It’s an old welding shop debate: Should you push or pull while MIG welding (GMAW)?

Some may get riled up defending their position, and the facts may get lost in the buzz. But the reality is far tamer, and pushing and pulling both have their strong and weak points.

So, it’s worth knowing the facts if you want to be a better welder. With a quick YouTube search, you can find various videos, some with rigorous testing, that show us what’s going on between the metal and MIG wire.

You’ll also learn that the strength of the weld is about the same whether you push or pull the weld.

Ultimately, the specific job, the materials and equipment, and your personal preference determine whether you should push or pull.

What Are The Differences Between Pulling and Pushing?

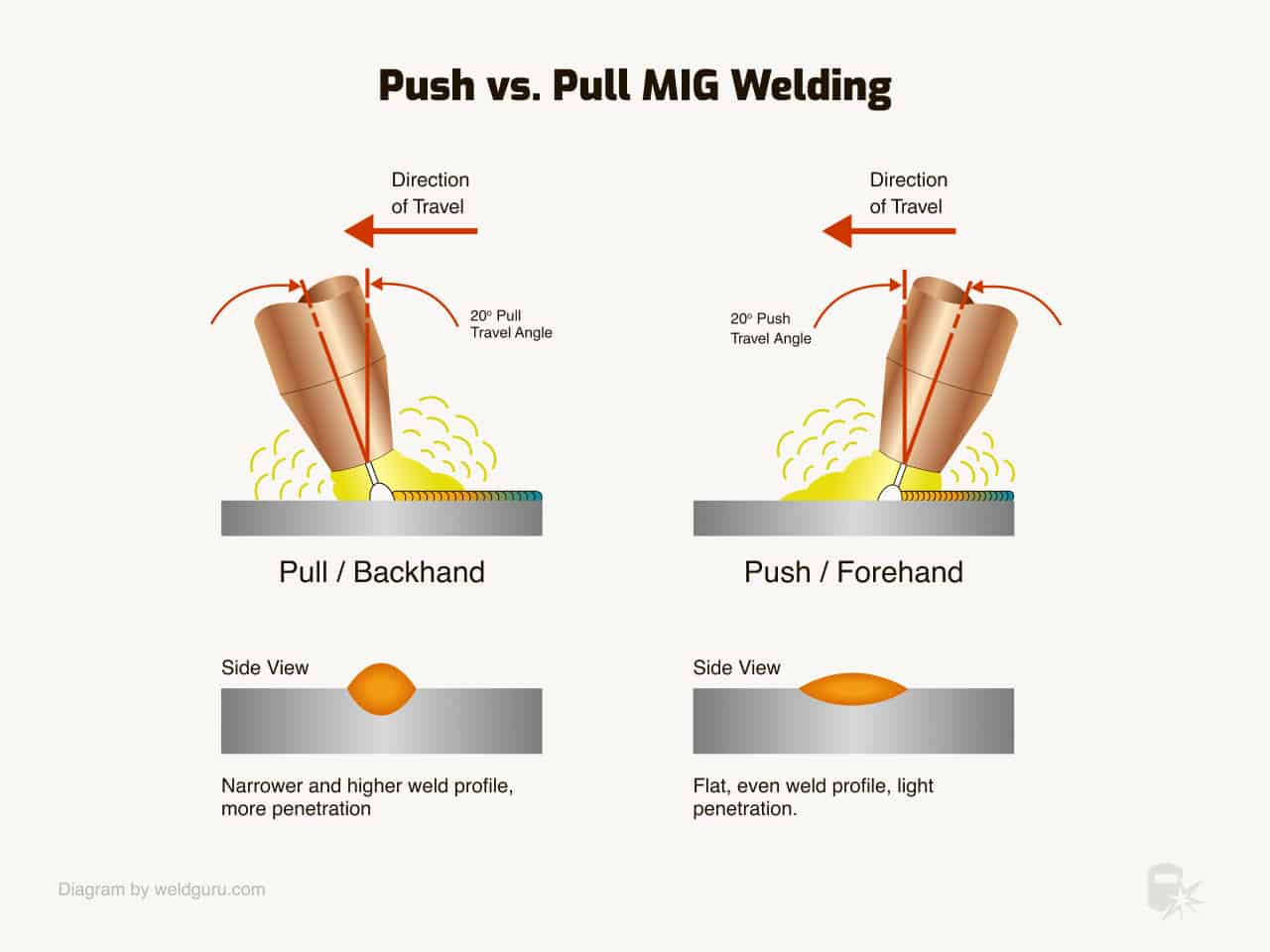

While many think efficacy is the most significant difference, the final appearance is the most noticeable contrast between pushing and pulling a MIG weld.

Sure, pulling gives you a little deeper penetration, but the bead is relatively narrow.

© weldguru.com – Image usage rights

Pushing provides a bit less penetration, but it grabs significantly more metal with a broader bead. So, the strength of a pushed or pulled weld is about the same.

So, this controversy comes down to two essential questions: How well does it hold? How does it look?

Related: Overview of Gas Metal Arc Welding

Pulling The Weld

Pulling a MIG weld means tilting the torch away from your starting point and dragging the weld. Some say this cuts further into the base metal, giving you a deeper and stronger weld.

