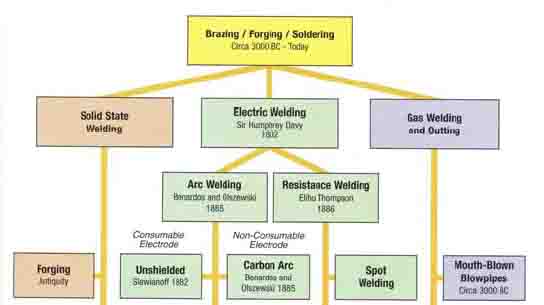

The answer to questions like who invented welding and when did it happen are hard to answer.

The development of modern welding was a long, slow, gradual affair.

Findings and inventions led to new discoveries, and so on. But for those who want to know, we have answers to some of the most common questions.

When Was Welding Invented?

Metalworking is ancient, beginning 7 to 8 thousand years ago. The first welding techniques appeared sometime in the fourth or third century B.C.

Modern arc welding emerged much later, starting in the late 19th century.

Where did Welding Originate?

Ancient civilizations, such as the Egyptians and Greeks, worked metal with the discovery of copper, bronze, silver, gold, and iron, then metalworking later progressed to include steel.

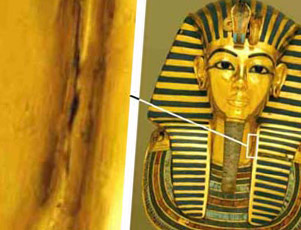

Gold ornaments made in the third century B.C are considered by many to be the first welded pieces.

So, welding is ancient, but in the beginning stages its use was reserved for special occasions. Gold jewelry for a Pharo for example.

When Was Welding First Used Widely?

Around 1800 B.C., forge welding appeared. This technology consisted of heating metal to a precise temperature, then fusing the pieces by pounding. It did not change for a long time and it was the first welding process that brought welding to the “masses.” It was even used to build an iron pillar in Delhi, India about 310 AD.

Forge welding is not the earliest known form of welding. But for the first time, welding could be used for more than just jewelry and weapons for the rich. Things like plows and other tools could now be fashioned for farmers and other working people.

In the 15th and 16th centuries, the image of a blacksmith pounding on a hot piece of metal became iconic. During the Industrial Revolution in the 17th and 18th centuries, when new ideas like blast furnaces came along, forge welding finally began to wane.

The Invention of Arc Welding

In the early years of the 19th century, two important events set the stage for modern welding, the discovery of the electrical arc in 1800 and acetylene in 1836.

When Was Arc Welding Invented?

In 1881, Auguste De Meritens, working in the Cabot Laboratory in France, created an arc that could weld lead, using carbon (i.e., graphite) electrodes based on Davy’s earlier findings. But it was not hot enough to weld iron.

Due to its limitations, many historians overlook this development as the actual invention of arc welding. But it is the first arc welder to appear.

Who Invented Arc Welding?

In 1800, Sir Humphry Davy formed the first electric arc between two carbon electrodes. This was the inspiration for all the forms of arc welding to follow in later years.

Acetylene was discovered by Sir Humphry Davy’s cousin, Edmund Davy, in 1836, providing a controllable heat source for welding and cutting. But it was not practical until about 1900 when a suitable blowtorch was developed. This was the start of oxyfuel welding and cutting and it is still popular today, mostly for cutting metal.

