Welding is the practice of joining separate metal pieces by melting, then fusing them.

There are quite a few welding processes, including many you may never have heard of.

Some high-tech methods use lasers, microwaves, or electromagnets.

There are also low-tech methods like melting with a torch or forge, then hammering two pieces into one.

Here’s a look at the four most commonly used welding processes.

Four Common Types of Welding Processes

There are many types of welding processes, but the four most common welding processes are:

- MIG Welding (GMAW)

- TIG Welding (GTAW)

- Stick Welding (SMAW)

- Flux Cored Arc Welding (FCAW)

Some of the reasons they’re so dominant:

- Industrial demands

- Affordability for DIY craftsmen

- With TIG welding, very high quality is key.

- Easy to learn (except TIG)

They’re all arc welding processes, meaning the workpiece, the grounding clamp, and the electrode complete an electrical circuit when the electrode makes contact. Lifting creates an arc.

This arc of electricity reaches thousands of degrees, melting the metal and causing separate pieces to flow together. The electrode uses a filler metal that melts and fills the gap, becoming part of the single piece of metal.

Thousands of degrees of surface heat generate chemical reactions with air and substances like oil or rust. Oxygen and nitrogen cause brittleness, rusting, porosity, and possible failure.

Each process shields the molten weld puddle from air and surface contaminants by flooding the arc region with inert gases, which don’t react to other chemicals. Finished welds are much stronger, more consistent, and much cleaner without contacting the air while reaching fusion.

