Welding can be a risky gig if you ain’t got the right gear.

The most important piece of kit for any welder is a solid welding helmet. With different type of helmets out there, it’s important to know what’s what so you can get the job done right.

Yup, ANSI says your helmet gotta have lenses to protect your eyes from UV and infrared light, as well as heat.

But that doesn’t mean you gotta settle for any old helmet.

There’s different types, styles, and designs to choose from, so you can pick one that fits your personal taste.

Let’s take a look at what’s available!

The 5 Types of Welding Helmets

There are five basic types of welding helmets.

The one that’s right for you depends mainly on your personal preference and the kind of job you need to get done.

Below we’ll lay out the advantages and disadvantages of each type.

1. Variable Shade Auto Darkening Welding Helmet

One of the most recommended styles of helmets for welding is auto-darkening. These helmets feature an LCD controlled by light sensors mounted near the lens.

When you put one of these helmets on, you can see normally. But, when you strike an arc, the light sensors automatically adjust the display to darken your view and protect your eyes.

Most auto-darkening welding helmets feature a shade variation of #8 to #13. You can set the shade level depending on your project and the power of your welding torch. When doing so, it’s best to start darker than you think you’ll need and adjust down from there to prevent over-exposing yourself to the brightness of your arc.

The great thing about auto-darkening helmets is that you can see clearly through them before you start working. In this way, you can assess the weld piece and your surroundings before you you strike an arc and get to work.

If all of this sounds great, it is, but it comes at a price. In general, auto-darkening welding helmets are the most expensive you can get.

For many, they’re well worth the cost, but others argue they’re not necessary for most welding jobs and worry about their potential to stop working.

Pros

- You can choose your shade level to fit the job type.

- You can see clearly through the lens before you strike an arc.

- You don’t have to remove the helmet to check your work.

- The lens automatically darkens when you strike an arc.

- Many recommend this type of helmet for safety.

Cons

- It is the most expensive helmet for welding.

- The LCD requires power

- Batteries need replacing

- Solar power can take time to charge

See the Best Welding Helmets for the money here

2. Fixed Shade Auto Darkening Welding Helmet

Not as common anymore, but with a fixed shade helmet, you get the same auto-darkening feature when you strike an arc, but with only one shade.

In other words, you won’t have the ability to choose between shades like a variable shade auto-darkening helmet.

That said, if you tend to work on the same kinds of projects with the same materials, you may not need an adjustable setting.

If you only need a welding helmet for one particular welding process, then a fixed shade auto-darkening helmet may be an option for you.

Having said that, I would not recommend getting one of these days when you can get a full auto-darkening helmet for a similar price.

Pros

- Very affordable compared to a variable shade auto-darkening helmet.

- Ideal for those who perform the same welding process over and over.

- You won’t need to change shade strength for many standard welding jobs.

Cons

- A different lens may be needed to perform a different welding process.

3. Passive Welding Helmet

A passive welding helmet is a standard helmet with a fixed shade lens that is always dark. The most common lens found on passive welding helmets is a #10, but you can also purchase lenses to cover the different shades.

The problem with this type of helmet is that you need to remove it to see what you’re doing before you strike an arc. If you’re new to welding, this can be a problem as you can’t see your work through the lens.

However, many experienced welders know how to line up their work, strike an arc, and complete the weld using a passive welding helmet.

This type of helmet is good for experienced welders on a budget, as they tend to be highly affordable. Plus, lenses are relatively inexpensive, so you can buy different shades to use for various welds. Passive welding helmets are also lightweight and can take a lot more punishment than other types. However, they’re inconvenient to use.

Pros

- It is a lot cheaper than auto-darkening helmets

- It is lightweight, simple, and easy to use

- Lenses are inexpensive and easy to replace

Cons

- The lens stays dark

- You must remove the hood to check your work between arcs

- Lenses break easily

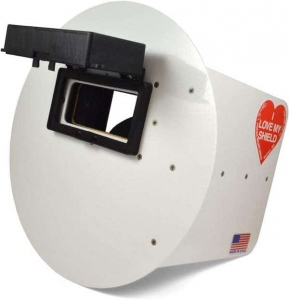

4. Pancake Welding Helmet

Pancake welding helmets are typically used by pipeline welders and feature a circular shield attached to what’s called a “balsa box”.

This type of helmet rests over your eyes and is secured to your face by a strap. The round shield protects your face and provides a view of your work through a darkened viewing window.

The real advantage of this kind of helmet is how lightweight it is. The box attached to the round shield that fits over your eyes is made primarily out of balsa wood, which is exceptionally light.

The balsa box also surrounds your eyes, blocking out external sunlight. For this reason, pancake helmets are often recommended for anyone welding outside, as traditional-styled helmets can let in too much sunlight.

Pros

- Pancake welding helmets are lightweight and can be worn for extended periods.

- The pancake shape of the helmet shields all sides of your face.

- The balsa box goggles block light from all angles and from behind to give you a clear view.

- The softness and lightweight of the balsa box provide a comfortable fit.

Cons

- It’s not designed for indoor welding.

- Pancake welding helmets are only used for pipeline welding and other outdoor welding projects.

5. Leather Welding Mask

They fit over the top of your head and cover everything from your neck up, with a google shield for your eyes. They are equipped with a darkening lens that flips up and down.

This type of helmet is designed for working in enclosed spaces. It’s also ideal for welding overhead as it protects you from falling sparks and debris. What’s more, it’s heat-resistant and generally made from durable leather.

Pros

- It consists of durable leather to provide comfort and strength.

- It covers your entire head and eyes to protect you against sparks and debris.

- Leather welding masks are ideal for working in enclosed spaces and for overhead welding.

Cons

- It is not as versatile as other welding helmets.

- It can be hot and uncomfortable to wear for extended periods.

Choosing the Right Helmet

Choosing between different types of welding helmets depends mainly on the type of welding you’re doing and your personal preferences.

A passive welding helmet can get the job done, but variable shade auto-darkening helmets are certainly the safest and most versatile option if you can afford it.

The bottom line is always to have safety in mind. Remember, no matter how long you’ve been doing it or how much experience you have, welding can be dangerous.

For anyone buying their first helmet, I would strongly consider equipping themselves with a variable shade auto-darkening helmet.

Related read: 3 Tricks to Clean a Welding Helmet Lens