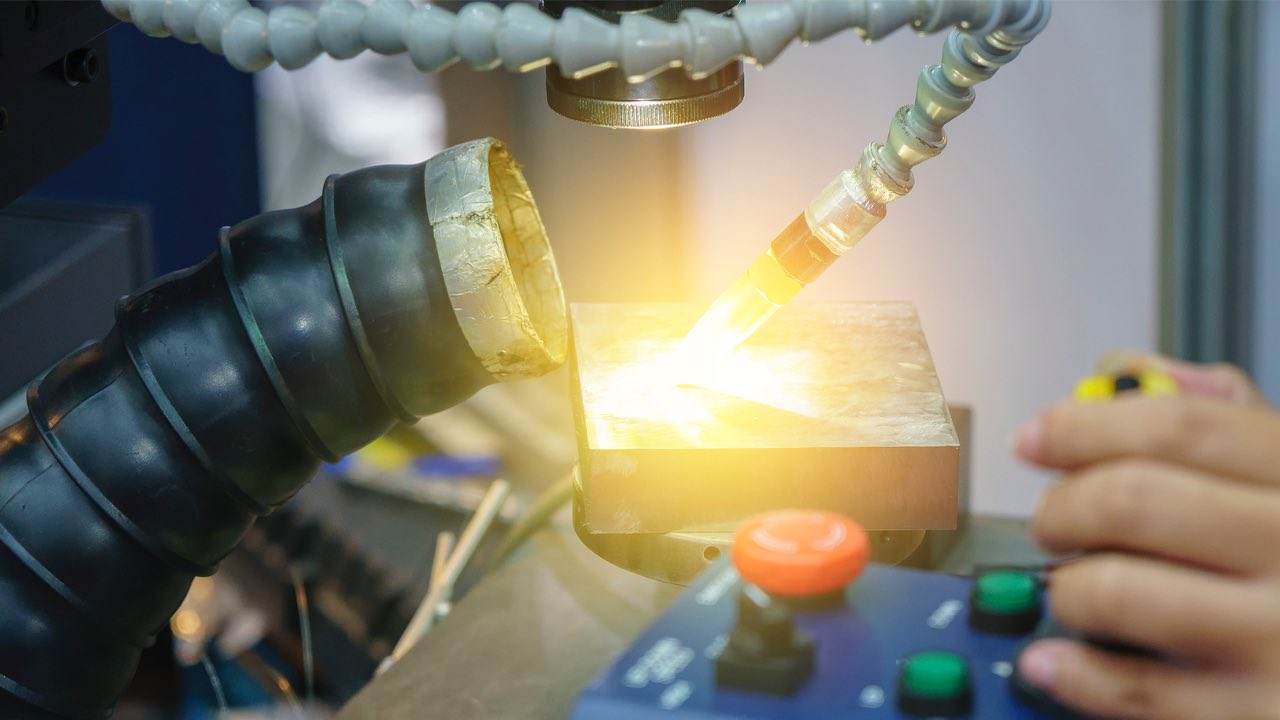

Technology has given us some incredible inventions, and many seem to come straight out of a movie. For example, laser cutting has been available for years, and laser welding is not only viable, but it is also already in use.

This “high-tech” form of welding is new or unfamiliar to many welders.

This article presents the laser welding process, describes how it works, explains where to use it, and details the pros and cons.

What is Laser Welding?

Laser welding, also known as laser beam welding (“LBW”), is a technique in manufacturing whereby two or more pieces of material (usually metal) are joined together through the use of a laser beam.

It is a non-contact process that requires access to the weld zone from one side of the parts being welded.

The heat created by the laser melts the material on both sides of the joint, and as the molten material mixes and resolidifies, it fuses the parts.

The weld is formed as the intense laser light rapidly heats the material – typically calculated in milliseconds.

The laser beam is a coherent (single-phase) light of a single wavelength (monochromatic). The laser beam has low beam divergence and high energy content that will create heat when it strikes a surface

Like all forms of welding, the details matter when using LBW. You can use different lasers and various LBW processes, and there are times when laser welding is not the best choice.

So, let’s delve into the laser welding types, how they work, and where they are typically used.

