Arc welding flux consists of minerals, alloying materials, and chemical additives. Its primary purpose is to prevent harmful reactions of the molten metal and filler material with atmospheric gasses as an alternative to shielding gas.

Manufacturers often apply or integrate the flux into a consumable electrode for ease of use. Simply weld, and while the consumed electrode fills the joint, the flux becomes consumed, giving all its benefits depending on its added minerals, chemicals, and alloying elements.

No need to select, buy, handle, or apply the flux separately. For this reason, arc welders use the pre-manufactured flux/electrode combo for most welds. But specialty applications may use flux in many other ways.

Flux protects welds from reactive gasses in the atmosphere and provides arc stability. This combination of features aids in creating strong, decent-looking welds with no need for shielding gas.

However, arc welding uses many flux mixtures, depending on the metal, and various techniques can employ the flux. The assembled information in this article presents what flux is and how it shows up in arc welding.

What Is Flux?

Flux is a complex composition made from both organic and inorganic materials.

The different ingredients have specific uses, such as producing shielding gas or creating slag designed for specific applications.

For example:

- Silica and lime: flux agents that remove iron and impurities during steel production

- Titanium dioxide and iron powder: can produce slag when added; iron powder also increases the heat in the welding arc, increasing penetration and travel speed

- Ammonium chloride, resin acids, zinc chloride, hydrochloric acid, and borax: can enhance or impart certain properties in the mixture

- Wood flour, limestone, and cellulose: generate gasses that shield the weld from atmospheric gasses

Serious chemistry is happening inside a flux mixture. The actual flux mixture depends on the metal and its specific alloy. So, having the right flux for the weld is important.

How Does Flux Work?

Flux “melts” into the weld pool, rising to the top and creating slag. It simultaneously reacts with the heat and releases a shielding gas.

So, the slag and gas formation protects the weld from the natural reactive gasses in the atmosphere.

© weldguru.com – Image usage rights

But slag formation also purifies the weld, which is a good thing. But once the weld has hardened, the welder must remove the slag using a wire brush, chipping hammer, or an angle grinder.

The resulting slag is why some welders refer to any welding process using flux as “slag welding.”

What Arc Welding Processes Use Flux?

The procedures used to employ flux while arc welding can vary. But the two most common types of flux involve factory application of the flux to stick electrodes (SMAW) or a flux-cored wire (FCAW)

Another common method used in the pressure vessel industry involves casting the flux as a blanket over the arc, known as submerged arc welding (SAW).

Let’s take a closer look at all three.

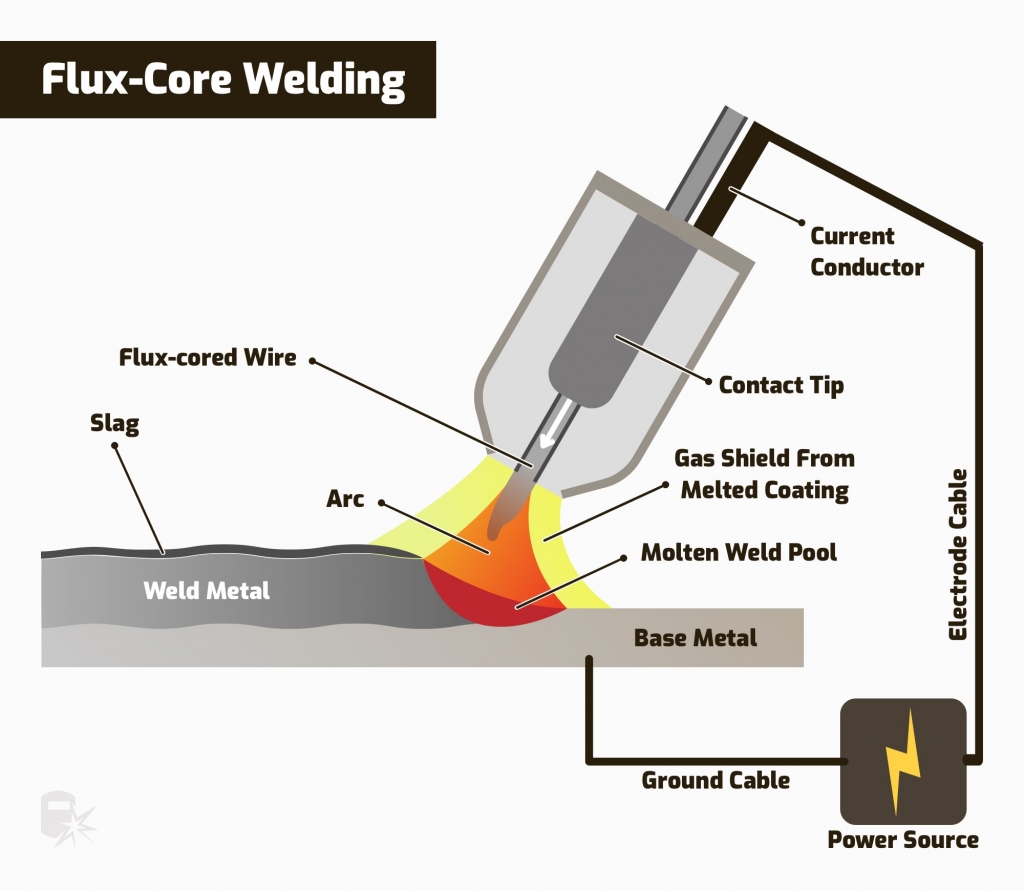

Flux-Core Welding (FCAW)

