Welding is a dangerous profession, which makes safety a top priority.

Among your arsenal of safety tools, a good auto-darkening welding helmet is probably the single most important item – and for good reason.

A welding helmet’s job is to protect you from radiation (ultraviolet and infrared), sparks and spatter, and a myriad of other hazards often found in a welder’s environment.

There are approximately 10,000 eye injuries related to welding each year (U.S. Consumer Product Safety Commission), so helmet choice is critically important.

This guide will help you choose the helmet that’s right for your needs.

Fixed vs. Variable Shade Lenses

The first decision you’ll have to make is deciding between a fixed and variable-shade lens.

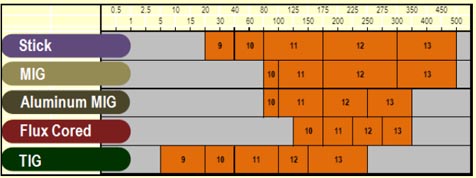

Fixed-shade helmets can only darken to a single, pre-defined shade (usually a #10 shade), while variable-shade helmets can darken to a number of shades, depending on the welding process being used and materials being welded.

The decision comes down to how flexible your welding needs are going to be.

If you’re going to be welding only a single material using a single process, then a fixed-shade will suffice.

If, on the other hand, you’d like to be more flexible with the materials you’re welding and the welding processes you’re using, then a variable shade is definitely the way to go.

Related Read: Types of Welding Helmets Explained

Lens Reaction Time Chart

Put simply, this is the time it takes the lens to darken, or switch, from the normal shade (usually #3 or #4), to the protective, darker shade.

The darkening occurs the moment the weld sparks and should be extremely fast in order to protect the eyes from any exposure to radiation.

Even if there’s a slight delay, the resultant exposure could cause discomfort and a dry feeling in the eyes, also known as ‘arc eye’. Over months and years of exposure, real damage could be done to the eye.

As a rule of thumb, the simpler helmets will have a reaction time near 1/3,600 of a second, and the more robust versions can get up to speeds of 1/20,000 of a second. To make it clearer: the larger the fraction number is, the faster the lens reaction time.

Arc Sensors

As you’ve probably understood, ADF helmets sport a number of sensors that detect the weld spark, which starts the darkening process.

The number, position and sensitivity of these sensors are important in order to be sure the helmet’s aware of surrounding light levels at all times, and darkens which it’s supposed to.

The difference between the basic helmets and the more professional variety is usually the number of arc sensors: basic helmets tend to have 2 sensors, while the more professional ones will have 3 or 4.

Unsurprisingly, the more arc sensors on the helmet, the less chance of the helmet failing to darken at a crucial time.

This is mainly because of the more sensors, the less of a chance of all of them being obstructed.

Usually, 2 sensors should be enough, but if you’re for example doing more out-of-position welding, more sensors can definitely help.

Welding helmets can come with mag lenses or “cheaters.” You can either buy lenses designed to clip to the helmet or wear corrective lenses under your helmet.

If you choose a clip, choose the lowest diopter that allows you to see clearly. If you are under 40, this is usually +1.75, with people age 40+ choosing a higher level.

Solar Power vs. Battery Power

All ADF helmets need some sort of power source – this mostly comes in the form of solar power panels or batteries (usually lithium) – or a combination of the two.

The lifespan of solar-powered batteries is usually counted in decades, which far surpasses their battery-powered counterparts.

They’re also cheaper in the long run as you don’t have to spend money on new batteries.

On the other hand, battery-powered helmets don’t need any forethought – unlike solar-powered helmets that need to be placed for a few hours out in the sun before they can run, battery-powered helmets can be used right away.

Once solar-powered helmets run out of power, they need to be recharged again: a process that can take a couple of hours.

Your best bet would be a combination of solar-assisted battery-powered helmets. This power source combines the best of both worlds – the ability to charge the battery cells through the solar panels, as well as the ability to switch batteries instantly when needed.

Auto-darkening helmets have many advantages such as automatically darkening when a welder strikes an arc.

Even if electronics fail, they provide some minimum levels of protection (ANSI Standard). Auto-darkening helmets come in variable or fixed shade options.

See how auto-darkening welding helmets work here.

A Few Final Points Of Consideration

The helmet’s weight is a crucial comfort factor and should not be ignored.

Since you’ll be wearing the helmet for hours on end, you’ll want to make sure it’s not too heavy, as even a few pounds, over the course of a full days work, will start to weight down on you.

This is especially true for passive helmets that need to be “head nodded” up and down constantly throughout the day, but ADF helmet users will also feel the effects over time.

Comfort is very important when choose a helmet – make sure to try the helmet on, adjust the straps and make sure the helmet fits snugly, but not too tightly.

Make sure the headband is of good quality and fits well – its job is to absorb perspiration and is extremely important in the hot, often humid welding environment.

As you can see, there are many things to take into account when purchasing a welding helmet. Take your time, think about your welding environment, and find a helmet that will suit your needs.

If you’ve done a good job, your helmet should last you for many years, and your safety will be assured.