Choosing the correct type of stick electrode is vital to stick welding success. Before you buy a box of electrodes, there’s still one more factor to consider.

You need to pick the right diameter welding rod for your project.

Selecting the suitable electrode diameter may seem straightforward, but that assumption couldn’t be further from the truth.

Most welders will follow the rule of thumb by picking an electrode a little smaller than the thickness of the base metal.

But there are many times when doing this will lead to disastrous results.

Impact of Rod Diameter on Stick Welding (SMAW)

The diameter of the welding electrode affects several aspects of the stick welding process.

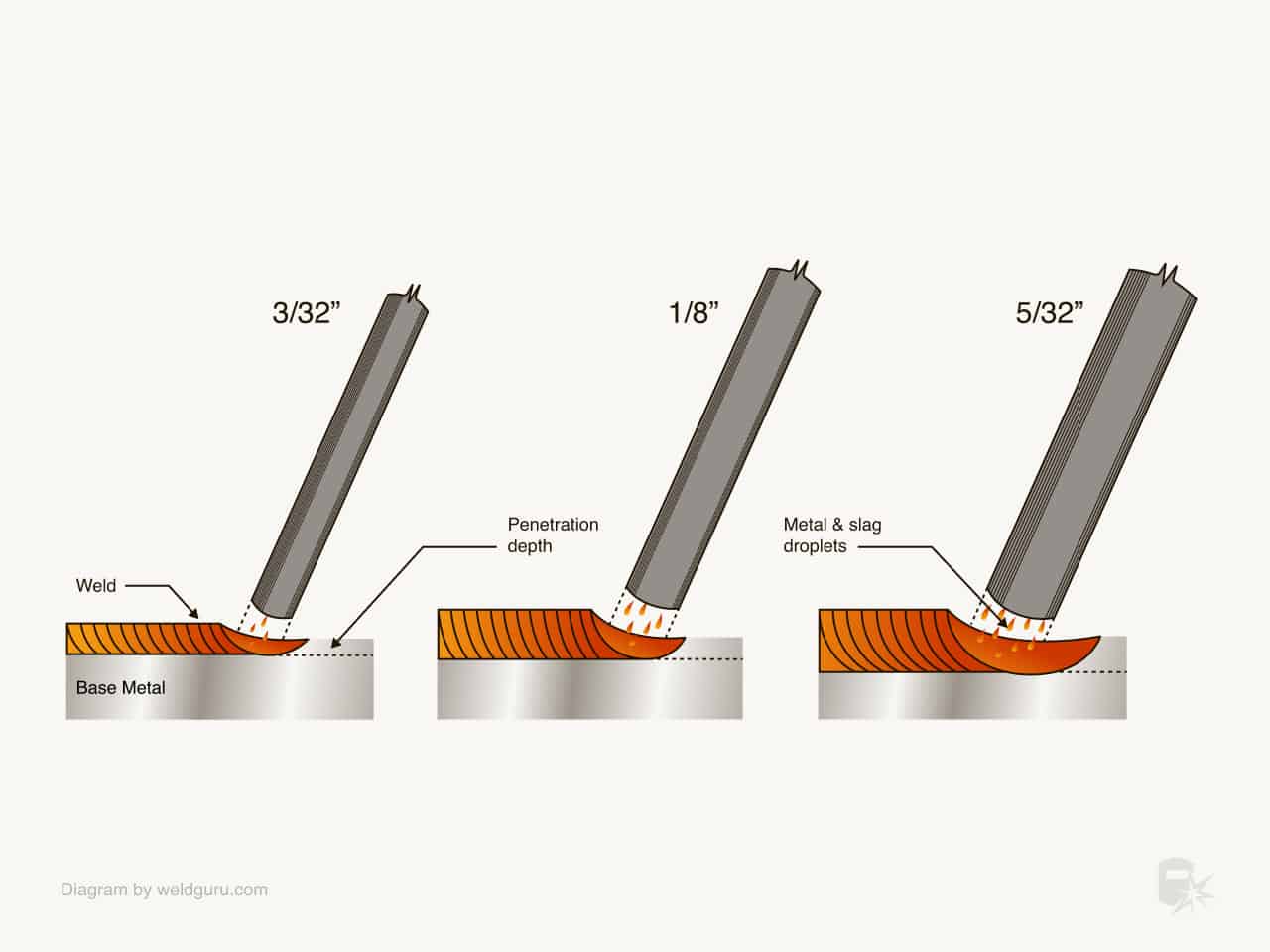

One of the more obvious examples is that thicker electrodes need higher amperages to create an effective welding arc.