© weldguru.com – Image usage rights

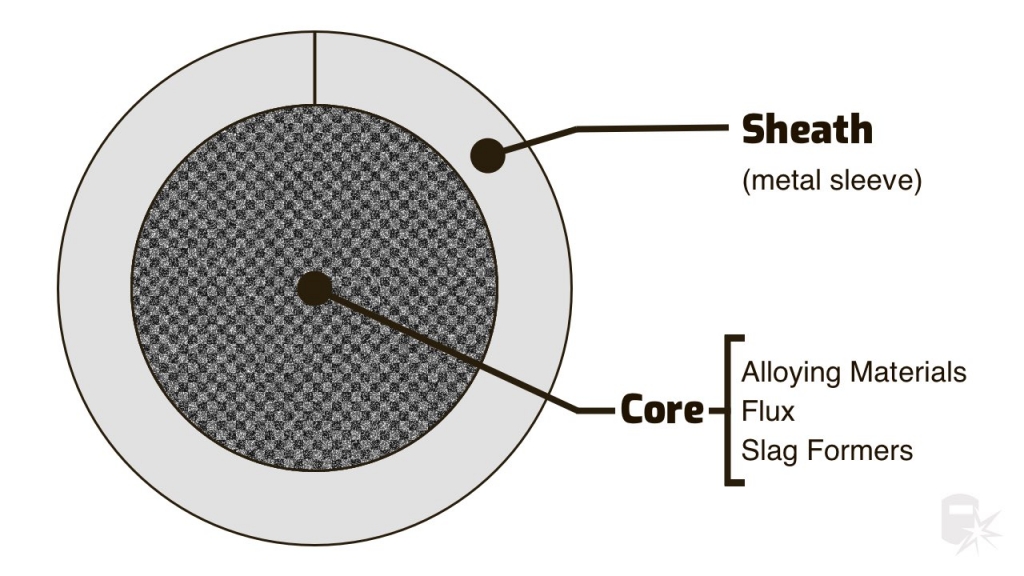

Flux-core welding (FCAW) uses a flux-cored wire where the consumable electrode is a hollow wire with an interior flux core.

With a metal outer “sleeve,” called a sheath, this flux-cored wire produces welds like MIG welding (GMAW).

An added benefit is welding without a gas bottle while providing the simple, fast wire feed to achieve high production rates that stick welding (SMAW) cannot match.

© weldguru.com – Image usage rights

Sometimes, people call flux-cored welding gasless MIG, and it’s popular for applications like windy conditions where shielding gas is useless as the wind blows away.

As mentioned, it’s similar to MIG welding, minus the gas tank. But it’s almost as easy to learn, which is why it’s popular for the beginner welder.

Also, in general, flux-core wire produces less slag than stick welding. This aspect makes it easier and quicker to remove.