The First Welding Machine

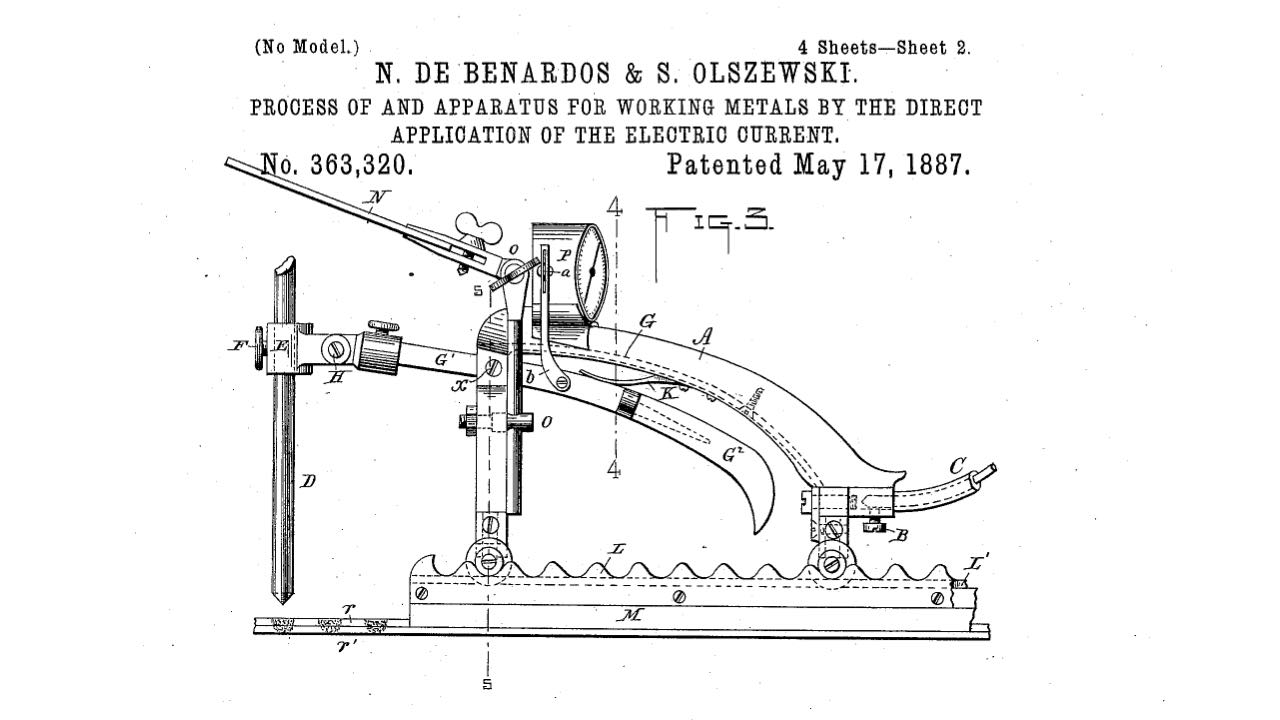

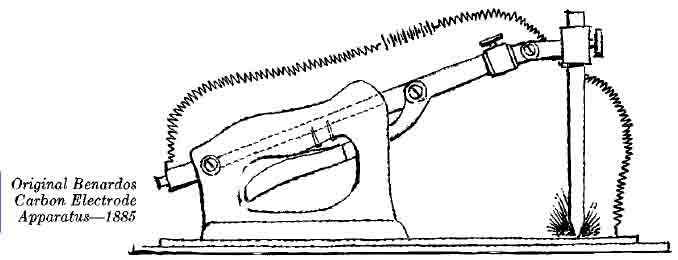

One of Meritens’s students, a Russian named Nikolai N. Benardos working in the French laboratory, received a patent for welding lead plates together. He, along with a fellow Russian, Stanislaus Olszewski, secured a British patent in 1885 and an American patent in 1887.

Notably, these patents detailed an early electrode holder and this is regarded as the birth of carbon arc welding. It is the first “machine” to appear designed to use an arc for joining two pieces of metal (in this case lead).

When Was Stick Welding Invented?

A Russian inventor, Nikolay Gavrilovich Slavyanov, introduced arc welding with consumable metal electrodes in 1888. This was the second form of arc welding invented, but it was also the first introduction of “stick welding.”

With the introduction of coatings on the metal electrode in later years to provide shielding for the molten metal, Slavyanov’s invention led to shielded metal arc welding (“SMAW”).

Notably, Slavyanov did not see his technique as a welding process, he instead called it electric casting of metals and envisioned its use in forging metal in a mold.

Later in 1890, C. L. Coffin received a U.S. patent for his arc welding method that utilized a metal electrode, similar to Slavyanov’s casting technique. Interestingly, Slavyanov and Coffin were unaware of each other’s work.

Who Invented Resistance Welding?

Elihu Thomson invented resistance welding sometime during 1876. Thomson, a prolific inventor, accidentally fused two copper wires together as he set up an experiment (Thomson was awarded almost 700 patents).

He made a note and later decided to try and weld metal at will with what he had stumbled upon. In 1886, he successfully patented his new resistance welding technique.

Birth of Widespread Electrical Power

Even with all the inventions by Thomson and others, modern electric welding did not take off until electricity was widely available in the early 20th century. Prior to easy access to AC current, electric welders ran on large batteries and it limited its use.

But Elihu Thomson not only invented resistance welding, he also played a key role in making the widespread use of electricity possible. In 1880, Thomson along with fellow science professor Edwin Houston established the Thomson-Houston, to sell arc lamp systems. They were successful and quickly diversified into other electrical markets.