But, when pulling, you are typically left with a thick, solid bead that protrudes from the base metal.

Most welders agree that pulling a MIG weld is easier because you’re simply drawing a straight line. You can do some weaving while pulling, but it won’t be as smooth as a pushed and weaved bead.

Also, by pulling, you usually have cool, unwelded metal to rest your hands and arms on, so you won’t get burned. This metal provides extra stability as you weld.

I like to pull a weld when welding a covered piece or doing a joint that needs a little more penetration—anything where aesthetics are a low priority.

Also, pulling is the way to go if you use flux-cored wire. This method prevents slag inclusions, where the flux gets trapped in the molten metal. Doing this leaves an ugly, rough, and porous weld.

Pros of Pulling:

- Easiest MIG welding method

- Unwelded (cool) metal is available as a hand/armrest

- Works with flux-cored wire

Cons of Pulling:

- Less pleasing to the eye

- Must grind smooth for visible welds

- You can’t see where you’re going as well as with pushing

- More grinding is usually required

Pushing The Weld

As the name implies, with this option, you tilt the torch toward your starting point and push the weld.

The hot bead will be under your hands, and you won’t be able to stabilize yourself on the metal as freely as you can when pulling. Pushing will give you a flatter weld with less penetration than pulling and will be a little quicker.

So, it takes a steady hand to properly push a weld, especially if you introduce weaving into your technique. The resulting weld will be a flatter, more symmetrical bead than pulling.

If I’m welding anything that’ll be visible, I always push the weld. It’s easier to add some weaving that results in a beautiful bead. But being able to see where you’re heading is the biggest perk of pushing.

You shouldn’t push a flux-cored wire. The push motion can trap flux within the molten metal, and this results in a porous, rough weld that is weak and ugly.

If you are going to push a flux-cored wire, make sure you stay on the leading edge of the puddle to avoid slag entrapment. Doing this takes a little more skill than pushing a flux-cored weld.

Pros of Pushing:

- Smoother, flatter beads

- Less grinding than when pulling

- More aesthetically pleasing

- Better gas coverage when welding

- Easier to weave

- Faster welding speed

Cons of Pushing

- Harder to master

- Can’t rest your hands on the hot bead

- More difficult when used with flux-cored wire

Pushing and Pulling With Different Metals

When welding different metals, pushing or pulling can make a difference.

Steel

You can choose the push or pull method if you’re MIG welding steel.

Welds that are flat or on an outer surface give you the most freedom to pick what you like. Your choices start to diminish when welding inside little nooks and crannies.

You may find that welding inside corners requires both the push and the pull method to do the job.

For some jobs, such as the pickets in handrails, you’ll find that it doesn’t matter if you push or pull. The welds are so short and hidden. You can get it done quickly, going in either direction.

The most important thing is going in one continuous direction once you start. Doing this will help you get a flow going, allowing you to work quickly and effectively while making consistent welds.

I once welded some big tire wells for trailers. In this case, they wanted the welds on the inside and hidden. It was a perfect situation to use the pull method, with its long, straight welds that nobody would ever see.

But when I got to the hitch to the frame, I switched to the push method with some weaving. These welds would be visible, but the customer wanted them ground smoothly. The push method was perfect, providing adequate welds that were easy to blend with a grinder.

Aluminum

If you find yourself MIG welding aluminum, you should always use the push method. Aluminum isn’t as forgiving as steel, and an incorrect pulling technique results in unsightly, impaired welds.

Aluminum is much easier to contaminate when welding than steel. It’s necessary to keep the welding torch tilted in the right direction when welding aluminum to allow the gas to do its job.

Suppose you were to pull when MIG welding aluminum; you would get less gas coverage. Less coverage exposes the weld pool to reactive atmospheric gasses, resulting in contamination that causes porous, rough, and weak welds.

Another reason to push when joining aluminum is the direction of travel where you point the heat.

When welding aluminum, you’re already welding it pretty hot. You don’t want any extra heat going where you’ve already been, only where you’re going.

So, pushing will give you a better-looking weld that’s easier to control.

Like with steel, pushing a weld produces a wider, flatter bead. Doing this includes more surface area in the weld. So, the joint is solid and robust.

With aluminum, you must have clean materials before welding. Use an aluminum wire brush, not a steel wire brush, to clean the joints you’ll be welding. This step is essential, so don’t skip it.

Lastly, you must move much faster when MIG welding aluminum than with steel. It’s a much lighter metal than steel, and it cannot take focused exposure to an arc’s heat nearly as long without blowing apart.

Read more on MIG welding aluminum in our dedicated guide here.

Wrapping It Up

Being too attached to pushing or pulling will ultimately get in the way of your progress. Both methods have their place, and you should know when to use each.

I’ve seen two guys standing around for 45 minutes, arguing over how to do the job when they could have done it either way. They were wasting time for no good reason. Don’t fall into that trap.

In general, welders face lots of options daily. But the ultimate purpose is always the same.

How well does it hold? How does it look?

The best method becomes clear when you approach the job and ask those questions.

You may have to push; you may have to pull. And, depending on the job, you may even be free to choose. So, it’s best to master both techniques because you never know when you’ll need to use them.