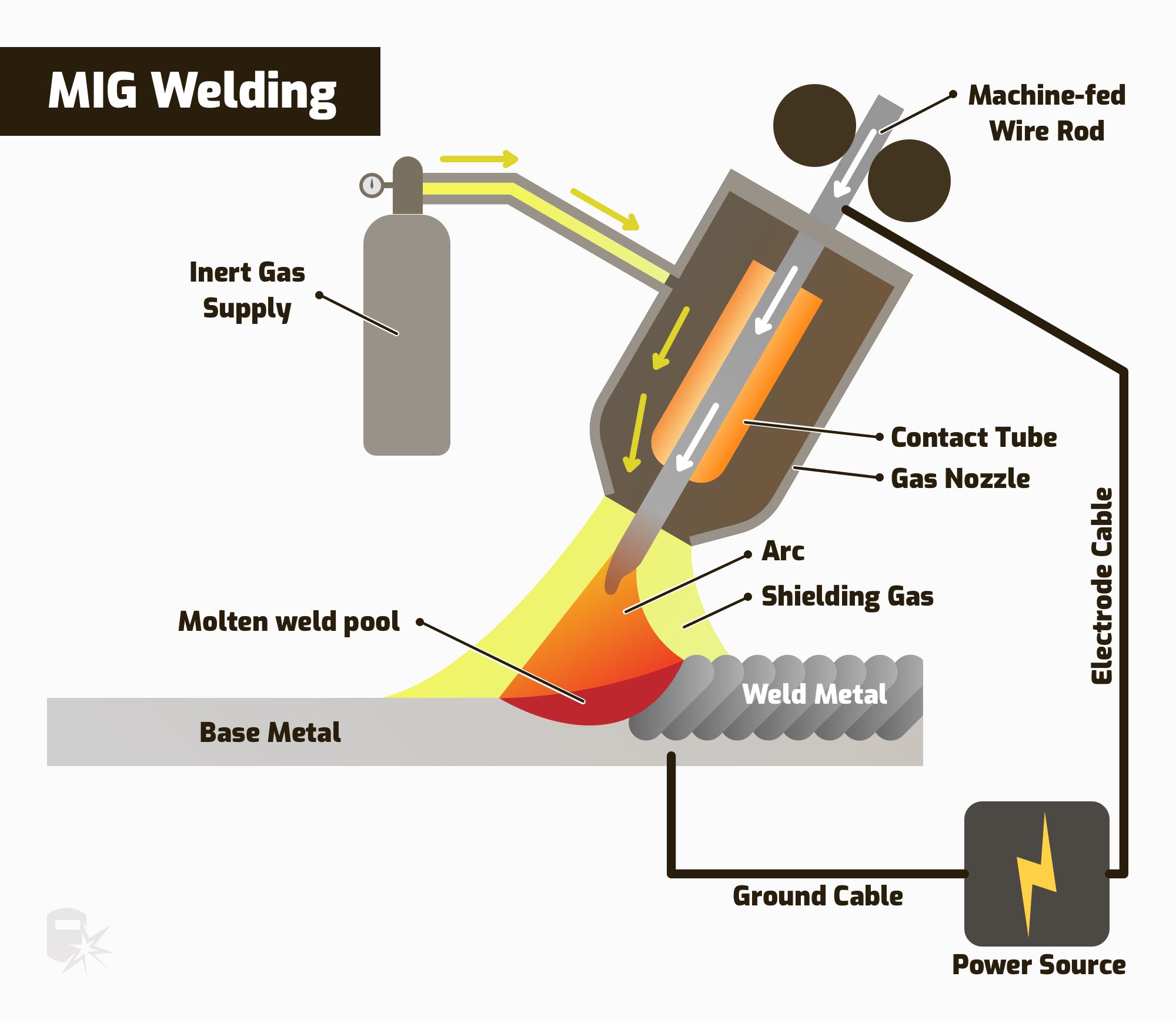

1. GMAW: Gas Metal Arc Welding (MIG Welding)

With MIG welding, the shielding gas comes from a pressurized bottle of inert gas. The arc is produced by a wire that also melts, filling the joint.

How It Works

GMAW welding is usually called MIG. In this process, the electrode is an electrically charged wire, continually feeding from a motorized spool into the weld while also flooding the shielding gas over the weld.

The welding lead to the MIG gun connects the power, has a sleeve inside to slide the electrode wire, and includes a gas hose as part of the MIG torch connection.

The shielding gas for MIG is usually carbon dioxide.

When It’s Used

If speed is an issue, you’re a beginner, or you need to keep the heat down, MIG welding is your best process. The shielding gas adds a layer of complexity but also provides good heat control and a clean weld.

