Few realize the many arc welding processes that exist, and even fewer understand the arc welding principle behind it.

However, arc welding is a basic concept every welder should know and understand, and a knowledge of all the forms of arc welding is a must.

This article covers the definition of arc welding, what it includes, the underlying concepts and mechanics of how it works, and its pro and cons.

What is Arc Welding?

Arc welding is the process of joining metal pieces together with high heat from an arc that is generated and sustained by an electric current. The power supply can be alternating current (“AC”) or a direct current (“DC”).

That’s pretty broad. So, it’s not surprising to find arc welding includes popular welding processes like stick, MIG, TIG, and flux-cored welding. All use an electric arc to weld.

Notice, this is more than just stick welding. Some use arc welding as slang to refer to stick welding. While it is a form of arc welding, it is not the only one.

How Does Arc Welding Work?

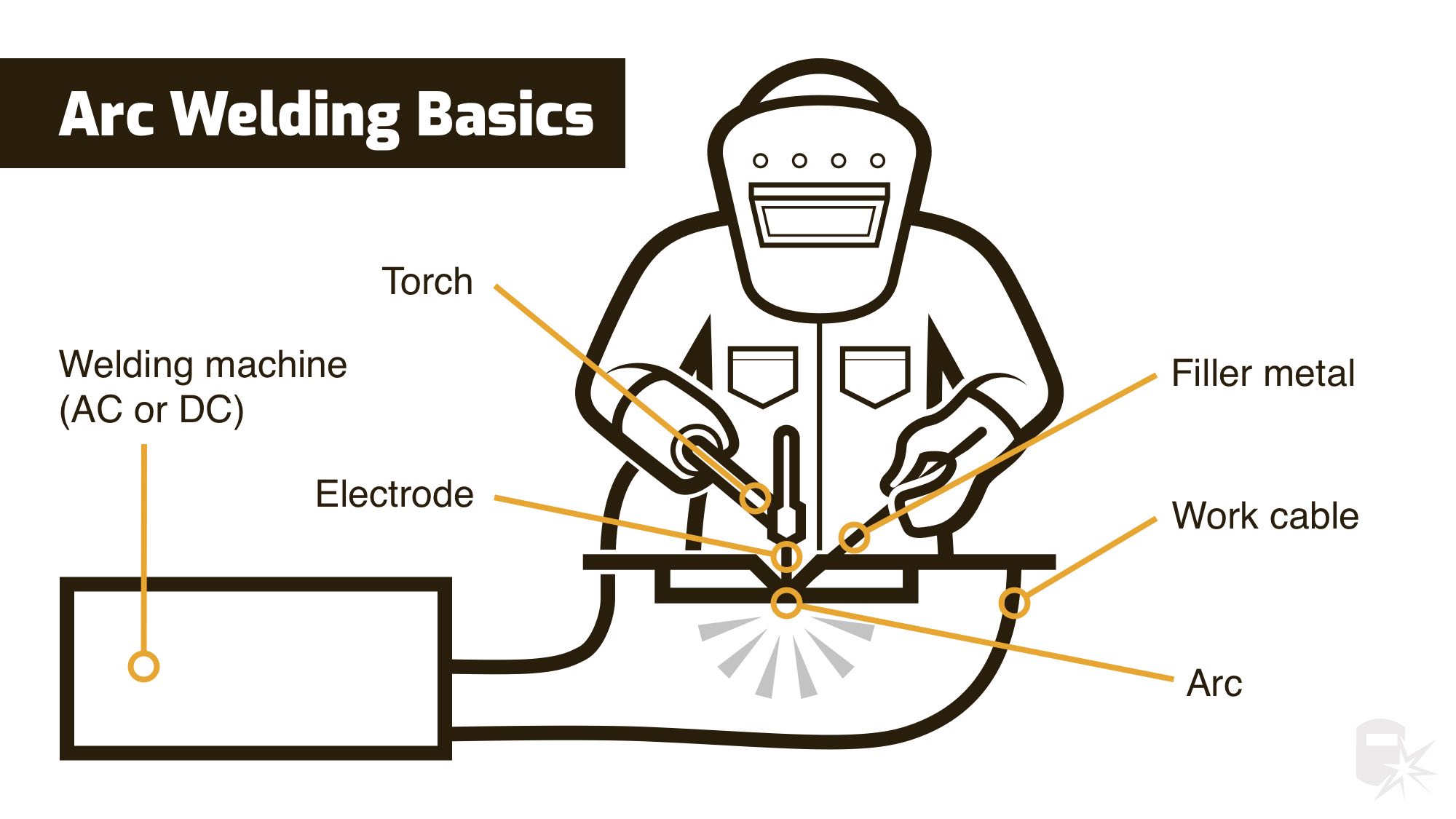

At a very basic level, all arc welders have five components:

- An Electrode and electrode cable

- A Ground Cable and Clamp (sometimes called a work cable)

- A Power Supply

- Metal workpieces

- An Arc

The power supply provides AC or DC to create and sustain the arc, and the electrode is either mechanically or manually moved along the joint to create the weld.

So, how hot is a welding arc that melts and fuses metal? About 6,500°F. This does the job of melting and fusing the metal pieces, but it also creates another problem.

At these high temperatures, molten metal can react with gases in the air. This causes problems like porous and weak welds, excessive spatter, and reduced productivity.

To eliminate these welding defects, it is common to provide some form of protection to the molten pool when arc welding. This usually comes in two forms.

One option is a special shielding gas flooded over the hot weld. The type of gas and flow rate must be correct for the shielding gas to keep the atmospheric air away from the molten metal.

The second choice is flux, which creates its own shielding gas and slag when exposed to the high arc welding temperature. The flux’s inert gas and slag “encapsulate” the weld and keep the gases in the air away.

AC vs. DC Currents

DC provides current that flows in one direction, and AC alternates the direction of current flow multiple times a second. For example, a 60 Hz AC supply would alternate the flow direction 120 times a second.

The current differences are important. For example, with DC, magnetic fields can form, induced by the consistent flow of electric current in one direction.

Magnetic fields can move the arc so that it does not travel the shortest gap between the electrode and metal. This can cause spatter, porosity, and incomplete fusion and often happens at inside corners or at the end of welds. This is called arc blow.

