of those working within.

Requirements in this section describe standards established for arc and gas welding and cutting.

A certified industrial hygienist should be consulted to understand the correct approach for your specific situation.

Overview

These requirements will govern the amount of contamination to which welders may be exposed:

- Dimensions of the area in which the welding process takes place (with special regard to the height of the ceiling).

- The number of welders in the room.

- Possible development of hazardous fumes, gases, or dust according to the metals involved.

- Location of welder’s breathing zone with respect to the rising plume of fumes.

In specific cases, there are other factors involved in which respirator protective devices (ventilation) should be provided to meet the equivalent requirements of this section. They include:

- Atmospheric conditions.

- Generated heat.

- Presence of volatile solvents.

In all cases, the required health protection, ventilation standards, and standard operating procedures for new as well as old welding operations should be coordinated and cleaned through the safety inspector and the industrial hygienist having responsibility for the safety and health aspects of the work area.

Screen Areas

When welding must be performed in a space entirely screened on all sides, the screens shall be arranged so that no serious restriction of welding ventilation fumes exists.

It is desirable to have the screens mounted so that they are about 2.0 ft (0.6 m) above the floor, unless the work is performed at such a low level that the screen must be extended closer to the floor to protect workers from the glare of welding.

The concentration of Toxic Substances

Local exhaust or general ventilating systems shall be provided and arranged to keep the number of toxic frees, gas, or dusts below the acceptable concentrations as set by the American National Standard Institute Standard 7.37; the latest Threshold Limit Values (TLV) of the American Conference of Governmental Industrial Hygienists; or the exposure limits as established by Public Law 91-596, Occupational Safety and Health Act of 1970.

Compliance shall be determined by sampling of the atmosphere. Samples collected shall reflect the exposure of the persons involved. When a helmet is worn, the samples shall be collected under the helmet.

Respiratory Protective Equipment

Individual respiratory protective equipment will be well retained. Only respiratory protective equipment approved by the US Bureau of Mines, National Institute of Occupational Safety and Health, or other government-approved testing agency shall be utilized. Guidance for selection, care, and maintenance of respiratory protective equipment is given in Practices for Respiratory Protection, American National Standard Institute Standard 788.2 and TB MED 223. Respiratory protective equipment will not be transferred from one individual to another without being disinfected.

Precautionary Labels

A number of potentially hazardous materials are used in flux coatings, coverings, and filler metals.

These materials, when used in welding and cutting operations, will become hazardous to the welder as they are released into the atmosphere.

These include, but are not limited to, the following materials: fluorine compounds, zinc, lead, beryllium, cadmium, and mercury.

The suppliers of welding materials shall determine the hazard, if any, associated with the use of their materials in welding, cutting, etc.

All filler metals and fusible granular materials shall carry the following notice, as a minimum, on tags, boxes, or other containers:

CAUTION

Welding may produce fumes and gases hazardous to health.

Avoid breathing these fumes and gases.

Use adequate ventilation. See American National Standards Institute Standard Z49.1-1973, Safety in Welding and Cutting published by the American Welding Society.

Brazing (welding) filler metals containing cadmium in significant amounts shall carry the following notice on tags, boxes, or other containers:

WARNING

CONTAINS CADMIUM – POISONOUS FUMES MAY BE FORMED ON HEATING

Do not breathe fumes.

Use only with adequate ventilation, such as fume collectors, exhaust ventilators, or air-supplied respirators.

See American National Standards Institute Standard Z49.1-1973. If chest pain, cough, or fever develops after use, call a physician immediately.

Local Exhaust Ventilation

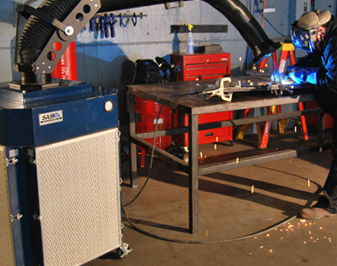

Mechanical local exhaust welding ventilation may be obtained by either of the following means:

- Hoods. Freely movable hoods or ducts are intended to be placed by the welder as near as practicable to the work being welded. These will provide a rate of airflow sufficient to maintain a velocity in the direction of the hood of 100 in linear feet per minute in the zone of welding.

- Fixed enclosure. A fixed enclosure with a top and two or more sides that surrounds the welding or cutting operations will have a rate of airflow sufficient to maintain a velocity away from the welder of not less than 100 linear ft per minute. Downdraft ventilation tables require 150 cu ft per minute per square foot of surface area.This rate of exhausted air shall be uniform across the face of the grille.A low volume, high-density fume exhaust device attached to the welding gun collects the fumes as close as possible to the point of origin or at the arc.This method of fume exhaust has become quite popular for the semiautomatic processes, particularly the flux-cored arc welding process.Smoke exhaust systems incorporated in semiautomatic guns provide the most economical exhaust system since they exhaust much less air they eliminate the need for massive air makeup units to provide heated or cooled air to replace the air exhausted.