Pros

- Good for production welding

- Continuous wire feed means easy to learn

- Good heat control

- Clean welds

- Easy to learn

Cons

- Wind can blow away the shielding gas

- All paint and rust must be removed

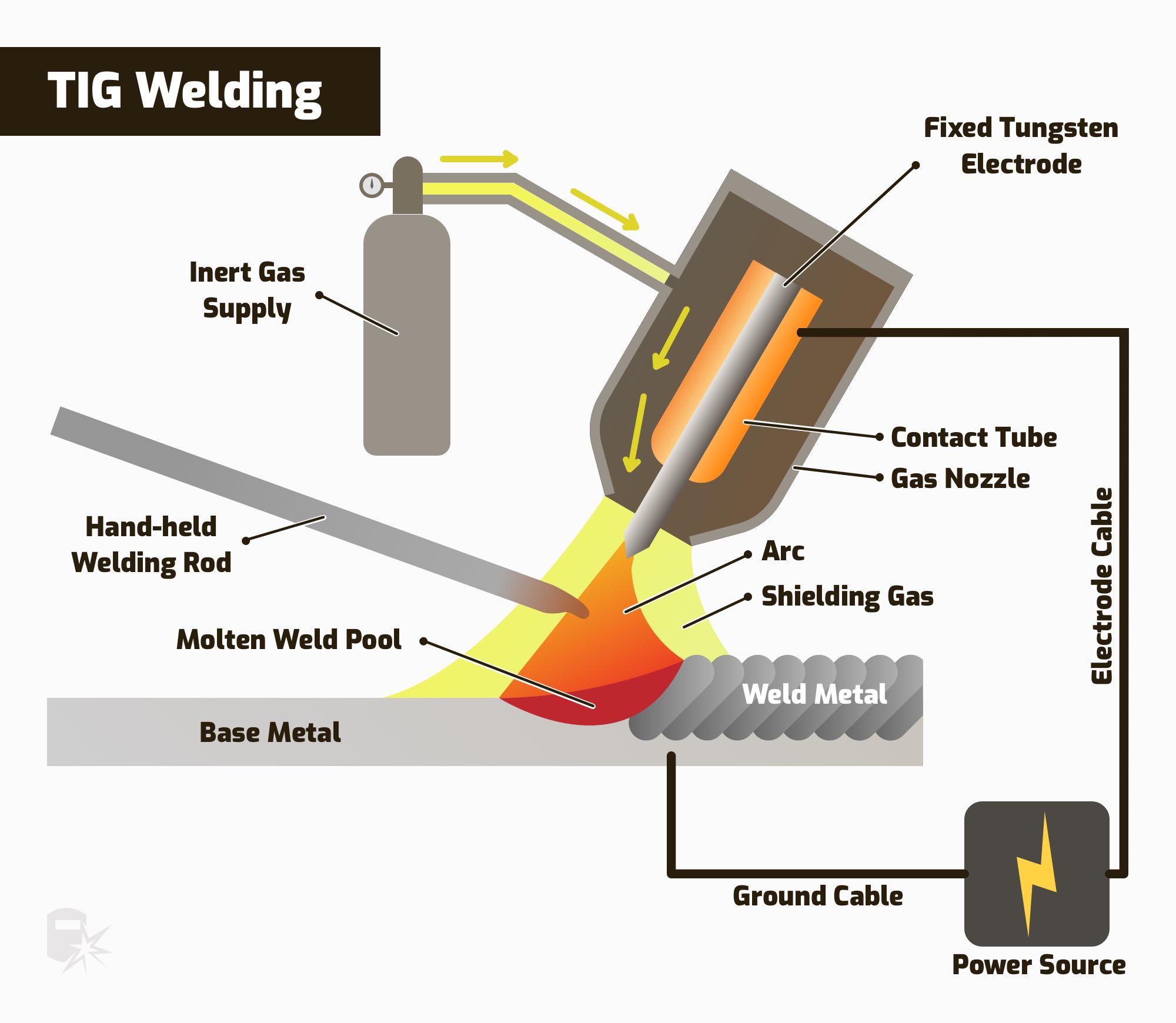

2. GTAW: Gas Tungsten Arc Welding (TIG Welding)

TIG is a difficult process to master. It takes more knowledge, dexterity, time, and experience than other processes but pays off with better, more beautiful, and stronger welds.

How It Works

The main way TIG differs from other processes is its electrode. The electrode in the torch is a short tungsten rod, sharpened to a point.

The difference is that the electrode isn’t consumed. Instead, while working the torch with one hand, the operator feeds a long rod made of filler metal into the weld puddle. This metal rod is consumed by the weld puddle. The electrode only strikes and maintains the arc to melt the metal as a flame torch would.

Favorable results depend greatly on the operator to handle the torch well, control the heat level and feed the filler rod at just the right speed. Like a MIG setup but with no wire feeding mechanism, the TIG torch connection carries pressurized inert gas to flood the arc region. The usual shielding gas for TIG welding is argon.

When It’s Used

TIG welding is used in places where strong and clean welds are needed. Some structures made by TIG welding are covered once built and can’t be maintained easily. Aircraft frames, electric devices, high-end electronics cabinetry, and race car roll cages are some examples.

Another case for TIG is the opposite situation, where the weld is always visible and requires a certain level of eye appeal or high-tech validation. Exposed hot rod frames, custom bodywork, or designer lawn furniture are some instances.