Read more: Flux Core vs. MIG Welding: Differences Compared

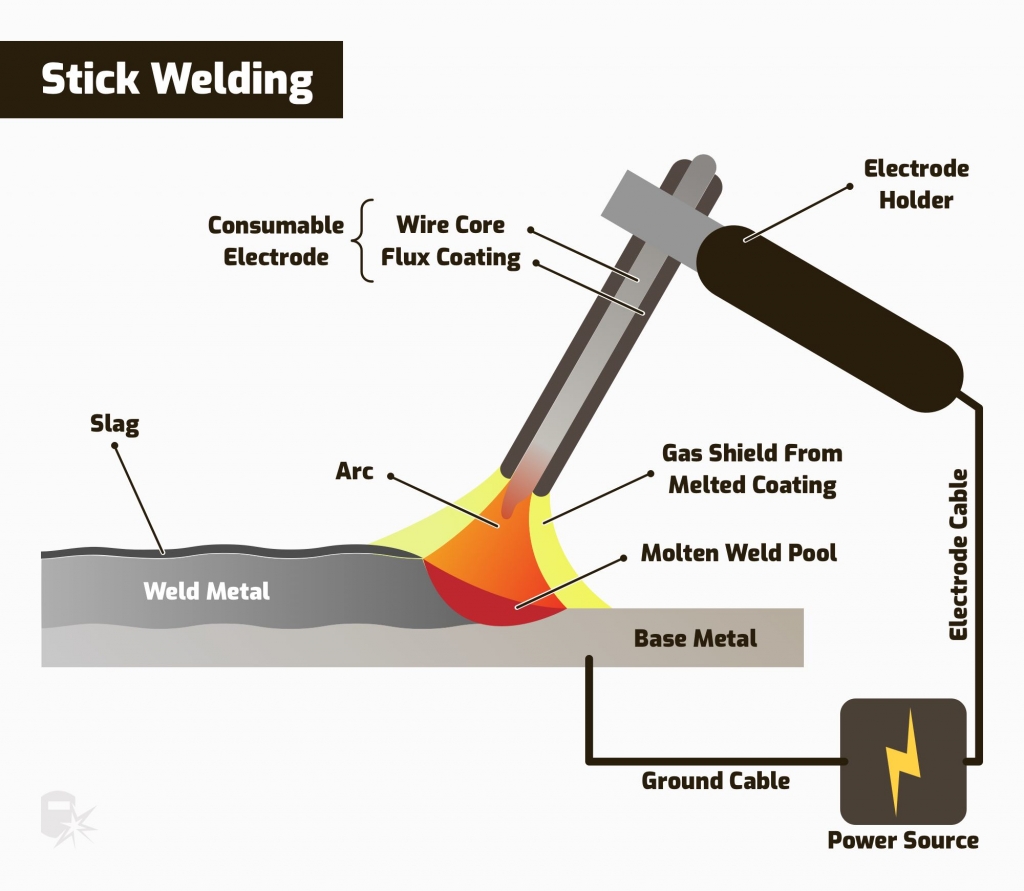

Stick Welding (SMAW)

© weldguru.com – Image usage rights

Stick welding (SMAW) rods have a solid, consumable electrode at their center, with an external flux coating. The composition varies depending on the weld, so the welder must buy an electrode designed for the metal.

Having chosen the correct welding rod for the application, a consumable electrode center is the filler material.

Plus, since the manufacturer applied the correct flux mixture at the factory to the outside of the electrode, it’s the proper flux.

The flux melts at a lower temperature than the base metal and rises to the top of the molten weld. When cooled, the flux forms into something called “slag.”

Flux rising to the top facilitates the shielding gas, removes impurities from the weld, and forms a protective slag, which protects the hot joint.

Stick welding is a classic process used in the shop or the field, and the necessary equipment is not that expensive. These features make it another popular flux-based choice among welders.

Submerged Arc Welding (SAW)

While not as popular as the prior two flux uses just discussed, submerged arc welding is a fairly common practice. This method continuously feeds an electrode into the joint, just like flux-cored welding. But the major difference is in the application of the flux. It’s not in or on the electrode.

The flux used is a granular powder, and it acts as a layer over the arc via a separate feed tube attached to a flux hopper. Since the process is applicable when high volumes of welding are necessary, this process is usually automated.

FAQs

Is Flux Hard To Use?

Flux-core wire feed systems don’t feel as smooth as a regular MIG machine. However, after running a few beads, it becomes clear that it isn’t much harder.

Shielded metal arc is tricky for many new welders. The electrodes have a lot to do with it. Welding rods with more flux are easier to work with.

Each rod has a specific purpose, which is something to remember when choosing an electrode.

Are Flux Welds Of Good Quality?

When using flux-cored wire, it can be harder to see the weld puddle, potentially resulting in less pleasing welds. But with practice, anyone can make decent-looking welds.

Likewise, stick welding will produce ugly welds when done with insufficient skill. It can also make beautiful welds when done properly. After removing the slag, the true character of the welds becomes visible.

Can You Use Flux Indoors?

Using flux-core wire gives off more potentially toxic fumes than using a normal MIG machine. The flux itself releases gasses strong enough to shield molten metal.

When welding indoors, keep the area as well-ventilated as possible and/or wear the proper respirator.

Do Flux-Based Methods Make Strong Welds?

Yes, the welds can be of high strength. The welds will be as strong as any other welding method with proper care and attention. Penetration is typically deeper when using flux, which helps provide added strength.

Are Flux-Based Techniques Easy Enough For A Hobbyist To Use?

Using flux-cored wire is a great way to learn the skill of welding. It’s a straightforward way to get the hang of a new skill.

Learning to stick weld depends on the electrode. For flat, horizontal welds on heavy material, 7024 is the best choice. So, that’s a good place to start. Then making the jump from 7024 to 7018 electrodes for vertical welds isn’t that large of a jump.

Wrapping It Up

Flux-aided welds play an important role in arc welding. The mixtures can be complex and vary, so a welder must have the right flux for the welding metal and position.

But for stick or flux-cored welding, the flux is “preinstalled” as long as the electrode/wire for the joint is right.

Since flux mixtures produce slag and gas, they protect the hot, molten metal instead of shielding gas. That means no gas bottle to lug around and no correctly setting gas flow rates. So, stick and flux-cored welding are popular with many welders who have learned the value of using flux-based methods.

Yes, there will be no pretty stacked dimes like a TIG (GTAW) weld. But flux does provide strong, contaminate-free joints when done right and, with a little practice, can make decent-looking welds.

Plus, since there’s no gas, things like welding in windy conditions are possible. MIG (GMAW) and TIG (GTAW) welding struggle to do that.

So, there are advantages to flux-aided arc welds, and it’s well worth the time and effort to learn about and practice with methods that use flux. It’s a valuable welding skill to have at one’s disposal and well worth learning.

Love these articles I do training for new employees who do not have a lot

of welding background these are down to earth easy to understand