Welding is full of challenges. Each project brings unique tasks, and you will make new mistakes, as well as learn valuable lessons. There is no avoiding it, welding is complex.

In this article, we will focus on full penetration welds, their importance, methods to achieve full penetration, and why you may want to avoid them in certain situations.

During your welding career, you will encounter full penetration often. So, you need to be knowledgeable about this commonly used welding term.

Without further ado, let’s dive in!

What is a Full Penetration Weld?

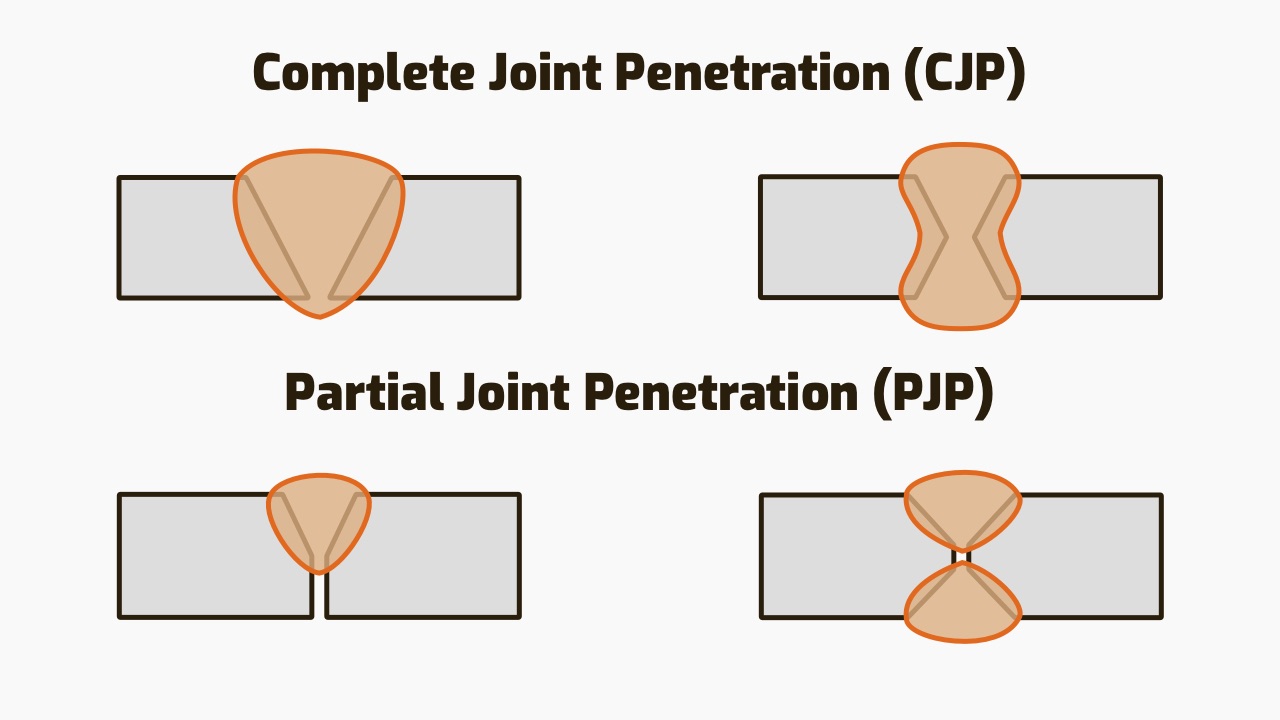

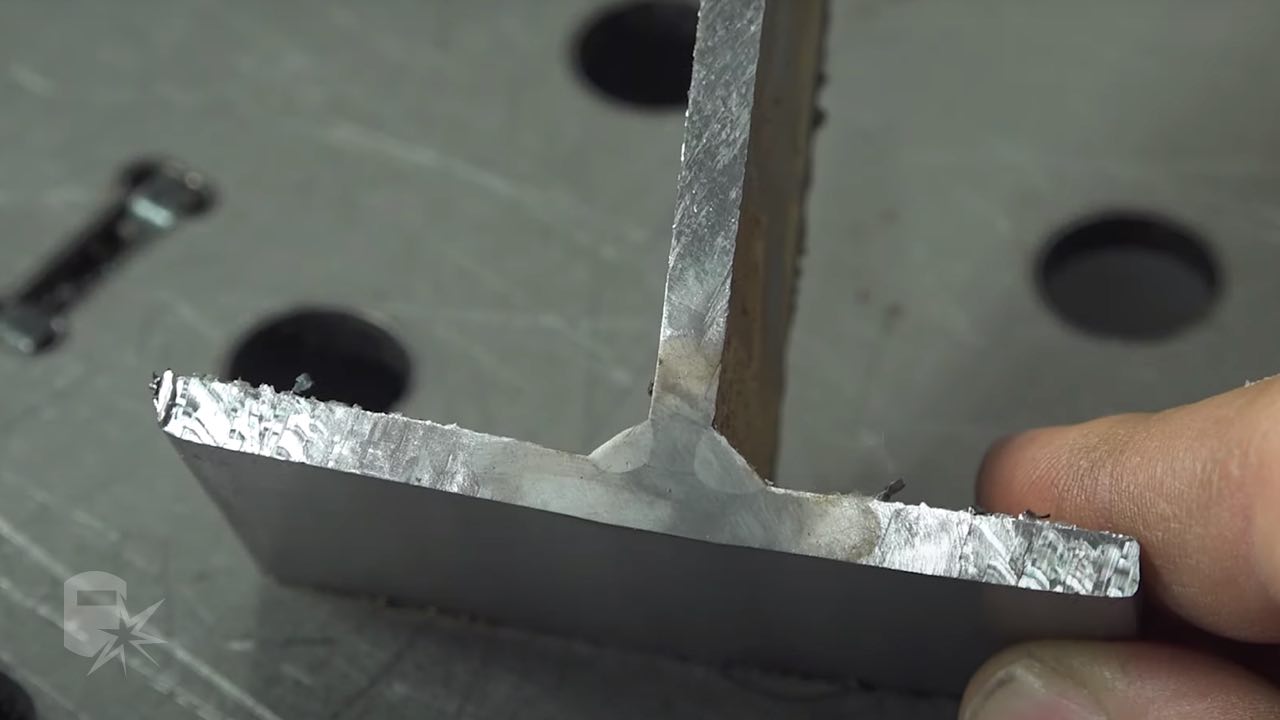

A full penetration weld, also known as complete joint penetration (“CJP”), involves a special kind of groove that allows filler material to fill the entire joint gap. That is, the weld penetrates from the toe (top) to the root (bottom) of the joint.

In contrast, a partial joint penetration (“PJP”), the second type of groove weld, does not reach the root. If you look at its cross-section, you will find gaps between the joined pieces.

To achieve CJP, the metal edges are usually beveled to assist in full penetration. U, J, and V-grooves are the most common groove shapes. If the base metal is a sheet or thin plate, the bevel is not required. This is called a square butt groove.

When properly done, a full penetration joint has better strength and durability. So, how do you do it properly and how strong is a CJP weld? Just keep reading to find out.

