Stick welding (SMAW) is one of the oldest forms of electric arc welding and the first introduction to welding for many welders. It’s a difficult process to learn and takes a lot of practice to become proficient at.

Learning to stick weld will be a frustrating process until you’ve developed enough muscle memory through repetition.

Having a few tips and tricks in your back pocket will help you improve your technique, learn to stick weld faster and avoid many mistakes beginners make.

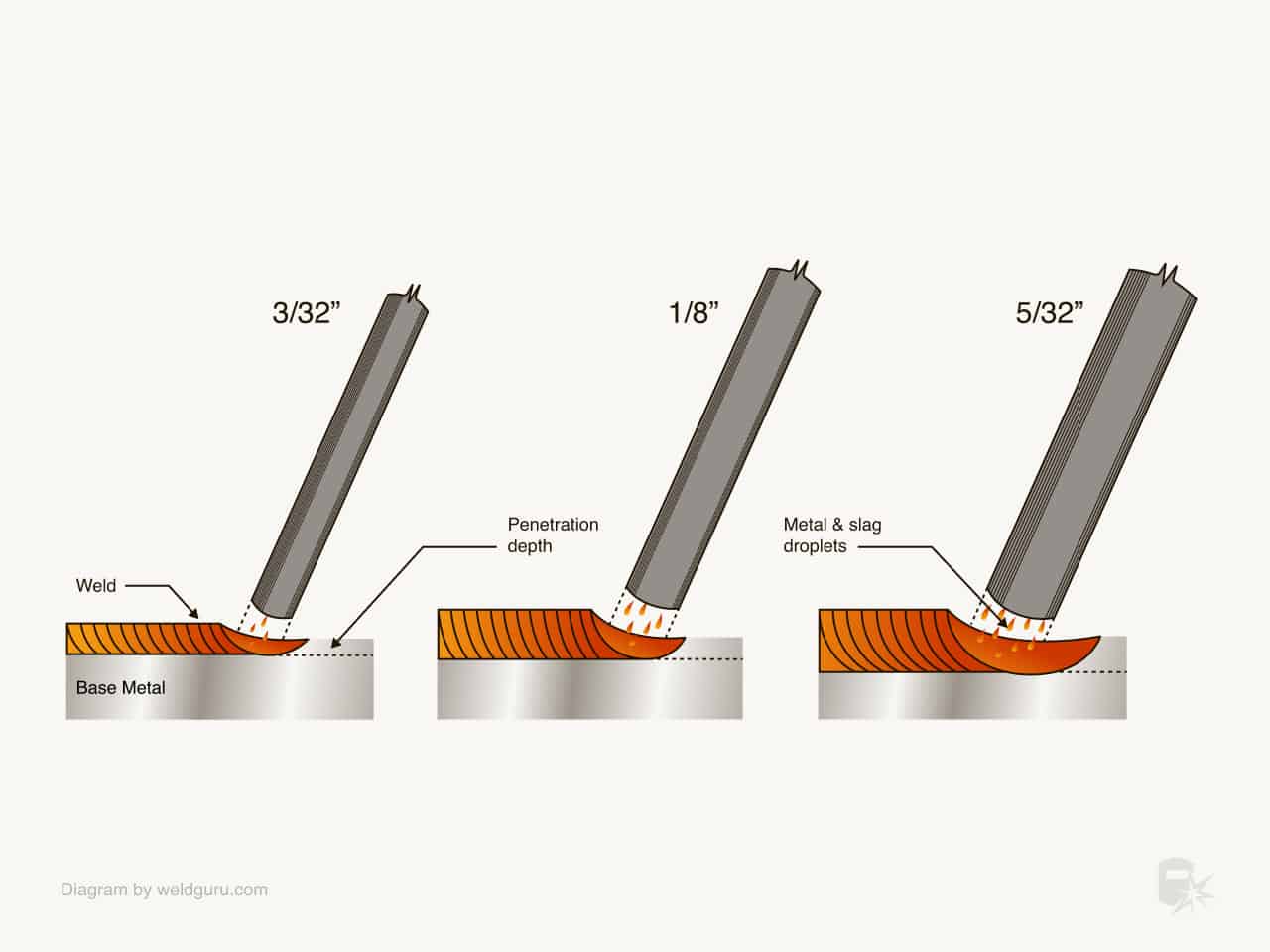

1. Use the Correct Rod Size

Stick welding electrodes come in a variety of diameters. It’s often tempting to try and find one size of electrode to do all your welding.