By 1890, Thomson-Houston and Thomas Edison’s company, Edison General, were two of the three biggest players in the American lighting industry (Westinghouse Electric Co. was the third).

By 1892, financier John Pierpont Morgan engineered a merger between Edison General and Thomson-Houston. The resulting company was named General Electric. GE and Westinghouse then figured out how to use alternating current (“AC”) and spread electric power to the masses.

Thomson at General Electric and another famous inventor, Nikola Tesla at Westinghouse, led the way in pioneering the modern use of alternating current. (Famously, Thomas Edison had favored DC, but it could not be transmitted over long distances safely.)

When the existing electric-powered welding technologies were combined with the widespread availability of electricity, arc welding became viable for most applications. But prior to WW I, welding of critical joints, like in shipbuilding, was avoided due to frequent cracking. However, the need for fast, military-grade welds during WW I and WW II drove significant development, resulting in considerable arc welding advances.

Who Invented TIG Welding?

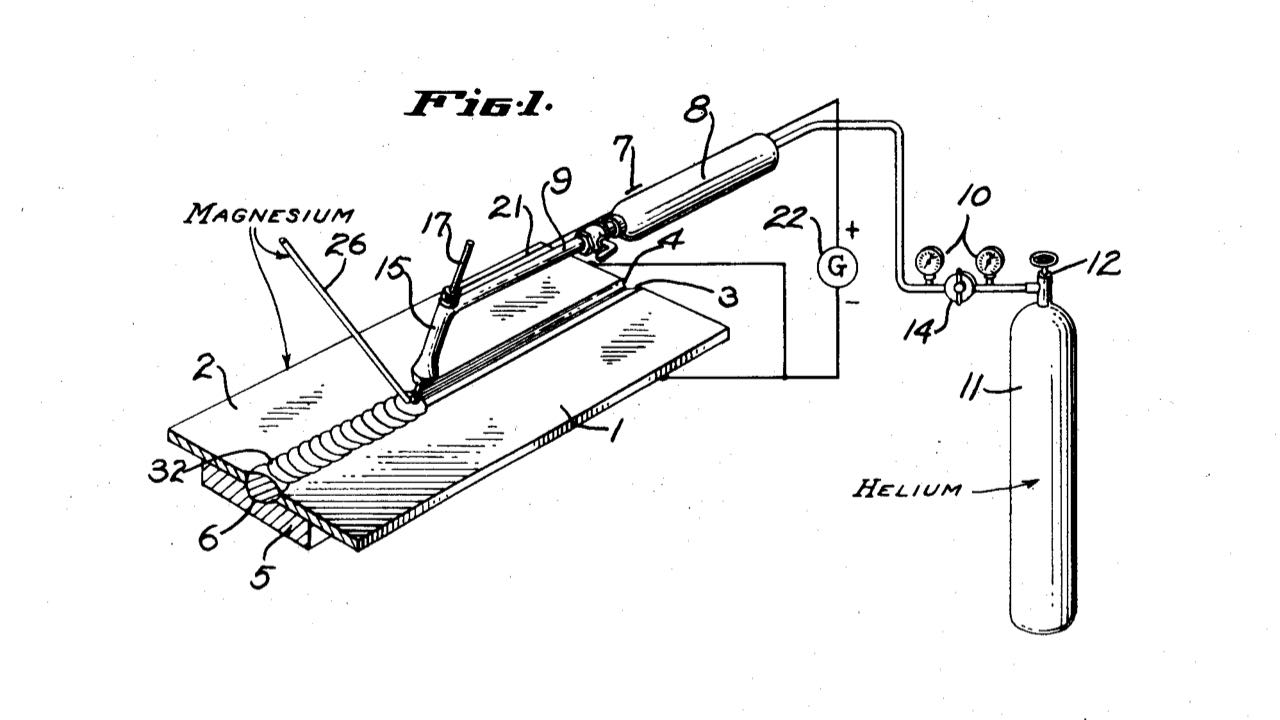

A significant advance occurred when Russell Meredith was issued a patent in 1942, which was the birth of TIG welding.

The available methods at that time were inadequate for welding aluminum and magnesium alloys. So, Meredith concocted an arc welding process that used a non-consumable tungsten electrode and an inert shielding gas (argon or helium) to protect the hot weld and electrode.