Local ventilation should have a rate of air flow sufficient to maintain a velocity away from the welder of not less than 100 ft (30 m) per minute.

Air velocity is measurable using a velometer or air flow inter. These two systems can be extremely difficult to use when welding other than small weldments.

The downdraft welding work tables are popular in Europe but are used to a limited degree North America.

In all cases when local ventilation is used, the exhaust air should be filtered.

Air Replacement

Ventilation is a prerequisite to work in confined spaces.

All welding and cutting operations in confined spaces shall be adequately ventilated to prevent the accumulation of toxic materials -or possible oxygen deficiency.

This applies not only to the welder but also to helpers and other personnel in the immediate vicinity.

Airline Respirators

In circumstances where it is impossible to provide adequate ventilation in a confined area, airline respirators or hose masks, approved by the US Bureau of Mines, National Institute of Occupational Safety and Health, or other government-approved testing agency, will be used for this purpose.

The air should meet the standards established by Public Law 91-596, Occupational Safety and Health Act of 1970.

Self-contained Units

In areas immediately hazardous to life, hose masks with blowers or self-contained breathing equipment shall be used.

The breathing equipment shall be approved by the US Bureau of Mines or National Institute of Occupational Safety and Health, or other government-approved testing agency.

Outside Helper

Where welding operations are carried on in confined spaces and where welders and helpers are provided with hose masks, hose masks with blowers, or self-contained breathing equipment, a worker shall be stationed on the outside of such confined spaces to ensure the safety of those working within.

Oxygen for Ventilation

Oxygen must never be used for ventilation.

Ventilation for Fluorine Compounds

In confined spaces, welding or cutting involving fluxes, coverings, or other materials in which fluorine compounds shall be done in accordance with paragraph 2-4 h, ventilation in confined spaces.

A fluorine compound is one that contains fluorine as an element in chemical combination, not as a free gas.

Maximum allowable concentration.

The need for local exhaust ventilation or airline respirators for welding or cutting in other than confined spaces will depend upon the individual circumstances.

However, experience has shown that such protection is desirable for fixed-location production welding and for all production welding on stainless steels.

When air samples taken at the welding location indicate that the fluorides liberated are below the maximum allowable concentration, such protection is not necessary.

Zinc

- Zinc Welding Ventilation in Confined spaces in confined spaces, welding or cutting involving zinc-bearing filler metals or metals coated with zinc-bearing materials shall be done in accordance with regulations on ventilation in confined spaces.

- Indoors, welding or cutting involving zinc-bearing metals or filler metals coated with zinc-bearing materials shall be done in accordance with local exhaust ventilation regulations.

Lead

- Confined spaces, welding involving lead-based metals (erroneously called lead-burning) shall be done in accordance with guidelines on ventilation in confined spaces.

- Indoors, welding involving lead-based metals shall be done in accordance with guidelines on local exhaust ventilation.

- Local ventilation in confined spaces or indoors, welding or cutting involving metals containing lead or metals coated with lead-bearing materials, including paint, shall be done using local exhaust ventilation or airline respirators.

Outdoors, such operations shall be done using respiratory protective equipment approved by the US Bureau of Mines, National Institute of Occupational Safety and Health, or other government-approved testing agency.

In all cases, workers in the immediate vicinity of the cutting or welding operation shall be protected as necessary by local exhaust ventilation or airline respirators.

Beryllium

Welding or cutting indoors, outdoors, or in confined spaces involving beryllium-bearing material or filler metals will be done using local exhaust ventilation and airline respirators.

This must be performed without exception unless atmospheric tests under the most adverse conditions have established that the workers´ exposure is within the acceptable concentrations of the latest Threshold Limit Values (TLV) of the American Conference of Governmental Industrial Hygienists or the exposure limits established by Public Law 91-596, Occupational Safety and Health Act of 1970.

In all cases, workers in the immediate vicinity of the welding or cutting operations shall be protected as necessary by local exhaust ventilation or airline respirators.

Cadmium

- General. Welding or cutting indoors or in confined spaces involving cadmium-bearing or cadmium-coated base metals will be done using local exhaust ventilation or airline respirators. Outdoors, such operations shall be done using respiratory protective equipment such as fume respirators, approved by the US Bureau of Mines, National Institute of Occupational Safety and Health, or other government-approved testing agency, for such purposes.

- Confined space. Welding (brazing) involving cadmium-bearing filler metals shall be done using ventilation as prescribed in the paragraph above on local exhaust ventilation, and ventilation in confined spaces, if the work is to be done in a confined space.

NOTE : Cadmium-free rods are available and can be used in most instances with satisfactory results.

Mercury

Welding or cutting indoors or in a confined space involving metals coated with mercury-bearing materials, including paint, shall be done using local exhaust welding ventilation or airline respirators. Outdoors, such operations will be done using respiratory protective equipment approved by the National Institute of Occupational Safety and Health, US Bureau of Mines, or other government-approved testing agency.