Scratch start and lift arc TIG ignition methods appear similar. But they are nothing alike.

The lift arc method produces much cleaner welds, which many use for professional-level jobs.

This article covers the main differences between the two arc-starting methods and why many prefer the lift arc option for the TIG process.

But since things are never black and white, we’ll also discuss the advantages and disadvantages of both.

What is Scratch-Start TIG?

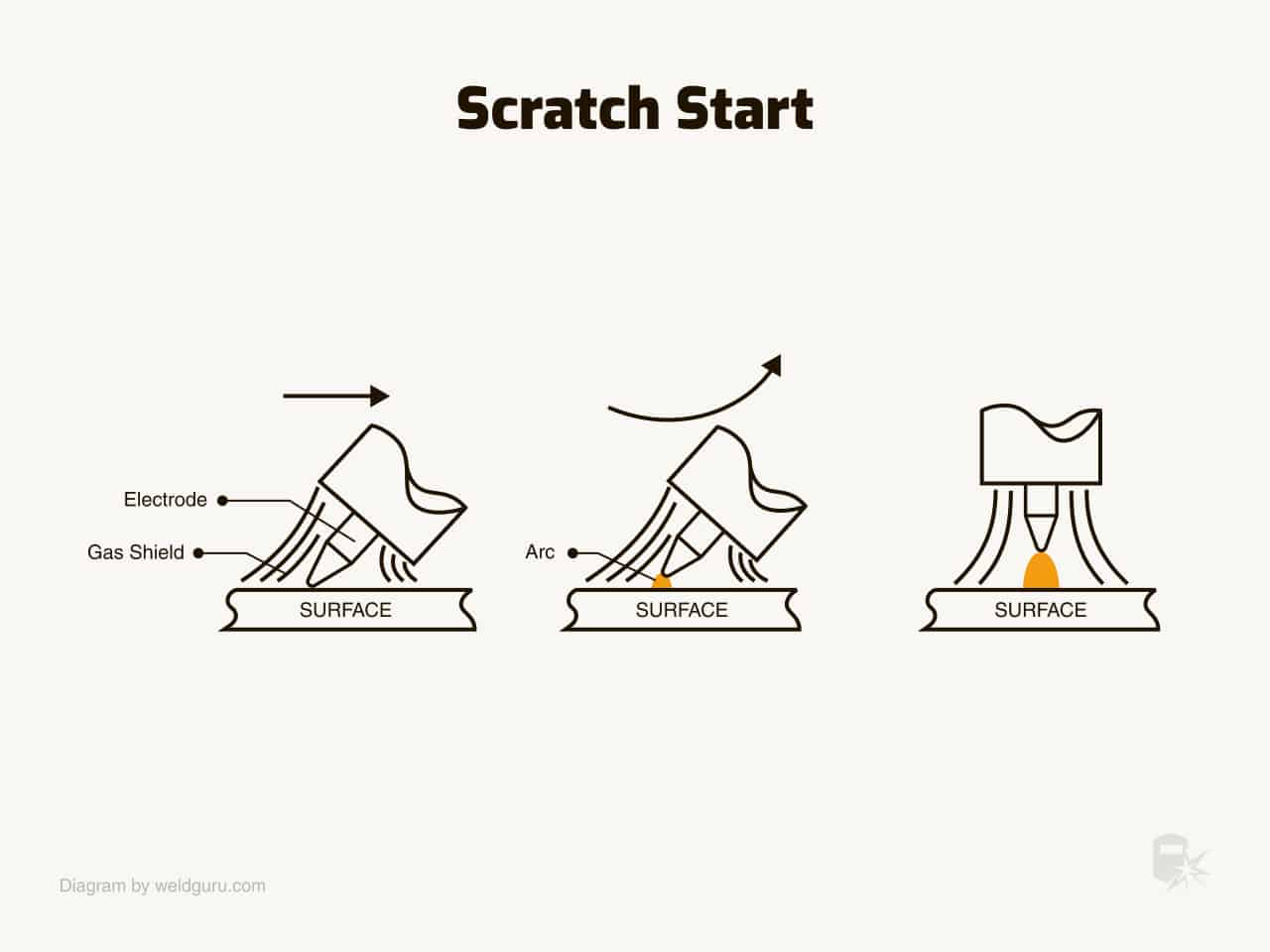

Scratch start TIG is an arc initiation method that requires scratching the tungsten electrode over the metal’s surface.

© weldguru.com – Image usage rights

It’s a basic way to start the arc using low-end TIG welders or converted stick machines.

But scratching the tungsten electrode on the metal piece is challenging. Since the tungsten electrode is electrically hot, it’s pretty easy to get the electrode stuck to the workpiece.

As a result, the weld becomes contaminated with tungsten inclusions, creating hard spots that can lead to cracks.

If the tungsten electrode sticks, you must grind out the weld and the electrode tip. Trust me when we say it’s no fun.

© weldguru.com – Image usage rights

Because it is easy to create problematic tungsten inclusions, using scratch start TIG for critical welds is not recommended.

Welding any structure that can endanger someone should the weld fail requires a more reliable arc initiation method like lift TIG or a high-frequency (“HF”) arc start.