So, it’s an issue with DC. But AC oscillates the current, and the magnetic fields are constantly being disrupted and never organize enough for arc blow to be an issue.

Also, DC welders are a bit more expensive to purchase. So, arc blow and initial costs are the two main cons for DC. You may even say just use AC arc welders. But for certain processes, like MIG welding, DC’s advantages far outweigh these disadvantages.

DC arc welders offer a smooth, easy-to-control arc, and they work better on thin materials. You also get less spatter, and in general, DC beads are “prettier.” For these reasons, you see DC is often used in arc welders, and many users prefer it over AC.

AC arc welders are often inexpensive and do not allow magnetic fields to be set up. So, it can be used in situations prone to arc blow. AC welders also penetrate well and are used in places like shipyards that regularly deal with thick pieces.

Another benefit of AC, it handles metals with problematic oxide layers on the surface, like aluminum. As the current oscillates, it efficiently removes the oxide layer that can interfere with and inhibit the fusion of the metal pieces.

Read more on the differences between AC and DC welding here.

What is Arc Welding Used For?

The most common and simplest form of welding is arc welding. So, it is found in use across all industry sectors, such as automotive, aerospace, oil and gas, manufacturing, power, construction, and many more.

Applications include vessels, pressurized vessels, pipes, tanks, ships, bridges, railroads, automobiles, farm equipment, metal art sculpture, trailers, etc.

In short, due to its quick and economic nature when joining metal, arc welding is used for just about any time two pieces of metal need to be joined. But the high heat generated can be a problem for some jobs. So, arc welding is not for every project.

Advantages & Disadvantages of Arc Welding

Like all things in life, arc welding has its strong points and drawbacks. These are summarized below:

Pros

- Good impact strength

- High production rates (lowers the cost per unit of weld)

- Strong, seamless welds with no air gaps

- Easy to learn and use

- Portable equipment, easy to store

- Versatile, works on many types of metal

- Affordable

- High-quality, strong welds

- Accessible (No license or special training needed)

Cons

- Toxic fumes need ventilation or respirators

- More waste than with other processes

- Requires practice to achieve a high skill level

- Burn through on thin materials

Types of Arc Welding

The electrode is the welder’s conductor where the current flows to or from the metal workpiece via an arc. Also, electrodes can be classified as consumable or non-consumable.