He called it the Heliarc system, but it eventually became known as gas tungsten arc welding (“GTAW”), or tungsten inert gas (“TIG”) welding.

TIG welding was a huge success and gave American industry the ability to build ships, airplanes, and other important items faster than ever imagined. President Roosevelt even bragged about the process in a letter to Winston Churchill.

Who Invented MIG Welding?

MIG welding was invented in 1948. The work done leading to this breakthrough was conducted by H.E. Kennedy of the Battle Memorial Institute, and H.M. Hobart and P.K. Devers at the Air Reduction Company.

This new process became commercially available and it was referred to as gas metal arc welding (“GMAW”), or metal inert gas (“MIG”) welding.

The tungsten electrode in the TIG process was replaced with a continuously fed, smaller diameter electrode wire and it used a constant voltage power source. Plus, the hot weld was protected by a shielding gas.

Metalworking and Welding Timeline

Metalworking and welding have a long history with research and developments continuing to this day. The timeline below highlights major developments with a focus on the welding of metals.

Welding B.C.

4000 B.C.

The first metalworking is thought to take place in Egypt, starting around 4000 B.C. In general, ancient civilizations started with copper and then progressed to bronze, silver, gold, and iron.

3000 B.C.

Sumerians produce swords that are made using hard soldering.

Egyptians use charcoal-generated heat to turn iron ore into sponge iron. The particles produced are hammered together producing the first instance of pressure welding (also called solid phase welding).

Queen Pu-abi’s tomb contains a gold bowl with a handle that is brazed to the bowl’s wall. Gold goblet also discovered that has a brazed fillet on the outside of the goblet.

3000 – 2000 B.C.

Humans start working with bronze between 3000 and 2000 B.C. to make things like jewelry, dining utensils, and weapons. During this bronze age, small gold circular boxes were made by pressure welding lap joints together.

1500 B.C.

Instances of iron smelting (becomes more common in 1200 B.C.).

1475 B.C.

A painting depicts brazing in the tomb of Vizier Rekh-mi-re.

1330 B.C.

Ancient Egyptians use solder and a blowpipe for metal soldering.

Welding and Cutting Journal 2005

1000 B.C.

Ironwork begins, bending the metal with the use of furnaces to produce swords and spearheads (e.g., the Catalan furnace).

Gold boxes in Ireland are fabricated by hammering lapped joints (a form of pressure welding).

900 to 850 B.C.

Egyptians make iron tools. In this era, iron grew slowly in popularity due to the familiarity and usefulness of bronze and copper.

Iron weapons have been found that can be traced to the Babylonians from about 900 B.C.

589 B.C.

During the Sui Dynasty, the Chinese developed the ability to turn wrought iron into steel.

The Japanese also manufacture steel through a welding and forging process to produce Samurai swords.

A.D. Welding History

60 A.D.

Pliny the Elder records the first written description in welding history of a gold brazing process. He describes how salts acted as a flux and how metal color determines brazing difficulty (i.e. color indicates the presence of oxides).

310 A.D.

Forge welding used in the Iron pillar in Delhi, India, weighing a total of 5.4 metric tons. (pictured above).

Other structures, weapons, and tools with similar construction are made in England, Scandinavia, and Rome. Interestingly, the source of iron for some theweapons and tools was meteors.

1000 – 1099 A.D. (11th Century)

The manuscript written by monk Theophilus includes a description of mixing flux for silver brazing. He indicates the use of sodium chloride and potassium tarpate. Metals are 66 percent Silver-Copper.

1375

The Middle Ages (5th to 15th century) brought a phase in welding history where forge welding was dominant.

14th Through 17th Centuries

1540

Vannoccio Biringuccio released De la Pirotechnia, which includes written descriptions of the forging operation.

Renaissance craftsmen gained skilled with the welding process, and welding continued to grow during the following centuries.

1568

Benventuto Cellini, an Italian goldsmith, writes about brazing a silver/copper alloy using a soldering process

1599

The first instance of the root word for weld (originally well). Also, the first cast-iron cannon is produced sometime in the 16th century.

18th Century

Most innovations during this time in welding history involved blast furnaces. Small incremental progress lasted until the middle of the 18th century and the beginning of the industrial revolution.

Even in the latter part of this century, though, the progress was more in how work was performed. For example, instead of one person completing an entire project, work was divided into smaller parts and assigned to semi-skilled labor.

1735

Evidence that platinum was used by pre-Columbian Indians in Ecuador.

