Cold welding joins metal together with little to no heat. It is one of the more interesting welding methods, and many metals can be cold welded thanks to the laws of physics and our understanding of material science.

In this article, you’ll learn what cold welding is, how it works, and what metals you can cold weld.

What is Cold Welding?

The cold welding process requires no heat input to join metal pieces together. The metal remains in the solid phase, and it is not molten at any time. So, cold welding is considered to be a solid-state welding process.

Instead, the energy necessary to bind the metal is applied in the form of pressure. Unlike fusion welding, such as arc welding and friction welding, cold welding doesn’t have a molten or a liquid metal phase, which is why it’s referred to as cold welding.

The applied pressure brings the surfaces of the workpieces together as close as possible. Once pressed together, the nanoscale distance becomes irrelevant, and metal atoms jump from one piece to another. This results in a near-perfect bond with almost no repercussions, and the two separate pieces of metal become a homogeneous mass.

But to achieve this, you need to clean the metal surfaces to perfection. Every metal has oxide layers that must be removed before attempting to cold weld. But we will discuss this further later in the article in more detail, But first, let’s look at some pros and cons of this process.

Pros

- A perfect process for welding aluminum, especially joining aluminum with copper, two metals that are a challenge using other welding processes

- Eliminates most heat-affected zone (HAZ) problems since there is no concentrated heat, and thus no HAZ, from a welding arc

- Provides a near-perfect welding joint without brittle intermetallic compounds, microfractures, and other joint weaknesses

- Able to join a vast array of dissimilar metals that are otherwise difficult to weld together

- Reduces the required skills needed for welding exotic metals

Cons

- The surface must be cleaned pristinely; it can require multiple steps of cleaning and preparing the metal

- Surface irregularities, contamination, and nanoscale molecular structures can hinder the results

- Difficult to achieve in an industrial setting because of dust and other debris in the air

- Carbon steel and hardened metals can’t be cold-welded, only works with non-ferrous ductile metal like copper, aluminum, lead, gold, etc.

- Irregular shapes are difficult to cold weld, and best results are achieved with flat surfaces

What is Cold Welding Used For?

Cold welding is used by numerous industries, including aerospace, automotive, electronics, and production.

It’s most commonly used when welding wires together, especially of dissimilar metals. Cold welding is also perfect when laying underground wires when there is the danger of flammable gasses catching fire from a heat-inducing welding process.

In addition, it’s often used to seal containers sensitive to heat, for example, containers with explosives.

In general, cold welding is employed when heat will cause too much damage or present a danger.

