There are three basic flame types: neutral (balanced), excess acetylene (carburizing), and excess oxygen (oxidizing) as shown below.

- A neutral flame is named neutral since in most cases will have no chemical effect on the metal being welded.

- A carburizing flame will produce iron carbide, causing a chemical change in steel and iron. For this reason a carburizing flame is not used on metals that absorb carbon.

- An oxidizing flame is hotter than a neutral flame and is often used on copper and zinc.

The Neutral Flame

The neutral flame has a one-to-one ratio of acetylene and oxygen. It obtains additional oxygen from the air and provides complete combustion. It is generally preferred for welding.

The neutral flame has a clear, well-defined, or luminous cone indicating that combustion is complete.

Neutral welding flames are commonly used to weld:

The welding flame should be adjusted to neutral before either the carburizing or oxidizing flame mixture is set.

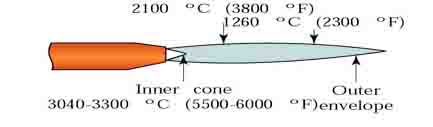

There are two clearly defined zones in the neutral flame.

- The inner zone consists of a luminous cone that is bluish-white.

- Surrounding this is a light blue flame envelope or sheath.

This neutral flame is obtained by starting with an excess acetylene flame in which there is a “feather” extension of the inner cone. When the flow of acetylene is decreased or the flow of oxygen increased the feather will tend to disappear. The neutral flame begins when the feather disappears.

The neutral or balanced flame is obtained when the mixed torch gas consists of approximately one volume of oxygen and one volume of acetylene. It is obtained by gradually opening the oxygen valve to shorten the acetylene flame until a clearly defined inner cone is visible.

For a strictly neutral flame, no whitish streamers should be present at the end of the cone. In some cases, it is desirable to leave a slight acetylene streamer or “feather” 1/16 to 1/8 in. (1.6 to 3.2 mm) long at the end of the cone to ensure that the flame is not oxidizing.

This flame adjustment is used for most welding operations and for preheating during cutting operations. When welding steel with this flame, the molten metal puddle is quiet and clear. The metal flows easily without boiling, foaming, or sparking.

In the neutral flame, the temperature at the inner cone tip is approximately 5850ºF (3232ºC), while at the end of the outer sheath or envelope the temperature drops to approximately 2300ºF (1260ºC). This variation within the flame permits some temperature control when making a weld. The position of the flame to the molten puddle can be changed, and the heat controlled in this manner.

The Carburizing Flame

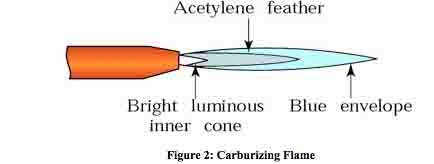

The carburizing flame has excess acetylene, the inner cone has a feathery edge extending beyond it.

This white feather is called the acetylene feather.

If the acetylene feather is twice as long as the inner cone it is known as a 2X flame, which is a way of expressing the amount of excess acetylene. The carburizing flame may add carbon to the weld metal.

Reducing or carburizing welding flames are obtained when slightly less than one volume of oxygen is mixed with one volume of acetylene.

This flame is obtained by first adjusting to neutral and then slowly opening the acetylene valve until an acetylene streamer or “feather” is at the end of the inner cone.

The length of this excess streamer indicates the degree of flame carburization. For most welding operations, this streamer should be no more than half the length of the inner cone.

The reducing or carburizing flame can always be recognized by the presence of three distinct flame zones. There is a clearly defined bluish-white inner cone, white intermediate cone indicating the amount of excess acetylene, and a light blue outer flare envelope. This type of flare burns with a coarse rushing sound. It has a temperature of approximately 5700ºF (3149ºC) at the inner cone tips.

When a strongly carburizing flame is used for welding, the metal boils and is not clear. The steel, which is absorbing carbon from the flame, gives off heat. This causes the metal to boil. When cold, the weld has the properties of high carbon steel, being brittle and subject to cracking.

A slight feather flame of acetylene is sometimes used for back-hand welding. A carburizing flame is advantageous for welding high carbon steel and hard facing such nonferrous alloys as nickel and Monel. When used in silver solder and soft solder operations, only the intermediate and outer flame cones are used. They impart a low temperature soaking heat to the parts being soldered.

The Oxidizing Flame

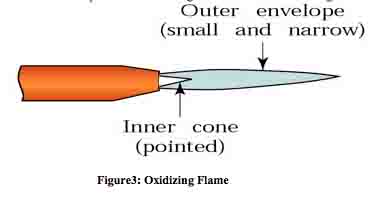

Oxidizing welding flames are produced when slightly more than one volume of oxygen is mixed with one volume of acetylene.

To obtain this type of flame, the torch should first be adjusted to a neutral flame. The flow of oxygen is then increased until the inner cone is shortened to about one-tenth of its original length. When the flame is properly adjusted, the inner cone is pointed and slightly purple.

An oxidizing flame can also be recognized by its distinct hissing sound. The temperature of this flame is approximately 6300ºF (3482ºC) at the inner cone tip.

Oxidizing welding flames are commonly used to weld these metals:

- zinc

- copper

- manganese steel

- cast iron

When applied to steel, an oxidizing flame causes the molten metal to foam and give off sparks. This indicates that the excess oxygen is combining with the steel and burning it.

An oxidizing flame should not be used for welding steel because the deposited metal will be porous, oxidized, and brittle. This flame will ruin most metals and should be avoided.

A slightly oxidizing flame is used in torch brazing of steel and cast iron. A stronger oxidizing flame is used in the welding of brass or bronze.

In most cases, the amount of excess oxygen used in this flame must be determined by observing the action of the flame on the molten metal.

Mapp Gas Welding Flames

The heat transfer properties of primary and secondary flames differ for different fuel gases. MAPP gas has a high heat release in the primary flame, and a high heat release in the secondary. Propylene is intermediate between propane and MAPP gas. Heating values of fuel gases are shown in table 11-3.

The coupling distance between the work and the flame is not nearly as critical with MAPP gas as it is with other fuels.

Adjusting a MAPP gas flame. Flame adjustment is the most important factor for successful welding or brazing with MAPP gas. As with any other fuel gas, there are three basic MAPP gas flames: carburizing, neutral, and oxidizing (fig. 11-3).

A carburizing flame looks much the same with MAPP gas or acetylene. It has a yellow feather on the end of the primary cone. Carburizing flames are obtained with MAPP gas when oxyfuel ratios are around 2.2:1 or lower. Slightly carburizing or “reducing” flames are used to weld or braze easily oxidized alloys such as aluminum.

As oxygen is increased, or the fuel is turned down, the carburizing feather pulls off and disappears. When the feather disappears, the oxyfuel ratio is about 2.3:1. The inner flame is a very deep blue. This is the neutral MAPP gas flame for welding, shown in figure 11-3. The flame remains neutral up to about 2.5:1 oxygen-to-fuel ratio.

Increasing the oxygen flame produces a lighter blue flame, a longer inner cone, and a louder burning sound. This is an oxidizing MAPP gas flare. An operator experience with acetylene will immediately adjust the MAPP gas flame to look like the short, intense blue flame typical of the neutral acetylene flame setting. What will be produced, however, is a typical oxidizing MAPP gas flame. With certain exceptions such as welding or brazing copper and copper alloys, an oxidizing flame is the worst possible flame setting, whatever the fuel gas used. The neutral flame is the principal setting for welding or brazing steel. A neutral MAPP gas flame has a primary flame cone abut 1-1/2 to 2 times as long as the primary acetylene flame cone.