Types of Laser Welding

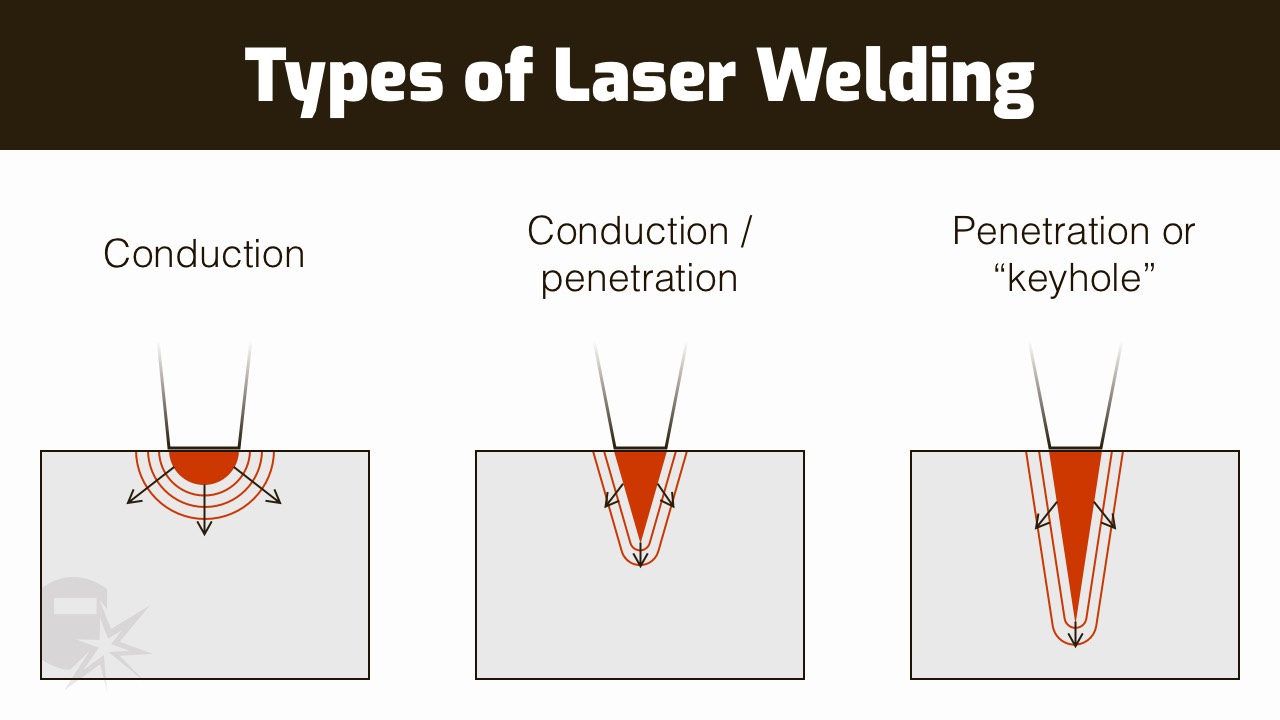

There are 3 types of laser welding:

- Conduction mode

- Conduction/penetration mode

- Penetration or keyhole mode

These types of laser welding are grouped by the amount of energy delivered to the metal. Think of these as low, medium, and high energy levels of laser energy.