How Does Cold Welding Work

© weldguru.com – Image usage rights

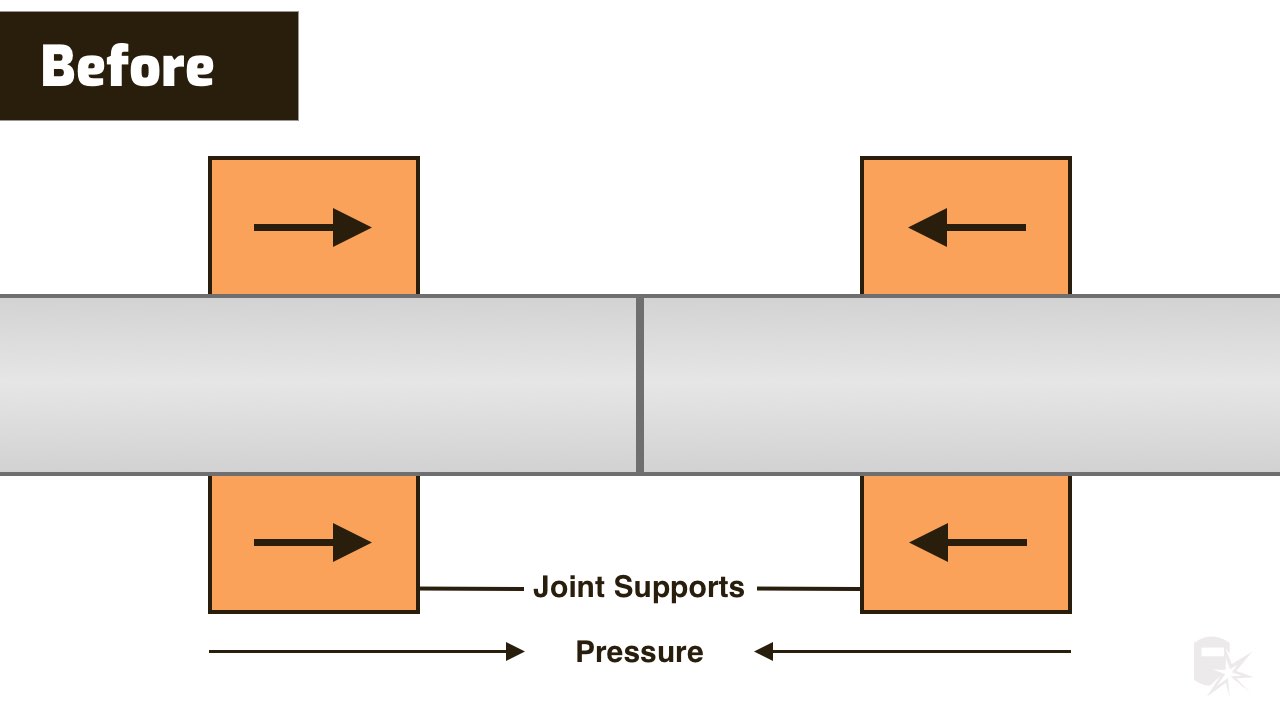

Cold welding joins metal at ambient temperatures without heat or electrical current flow in the joint. Applying force to the metal pieces forces out surface roughness and resolves minor surface irregularities. But the most important reason to apply pressure is to promote interatomic attraction between the two metal surfaces.

Before cold welding, you have to remove oxide layers from both metals. Every metal forms oxides on the surface, which makes the inner, pure metal inaccessible. That’s why pressing two uncleaned, oxidized copper pieces together, for example, will fail to achieve a weld.

To quote Richard Feynman, a famous physicist:

“The reason for this unexpected behavior is that when the atoms in contact are all of the same kind, there is no way for the atoms to “know” that they are in different pieces of copper. When there are other atoms, in the oxides and greases and more complicated thin surface layers of contaminants in between, the atoms “know” when they are not on the same part.”

So, when we clean the metal’s surface and apply enough pressure, the metals will form a uniform metallurgical bond. The newly formed metal will behave as if it was always a homogeneous piece.

But this requires an extreme level of cleanliness and the absence of surface irregularities. In real-world applications, this level of uniformity is achieved mainly when cold welding wires. That’s because the cold wire welding process pushes out impurities with almost perfect precision.

© weldguru.com – Image usage rights

Prerequisites for Cold Welding

The main cold welding prerequisites are pristine cleaning the metal surface and preparing the joint’s geometry. Flat joint surfaces work best, so flattening any irregularities in the shape is recommended.

The oxide layer and other impurities can be removed by degreasing, wire brushing, or mechanical and chemical methods. Grease and oil are typically present on the metal’s surface and must be removed before wire brushing. This is essential because the brush can force these impurities deeper into the metal. Thanks to the wire brush sharp bristles, soft metals like aluminum, copper, gold, silver, and others are the most susceptible to getting surface oils embedded below the surface.

After you clean the oils, you can proceed to strip away the oxide layer itself. Depending on the metal, different bristle materials and brush types may be recommended. It’s always good to check the metal’s specification sheet.

Is Cold Welding Strong?

The cold welded joint will be as strong as the parent metal if you properly conduct the necessary preparation. The joint strength depends on the metal’s properties. Unlike with other welding methods, cold welding’s joint strength cannot outperform the original metal strength.

The joint strength will be compromised if the joining surfaces aren’t sufficiently cleaned or have irregular shapes. But for typical cold welding applications like joining wire, maximum bond is not very difficult to achieve.

Possible Weld Joints

Since cold pressure welding works best with a large contact surface, it’s best to use butt and lap joints.

Butt welds are mainly used when welding wire and pipes together. That’s because it’s easy to trim the ends, get clean metal on the contact surface, and press the wires together.

When making a butt weld, the distance between the clamping points and the contact surface shouldn’t be too big because soft metals can bend sideways instead of joining.

The cold lap joint is a little tricky. Pressing sheet metal together will reduce its thickness due to the applied pressure. So, you should account for at least a 50% loss of thickness when preparing your project. Otherwise, the final welded part will not meet the project requirements.

Even if the weld is perfect, the thinned part could be unacceptable. Consider the metal’s ductility and softness, and make a few test welds to determine the resulting thickness.