1751

Axel F. Cronstedt, a Swedish chemist, discovers nickel and isolates it from a German ore.

1766

Hydrogen gas properties are described by Henry Cavendish, an English chemist and physicist.

1774

Discovery of oxygen.

1776

Lavoisier, a French chemist, establishes the principles of oxygen cutting.

19th Century

1800

Sir Humphrey Davy produces an electric arc between two carbon electrodes that were powered by a battery. It is the dawn of modern arc welding.

1808-1827

Sr. Humphrey Davy proves that aluminum exists and it is actually discovered by Friederich Wohler in 1827.

1828

Sponge platinum is welded together via cold-pressing, followed by hammering when hot.

1836

Acetylene is discovered in 1836 by Edmund Davy, but it was not practical in welding until about 1900 when a suitable blowtorch was developed.

1838

Patent issued to Eugene Desbassayrs de Richemont for fusion welding.

1839

Discovery of voltage generation with a homopolar device by Michael Faraday.

1841

Air hydrogen blowpipe developed by German H. Rossier for soldering lead.

1846

James Nasmyth, while working for the British Admiralty, discovers that preparing welding surfaces with a slightly convex profile facilitates squeezing the swarf and flux out of the joint. This increased the strength of the joint and was a major improvement in the forge welding process.

1856

James Joule welds a bundle of wires by using an electric current and the metal’s internal resistance to create heat. The resistance welding process was later perfected by Elihu Thomson.

1865

An Englishman, Henry Wilde, obtains the first electric welding patent in 1865. He joins two small pieces of iron by passing an electric current through the two separate parts, producing a fusion weld.

1876

The Otto Bernz Company develops and sells a gasoline-powered torch.

1881

The first documented use of fusion welding by Auguste de Meritens where he welded lead battery plates together with a carbon electrode. The welding took place in a box with a fixed electrode.

Advances in welding continued with the invention of the metal electrode by a Russian, Nikolai Slavyanov, and an American, C.L. Coffin, late in the 1800s. They were not aware of each other’s work.

Credit also goes to Eli Whitney who invented the idea of interchangeable parts. This led to the manufacture of iron dies and molds.

1885

Carbon arc welding uses an arc between a carbon electrode and the weld pool. The process is used with or without shielding or the application of pressure. The primary stated use was repair welding.

A patent is issued to Auguste de Meritens and N. Benardos, which notes that the carbon welding process can be used for welding two metals, severing metals, and punching holes in metal. The patent described both a solid carbon electrode and a hollow electrode that would be filled with powdered metals.

Since they intended the powder to melt and flow into the weld, they are credited by some with inventing metallic arc welding. Ultimately because of the limitations of this approach, they are not credited with this accomplishment by most historians, but this is the first appearance of an electric arc welding machine.

1886

Elihu Thomson applies for 2 process patents for “Apparatus for Electric Welding,” which marks the invention of resistance welding (RW). The first of many patents went to Elihu Thompson in 1885, but he continued to produce advances over the next 15 years and he held around 700 patents.

1888

A Russian, N.G. Slavianoff, is credited by most historians for discovering the use of bare metal electrodes for arc welding. He used the innovation to transfer metal across an arc, not to weld, but to cast metal into a mold.

Two students of Auguste de Meritens, N. Benardos and S. Olszewski, continue his work and were issued a patent for a welding process that used carbon electrodes (carbon arc welding) and an electric power source.

1889 – 1892

C.L. Coffin is considered to be the pioneer of welding in the United States and some of his more notable accomplishments are::

- 1889: received patent for flash-butt welding

- 1890: 2 patents for spot welding.

- 1890: Awarded first patent for metal electrodes.

- 1892: Patent for bare metal electrode arc welding process is awarded.

1890

The first known instance of a “torch” being used to break into a bank vault.

1892

Commercial acetylene is produced in North Carolina by mixing water and calcium carbide.

Baldwin locomotive begins to use carbon arc welding for locomotive repairs.

1895

Combustion of acetylene and oxygen discovered by Henri LeChatelier.

1897

Kleinschmidt introduces the use of copper electrodes.

20th Century Welding

1900

Around 1900, A. P. Strohmenger developed a coated metal electrode in Britain, which produced a more stable arc.

1901

Oxygen Lance invented by Ernst Menne.

1903

Edmond Fouché and Charles Picard develop the first commercial oxyacetylene welding torch. Oxyfuel welding can now be safely used without the application of pressure to the joint.

Thermite welding is invented.