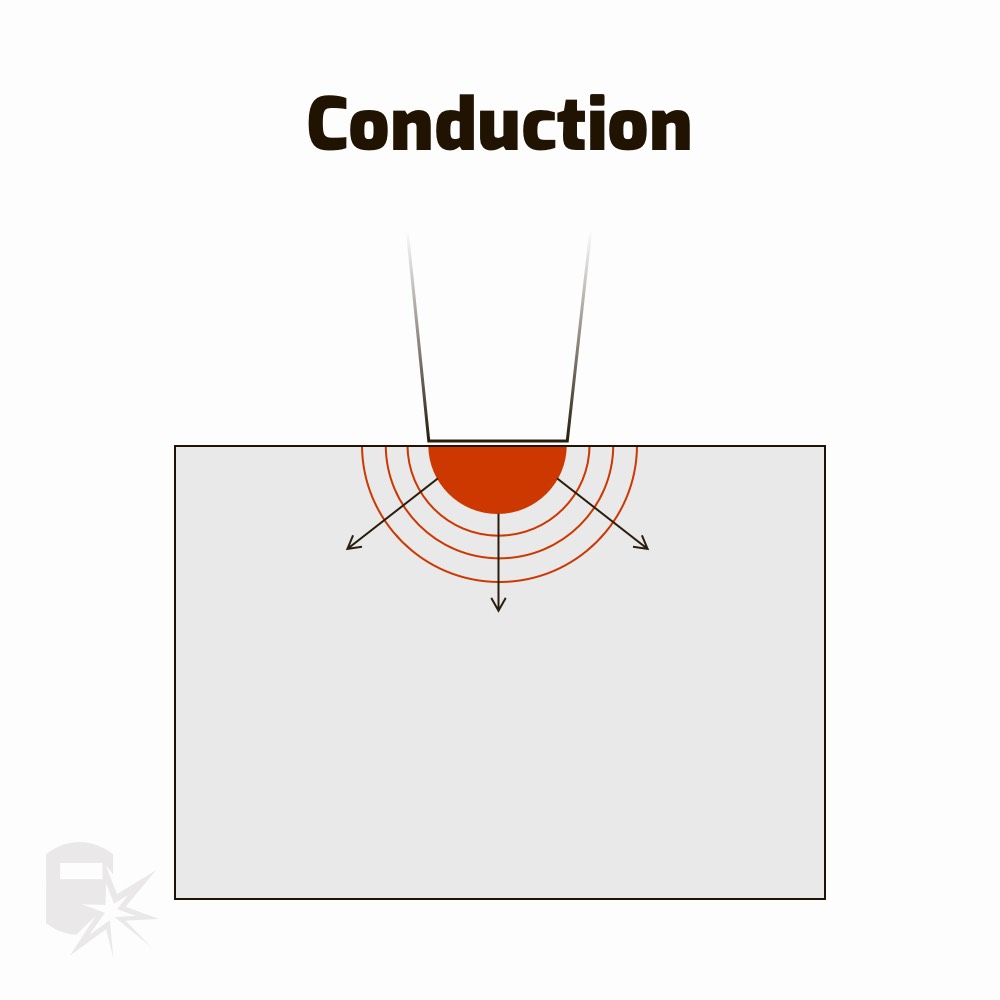

Conduction Mode

Conduction mode delivers low laser energy to the metal, resulting in low penetration with a shallow weld.

It is good for joints that do not need high strength as the results are a kind of continuous spot weld. Conduction welds are smooth and aesthetically pleasing, and they are typically wider than they are deep.

There are two types of conduction mode LBW:

- Direct Heating: The part’s surface is heated directly by a laser. Heat is then conducted into the metal, and portions of the base metal melt, fusing the joint when the metal resolidifies.

- Energy Transmission: A special absorbing ink is first placed at the joint’s interface. This ink takes in the laser’s energy and generates heat. The underlying metal then conducts the heat into a thin layer, which melts, and resolidifies to form a welded joint.

