MIG Welding Wires

In Gas Metal Arc Welding (GMAW), you won’t be using a stick electrode or a filler rod.

Instead, everything you need to deposit a weld comes from a spool of metal wire.

In this welding process, more popularly known as MIG, a gas tank (typically CO2 or argon) provides the shielding while the wire melts into the base metal.

Nowadays, it is the most common process for structural welding and product fabrication.

When a welder pulls the trigger on his MIG gun (shown below), a wire feed machine advances the wire out through a brass nozzle. This allows for pinpoint accuracy and an unobstructed view of what’s happening inside the joint.

Welding out of position is a lot easier than with SMAW. And since the spool holds about a mile’s worth of wire, you don’t have to stop and reload very often. (The term MIG, incidentally, stands for “metal inert gas”.

However, since CO2 and O2 are reactive gases, it’s more accurate to say MAG – metal active gas – when these gases are used.)

Wire Classification

There are two consumables to consider in the GMAW process – the gas and the wire.

Like stick electrodes, there’s a classification system for the different choices of MIG wire available that’s managed by the American Welding Society.

The American Society of Mechanical Engineers also has a code, but it’s nearly identical.

The AWS code for solid steel wire is known as AWS A5.18.

Here’s what the classification number for a common wire for mild steel, ER70S-6, indicates:

- ER – Electric Rod

- 70 – This two or three-digit number represents the minimum tensile strength of the weld metal, measured in pounds per square inch (PSI) multiplied by 1,000.

- S – Solid wire.

- 6 – This number (with sometimes a letter added) indicates chemical additives used in the wire which may affect the polarity setting on the machine.

The 6, in this case, indicates more deoxidizers have been added to the wire, which is helpful when welding on dirty or rusty steel.

The other general-purpose carbon steel wire type is ER70S-3. This one doesn’t have the added chemicals, so is used primarily on new or clean steel.

The most commonly used aluminum MIG wires are ER5056, a soft wire with good ductility, and ER5356, which is harder and has high tensile strength.

Stainless steel MIG wire includes designations like ER308, ER316, and ER308–L. The L stands for low carbon, which provides extra corrosion resistance.