While arc welding encompasses many processes, the electrodes used to support the arc vary greatly.

Consumable Electrode Types

Consumable electrodes melt and become part of the weld. They can also be referred to as welding wire depending on the process used.

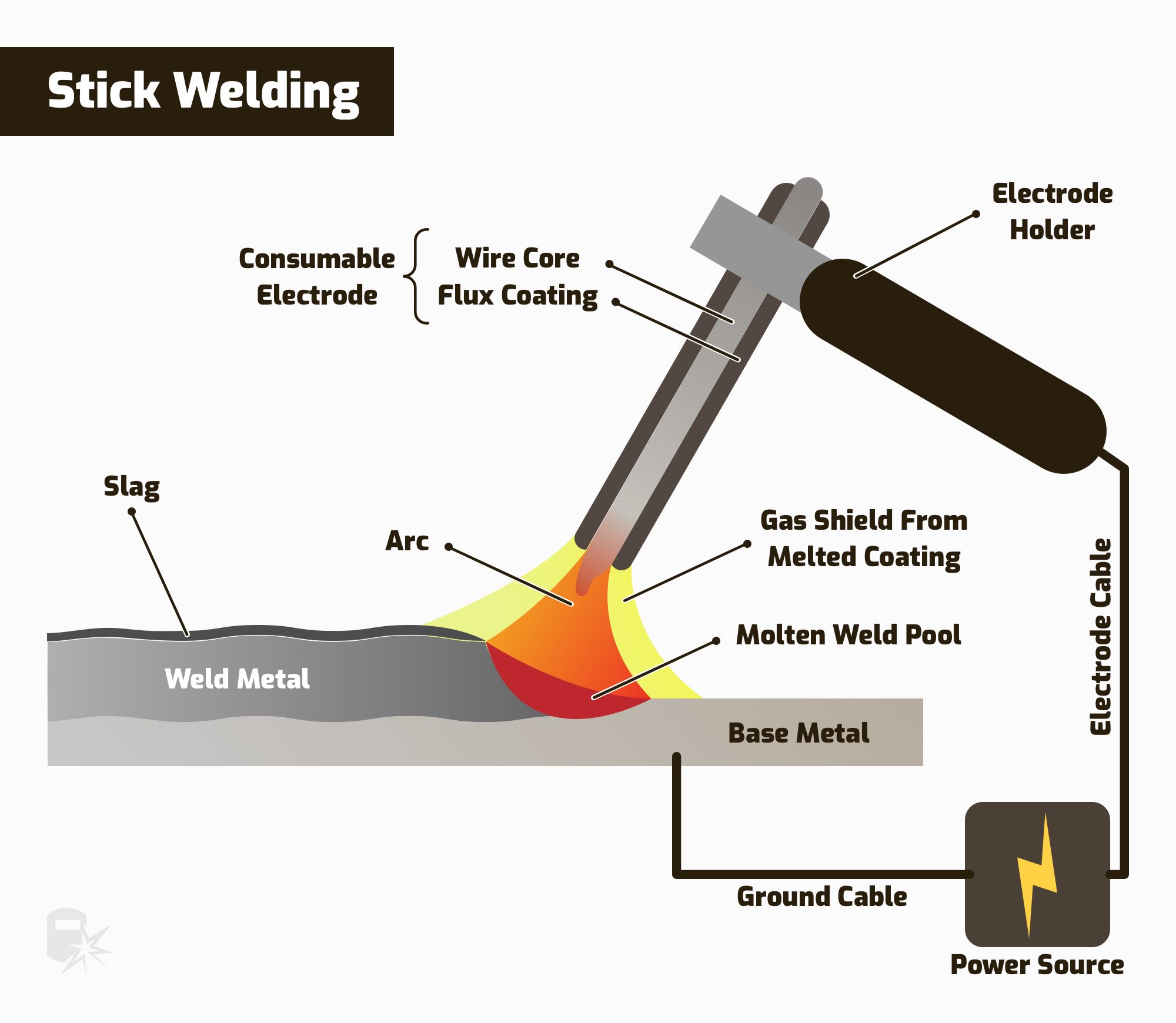

Shielded Metal Arc Welding (“SMAW”)

Stick welding, or SMAW, is also called arc welding. While it is true that all stick welders are arc welders, not all arc welders are stick welders (as proven by this list you are reading right now!).