First machine for resistance butt welding is introduced after merger between Allgemeine Elektricitats-Gesellschaft (AEG) and Union-Elektricitats-Gesellschaft (UEG).

1906

First resistance spot welding machines are produced. From 1906 to 1910, approximately 367 spot and seam welding machines are produced.

The LaGrange-Hobo welding method is introduced.

1907 – 1908

Oscar Kjellberg receives a patent for an electrode coating process for the shielded metal arc welding (“SMAW”) process. The coating helped to stabilize the arc, producing better welds than simpler, bare metal electrodes. A reaction of the coating with the weld’s heat also effectively shielded the weld, eliminating the need for a gas blanket.

The U.S. arc welding industry starts with two companies. The Siemund-Wienzell Electric Welding Co. is formed and they patent a metal arc welding method. A second company, also with German founders, starts up and is called Enderlien Electric Welding Co.

Lincoln Electric tests the first variable voltage DC welding machine.

1908

Bernardos patents the electro-slag process which enabled workers to weld thick plates in a single pass. The process he outlined is still popular today.

1909

A plasma arc system using a gas vortex to stabilize the arc is invented by Schonner while working at BASF.

The Quasi-arc electrode is invented, where the electrode is wrapped with an asbestos yarn by A.P. Strohmenger.

1910

Patent issued to Charles Hyde for brazing steel tubes with copper placed in the joint. The workpiece was then placed in a hydrogen furnace (i.e., oxygen-free environment) and heated, then capillary attraction drew the molten copper into the joint.

1911

The first 11 miles of pipeline is laid using oxyacetylene welding, just outside of Philadelphia.

Matters develops the plasma arc torch for heating a metal fusing furnace.

1912

Oscar Kjellberg receives a second patent for an electrode with a heavier coating of asbestos and a binder made out of sodium silicate.

Lincoln Electric introduces the first commercial welding machines to the market.

The first auto body is welded by E.G. Budd using spot welding.

Coated metal electrodes introduced by A.P. Strohmenger. The coatings were made from clay or lime. Also awarded a patent for an electrode coated with blue asbestos and a sodium silicate binder. This is the first time a consumable electrode produces an impurity-free weld.

1919

Alternating current welding is invented by C.J. Holslag but it did not become popular for another decade. Electric arc welding was the method used in the United States until 1920. However, the arc was unstable and the welds produced were not as strong as the metal being welded.

At first, oxyfuel welding was more popular due to its portability and relatively low cost. As the 20th century progressed, it fell out of favor for industrial applications and was largely replaced with arc welding, as electrode coverings or coatings (i.e., flux) continue to be developed. The coatings applied to the metal electrodes stabilized the arc and shielded the base material from impurities in the air.

Ship welding was not reliable due to frequent cracking until World War I. But during WW I, various military powers caused a major surge in the use of welding processes as they tried to determine which of the several new welding processes worked best.

1917

Gas shortage in England resulted in the industry turning to electric arc welding for producing bombs and mines.

1919

President Wilson establishes the United States Wartime Welding Committee of the Emergency Fleet Corporation.

The American Welding Society is established.

Development of the paper coated electrode by Reuben Smith.

The 1920s

During the 1920s, major advances were made in welding technology, including the introduction of automatic welding in 1920, where the electrode wire was fed continuously.

Shielding gas use received much attention, as scientists attempted to protect welds from the effects of reactive gasses in the atmosphere.

Porosity and brittleness were the primary problems, and the shielding that scientists developed included the use of gases like hydrogen, argon, and helium, or blends of them, as a protective layer of gas while the weld was hot.

The stick welding process also advanced quickly due to the improvements in the core wire and electrode coatings.

Also, X-ray technology made it possible to check the soundness of a weld. Some other notable 1920s’ events are:

- The British primarily used arc welding, and they even constructed a ship, the Fulagar, with an entirely welded hull. At one point the ship ran aground and stayed whole because it was welded and not riveted.

- The Americans were more hesitant but began to recognize the benefits of arc welding when the process allowed them to repair their ships damaged in New York Harbor at the beginning of the war. The source of the explosion and fire were disputed, but the repairs put welding on the map.

- Arc welding was first applied to aircraft during the war as well, as some German airplane fuselages were constructed using the process.

- General Electric employee P.O. Nobel developed direct current automatic welding.

- Before 1920, welding was done with D.C. current, which was provided by batteries. In the late 1920s to early 1930s, A.C. welding gained popularity.

