A welding career can be lucrative with some welding jobs paying as much as $42 an hour.

Also, 83% of people with welding jobs are offered medical benefits, a level that is higher than any other work sector (except government).

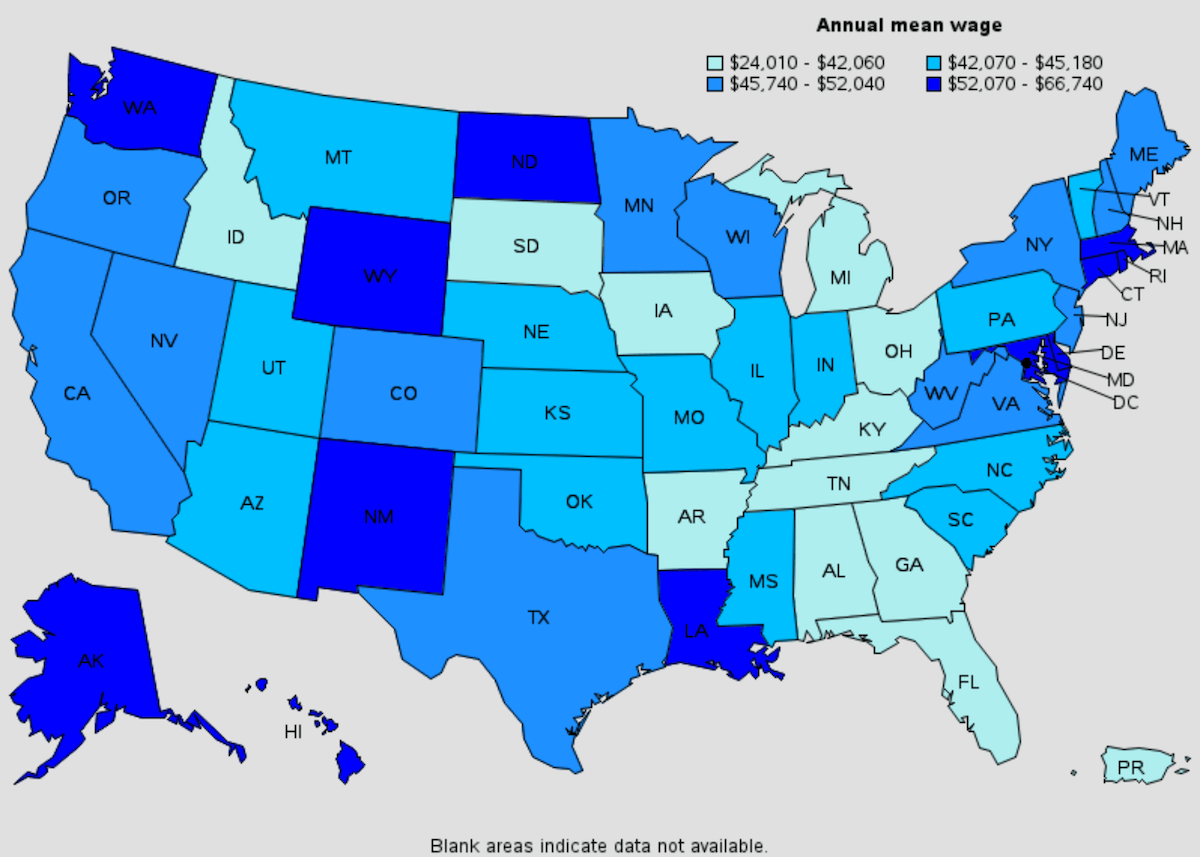

Welders in Alaska get the highest pay at $66,740 a year with an hourly mean wage of $32.09. (1) Most welding jobs are in the Dallas Metro, Houston Metro, LA metro and Chicago metro areas.

6 of every 10 welding, soldering and brazing workers were found in manufacturing.

Jobs were concentrated in fabricated metal product manufacturing, transportation equipment manufacturing (motor vehicle body and parts and ship and boat building), machinery manufacturing (agriculture, construction, and mining machinery), architectural and structural metals manufacturing, and construction.

Most jobs for welding, soldering, and brazing machine setters, operators, and tenders were found in the same manufacturing industries as skilled welding, soldering, and brazing workers.

Welding is used as a job skill or full-time job in the following industries:

- Robotics

- Engineering

- Racing

- Industrial sales

- Farm repair and fabrication

- Production welding

- Military careers

- Teaching welding

- Maintenance

- Ironworker

- Skilled trades

- Auto Technician

- Artists and Metal Sculpting

- Entrepreneurs in welding

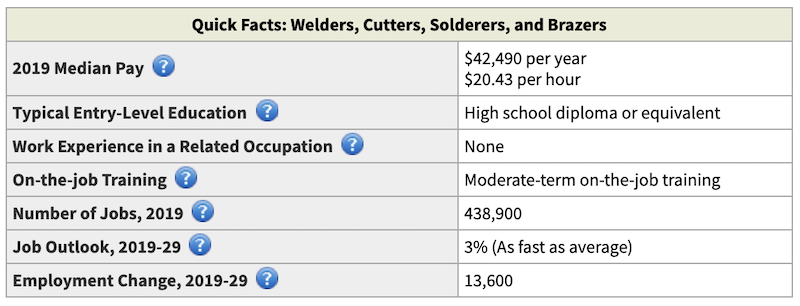

Employment estimate and mean wage estimates for Welding, Brazing and Soldering Careers

Welding Career Outlook

Employment of welders, cutters, solderers, and brazers is projected to grow 3 percent from 2019 to 2029, slower than the average for all occupations, but still optimistic if launching a welding career. Despite slower-than-average employment growth, skilled welders with up-to-date training should have good job opportunities.

