Welding is a profession that requires excellent skill and diversity. It can lead to a respectable career if you put your heart and soul into it.

However, its multivariate nature also makes it prone to errors. New welders must be mentally prepared to tackle such issues.

One of the most problematic defects found in welding is slag inclusions.

This article will explain what it is, how to identify it, what causes it, and what can be done to prevent it from happening.

What is Slag Inclusion?

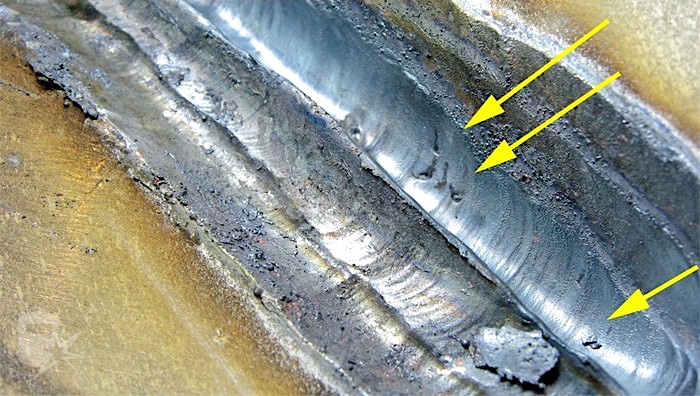

© weldguru.com – Image usage rights

Slag Inclusions are a common welding defect that occurs when slag, a welding by-product, gets stuck inside the weldment. This is an unfavorable condition that creates performance issues down the line.

In most cases, it is a result of bad welding technique or improper selection of components and parameters.

This defect primarily occurs in flux-based welding techniques like stick welding and flux-cored arc welding.

Why only flux-based methods?

To clarify this, let’s begin by discussing flux and slag…

How is Slag Different from Welding Flux?

Flux is a combination of compounds that enters the molten weld pool with the filler metal.

As it melts, it reacts with Oxygen/Nitrogen in the surrounding atmosphere to create its respective Oxides/Nitrides. This prevents these gases from oxidizing the base metal(s).

Some of it dissolves into the weld pool and undergoes similar reactions with impurities inside the base metal.

These non-metallic products from these chemical reactions are collectively known as slag.

Slag rises to the top of the pool because of its low density. Upon reaching the weldment’s surface, it solidifies to create a layer of protection between the molten metal and air, blocking further reactions between the two.

This way flux, which eventually becomes slag, shields the weld pool from the air and rids it of internal impurities.

To sum it up, flux is an essential input that keeps the weldment pure from non-metallic impurities. Slag is a waste product that must be removed from the joint after the welding is finished.

Here’s a short clip of how slag inclusion happens with the cold metal transfer process:

Why is it Unfavorable?

A good quality weld joint is identified by its uniform composition. Any discontinuities in its internal structure, micro or macro, render it faulty.

Slag inclusions create these discontinuities resulting in a faulty weld. The gaps filled with slag are prone to stress concentrations and local strains, both of which are detrimental to the weldment’s strength.

Also, slag prevents natural interactions between individual grains, further compromising the mechanical integrity of the weldment.

Slag inclusions can also allow liquids/gases to seep through them. In structures like water-tight vessels or leak-proof gas containers, this can be catastrophic.

Rust is another issue if the slag has corrosive tendencies. If the weldment catches rust, the harmful effects of these micro-defects can multiply.

How to Identify Slag Inclusions?

There is no way to avoid slag inclusions completely. Hence, every welder must know how to identify them.

Most of the time, inclusions are visible to the eye. Such inclusions have a clear, glass-like appearance. They are either in the form of thin lines or pinholes.

They are scattered randomly, sometimes as clusters and occasionally as secluded spots. Non-Destructive techniques like dye penetration testing can pinpoint their exact locations.

Other times, slag inclusions lie deep within the weldment. X-Ray or ultrasound analysis can help locate them.

Common Slag Removal Techniques

Once identified, welders use a variety of methods to remove slag inclusions.

If they are on or near the surface, a simple wire brush or chipping hammer is enough. Grinding is suitable to deal with deeper inclusions.