1923

Founding of the Institute of Welding Engineers.

1924

The first all-welded buildings constructed by U.S. Boiler.

1925

Half of the American homes have access to AC electricity (it increased to 75% in 1930, and by 1940 most homes except very rural areas). This is due in large thanks to the work of men like Elihu Thomson at General Electric and Nikola Tesla at Westinghouse. Credit also goes to men like Ampere, Oersted, Wheatstone, Faraday, Ohm, and Henry for advances in generating and distribution of electricity during almost 100 years leading up to this point. The widespread availability of electricity was vital for electric arc welding’s growth.

1926

P.K. Devers and H.M. Hobart test welds using a blend of helium and argon as a shielding gas.

The Naval research laboratory releases a paper on the use of X-Rays to test welds.

1927

A.O. Smith employee John J. Chyle patents the first extruded all position titanium electrode later called the E6010 type.

1928

First welded railroad bridge created by Westinghouse to transport large generators.

1929

Lincoln Electric produces the Fleetwood 5 heavy coated electrode.

American Welding Society establishes welding symbols.

1930

Patent issued to H.O. Hobart for arc welding process with a new “automatically” fed electrode, which later became GMAW (Gas Metal Arc Welding) or MIG welding.

Submerged arc welding developed by the National Tube Company, and continues to be popular today.

An all-welded merchant ship created.

Stud welding was introduced to the market, which soon became popular in shipbuilding and construction.

By 1930, arc welding was lower in cost than riveting and gas welding.

Patent issued to Devers and Hobart for use of an electric arc within an inert gas atmosphere. Not well received by the welding industry initially because of the high cost of gas (helium and argon) and poor torch availability.

1931

Welding of stainless steel (originally called shot welding) by E.G. Budd Manufacturing.

1934

A timing controller for resistance welding is developed by Westinghouse (originally called an Ignitron).

1935

SAW (submerged arc welding) process that uses continuous wire feed and granulated flux is introduced. The process was originally called Union Melt. Submerged arc welding was later used during the defense buildup in shipyards and ordnance factories. It is one of the most productive welding processes and remains popular today. The concept of an automatically fed wire electrode would later be used to invent MIG welding.

British welding electrode standard established.

Solid extruded electrode released.

1936

First A.C. welding machine introduced by Miller Electric Manufacturing. The method had a high rate of metal deposition (ratio of the deposited metal’s weight to the net weight of electrodes consumed) and an absence of arc blow (the deflection of an electric arc from its normal path due to magnetic forces).

1937

The use of welding is confirmed in structural steel buildings (metal arc welding in mild steel).

1938

Gravity welding introduced by K.K. Madsen.

Germans weld ships to reduce weight which allows for the design of larger vessels.

German patent given to George Hafergut for the Firecracker welding process.

1939

Use of aluminum spot welding recognized for aviation use.

1940 – 1941

Gas tungsten arc welding (GTAW), after decades of development, was finally perfected in 1941 (patent issued in 1942). Invented by Russel Meredith, he initially called it HELIARC. But it later became known as tungsten inert gas (“TIG”) welding. The water-cooled torch could use high amperage and not get too hot to hold. Gas Tungsten arc welding uses an arc between a non-consumable tungsten electrode and the weld pool. The process is used with shielding gas and without the application of pressure to the joint. The TIG process worked well for magnesium, stainless, and aluminum.

Army discovers the practicality of stainless steel, aluminum, and magnesium in equipment such as fighter planes.

Formation of the Canadian Welding Association.

Dip soldering technique developed for printing wiring boards. It is the first mass soldering process.

1942

US Patent issued to George Hafergut for Firecracker Welding.

U.S. patent issued for GTAW welding (i.e., TIG welding) to Russel Meredith of Northrup Aircraft, Inc., which was developed for Dr. John K. Northrup’s XP-56 airplane body.

1943

Gas metal arc welding (GMAW) is invented by C.B. Voldrich, P.J. Rieppel and Howard B. Cary. Developed at Dow and Northrup Corporations and then licensed to Linde Corporation.

The Sciaky company starts to sell a three-phase resistance welder.

1945

Development of an experimental hand-held MIG gun at the Battelle Memorial Institute (Columbus, Ohio)

Welding replaced riveting as the main method of assembly for ships with 5,171 vessels constructed through 1945.

1948

Gas metal arc welding became commercially available in 1948 (“GMAW” superseded earlier terms of metal inert gas (MIG) and metal active gas (MAG)), allowing for fast welding of non-ferrous materials, but requiring expensive shielding gases.