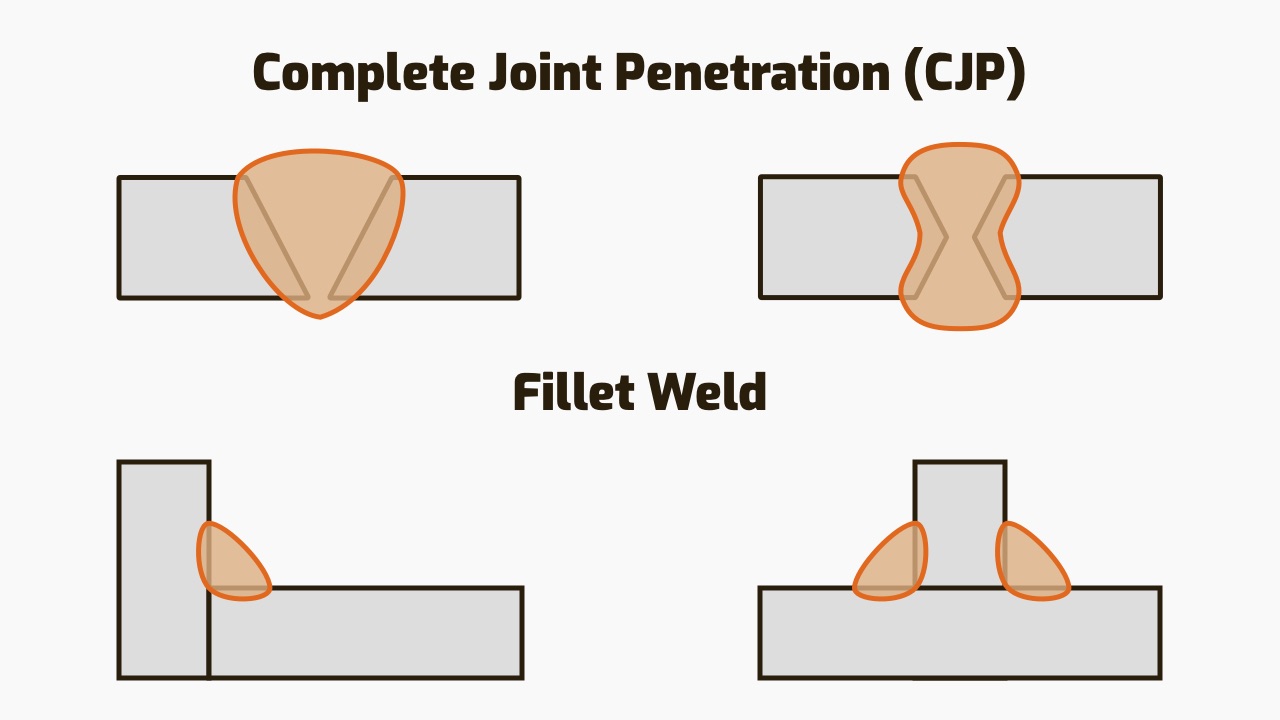

What is the difference between full penetration weld and fillet weld?

There is some confusion over the difference between full penetration welds and fillet welds. So, let’s clear that up.

A fillet weld joins two pieces of metal that are perpendicular or at an angle. The geometry of the joint means the root of the weld is not found down the gap between the two pieces.

So, full penetration cannot be achieved in fillet welds. With a fillet weld, the weld is deposited on the top surfaces of the pieces and it does not penetrate along the gap between the metal.

As dictated by the geometry, butt welds that can achieve CJP and fillet welds are two completely different joints. Fillet joints will not, since the geometry does not allow CJP.

Why is Full Penetration in Welding Important?

Full penetration welds have numerous desirable properties. These can improve the joint quality. For this reason, they are mostly used for high-performance parts.

High Strength – How strong is a full penetration weld?

Full penetration welds have superior strength compared to other types of welds.

The keyword is “fusion.” During the weld, the base metals and filler melt and solidify as a unified, fused weldment. The more fusion (or mixing), the higher the joint strength.

In CJP, the deep penetration allows for increased fusion and therefore better strength. For example, load-bearing assemblies often use full penetration welds to handle large loads.

These welds are so strong, if done correctly, they will be stronger than the parent metal itself. Meaning the steel will fail before the weld does.

Corrosion Resistance

Welds with CJP are also more corrosion-resistant than PJP welds. Corrosion tends to initiate in air pockets, gaps, and holes inside the weld. These voids can trap moisture and dirt, which are needed for corrosion.

A full penetration weld provides a higher volume of filler metal and leaves no gaps between the joined pieces. This increases the joint’s corrosion resistance.

How to Achieve a Full Penetration Weld

Full penetration welding requires proper welder settings and a stable welding hand.

As a welder, you need to be aware of all the involved variables so you can weld according to specifications and troubleshoot problems.

High Current

To achieve good penetration, high current contributes to better weld penetration. In general, the higher the current, the higher the heat input and the deeper the penetration.

Power density is what is actually important for good penetration. But current and power density have a direct relationship. So, high current is the first factor to consider when aiming for CJP.

In some cases, you can simply crank up the amperage in the power supply. With automatic wire feed techniques (like MIG), current can be pushed higher by increasing wire feed speed (“WFS”). This reduces the arc gap, increasing the current as a result.

However, you must be careful. Very high wire feeds cause erratic arcs. Do not increase the WFS to the point where you risk a bad weld with low penetration.

Voltage: Not Too High or Too Low

Voltage has an interesting relationship with weld penetration. It may come as a surprise to learn that high voltages lead to low penetration.

While high voltage increases power density, it also spreads the arc out. So, high voltage welding creates a wider bead with good fusion. But it does not penetrate deep into the material.

If you are seeing low penetration and suspect a problem with the voltage, consider lowering it. However, this is where the catch comes in. If you decrease it too much, the power density may fall to a point where the arc is not sustainable enough to penetrate.

Therefore, the voltage then needs to be within a certain range for full penetration welding. You can determine this range from charts, experts, or with experience.

You can play with the voltage while staying inside the optimal range. But as soon as you venture outside of it, you will see low joint penetration.

Increasing your stick out will also increase your voltage. Therefore maintaining proper stick out is important.