But, scratch start works well to weld carbon steel and stainless steel with hobbyist projects like furniture and metal art.

I wrote extensively about scratch start TIG in our other article, where we also covered converting a stick welder to a DC TIG scratch start machine.

What is Lift Arc TIG?

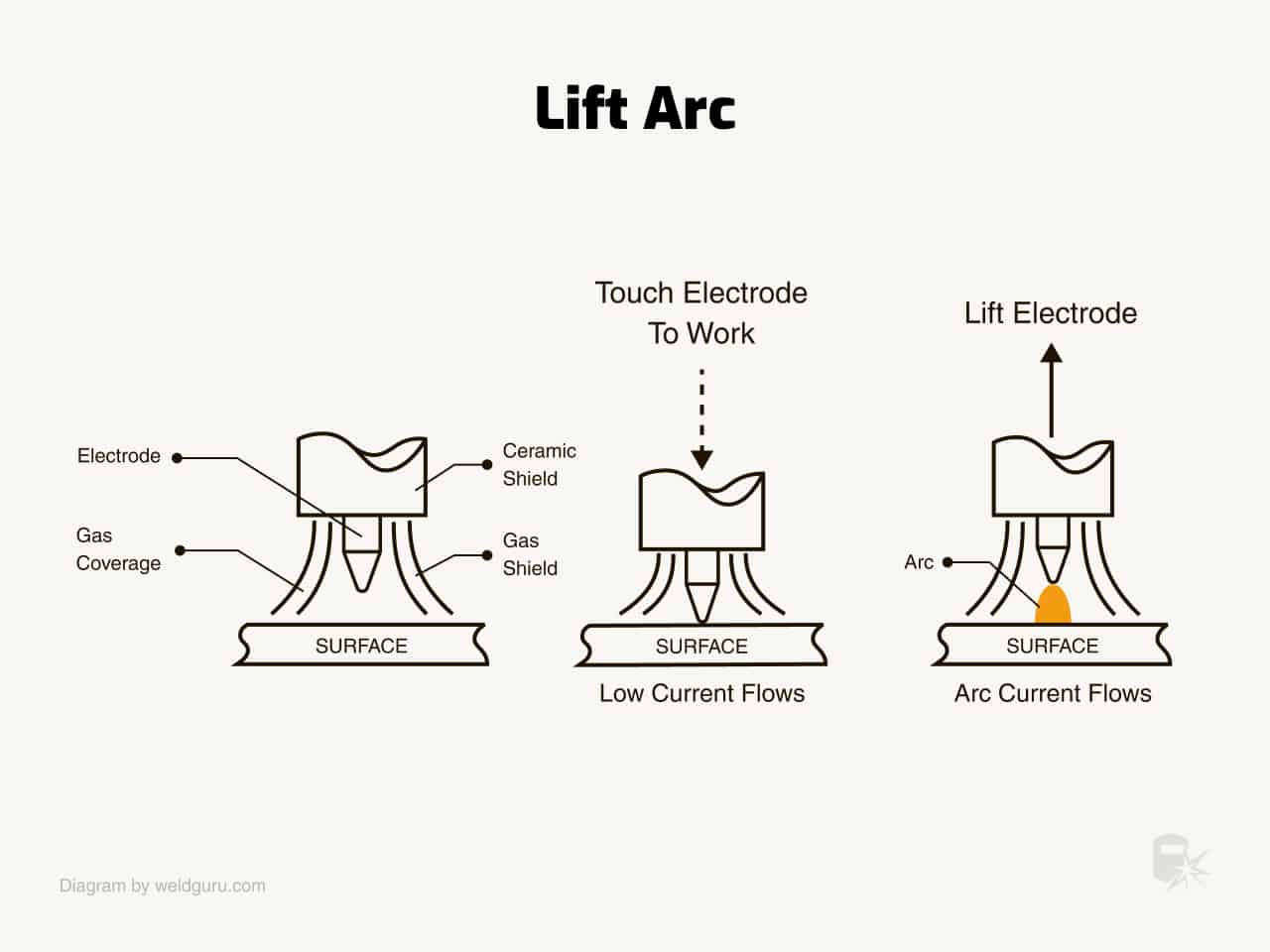

The lift arc technique touches the workpiece with the tungsten tip and then lifts the electrode upwards.

The lift arc initiation doesn’t require scratching the surface of the welded material, as the tungsten electrode outputs a low current to prevent sticking to the metal piece.

© weldguru.com – Image usage rights

Note there is no scratching in the image above, just a simple touch. The arc is initiated between the tungsten and the workpiece as you lift the electrode.

Therefore, a significant difference between lift TIG and scratch start is that with the lift TIG, you cannot stick the tungsten electrode to the metal.

Since the initial current is low and only lets the machine know that you’ve touched the metal, it cannot melt the tungsten or the welded part. That means no tungsten contamination and no grinding and redoing welds.

To correctly use the lift TIG process, you must first touch the base metal with the tungsten tip. Then click the power button on the torch or press the foot control to activate a tiny trickle current.

Finally, slowly lift the TIG torch just a little. Once the machine senses that the trickle electric circuit is broken, it will activate the arc with the larger amperage output you’ve set on the welder.