The “shielded” inert gas metal arc process was introduced by the Air Reduction Company at the AWS show in Philadelphia. Gas metal arc welding uses an arc between a continuously fed metal filler/electrode wire (i.e., consumable) and the weld pool.

The process also used shielding from an externally supplied gas and without the application of pressure to the joint. Initially, the GMAW process was used only for non-ferrous metals due to cost.

The first Department of Welding Engineering department is started at Ohio State University.

SIGMA (Shielded Inert Gas Metal Arc) welding developed to weld thicker plates.

1949

Westinghouse introduces Selenium Rectifier welding machines.

1950s

Shielded metal arc welding was developed during the 1950s, using a consumable electrode and a carbon dioxide atmosphere as a shielding gas. It quickly became the most popular metal arc welding process.

A.C. – D.C. rectifier welding machines were introduced with built-in frequency for TIG welding. Miller Electric developed the Miller controlled wave a.c. welder which was used for critical welds on missiles and aircraft.

Electric beam welding process launched by A.J. Stohr.

Wave soldering to attach electronic components to printed cicuit boards is introduced.

E.O. Paton welding institute develops Electrostag Welding (ESW).

1951

The DryRod electrode oven was introduced to control moisture levels in electrodes.

1957

Flux-cored arc welding process debuts (FCAW), where a self-shielded wire electrode could be used with automatic equipment, resulting in greatly increased welding speeds.

Plasma arc welding is invented. Patented in 1957 by the National Cylinder Gas Company.

1956

Friction welding process was introduced by Russia.

1958

Electroslag welding released and it was later followed by its cousin, electro-gas welding, in 1961.

Other recent developments in welding include the breakthrough of electron beam welding, making deep and narrow welding possible with a concentrated heat source.

1958 – 1959

A short arc process was introduced (sometimes called GMAW-S). The process uses wires with small diameters and a refined power supply.

1960

Following the invention of the laser in 1960, laser beam welding would debute several decades later and has proved to be especially useful in high-speed, automated welding. This process, however, is quite expensive due to the high cost of the necessary equipment. So, it has limited applications.

Explosive welding is introduced.

1962

Sciaky, Inc. welds Mercury Space capsule (created with an outer and inner titanium shell).

Due to the small size of each titanium sheet, three metal layers needed to first be welded together, and then the triple-ply sheets needed to be welded to form larger panels. The TIG process was employed without using a filler metal. Source: NASA Manual, Welding Procedures for Titanium and Titanium Alloys

1963

Marked by developments in weld testing. The Varestraint Test determines if a base metal can be welded as well as the viability of different welding processes for the alloy.

Wall-Colmony introduces the Fusewelder Torch.

The fuse-welder is an oxyacetylene torch that is frequently used when a weld needs to be built up and to finish hard surfacing welds.

1965 – 1967

Welding and cutting with CO2 lasers.

Gravity welding starts in the U.K.

1969

Russians weld in space on SOYUZ-6.

1970

New soldering technologies are introduced to support electronic miniaturization, like:

- Vapor phase

- Infrared

- Hot gas

Modern Welding

Today there are over 90 welding processes with constant research on new metals used by the nuclear, space, and shipbuilding industries. Many changes occurred in the 1980s and 1990s where welding moved from art to science.

- Robotic welding

- On-board computers

- State-of-the-art electrodes

- Exotic multiple gas mixes

1991

Friction Stir welding introduced by TWI.

1999

The Edison Institute develops a method that leads to a 300% increase in flux penetration into a weld.

2000

Introduction of magnetic pulse welding.

An X-Ray is used to weld a metal/matrix composite.

Diode laser welding, once limited to compact disks, laser printers, and laser pointers, is used in manufacturing to weld Type 304 Stainless steel (0.024 inch) and Titanium foil (0.005 inch thick), plus laser brazing with a silicon-bronze brazing wire.

2008

Development of laser-arc-hybrid welding.

2013

Development of Gas Metal Arc Welding-Brazing, a process for welding steel used in autos. The process uses a filler metal comprised of silicon with a copper alloy.

Low-carbon steel and aluminum welding using a lap joint and laser technology.

2015

Vaporizing Foil Actuator Welding (VFAW) developed by The Ohio State University joins dissimilar metals. The process is a similar to a combination of explosive welding (ExW) and magnetic pulse welding (MPW).