It is a very simple process that uses stick electrodes that are externally coated with flux. The flux reacts with the high heat of the weld and shields the molten pool.

Like the MIG or fluxed-core electrodes, the stick is consumed in the process, and it acts as the filler material. But unlike GMAW or FCAW, there is no automated electrode feed. So, stick electrodes must be manually replaced when used up.

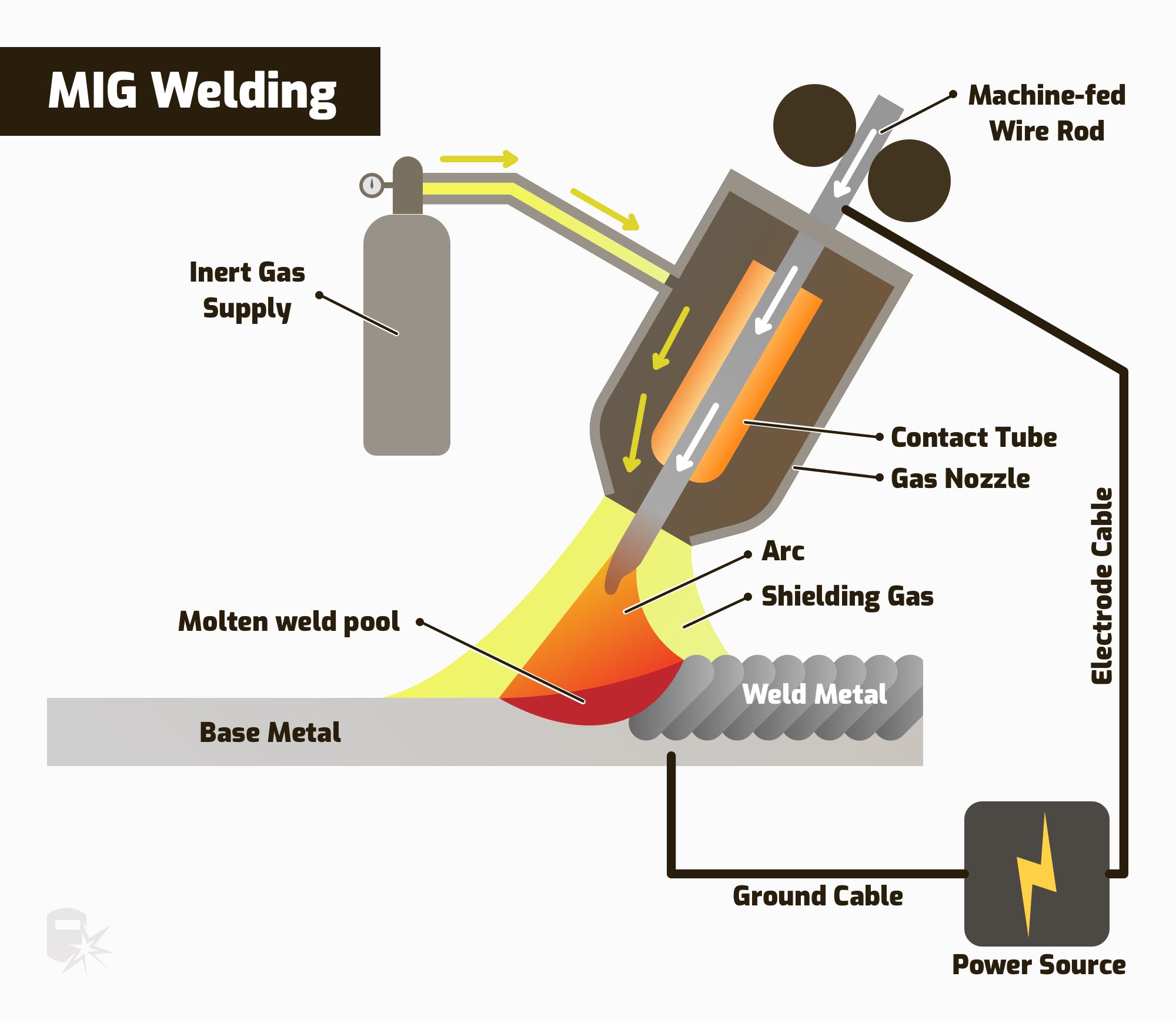

Metal Inert Gas Welding (“MIG”)