Wire Diameter

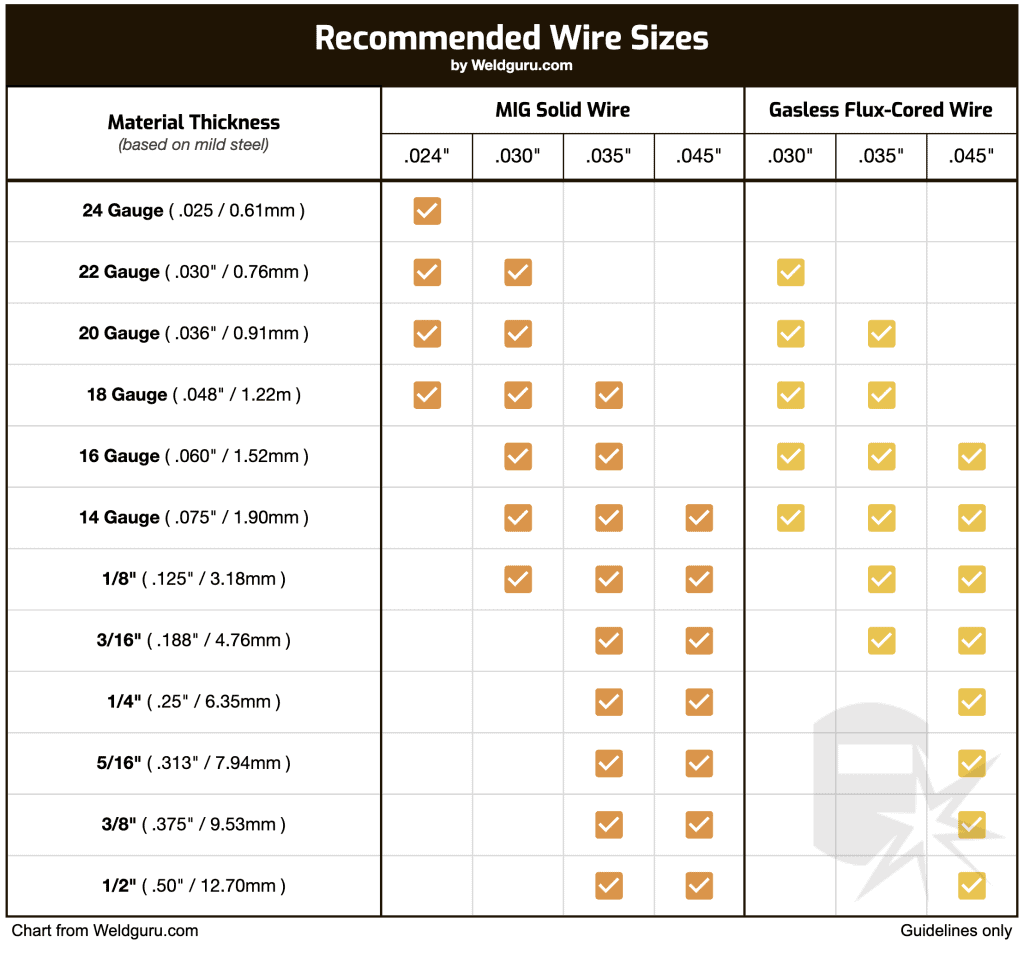

Once a wire type is determined for your welding equipment, two additional pieces of information are needed in order to purchase this consumable.

The first is the wire diameter, which is usually given in thousands of an inch. The most common sizes for welding on sheet metal are 0.35 and 0.45.

Wire Quantity

In making a MIG wire purchase, your last decision involves the quantity of wire and how it’s housed.

For instance, Lincoln Electric offers ER70S-6 as a 44-pound spool or a 1,000-pound drum.

Obviously, the wire feed mechanism on the welding machine will dictate which option is chosen. (A small non-industrial MIG machine uses a much smaller spool than you see in the photo below.)

MIG wire can also be ordered in “TIG cut lengths”. This refers to the three-foot strands used in TIG welding. Diameter sizes in this case are not given in decimals but rather as normal TIG rod sizes, such 1/16 or 3/32.

Related: Best MIG Wire

Wire Settings

The table below is commonly found in consumable spec sheets and is worth copying for reference. It tells you how to set the controls on your equipment and which gas you need, depending on the welding process.

Related read: MIG Welding Settings – How to set the correct parameters

Flux-Cored Wire

Using “cored” wire allows a MIG welder to skip the tank of CO2 or argon and weld without the gas. That’s because the wire core contains ingredients that do the job of shielding the weld pool.

Like stick rod coatings, the core of the wire contains a flux agent that substitutes for the tank of shielding gas. This is particularly helpful when welding outdoors since a stiff breeze is enough to disperse a compressed gas. The process is formally known as Flux-Cored Arc Welding (FCAW).

Read more: Flux in welding – What does it do?

Flux-cored wire also enables a welder to use higher amperages and larger diameter wires than solid wire. The process is used extensively in structural welding outdoors. While cored wire costs significantly more than solid MIG wire, you don’t have to deal with tanks of gas or wait for the wind to die down before you can weld.

Despite the shielding additives, flux-cored wire is skinny enough to shoot out of a MIG gun. And the slag that comes with those ingredients is a fraction of what appears in the SMAW process.

Regular flux-cored wire is often referred to as Self-Shielded or Innershield, a brand name that Lincoln Electric sells. (Hence, when no gas tank is used, the process is formally known as FCAW-S.)

Flux Core Wire Classification

Mercifully, the AWS standard for carbon steel flux-cored wire (AWS A5.20) varies only slightly from the MIG solid wire code.