Thicker electrodes also provide faster welding speeds, greater penetration, and more heat. These are aspects that make them a great choice for welding thicker materials.

© weldguru.com – Image usage rights

One issue of welding with larger-diameter electrodes is that it’s challenging for beginners. These rods burn hot and have high deposition rates.

Keeping up with fast welding speeds and manipulating the large puddle can be tricky if you’re not used to it.

Smaller diameter electrodes are great for welding thinner materials or in cases where you need a smaller, more precise weld.

For example, if the part you’re working on calls for a 1/8″ (3.2 mm) fillet weld, but the material is 1/2″ (12.7 mm) thick, you would not want to use a 5/32″ (4 mm) electrode.

Instead, you would choose the largest electrode to give you a perfect 1/8″ fillet weld.

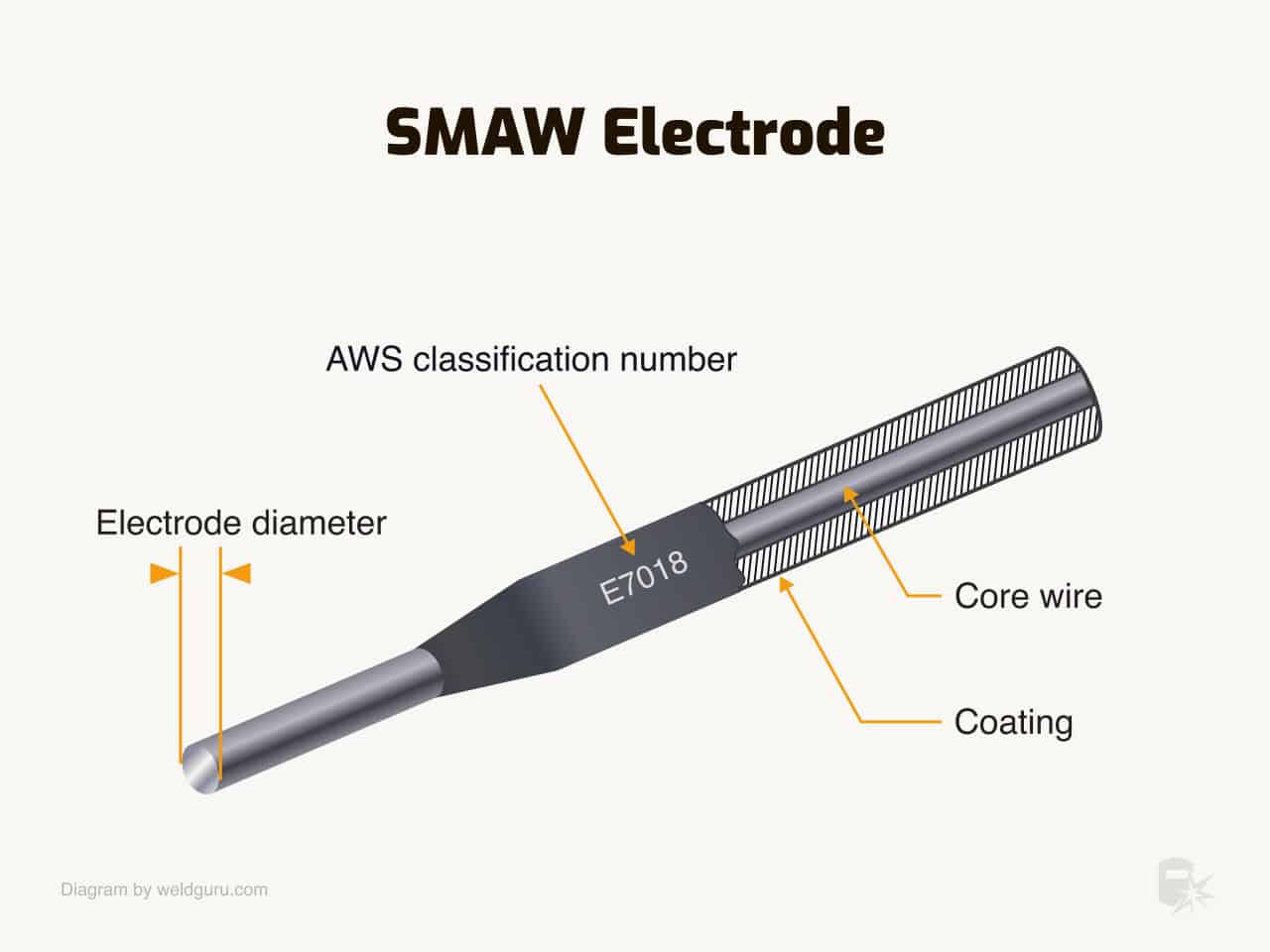

How To Measure the Diameter of a Welding Rod

The size of a stick welding electrode is the diameter of the metal core, not the outside diameter.

© weldguru.com – Image usage rights

The reason for this is that the total outer diameter will vary depending on the thickness of the flux coating.

For example, a 1/8” (3.2 mm) 7018 electrode will have more flux and a larger outer diameter than a 1/8” 7011 electrode. A 1/8” 7024 electrode will have a larger diameter still.

All these electrodes have the same diameter core and classify as 1/8” (3.2 mm) stick electrodes.

The Impact of Selecting The Incorrect Rod Size

Picking an electrode that’s either too large or too small for the task at hand will lead to frustration, bad welds, and the potential for ruined parts.

Often, poor electrode size choice can lead to expensive re-work.

The problems that poor electrode choice cause are avoidable as long as you understand and consider the consequences.

Consequences of Choosing an Electrode Size Too Small

There are many times when you might want to pick an electrode that’s smaller than usual. Most often, choosing an electrode that’s too small will lead to less penetration and a lack of fusion.

Smaller electrodes use lower amperages. The arc generates less heat, which makes melting the base metals challenging.

The weld will also be smaller, meaning you’ll need more passes to get the required weld size.

Problems With Oversized Electrodes

When using an electrode that’s too large, the high heat will cause more distortion. The welding arc can also melt a hole through the base metal.