MIG welding is also called gas metal arc welding (“GMAW”). It uses a roll of wire that feeds to the welding gun that acts as its electrode.

This wire is consumed in the welding process, which allows the wire to also act as a filler material for the weld. So, the wire alloy is usually matched to the metal being welded.

MIG welding also uses a shielding gas pumped to the welding torch. This means you must also have a bottle of gas, as well as the welder, to use the GMAW process.

Related: Arc welding vs MIG welding – Differences Explained

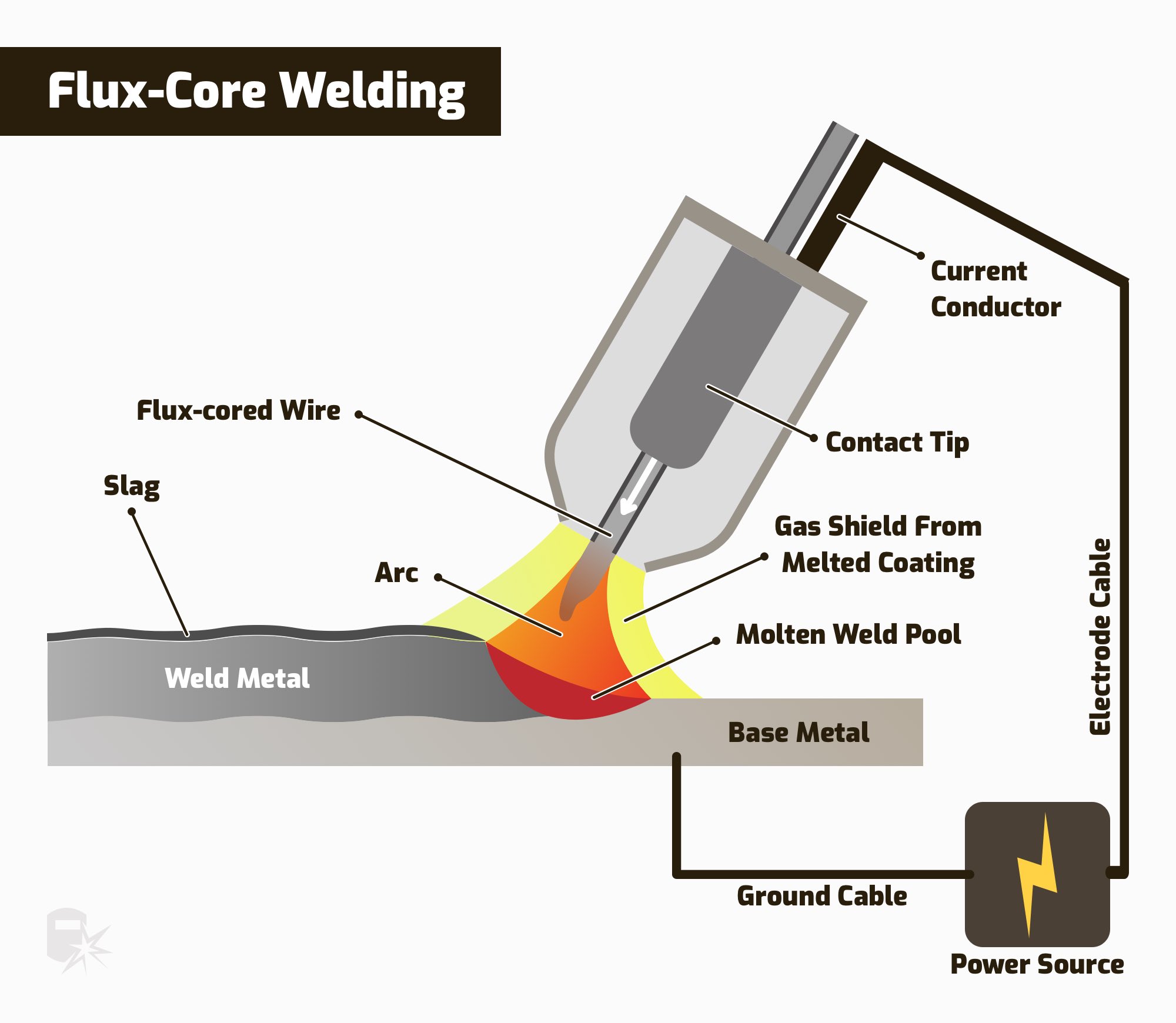

Flux-Cored Arc Welding (“FCAW”)

Flux-cored arc welding is a very similar welding process to MIG welding. A wire acts as the electrode, and it is continuously fed to the gun by the machine. The wire is consumed as you weld, but that also allows it t serve as the filler material.

However, unlike the solid MIG wire, the core of this electrode is hollow, and it is filled with flux and other additives. This allows the flux to generate shielding gas and slag when heated, both of which shield the weld. This eliminates the need to have bottled gas like MIG welders.

Submerged Arc Welding (“SAW”)

Like GMAW and FCAW, submerged arc welding uses a continuously fed wire electrode that is consumed in the weld. But the weld pool is immersed in a layer of powdered flux.

This blanket of fusible flux becomes conductive when molten, providing a sound electrical connection between the metal and the electrode. The flux also prevents spatter and sparks. In addition, the layer of powdered flux suppresses fumes and ultraviolet radiation.

Arc Stud Welding (“SW”)

This specialty process is designed to weld fasteners (“studs”) in place. It uses a specially designed fastener that also acts as an electrode.

The stud is placed in a special gun that creates an arc at the base of the fastener, and then it presses the stud down into the molten pool. It results in a fastener strongly welded to the metal base.

The application may or may not require shielding gas, and there is a special ferrule placed around the weld to concentrate the heat and contain the molten metal. After the weld is done, the ferrule is removed and discarded.

Electro-Slag Welding (“ESW”)

ESW is used only in vertical joints to weld two pieces at least 1” thick. The gap in the pieces is filled with flux, and an automatically fed wire electrode is embedded in the flux inside the gap.

A current then passes and generates an arc. But once the flux melts, the molt flux’s electrical resistance generates the weld’s heat, about 3,500°F.

The requirement to first fill the joint with flux and hold the molten flux while welding is why this is a vertical-only joint application. You also need to install a backer, or starting plate, at the bottom of the joint to hold the flux in place before initiating the arc.

Non-Consumable Electrode Types

Non-consumable electrodes maintain their structure and are used in combination with filler metal, or, use the base metal to fuse the join.