When performance is essential, removing the defect altogether is also a professional practice. In such cases, welders redo the cavity and fill up all pinholes with a new filler.

Main Causes of Slag Inclusions

As mentioned at the start, welding is not a single-factor process. There are multiple things at play that need to be accounted for.

Consequently, there are numerous reasons behind slag inclusions. We will discuss its major causes one by one to keep it simple.

Type of Flux Used

Flux becomes slag. This fact is enough to emphasize the importance of flux composition.

Material properties of the slag play a huge role in creating slag inclusions. The main qualities to consider are wettability, surface tension, and freezing rates.

Some fluxes are inherently high quality in this regard. Rutile fluxes, for example, exhibit high surface tension which promotes a flatter weld bead. The resulting slag quickly rises to the top and accumulates at easily accessible points.

Basic fluxes, specifically ones containing calcium carbonate content, are notorious for causing slag inclusions. The slag tends to dip into the pool due to its high wettability rather than rise to the surface.

It also creates a much harder slag which is more difficult to break and remove, especially when completely inside the weldment.

Welding Parameters

Professional-grade welding is all about setting the correct parameters. Speed and amperage are the two biggest factors in determining the extent of slag inclusions.

Amperage

Amperage sets the energy density, which is linked to how the filler/flux is deposited into the pool.

Setting the amperage too low means that slag would tag along the electrode rather than stay in the pool it leaves behind. This aggravated movement leads to greater mixing of slag in the pool, which means more inclusions.

Low amperage also means a lower overall temperature. In this case, the pool solidifies quickly and traps in slag yet to rise to the surface.

Welding Speed

Welding speed is another factor to consider. High travel speed does exactly what low amperage does. It concentrates the slag in colder regions (ahead of the stick’s travel) instead of the hotter pool, which is more likely to solidify prematurely.

Low electrode travel speed causes other issues. If the electrode stays too long on a spot, a lot of filler and slag gets deposited in the surrounding pool. More weight and a higher mass ratio of slag are bound to cause more inclusions.

Poor Welding Technique

The welder’s inexperience or failure to adopt recommended practices can also cause slag inclusions.

The electrode’s size selection and angle are significant factors. Too big an electrode and you get extra slag, which is clearly a problem.

The electrode angle needs to be within a certain range too. If it is too close to the horizontal, slag will fall near or ahead of the electrode-pool contact point, solidifying before it should.

On the other hand, too steep an angle leaves no room for manually controlling the slag’s movement through the stick. It causes spatter, and it is pretty much up to the local forces to decide where it goes.

Maintaining a regular arc gap and electrode angle are also very important. The slightest disturbance in these leads to a different slag behavior.

Bad Practices

Welding on dirty and irregular surfaces can cause slag inclusions. Uneven surfaces have gaps and craters which can trap slag. In addition, it is very easy to create undercuts on an imperfect surface, even if you are using the proper technique.

Slag Inclusions are a bigger issue in multi-pass weld joints. Each pass requires cleaning of the previously laid weld, so more chances of errors. Moreover, since the surfaces are weld beads themselves, there is bound to be some unevenness and regions of depth around the weld toes.