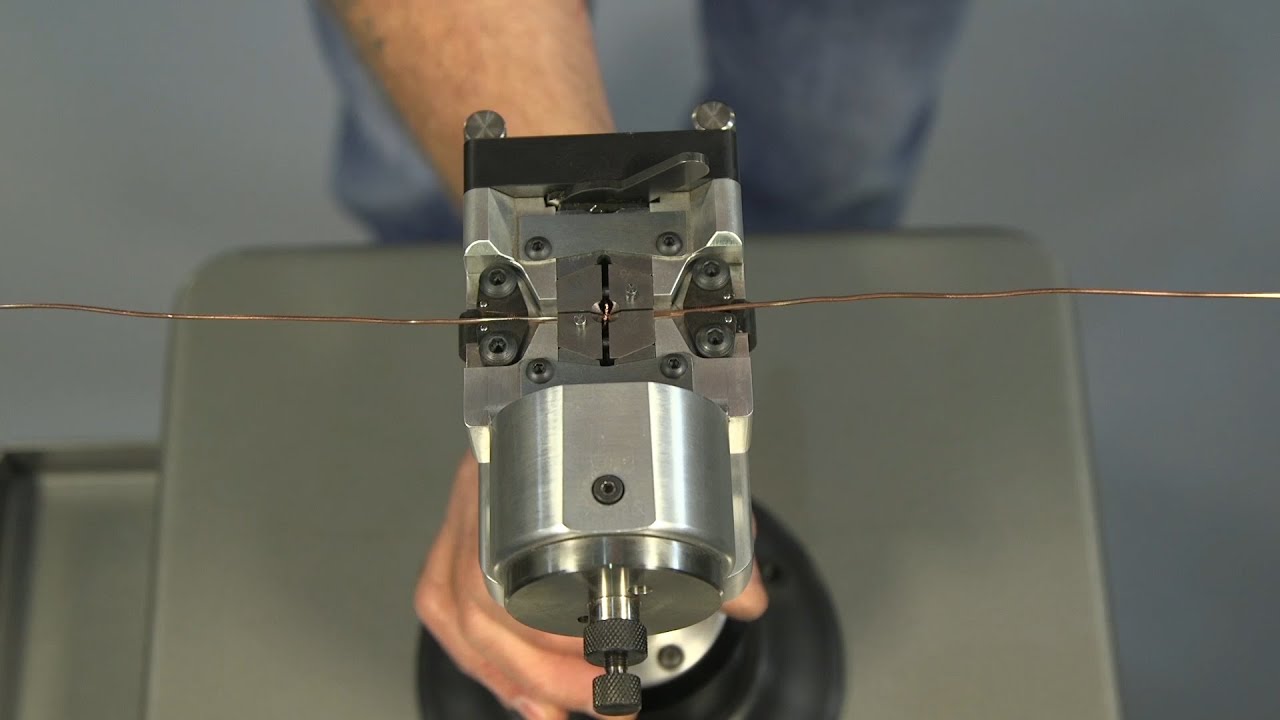

Cold Welding Machines For Joining Wires

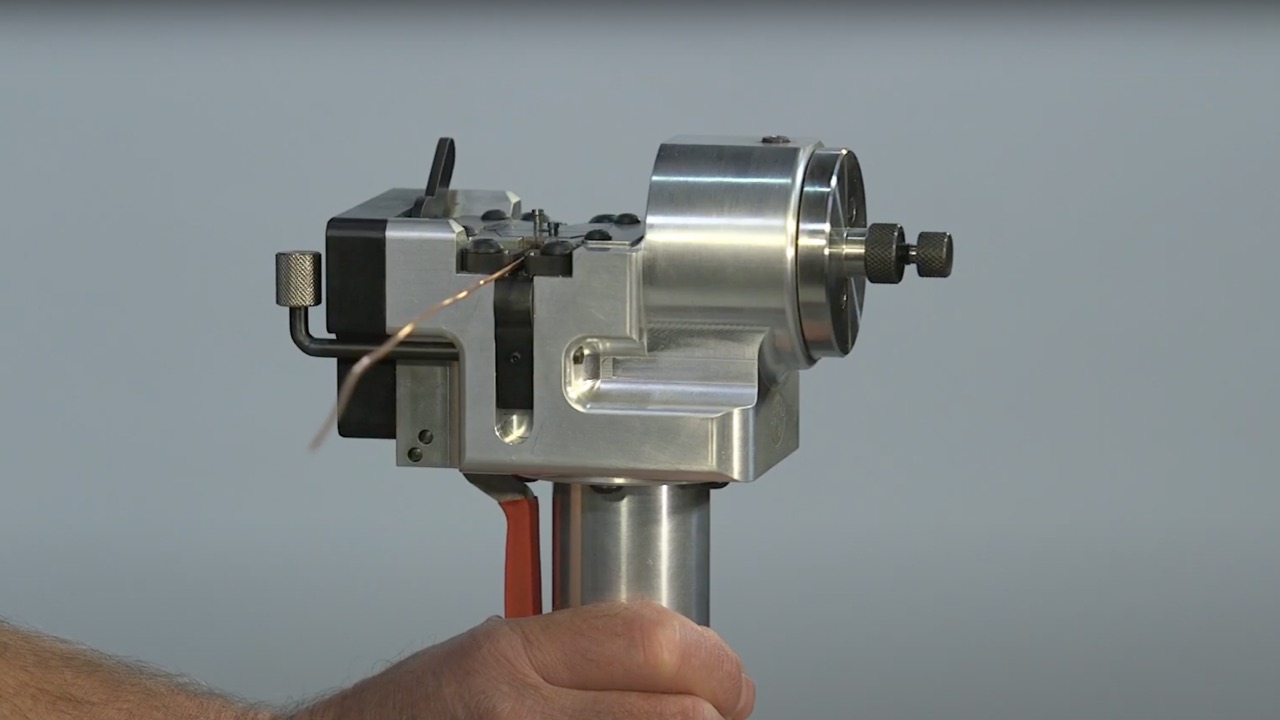

Cold welding machines are hand-operated for small wire diameters. But larger diameters require a pneumatic or electric-pneumatic operation. Most of these machines are portable and can handle wires, rods, and strips.

Using an air hydraulic intensifier, a portable cold welding machine will generate extreme pressure. On the operator’s side, there is a “welding head.” It’s located on the top of the machine and serves to accept a welding die, offer stability, and control the applied pressure.