The weld beads generated are also going to be wider and more fluid. One issue that this causes is slag getting trapped inside the weld joint, causing a slag inclusion.

Depending on the type of joint fit-up, a larger electrode may also be too large to fit into the joint well enough to allow the arc to reach the root of the weld.

This effect leads to a lack of full joint penetration with your weld.

The Importance of Base Metal Thickness in Rod Size Selection

The basic rule to remember is always to select a welding rod smaller than the thickness of the base metal. There are almost no reasons why you would ever want to use an electrode larger than the material’s thickness.

For material less than 3/16” (4.8 mm) thick, you’ll want to use an electrode one size down from the material thickness. You can use an electrode size half the material thickness without any issues, but don’t go any smaller than that.

If the material exceeds 3/16” (4.8 mm), you must consider other factors, such as the welding position, joint fit-up, and desired size.

Welding Position & its Influence on Rod Size Selection

One aspect that determines electrode size is the position of the weld joint. You can use a larger electrode for flat and horizontal welds because gravity pulls the weld puddle into the joint.

Since the molten weld can fill the joint and freeze without issue, the larger puddles and higher heat of bigger electrodes aren’t a problem.

Vertical and overhead welds need smaller diameter electrodes because they use lower amperages, meaning the weld puddle is smaller and freezes faster.

This aspect is important because gravity pulls the liquid metal down and away from the joint, so the faster the puddle freezes, the better.

Smaller weld puddles are also easier to control, which is important for out-of-position welding.

Related: What Do The Numbers On A Welding Rod Mean?

Most Common Rod Sizes and Their Applications

Stick welding electrodes come in diameters from 1/16” (1.6 mm) to 1/4” (6.35 mm). But the most common sizes you’ll encounter and use are:

- 3/32” (2.4 mm)

- 1/8” (3.2 mm)

- 5/32” (4.0 mm)

With these three sizes, you’ll be able to tackle most welding projects that come your way.

For material smaller than 1/8″ (3.2 mm), a 3/32″ (2.4 mm) rod will be a good choice.

Anything up to 1/4″ (6.35 mm) thick would be best welded with a 1/8″ (3.2 mm) electrode, and thicker metal would use 5/32″ (4.0 mm).