The problem is that if you’re welding different material thicknesses, you’ll need a selection of electrode sizes.

© weldguru.com – Image usage rights

Welding with the wrong-sized electrode can result in welds lacking fusion, blowing through the material, excessive heat input, and poor arc initiating, to name a few.

To cover most of the welding, you’ll probably need 3/32”, ⅛”, and 5/32” sized electrodes, which will cover most of the bases.

2. Use a 7018 Electrode for Cleaner Metal

The great thing about stick welding is that you can weld on dirty, rusty, or contaminated materials.

6010 and 6011 electrodes are excellent for this, but the welds they produce don’t look as nice.

When welding on clean steel, use a 7018 electrode to get sound welds that look nice.

The purpose of 7018 electrodes is specifically for welding on clean steel, and they won’t perform as well on dirty or sub-par materials.

Not sure what the numbers on the electrode mean? Read: Welding Rod Numbers Explained.

3. Don’t Reuse a Partially Used Up Electrode

If you’re a beginner, using up as much of the electrode as possible when stick welding is always best. If you use half an electrode, you’ll often find that restarting the arc is difficult.

As you try to strike an arc, the electrode tip can stick to the surface of the metal instead of establishing a stable arc. This possibility is only part of why you should not reuse a partially used electrode.

A partially used electrode can also make the flux unstable and fall off during welding. This occurrence opens your weld to many weld faults, such as inclusions and porosity.

When you become more comfortable starting the arc, you should learn to reuse the electrode to save on consumables and money.

4. Keep Your Electrode Rods Clean & Dry

Stick welding electrodes must be clean and dry to be effective. When you buy a box of electrodes, they’re sealed in plastic or foil.

Always keep the electrodes in their packaging until you need to use them.

Once you break the seal, the electrodes must stay dry and clean, or they’ll absorb the moisture in the air or become contaminated by dust.

For some electrodes, such as low-hydrogen, you must store them in a rod oven to keep them dry.

This is an example of a portable electrode oven. They prevent moisture from contaminating your welding electrodes and maintain low hydrogen weld deposit properties. Moisture is a common cause of weld cracking or porosity.

These rod ovens will hold the electrodes at a constant temperature, normally 250F, keeping them from absorbing moisture.

5. Clean That Metal

Even though you can weld on dirty steel with stick electrodes, there’s no reason you should do that if you can avoid it.

If you clean the steel first, your welds will be cleaner, more structurally sound, and better looking.

© weldguru.com – Image usage rights

Grind the mill scale off the surface, remove rust, and clean any dirt and grime before doing any stick welding.

The arc will start easier and be more stable, the weld will penetrate better, and fewer weld defects will occur.