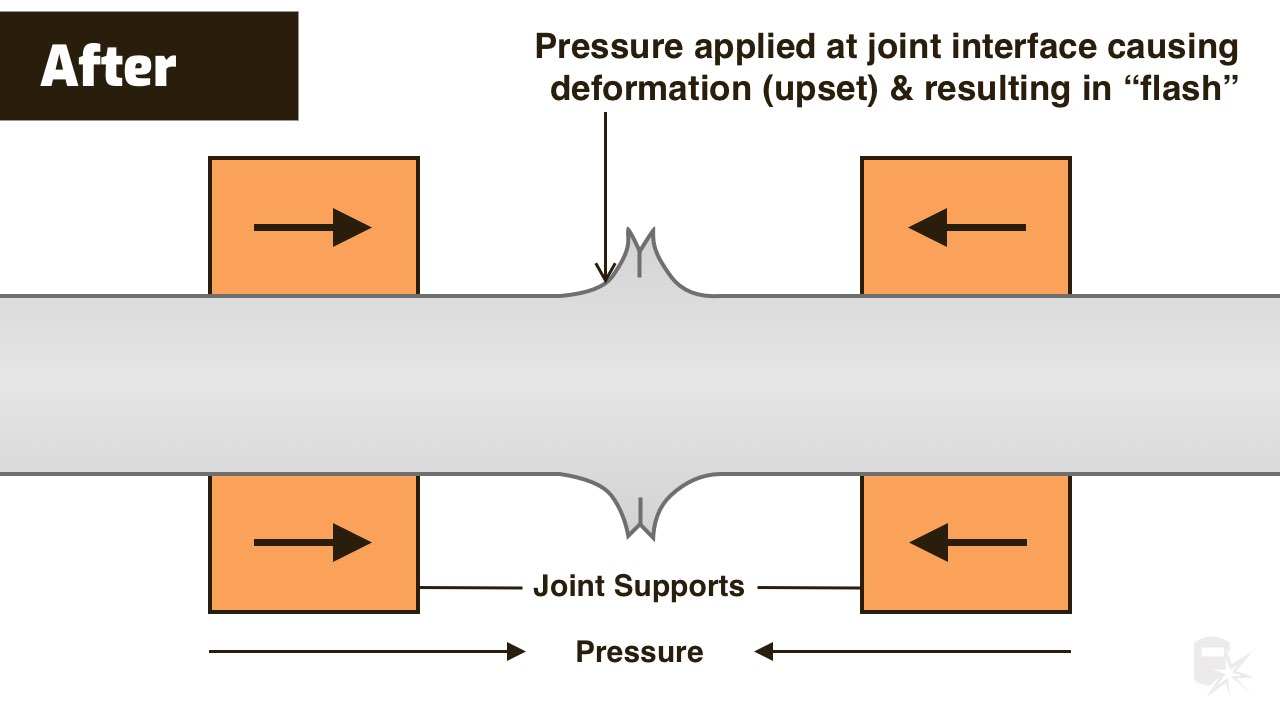

After the die is placed and secured into the die pocket, the wires/rods are fed in on the sides. Applying pressure causes the die to grip the wires near endpoints and push them together tightly. As a result, minuscule impurities that remained on wires’ cross-section surfaces are squeezed out from their cores outwards. That’s why cold welding wires create a better joint bond than welding sheet metal. This is only possible because wires have a small joining surface area, unlike sheet metal.