Below is a chart that will give you a starting point for choosing the correct welding rod size.

| Base Metal Thickness | Electrode Diameter | Amp Range |

|---|---|---|

| Up to 3/16″ | 1/16″ (1.6 mm) | 20 – 45 |

| Up to 1/4″ | 3/32″ (2.4 mm) | 40 – 125 |

| Over 1/8″ | 1/8″ (3.2 mm) | 75 – 165 |

| Over 1/4″ | 5/32″ (4.0 mm) | 110 – 220 |

| Over 3/8″ | 3/16″ (4.8 mm) | 140 – 275 |

| Over 3/8″ | 1/4″ (6.35 mm) | 210 – 415 |

| Over 1/2″ | 5/16″ (8.0 mm) | 275 – 525 |

The Challenges of Small-Diameter Rods

You’d choose to weld with smaller diameter electrodes when welding on thinner metals or where you want a smaller weld size.

You’ll notice some issues once the electrode size gets below 1/8″ (3.2 mm).

- 1/16” and 5/64” electrodes are very thin and tend to vibrate as you’re welding. Even with a steady hand, it’s difficult to keep the end of the electrode pointed at the root of the weld joint.

- You choose these smaller electrodes when welding material less than 1/8” thick. Stick welding isn’t an appropriate process for welding materials thinner than 1/8” unless you’ve had a lot of practice.

- Small electrodes also need to run at low amperage, which some welding machines find difficult to deliver.

- The lower amperage makes it more difficult to keep the arc going, resulting in your electrode sticking to the parent metal once you lose your arc.

Issues With Larger Diameter Rods

When welding on thick materials or wanting fast, hot welds, choose an electrode on the upper end of the size spectrum.

Electrodes with diameters over 5/32” present challenges you’ll need to overcome.

- Additional Power: The larger the electrode size, the more amperage you’ll need. The stick welding machines which use either 120 or 220-volt power won’t deliver the required high current. You must invest in a larger, more powerful three-phase welding machine. Make sure you have a high-duty cycle also to run these thicker electrodes.

- Puddle size & skill: The puddle these electrodes make is much larger and more difficult to handle than you’re used to. Making good welds using large electrodes takes a lot of practice and skill.

- Safety concerns: The higher amperage creates more UV radiation, fumes, and heat, which you’ll need to protect yourself from.

Practical Examples of Stick Electrode Size Selection

Selecting the correct electrode size can be confusing at times. Generally speaking, you’ll use 6010, 6011, 7018, or 7024 electrodes to do most of your stick welding.

There are other electrode options, but these are the most common and accessible.

To help you understand some of the logic behind the correct choices, I’ve come up with a couple of common examples:

Example 1: Welding 1/2” Plate

If you need to weld two pieces of 1/2” plate together, in either a fillet or butt joint, the rod size I would choose is as follows:

- For a flat or horizontal fillet weld, 5/32” is a good size rod for a 1/2” multi-pass weld. I would also choose this electrode size for flat and horizontal butt welds, except for the root pass, for which I usually select a 1/8″ 7024 electrode.

- If you need to weld in the vertical or overhead positions, drop the electrode size to 1/8” for either a fillet or butt weld. It’s possible to weld overhead with a 5/32” rod, but the smaller puddle that a 1/8” 7018 electrode gives you is much easier to control.

Example 2: Welding 1/8” Sheet Metal

Welding on sheet metal means you’ll be doing all your welding using only one pass.

The electrode you choose needs to produce a weld that’s large enough without having to resort to a multi-pass weld.

I don’t use 7018 when welding sheet metal. I instead choose either a 6010 or 6011 electrode.

- For the flat and horizontal, I would use a 3/32” electrode.

- I would not weld sheet metal with a vertical up technique. Instead, I would use a dragging vertical down technique, using a 3/32” electrode.

- For overhead, I would stick with a 3/32” electrode but run it at the lower end of the recommended amperages to keep the puddle smaller.

New to stick welding? Check out these stick welding tips for beginners.

Wrapping It Up

Selecting an electrode size can be confusing at times. The best advice I can give you is always to choose a rod thinner than the thickness of the material you’re welding.

Aside from that, take the time to practice with the three common electrode sizes on different thicknesses of material.

It’s only through experience that you can understand the capabilities of each size electrode.