Lift arc TIG has become widely available, and TIG machines that support it are not as expensive as they used to be.

Scratch start TIG welders are hardly even sold anymore. Even hobby welders prefer to start their TIG welds with lift arc nowadays.

Related: TIG Welding Process Explained

Scratch Start vs. Lift Arc TIG

Now that we’ve explained the principles of how these two arc-starting methods work let’s compare them head-to-head.

While lift TIG is better and usually the preferred option, the scratch start method has some advantages in certain situations.

Advantages of Scratch Start TIG

The most significant advantage of scratch start TIG is that it’s accessible if you already own a stick welding machine.

Attach an air-cooled TIG torch with a gas valve to your stick welder, add some gas, and you’re ready to start. So, all you have to purchase is a TIG torch and an argon shielding gas cylinder.

It’s a simple way to try out the TIG welding process without buying a new welder. The disadvantages of scratch start shouldn’t put beginners off because weld quality is not paramount for most DIY welding projects.

You can get one cheap if you don’t have a stick welder. Most budget inverter stick welders will perform scratch start TIG well.

So, if you are interested in TIG welding and don’t want to spend more money, an inexpensive stick welder as a power source will do just fine.

Disadvantages of Scratch Start TIG

The main disadvantage of scratch start is the high probability of tungsten contamination. Even if you don’t stick the electrode to the metal, the scratching action is enough to erode some tungsten into the weld pool.

But beginners will often stick the tungsten to the metal, which is frustrating. Re-grinding the workpiece and tungsten electrode is time-consuming and increases the necessary effort to get the job done. Plus, tungsten electrodes are not cheap.

Every time the tungsten tip sticks and breaks off, you must regrind a new tip, and the electrode life expectancy is shortened prematurely.

In short, the scratch start method is not a clean process, no matter how you slice it. The welds can become contaminated, and welding takes far more effort with scratch start than lift TIG or HF start.

But if it’s all you’ve got, it works fine for DIY and simple welding jobs.

Advantages of Lift Arc TIG

The most notable advantage of lift arc is the clean welds. Weld contamination by tungsten doesn’t happen very often, so lift arc TIG easily passes an x-ray test.

Professionals use the lift TIG start machines regularly to make precise, clean TIG welds in critical industries like aerospace, transportation, food processing, and energy.

Additionally, it’s much easier to initiate the arc with a lift TIG capable welder. Hobbyists or people learning to TIG weld find lift arcs far easier to use.

Plus, you don’t have to worry about tungsten sticking or eroding, which diminishes the need for constant regrinding of the joint and tungsten electrode.

An often-overlooked advantage of lift arc is that it can replace HF TIG start when working around sensitive equipment. High-Frequency TIG can interfere with CNC machines, smartphones, laptops, radio towers, car electronics, and medical equipment.

So, lift TIG is an excellent solution when you encounter potential interference issues. However, while unlikely, it’s still possible to make slight tungsten inclusions with a lift arc.

So, we would be remiss if we did not mention that HF arc initiation is still the number one method employed by professional TIG welders with critical welds.

Disadvantages of Lift Arc TIG

There aren’t any actual disadvantages to lift arc compared to scratch start TIG. The only downside of lift arc is that you must purchase a TIG welder or multi-process machine that supports it.

But today, most inexpensive constant current (“CC”) inverter welders include lift TIG, not scratch start.

If you use an older stick welding machine to TIG, you are limited to scratch start if you wish to TIG weld. So, in that sense, lift arc starts are at a disadvantage because it requires more specialized equipment.

But, since you can get a lift TIG capable welder for less than $200, we cannot really complain. For example, the YesWelder ARC PRO 165A supports MMA and lift arc DC TIG and costs less than a week’s worth of groceries.

Related: List of The Best TIG Machines

Summary Table of Pros and Cons

| Feature | Scratch Start TIG | Lift Arc TIG |

|---|---|---|

| Chance Of Weld Contamination | High | Low |

| Chance Of Tungsten Electrode Contamination | High | Very Low |

| Arc Starting Difficulty | Hard | Easy |

| Arc Starting Method | Scratching the metal surface | Lifting electrode upwards |

| Application | DIY, non-critical jobs | DIY and professional jobs |

| Works With Any Stick Welder | Yes | No |

Video Comparing the Two TIG Start Methods

You can watch the YouTube video below to help you visualize the differences between the scratch start and lift TIG.

There are many videos on the internet, but this one plainly demonstrates the differences.

Plus, it compares the two arc starting methods with HF ignition to paint you a complete picture of your choices for TIG arc initiation.

Wrapping It

Lift TIG is better across the board. So, unless scratch start is all you have, consider getting a machine with lift TIG capabilities.

If you are a hobbyist welder and already own a stick welder, you can get by with the scratch start method, especially if all you want to do is try out TIG welding without buying a new welder.

But lift TIG offers a far better experience and better quality welds. You’ll waste fewer tungsten electrodes and have less need for regrinding of the failed welds.

If you’re having trouble with TIG welding, then make sure to check out these essential TIG tips to up your TIG game.