Pressure is applied a minimum of four times to eliminate all of the impurities. This process is called a “multi upset principle.” After the wires have bonded, you can remove them from the machine and chip away the residue around the joint area.

Cold Welding vs Hot Welding

Hot welding methods involve an electrical arc, internal resistance, or an active flame to melt and fuse metal. Cold welding is best suited for non-ferrous metal and specific applications, while hot welding has many more uses.

| Feature | Cold Welding | Hot Welding |

|---|---|---|

| Requires Heat | No | Yes |

| Requires Electric Arc | No | Yes |

| Welds All Metals | Non-ferrous and carbon-free | Yes (few rare exceptions) |

| Application Scope | Limited | Much Wider |

What Metals Can Be Cold Welded?

Metals that can be cold welded include copper, aluminum, lead, zinc, 70/30 brass alloy, nickel, silver, silver alloys, platinum, and gold. It can also weld 2xxx and 7xxx series of aluminum alloy. These can’t be fusion welded because they tend to crack under heat, and they are challenging to join with welding methods other than cold welding.

It is impossible to cold weld carbon steel or any metal that contains carbon. This limits the cold welding application a lot because carbon steel is by far the most welded metal.

Cold welding works best with metals that have a face-centered cubic arrangement of atoms that don’t work harden quickly. All metals that work harden quickly tend to crack before the pressure from cold welding can create a bond. That’s why only highly ductile metals outlined above can be cold welded.

Different Types Of Cold Welding

There are no different cold welding types. Instead, there are three similarly named methods. Let’s have a brief look at these processes.

Cold Metal Transfer

Cold metal transfer (CMT) is a fusion welding process that uses a welding arc to create a joint. It’s often mislabeled as “cold welding,” causing confusion. CMT is a MIG welding process that requires about 90% less heat input than a regular MIG welding process.

Since this arc welding method is so “cold,” it solves many problems like the actual cold welding process. However, you shouldn’t mistake these two.

The CMT uses an electrical arc, filler metal wire, and we can use it with metals where cold pressure welding is not an option. But the CMT relies on precise filler wire retraction upon arc initiation to control the heat input.

It’s only possible for a robot to do this, and it’s not economical if cold pressure welding is an option.

TIG Cold Welding

Like with the CMT above, the TIG cold welding has no relation with the method described in this article.

Some TIG welding machines have a “cold” setting that essentially limits the heat input. It achieves this by applying an electric arc to a tiny spot for just a fraction of a second.

The temperature is minimal because any generated heat will dissipate quickly, especially with a highly conductive metal like aluminum.

This is useful when welding very thin sheets of metal and wires. But you could achieve something similar with any advanced TIG welder using the pulse settings.

You will get low heat TIG welds by setting a low pulse current and a high time dilation between the pulses. But low heat is sometimes not good enough, so whenever cold pressure welding is an option, it will make a better joint.

JB Weld

JB Weld is a brand name for an epoxy bonding system used with metal, concrete, brick, fiberglass, etc. While it’s called an “Original Cold-Weld Formula,” it doesn’t really create a weld between the metals.

Unlike the cold welding process, there is no interatomic attraction, and the two metals don’t fuse to become a homogenous mass.

JB Weld is a good method to adhere metal, but it won’t be welded together. The product is a two-component epoxy, a base, and an activator. When you mix and apply this product to the metal parts, you should secure them with the clamps and begin the curing process.

It has a tensile bonding strength of 5020 PSI, providing a weak bond compared to a typical E6010 stick electrode with 60,000 PSI.

It’s no substitute for an actual weld unless you make minor repairs around the home. But some people do confuse it with the cold welding process.

A Brief History of Cold Welding

Cold welding history started in the Bronze Age, around 700 BC, but it was not as sophisticated as today. Archeologists have excavated many tools and utensils from this time period that were formed using a primitive cold welding process.

However, the first documented scientific experiment on cold welding was performed in 1724 by Reverend J. I. Desaguliers. He discovered that if he pressed and twisted two lead balls together, they would form a solid joint. He tested the bond strength on a steelyard with good results.

The next notable point in history was the Second World War when light-alloy aircraft elements were cold-welded in Germany. With the industrial progress that followed, cold welding became more advanced and led to what it is today – a well-understood process used in specialized settings.

Is it ok if I use your article in an email?

Sure! All I ask is that you link back to the article as the resource.

Thanks for taking the time to read.

Thanks for the feedback Ron