Pros

- AC TIG welds aluminum and magnesium alloys

- DC TIG welds brass, copper, steel, stainless steel, and titanium

- Best quality, highest precision

- Able to weld very thin materials

- No slag

Cons

- It takes more skill and experience to master

- TIG machines are more costly

Related read: Differences Between MIG & TIG

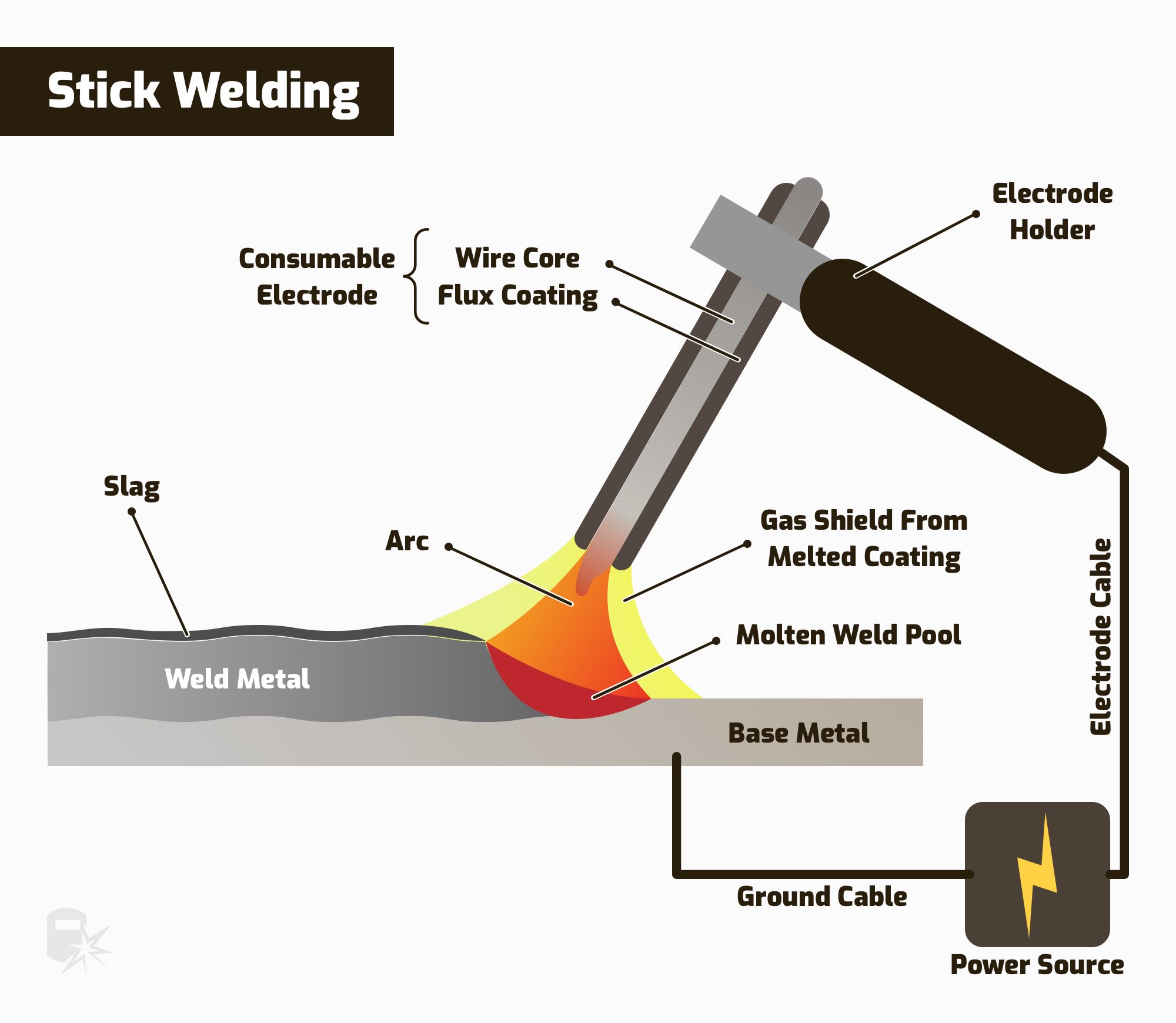

3. SMAW: Shielded Metal Arc Welding (Stick Welding)

Stick welding came first, and it’s the simplest concept. People have been stick welding since the late 1800s. It has the oldest, simplest, and most proven technology.

How It Works

A stick welder has a power source and big cable leads with an electrode holder on one lead and a heavy clamp for the workpiece on the other. The electrode is a metal rod, like a piece of thick wire. They come in different metals and alloys.

The diameter of the welding rod varies. It’s selected according to the thickness of the metal. Welding rods are covered with a thick coating of a material called flux that burns in the arc, generating a gas to shield the welding puddle.

As the metal cools, the flux forms a thin, brittle crust called slag that must be chipped off and brushed away.

When It’s Used

If it can be welded at all, it’s welded by stick. Stick arc is preferred when it’s hard to reach the weld, or there’s rust, oil, and other contaminants at the weld joint. It works well on steel, cast iron, aluminum, stainless, and hard surfacing on farm equipment.

Pros

- Easy to learn

- Affordable

- Not contaminant sensitive

- You can weld almost any metal

Cons

- Thin metal can be hard to work

- Generates a lot of heat.