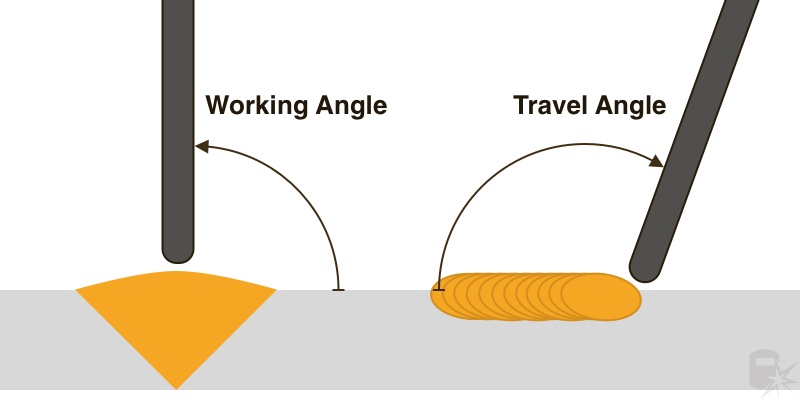

Low Travel Angle

Travel angle is the angle between the filler rod/torch/gun and an imaginary, perpendicular line to the workpiece. In order to achieve CJP, you should keep the travel angle low, preferably below 20 degrees. Or in other words, close to perpendicular to the workpiece.

Its effect on penetration is similar to what you read in the voltage section above. A higher travel angle (less perpendicular) creates wide but shallow beads. It also causes more spatter because the force with which the filler is deposited in the weld pool is high.

You also want this travel angle to be while dragging/pulling the electrode as this will give you more penetration than if you push your electrode.

Balanced Travel Speed

The electrode travel speed also affects joint penetration. The electrode is the weld pool’s source of energy. If you quickly move it away from a point during welding, that particular point will receive less energy. This causes lower penetration.

Thus the travel speed must be slow enough to deliver ample energy if CJP is the desired result.

But slowing it down a bit too much is bad, too. A slower-than-required travel speed creates a fuller weld pool that can easily flow away from the electrode (due to its high volume) rather than penetrating into the surface.

There is an optimal speed, and to find it you must practice often and gain the necessary experience. Always look at the width of your weld puddle and keep that same width to have a steady travel speed.