6. Use the Right Starting Technique

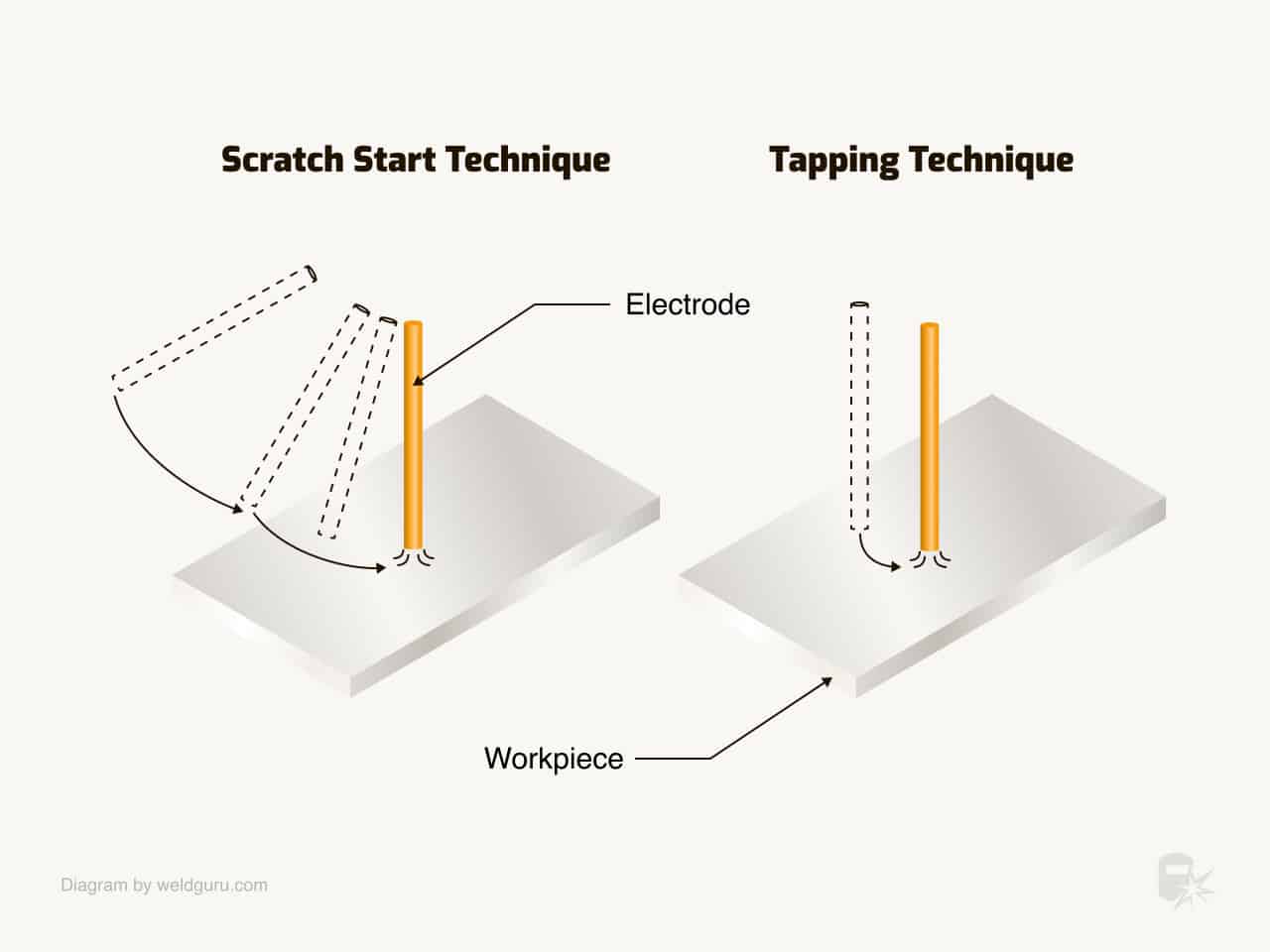

There are two ways to start the arc. You can either scratch the electrode tip across the surface or tap it.

It’s good to learn how to use both techniques to begin your stick welding arc, but between the two, scratch starting is best for beginners.

© weldguru.com – Image usage rights

To tap start the electrode, you’ll stab the metal with the tip in a tapping motion until an arc forms. Using the tapping method often will lead to the end of the electrode sticking to the metal, leading to frustration.

However, this method is good for starting the arc at a specific spot.

To scratch start the electrode, you only need to drag the electrode tip lightly across the metal surface. Once the arc forms and is stable, all you need to do is to maintain the arc length and start welding.

The motion is a lot like striking a match, which is why beginners often find it easiest to learn.

7. Use the Correct Arc Length

Arc length is very important in stick welding, and it can be tricky to maintain the right arc length.

As a rule of thumb, try to keep the electrode tip about one electrode diameter off the material’s surface.

© weldguru.com – Image usage rights

For example, a ⅛” electrode has an arc length of about ⅛”. As the weld progresses and the stick electrode gets shorter, you must move the electrode holder closer to the weld joint steadily, maintaining that distance.

With practice, this becomes second nature, and you’ll develop good muscle memory.

If you have an arc length that’s too long, you’ll get more spatter, wider beads, and an erratic arc. On the other hand, if the arc length is too short, the electrode will stick to the material.