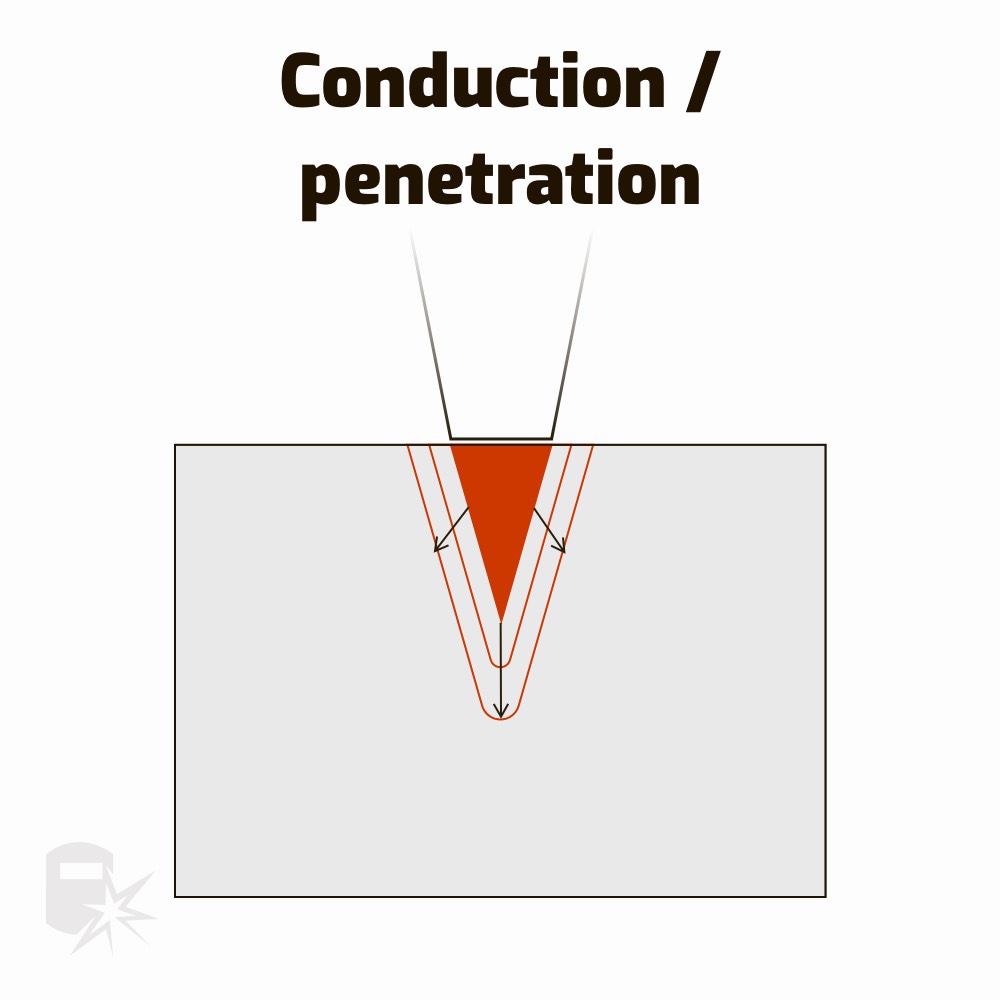

Conduction/Penetration Mode

Some may not acknowledge this as one of the modes. They feel there are only two types; you either conduct heat into the metal or vaporize a small metal channel, allowing the laser down into the metal.

But the conduction/penetration mode uses “medium” energy and results in more penetration. But the laser is not strong enough to vaporize metal like in the keyhole mode.