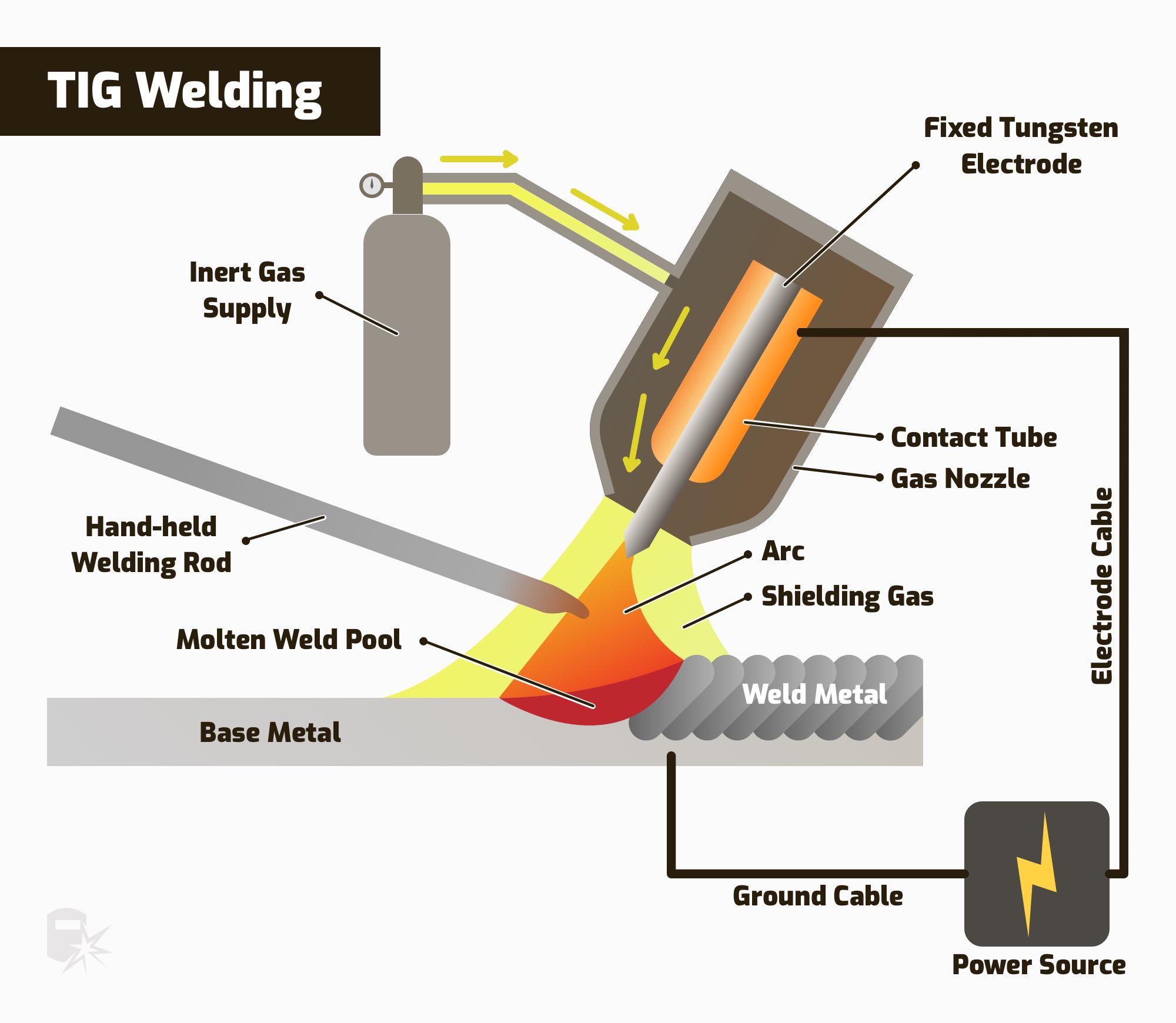

Tungsten Inert Gas Welding (“TIG”)

TIG welding is sometimes referred to as gas tungsten arc welding (“GTAW”). The tungsten electrode employed is not consumed while welding. As such, a separate filler rod must be fed with your second hand, making TIG welding a two-hand process.

The tungsten electrode chemistry, or the alloy, varies depending on what you are welding. Also, the process is not as easy to learn as some other forms of welding, and it takes some practice to master.

Plasma Arc Welding (PAW)

Inside a plasma welding torch, an electrode is located within a copper nozzle with a pinhole at the tip. A pilot arc is initiated between the non-consumable tungsten electrode and copper tip. This heats the shielding gas to very high temperatures, which creates plasma.

To weld, the plasma is expelled through the pinhole, and it “shoots” at the weld. The plasma is electrically conductive, and an arc then forms between the tungsten electrode and metal workpiece.

By forcing the plasma through a constricted orifice, the torch delivers a high concentration of heat to a small area. With high-performance welding equipment, the plasma process produces exceptional welds.

Since the electrode is not consumed, you may need an additional filler rod to achieve the desired results.

Wrapping It Up

Hopefully, this article provided some insight into what arc welding is, how it works, and the pros and cons.

You can use AC or DC to drive the arc when arc welding. Each current has advantages, and users need to know when to use each.

Last but not least, we also covered the various forms of arc welding and the differences between these processes. Each form of arc welding uses different electrodes, and selecting the proper electrode is essential for good results.