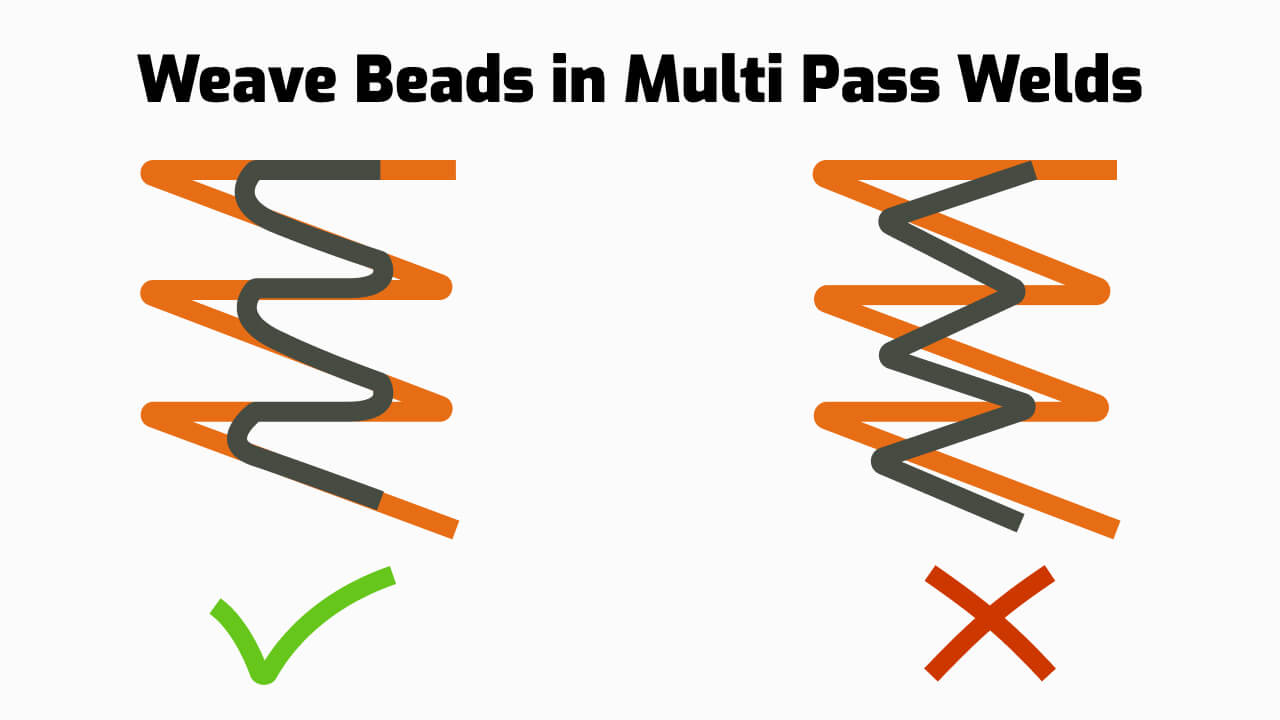

If you are using weaving motions, non-overlapping weave patterns can create cavities near the weld toes that trap slag. Welders must take care to maintain the same ‘wavelength’ or ‘frequency’ of each weaved pass to minimize slag inclusions.

© weldguru.com – Image usage rights

How to Prevent Slag Inclusions?

It is pretty clear that slag inclusions are a severe issue in welding with multiple causes. Identifying the problems is not enough; you must act to eradicate them.

Preventing slag inclusions can be a daunting task. This is exactly why welding is a highly technical job!

Preparation and Post-Processing

What you do before and after welding matters a lot. Cleaning off any moisture, oils, and dust particles from the surface before welding is necessary if you aim for minimal defects.

Using a grinder to create an even surface with the desired shape is also imperative. Take care not to generate undercut tendencies or bad edges.

After the weld, remove all possible slag before laying additional welds. If you are lucky enough to get a concave/flat bead, this is a piece of cake. For convex beads, do not make the mistake of ignoring slag in the toes.

Optimal Parameters & Techniques

We have already gone over the issues stemming from parameters and welding techniques. Avoiding bad practices and finding the right balance between optimal operating ranges is the key to get a slag-free weld.

It is essential to set the amperage high enough to avoid the slag solidifying early and prevent it from sticking to the electrode.

The speed should be constant and within the desirable range. It should allow the slag to go through its complete cycle: reaction, wetting, rising to the top, freezing. If you feel this is not the case, consider slowing down a bit.

The welder also needs to find the sweet spot for electrode angle. The ideal scenario is that the angle is optimized to take full leverage of gravity (in both horizontal and vertical welds).

This means that the slag simply slides into the weld pool and surfaces automatically, without much manipulation required. Of course, manipulating the electrode’s angle is a necessary step to achieve this!

Conclusion

Welding is never an easy job. The depth of this field is inarguably unparalleled in the sphere of manufacturing processes.

We hope this effort to break down slag inclusions has helped. Remember, however, knowing everything will not make you a good welder. It is the experience, augmented by knowledge, which matters.