Instead of ER, an E (for electrode) begins the number in the case of all flux-cored wire.

And instead of an S for solid wire, you’ll see either a T for tubular, or C, indicating a “composite” wire.

E70C-6 is an example of a general-purpose flux-cored wire.

The number 7 in the classification refers to tensile strength, multiplied by 10,000 (instead of 1,000 in the case of a non-cored MIG wire).

0 indicates the welding position. (A zero means the wire is only good for horizontal or flat welding.)

One of the most frequently used flux-cored wires in building construction is Lincoln Electric’s Innershield 232, (aka NR-232), which conforms to AWS E71T-8.

The digit 1 indicates the wire can be used in all positions. The 8 signifies low hydrogen, which calls to mind the common stick electrode E7018.

NR-232 is popular because its chemical composition meets seismic requirements for earthquake zones like California. On the downside, the wire is more difficult to work with than wires that don’t have the same level of seismic toughness.

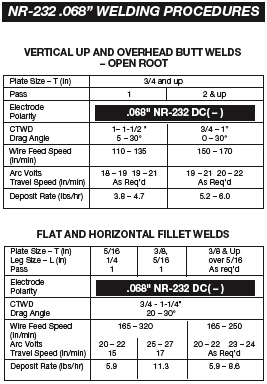

The chart below lists recommended parameters for NR-232 (“NR” said aloud sounds like “inner”, which makes it easy to remember.)

The number .068 in the chart is the wire’s diameter. Notice the polarity is DCEN. The designation CTWD stands for “contact tip to work distance”, which affects the amount of current moving through the joint. The “deposit rate” helps the purchaser calculate how much wire will be needed for a project.

Using Shielding Gas And Flux – Cored Wire Together

When compressed gas is involved in FCAW, the welding process is known as either Gas-Shielded or Dual-Shielded Flux-Cored Welding, since both the flux ingredients and compressed gas produce the shield. The formal designation is FCAW-G.

Here’s a more complicated example of a flux-cored wire, E71T-1C JH8, which breaks down like this:

- E – Electrode

- 7 – Tensile strength measured in pounds per square inch (PSI), multiplied by 10,000; in this case, 70,000 PSI. Note the difference with MIG, which uses two numbers multiplied by 1,000.

- 1 – All-position welding capability

- T – Tubular wire

- 1 – This is a wire usability specification. The options range from 1 to 14). The 1 here indicates that the wire has a rutile slag system (which means the chemical additives are acidic). Rutile coatings provide good weldability (low spatter, good arc quality and weld puddle control), but the mechanical properties are not considered as robust as a basic slag system.

- C – This letter indicates that the wire requires CO2 shielding gas. (M would indicate an argon/CO2 shielding gas blend. )

- JH8 – The last 3 are optional codes.

- J – designates that the electrode meets the requirements for improved toughness.

- H8 – designates the maximum amount of diffusible hydrogen the wire can contain. In this example, less than 8 ml of hydrogen is permissible for each 100 g of weld metal. The lower the number, the less hydrogen allowable in the wire, and therefore a lower chance for hydrogen-induced cracking in the final weldment.

This code is taken from AWS standard A5.29/A5.29M:2020 (Specification for Low-Alloy Steel Electrodes for Flux Cored Arc Welding)

Related: Best Flux Cored Wire

Rounding It Up

As you can see, the many variables involved in choosing the right wire will take a while to learn.

It’s a good idea to focus on the most common rod classifications at first and absorb the rest of the arsenal over time.

That said, as an entry-level welder, however, you may find yourself having to stock consumables or replace empty spools on MIG machines for seasoned veterans.

So exercising due diligence correctly selecting and storing wire products is essential to preventing costly mistakes when a welding operation begins.

The American Welding Society has handbooks available for purchase, but the cost can be prohibitive.

Check with your school or workplace to see if you can access a handbook and photocopy any info you need to place in your literature binder.