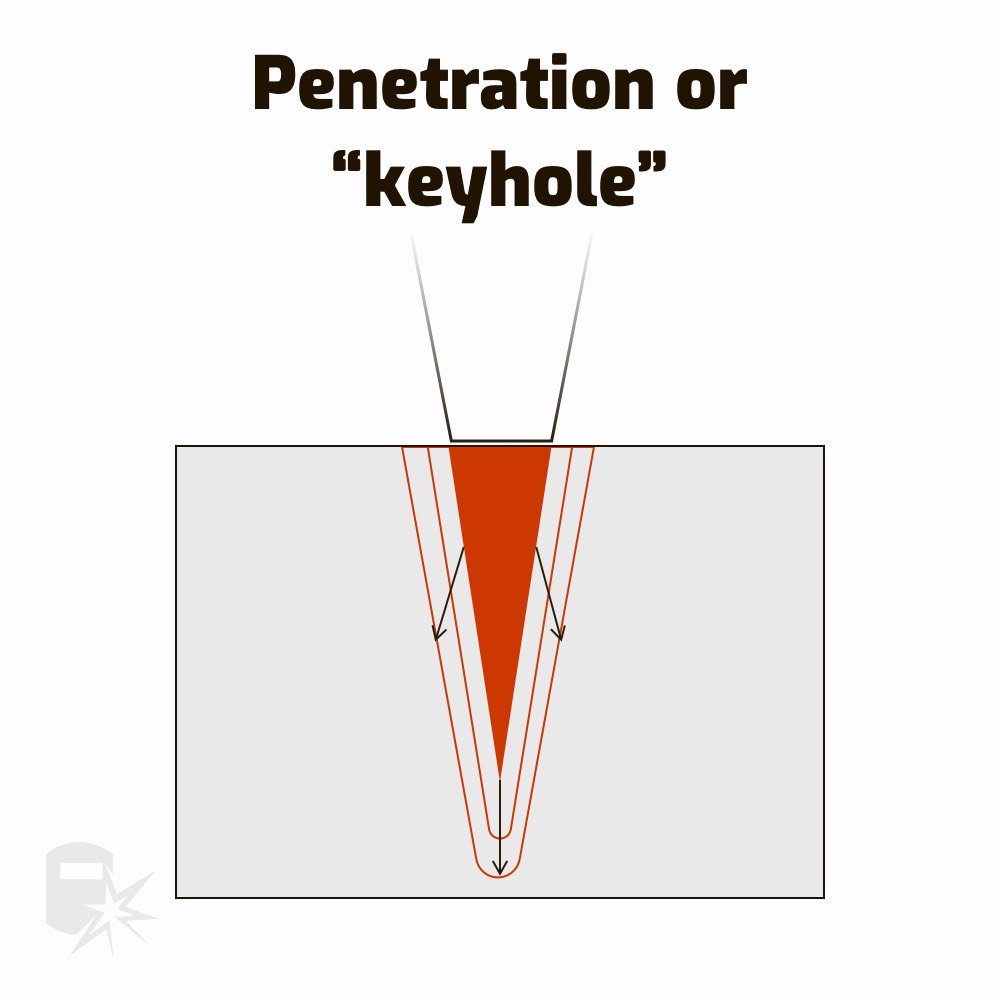

Penetration or Keyhole Mode

This mode creates deep, narrow welds. So, some call it penetration mode. The welds made are normally deeper than wide and stronger than conduction mode welds.

With this type of LBW welding, a high-powered laser vaporizes the base metal, creating a narrow tunnel known as a “keyhole” that extends down into the joint. This “hole” provides a conduit for the laser to penetrate deep into the metal.

Types of Lasers Used in welding & Cutting

The primary types of lasers used in welding and cutting are:

- Gas lasers: use a mixture of gases such as helium and nitrogen. There are also CO2 or carbon dioxide lasers. These lasers use a low-current, high-voltage power source to excite the gas mixture using a lasing medium. Operate in a pulsed or continuous mode.

Carbon dioxide lasers use a mixture of high purity carbon dioxide with helium and nitrogen as the lasing medium. CO2 lasers are also used in dual-beam laser welding where the beam is split into two equal power beams. - Solid-state lasers: (Nd:YAG type and ruby lasers) Operate at 1micrometer wavelengths. They can be pulsed or operate continuously. The pulsed operation produced joints similar to spot welds but with complete penetration. The pulse energy is 1 to 100 Joules. Pulse time is 1 to 10 milliseconds.

- Diode lasers: are used for materials that are difficult to weld using other methods, for hard-to-access areas, and for extremely small components. Intert gas shielding is needed for more reactive materials.

Suitable Metals for LBW

Laser welding works with many metals, like:

- Carbon Steel

- Aluminum

- Titanium

- Low alloy and stainless steel

- Nickel

- Platinum

- Molybdenum

- Kovar

Typical LBW Joints

The four joints where laser welding works well are:

- Butt Weld

- Filler Lap Weld

- Overlap Weld

- Edge Flange Weld

How Does Laser Welding Work?