Polarity

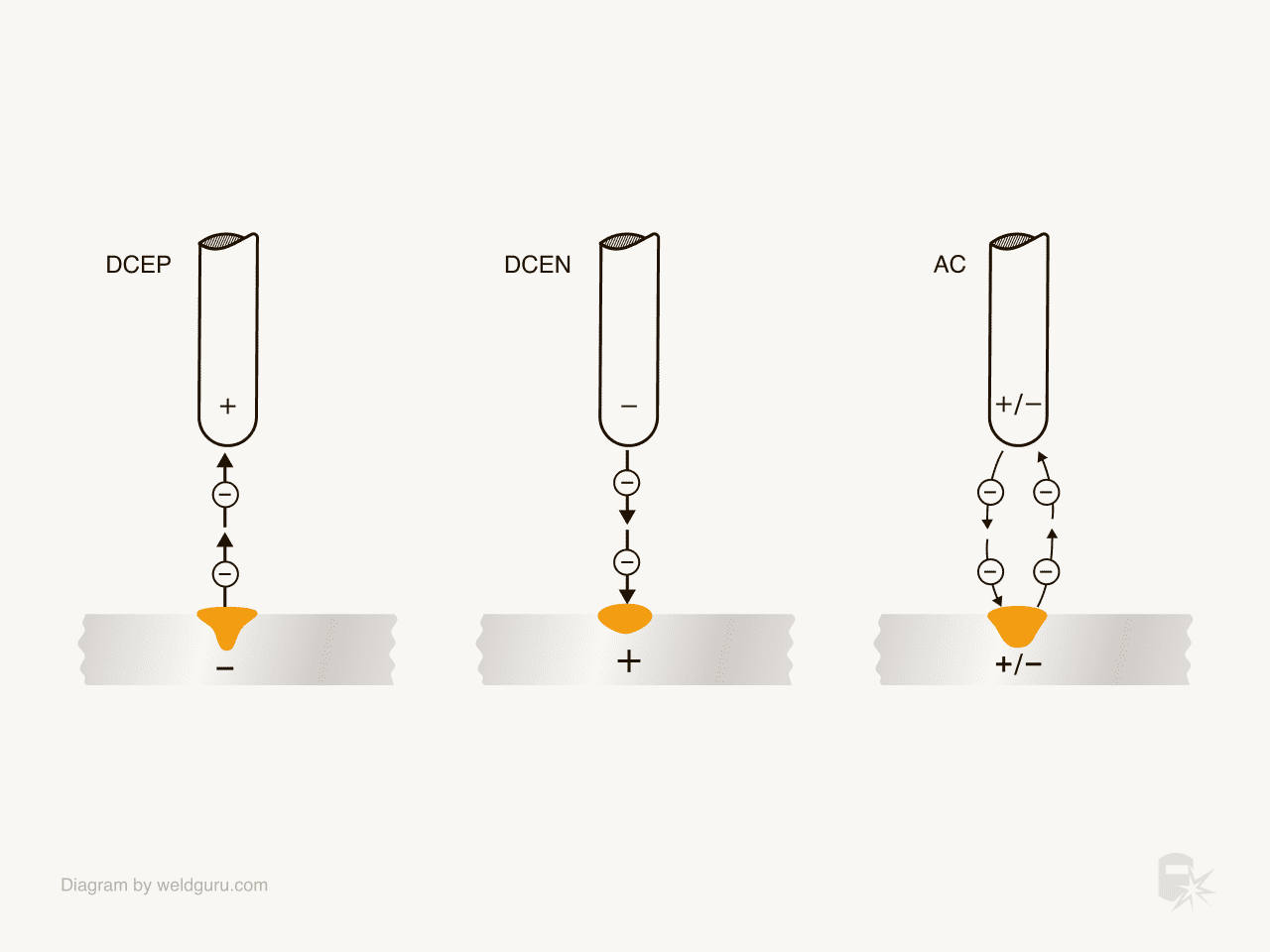

Polarity is also a factor in determining the depth of penetration. The relationship between the two is fairly straightforward.

The current direction is determined by the polarity used, and this dictates whether the base metal or electrode receives the greatest amount of heat.

© weldguru.com – Image usage rights

If energy is concentrated in the base metal, there is more heat in the workpiece and deeper penetration due to a deeper weld pool.

In contrast, energy being concentrated on the electrode/filler side decreases penetration. The joint interface does not get the hottest,it is the electrode or filler that gets the bulk of the heat.

DC+ polarity is thus the setup you should go for if you want a full penetration weld.

Electrons move from negative to positive. So if your base metal is negative, electrons flow from the workpiece to the electrode. This will concentrate about 70% of the heat in the workpiece and around 30% in the electrode.

Generally, heat is concentrated in the negatively charged component as electrons pass through it first. You can also think of it as the heat travelling from negative to positive, so naturally the negative side is hotter.

For better penetration, we always prefer DC+ polarity (positive electrode, negative workpiece) as it creates a deeper weld pool in the workpiece. As a result, the filler reaches deeper into the base metal and you can more easily achieve full joint penetration.

Electrode Selection

The electrode composition and diameter are important factors in weld penetration.

Some electrode grades are designed to penetrate. This can either be their thermal properties, the viscosity of the puddle they form, or electrical affinity that suits a certain polarity (DC+ in this case).

As for the rod diameter, smaller is better. In a smaller electrode, the charge flows through a smaller cross-section. This means that the current density is higher. Due to the reasons discussed above, the higher current density produces penetrating welds.

Downsides of Full Penetration Welding

Up to this point, we highlighted the positives of full penetration welding. It may seem foolish not to have CJP but there are times when its cons outweigh the pros.

A major side effect of full penetration welding is excessive admixture. In simple terms, the needed high-energy causes extra-base metal to melt into the weld pool.

This high heat also disrupts the mechanical properties of the base metal at the weld interface. The resultant heat-treated material is weaker, deformed, and crack-prone. A more technical way of saying this would be that the heat-affected zone (“HAZ”) is bigger.

This admixture problem can also lead to a dilute admixture. That means that the ratio of filler to the base metal in the joint is not ideal. This creates performance issues down the line as well.

When welding thinner sections, in severe cases the high energy can also burn a hole in the base metal. Welders call this burn-through and obviously, this is not what you want to happen with a workpiece.

Keep these downsides in mind when you are considering a full penetration weld. There are situations where it might be a good idea to sacrifice little penetration for enhanced mechanical integrity.

Wrapping It Up

Full penetration welds require skill, knowledge, and proper welder settings. Welding charts can help you get a starting point for your voltage, amperage, WFS, etc. But there is no substitute for actual experience.

Also, your technique impacts weld penetration. Your travel angle and speed are two important variables to get right. Plus, you should bevel the edges for thicker stock. So, practice is paramount and you would be wise to seek out advice from experienced welders.