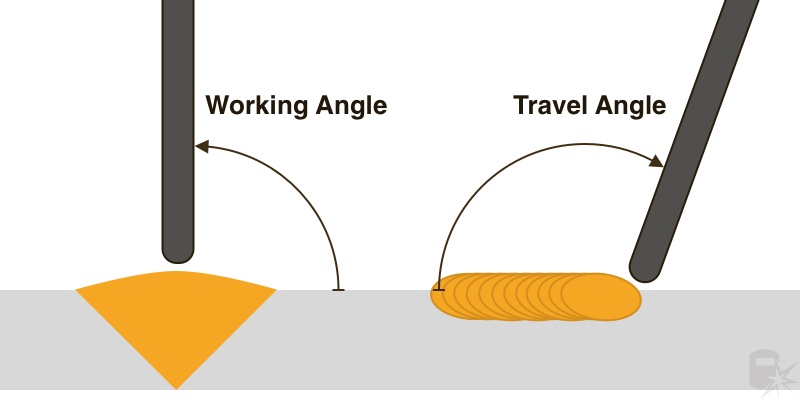

8. Use the Right Travel Angle

I’ve found the best travel angle range for stick welding is between 10 and 20 degrees, with 15 being the sweet spot.

You may want to adjust the travel angle depending on the situation.

© weldguru.com – Image usage rights

A travel angle closer to 0 degrees will direct more heat into the joint, and an angle steeper than 15 degrees will direct less heat.

You can play within this range depending on how much penetration you want or need.

9. Drag Your Weld

When stick welding, always use a dragging technique. If you try to push the weld, you’ll end up with slag inclusions and other weld faults.

Dragging the weld also lets you see how the weld is going and enables you to watch the size and condition of the weld puddle.

As the old saying goes… with slag, you drag.

10. Keep a Consistent Travel Speed

Travel speed is challenging to maintain but is critical to get a consistent-sized weld.

The best way to keep a steady travel speed is to watch the size of the weld puddle and adjust your travel speed to keep the puddle the same size.

11. Manipulating the Electrode

You can drag the electrode through the joint, but you’ll have better results if you manipulate the electrode.

Use a slight weave or small circles to wash the weld metal into the base material, preventing undercut.

Vertical up welds need a large weave pattern to stack the weld metal up the joint while maintaining a structurally sound weld.

12. Keep Your Head Out of the Fumes

Welding fumes are toxic; you should do everything possible to avoid breathing them in. The first step is to keep your head out of the smoke the weld creates.

© weldguru.com – Image usage rights

This action keeps you from directly inhaling the smoke and fumes and makes it easier to see the weld puddle.

Also, always wear an appropriate respirator to protect your lungs.

13. Watch Out For Common Mistakes

You’ll inevitably encounter problems with your welds occasionally. Most of these problems are correctable by adjusting your settings or technique once you notice that you’re having an issue.

A too-long arc often causes spatter, but if tightening the arc doesn’t help, you might also have to adjust the welding amperage.

Porosity is usually the result of contamination in the weld area, but an arc length that’s too long will also cause it.

Undercut in a grooved section on the toe of the weld is normally too much current or a high travel speed. Start by dropping the travel speed and current to combat undercut.

Using a weaving technique is another way to avoid this fault.

Trouble starting the arc is a common issue with stick welding and is usually the result of poor technique.

Some electrodes, such as 7018, are prone to sticking, and you must learn how to strike an arc through practice.

Lack of fusion and penetration cause too little welding current or a travel speed that’s too fast.

Knowing what issues to look for and how to deal with these faults is critical to stick welding success.

14. Use Dry Runs

One of the best ways to ensure you’ll produce the best welds is to do dry runs. To do a dry run, turn the welding machine off and drag the electrode through the joint as if doing a weld.

Doing a dry run will prove whether you can comfortably do the weld. If you notice that something is preventing you from staying comfortable, you can correct yourself.

The best part is that you can do as many dry runs until you know you have the technique and position dialed in.

I always do a quick dry run before stick welding, especially if I haven’t done it in a while.

Wrapping It Up

Learning to stick weld is a process that will take time, experience, and practice. These tips and tricks will help you make the process easier or level up your stick welding skills.

Above all else, the best advice I can give you is to practice, practice, and practice.