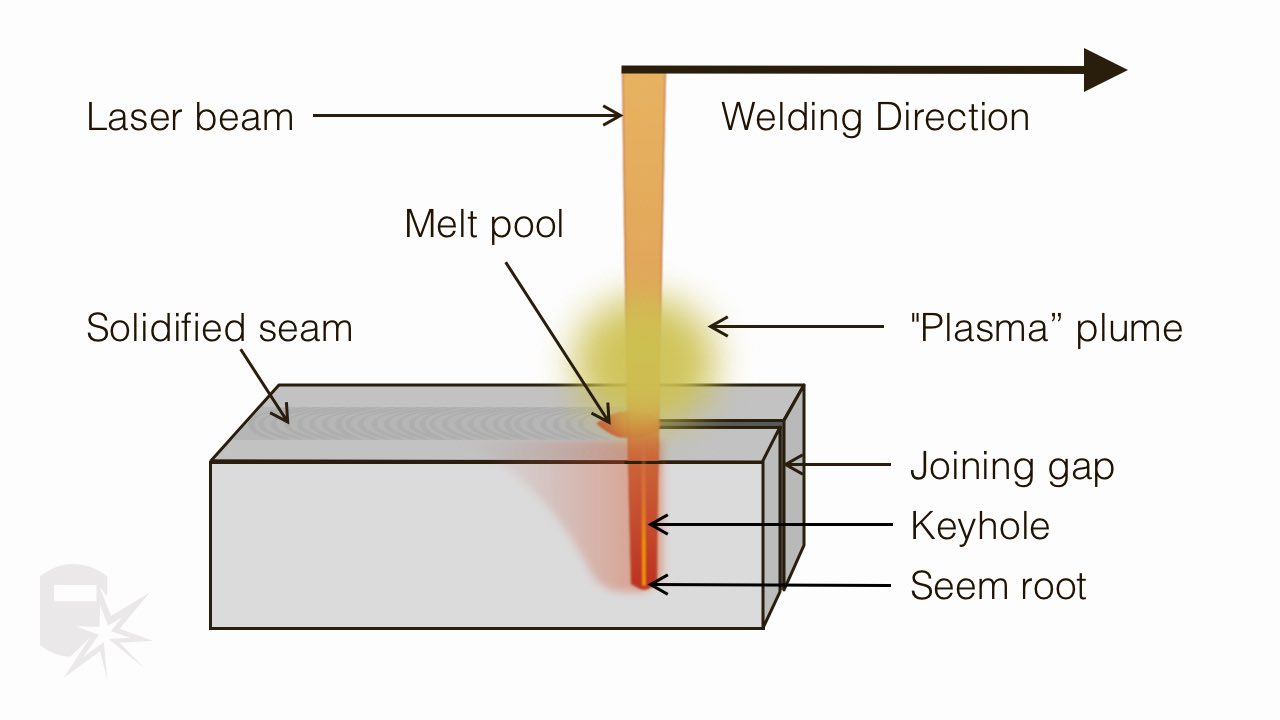

Laser welding works by introducing heat into a joint with a powerful laser beam. The material is melted on each side of the joint and fuses the parts when it resolidifies.

At a minimum, you need a laser and the optics to focus it where you want, a way to move the beam precisely over the joint, and a worktable to fit up and hold the parts.

The actual process of refining, or “organizing,” light waves with optics into a narrow, highly energetic beam is quite complex. So, the mechanics of how a laser works are beyond the scope of this article. But you can find more detail if you are interested in this article.

There are many laser types with different levels of power. But the right beam can quickly heat metal on both sides of a joint to high temperatures.

The laser applies the needed energy fast. Depending on your laser and workpieces, you may need to shoot the beam at the metal in pulses that last for only a few milliseconds. Or, a continuous beam may be best. It depends on how much power is needed, and you do have a fair amount of control over how the LBW setup applies heat to the parts.

Of course, the molten metal will take a few seconds to cool and resolidify. But overall, it is a swift weld process, making it a highly productive way to join parts.

For this reason, LBW is popular where high welding rates are needed, like production lines.

What is Laser Welding Used For?

Many places where you find laser welding focus on the high production of clean, good-looking welds. These include:

- Automotive manufacturing

- Jewelry making

- Hydraulic and fluid control parts

- Distortion critical thin shell assemblies

- Foils

- Fuel rails

- Medical instruments

- Stainless steel heat exchangers

- Thin gauge metal boxes/parts/tubing

Laser Welding Vs. Arc Welding

The main difference between laser welding and arc welding is how the joint is heated. Laser welding uses a powerful beam of light, and arc welding uses an electrically driven arc.

So, the laser alone imparts heat to the metal with LBW. Nothing contacts the base metal at the joint except the laser beam, and the beam can shoot over long distances, allowing it to access places an arc cannot.

Also, most of us are very familiar with arc welding (e.g., MIG, TIG, stick, flux-cored). But that is not as true for laser welding. Conventional welding has been around for a while, and it is more widely understood.

Arc & Filler

One of the first things that jump out is the lack of an arc or electrode in laser welding.

In addition, since there is no filler material used in many laser welds, LBW results in flat, smooth welds. With arc welding, you get raised beads that often have burrs.

Fit-Up

Another major difference is found in the necessary fit up. You need a tight, clean fit for laser welding, or the weld is compromised.

The LBW fit needs to be almost “perfect.” Fit-up needs to be good with conventional arc welding but not perfect, like laser welding. So, arc welding is more tolerant to imperfections in the joint layout since it also employs a filler material.

Investment

The initial investment for TIG, MIG, stick, and flux-cored welders is significantly less than laser welding. For many shops, the initial cost of laser welding is prohibitive.

Laser welding is also a complicated, expensive process to set up. So, in general, the more conventional arc welding is more approachable from cost and setup.

Speed

But when it comes to speed, laser welding speeds through the work once you set it up. Speed is one of LBW’s strongest advantages, if not the strongest.

But keep in mind that laser welders require plenty of maintenance, including downtime and added cost.

Technology

Another big difference is the optics found in laser welding. They are high-tech and “cool.” But they are also sensitive and not durable enough for places like construction sites. So, arc welders are more useful in rough environments.

Heat

One last point, LBW imparts less overall heat to the base metal, in some cases 85% less than arc welding. So, laser welding is hard to beat with thin stock and foils.