- It takes a lot of time

Also read: Differences between MIG and Stick

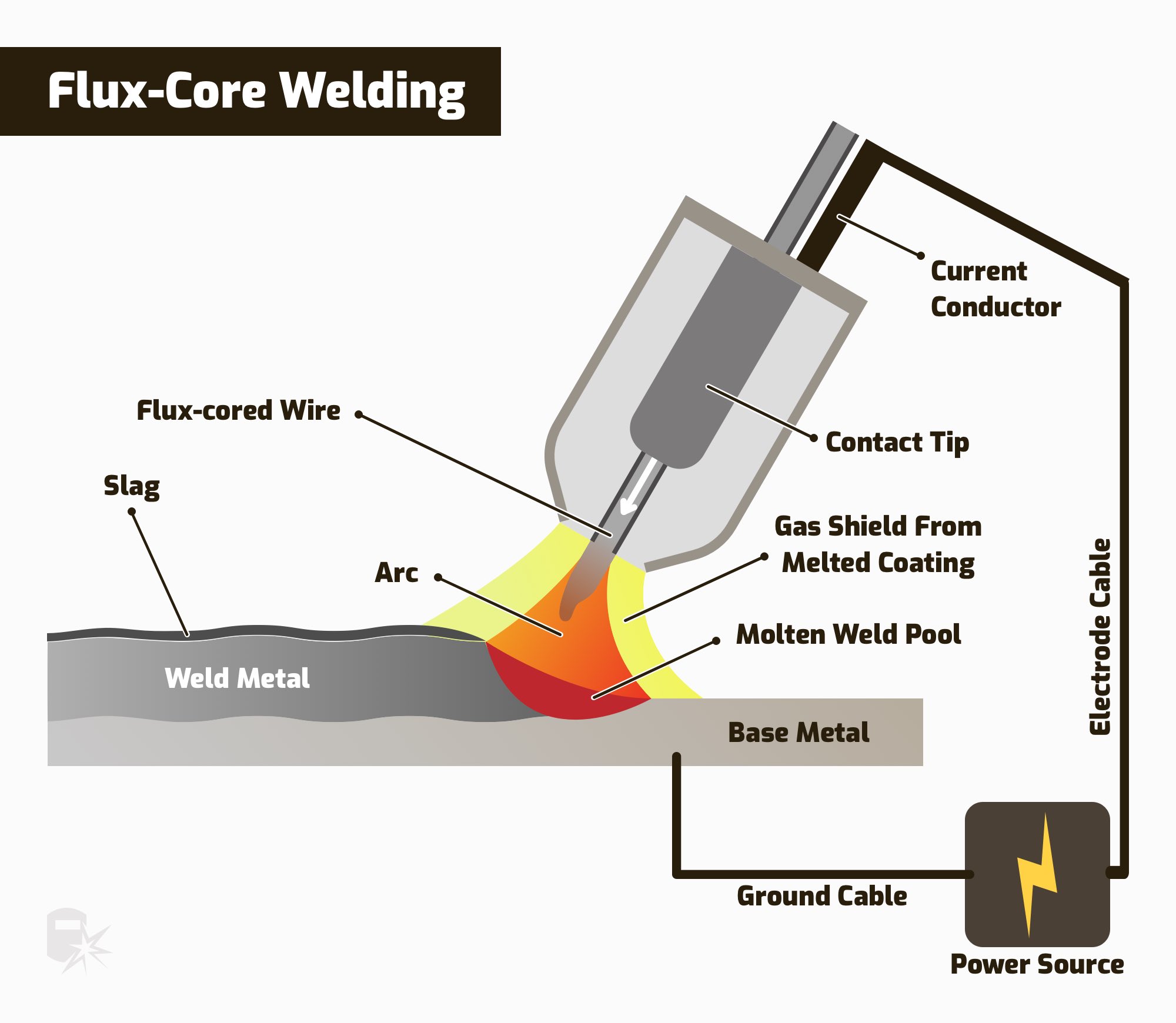

4. FCAW: Flux Cored Arc Welding

Flux core welding. also known as gasless MIG welding, is a highly versatile process known for low cost, easy learning, and strong results. It’s also used in manufacturing, but with shielding changes and bigger machines.

How It Works

Like how the stick process has an electrode coated in flux, the FCAW process uses a hollow wire filled with flux.

FCAW feeds a spool of wire through the welding lead as MIG does. You can weld faster than stick welders because the only time you change the electrode is when the wire spool runs out.

FCAW-S and FCAW-G

There are two flavors of flux core welding in main use.

FCAW-S

The “S” means “self-shielded,” and it’s the most common flux core technique because it’s inexpensive, simple, and effective in a breeze.

FCAW-G

Also known as dual-shielded wire welding, the “G” means that an external shielding gas is used in addition to the standard flux core wire. This approach provides a smoother, more controllable arc than FCAW-S and MIG processes.

When It’s Used

Most commonly, flux core welding is seen among hobbyists, small businesses, and fabrication shops because it provides great penetration, heat control, and ease of use at an inexpensive cost compared to MIG welding.

Pros

- Probably the easiest process to learn

- Works well on dirt, paint, and rusty material

- Can be used in windy conditions

- Handles thick steel well

Cons

- Slag needs to be removed

- Produces a lot of spatter

Related: Differences Between Flux Core & Stick Welding

Wrapping it Up

While there are a lot of ways out there to weld, these four processes dominate. Don’t be afraid to ask questions of any welders you know. Once you’re familiar with what each process brings, you’re better equipped to make important decisions.