You can get nice welds with no blow-throughs, even with foil. That is hard to do with arc welding.

With thick metal, arc welding may have an advantage. For thick stock, you need a strong laser and that means very high costs and a powerful, dangerous laser.

For these reasons, laser welders are often limited in the thicknesses they can handle.

Tightly controlled industrial operations in a secure space are needed to safely use a laser powerful enough for the really thick stuff.

Laser Welding vs. Arc Welding: Advantages & Disadvantages

Arc Welding:

Pros

- Use of filler material allows for some imperfections or small gaps in the fit-up

- Faster set up, easier to use manually

- Lower initial investment

- Can handle very thick material better in more applications

- No sensitive parts like optics can be used at construction sites or other harsh places

Cons

- Foils and thin gauges can burn or warp

- Larger Heat Affected Zone (“HAZ”) and exposed parts to more heat

- TIG can cause tungsten contamination, and inclusions are possible with most arc welding from things like slag

- Slower, less production

- Leaves a raised bead and burrs, as well as spatter

- Higher cost per foot of weld

Laser Welding:

Pros

- Very precise, repeatable welds (can be guided by CAD or CAM programs)

- Smooth, clean welds with no slag or spatter

- Smaller Heat Affected Zone (“HAZ”) and overall less heat is applied to parts

- Handles thin gauges and foil well

- Fast/high production rates

- Lower risk of tungsten contamination or inclusions

- Welds metal, glass, and plastics

- Welds magnetic metals with no arc blow

- Lower cost per foot

- Can be used in open air for some applications (i.e., no shielding gas)

- Welds dissimilar metals well

- No filler is needed for most applications

- Can weld small parts and hard to access places

Cons

- Needs a “perfect” fit-up & the laser must be aligned properly

- Using filler material when needed is more complex and expensive

- A high initial investment needed

- Complicated to set up and “dial-in”

- Automation is more difficult in many cases

- Cannot weld thick material as easily

- Aluminum and copper can be fussy due to their high thermal conductivity

- High maintenance requirements/costs

- Rapid cooling causes cracking in some metals

- Optics are fragile and easily damaged, not appropriate for harsher environments

- Shielding gas is needed in some applications

Quick FAQs

What Is A Laser Beam?

Light Amplification by Stimulated Emission of Radiation (or “LASER”) refers to a device that synchronizes light waves to move in the same direction with the same wavelength. The synchronization is referred to as coherent waves, and when focused, a coherent beam can travel long distances and deliver large amounts of energy.

Is Laser Welding As Strong As MIG?

A proper keyhole laser weld is stronger than a MIG weld due to the smaller HAZ and the narrow, deep penetration. But a conduction weld is weaker. It depends on the type of laser weld used.

Is Laser Welding Stronger Than TIG?

A proper keyhole laser weld does have higher tensile and bending strength than a TIG weld. But a conduction laser weld may be weaker since it is more like a spot weld than a TIG weld. It depends on the type of laser weld used.

How Thick Can A Laser Welder Weld?

A laser’s power determines the maximum thickness a particular welder can handle. For example, a 1000W handheld unit can penetrate 2-3 mm into stainless steel. A more powerful laser means it can weld thicker material. The other option is to laser weld from both sides, doubling the thickness you can weld. But with a big enough laser, you could weld thick stock.

Wrapping it Up

In short, laser welders are fast and put out high weld footages per hour, which is why they are usually employed in applications where high production is the main priority. But they also have a small HAZ and produce clean, aesthetically pleasing, strong welds. Laser welders are also superior with fragile pieces and metallic foils since they introduce less heat into the base metal.

However, laser welders require tight, really tight fit-ups, and they are expensive to purchase. Plus, LBW requires constant maintenance, and the optics are fragile and easily damaged.

In contrast, the upfront costs for conventional arc welders are lower, and the various arc welding processes are easy to use. They are also at home on construction sites or in a crop field since they have no sensitive optics to damage. Plus, they are more forgiving with less than perfect fit-ups because they use a filler material.

On the downside, arc welders use consumables that must be purchased and replaced periodically. So, the cost per foot of weld is higher. In addition, they also can create issues like inclusions, spatter, and slag.

So, the differences between laser and arc welding are pronounced. But they both have their uses, and you should not view the disparities negatively. It’s wonderful that welders live in a time with so many options, even if it gets confusing at times.