The median annual wage for welders, cutters, solderers, and brazers was $42,490 in May 2019.

Employment of welders, cutters, solderers, and brazers is projected to grow 4 percent from 2014 to 2024, about as fast as the average for all occupations. Skilled welders with up-to-date training should have good job opportunities.

The Economy and a Welding Career

The major factor affecting a welding career is the health of the industries in which they work.

The manufacturing sector, which employs the most welding, soldering, and brazing workers, is expected to continue to decline as more manufacturing moves overseas.

Because almost every manufacturing industry uses welding at some stage of manufacturing or in the repair and maintenance of equipment, this overall decline will affect the demand for welders, although some industries will fare better than others.

Construction

The construction industry is expected to have solid growth over the next decade and increasing demand for welders.

Government funding for shipbuilding as well as for infrastructure repairs and improvements are expected to generate additional welding jobs.

Automation Reduces The Number of Welders Needed

Pressures to improve productivity and hold down labor costs are leading many companies to invest more in automation, especially computer-controlled and robotically controlled welding machinery.

This will reduce the demand for some welders, solderers, and brazers because many repetitive jobs are being automated.

The growing use of automation, however, should increase demand for welding, soldering, and brazing machine setters, operators, and tenders.

Construction Will Help Employment

Welders working on construction projects or in equipment repair will not be affected by technology change to the same extent, because their jobs are often unique and not as easily automated.

Technology and Welding Careers

Despite slower-than-average job growth, technology is creating more uses for welding in the workplace and expanding employment opportunities.

For example, new ways are being developed to bond dissimilar materials and nonmetallic materials, such as plastics, composites, and new alloys.

Also, laser beam and electron beam welding, new fluxes, and other new technologies and techniques are improving the results of welding, making it useful in a wider assortment of applications.

Improvements in technology have also boosted welding productivity, making welding more competitive with other methods of joining materials.

Welding Definition

Welding is the most common way of permanently joining metal parts.

In this process, heat is applied to metal pieces, melting and fusing them to form a permanent bond.

Because of its strength, welding is used in shipbuilding, automobile manufacturing and repair, aerospace applications, and thousands of other manufacturing activities.

Welding also is used to join beams when constructing buildings, bridges, and other structures, and to join pipes in pipelines, power plants, and refineries.

Anyone embarking on a welding career will use many types of welding equipment set up in a variety of positions, such as flat, vertical, horizontal, and overhead.

They may perform manual welding, in which the work is entirely controlled by the welder, or semiautomatic welding, in which the welder uses machinery, such as a wire feeder, to perform welding tasks.

Types of Welding

There are about 100 different types of welding. Arc welding is the most common type.

Standard arc welding involves two large metal alligator clips that carry a strong electrical current.

One clip is attached to any part of the workpiece being welded. The second clip is connected to a thin welding rod.

When the rod touches the workpiece, a powerful electrical circuit is created.

The massive heat created by the electrical current causes both the workpiece and the steel core of the rod to melt together, cooling quickly to form a solid bond.

During welding, the flux that surrounds the rod’s core vaporizes, forming an inert gas that serves to protect the weld from atmospheric elements that might weaken it.

Welding speed is important. Variations in speed can change the amount of flux applied, weakening the weld, or weakening the surrounding metal by increasing heat exposure.

Two common but advanced types of arc welding are Tungsten Inert Gas (TIG) and Metal Inert Gas (MIG) welding.

TIG welding often is used with stainless steel or aluminum. While TIG uses welding rods, MIG uses a spool of continuously fed wire, which allows the welder to join longer stretches of metal without stopping to replace the rod.

In TIG welding, the welder holds the welding rod in one hand and an electric torch in the other hand. The torch is used to simultaneously melt the rod and the workpiece.

In MIG welding, the welder holds the wire feeder, which functions like the alligator clip in arc welding.

Instead of using gas flux surrounding the rod, TIG and MIG protect the initial weld from the environment by blowing inert gas onto the weld.

Like arc welding, soldering and brazing use molten metal to join two pieces of metal. However, the metal added during the process has a melting point lower than that of the workpiece, so only the added metal is melted, not the workpiece.

Soldering uses metals with a melting point below 800 degrees Fahrenheit; brazing uses metals with a higher melting point. Because soldering and brazing do not melt the workpiece, these processes normally do not create the distortions or weaknesses in the workpiece that can occur with welding.

Soldering commonly is used to join electrical, electronic, and other small metal parts.

Brazing produces a stronger joint than does soldering, and often is used to join metals other than steel, such as brass. Brazing can also be used to apply coatings to parts to reduce wear and protect against corrosion.

Being A Welder

Skilled welding, soldering, and brazing workers generally plan work from drawings or specifications or use their knowledge of fluxes and base metals to analyze the parts to be joined.

These workers then select and set up welding equipment, execute the planned welds, and examine welds to ensure that they meet standards or specifications. They are even examining the weld while they’re welding.

By observing problems with the weld, they compensate by adjusting the speed, voltage, amperage, or feed of the rod.

Highly skilled welders often are trained to work with a wide variety of materials in addition to steel, such as titanium, aluminum, or plastics. Some welders have more limited duties, however. They perform routine jobs that already have been planned and laid out and do not require extensive knowledge of welding techniques.

Automated welding is used in an increasing number of production processes. In these instances, a machine or robot performs the welding tasks while monitored by a welding machine operator.

Welding, soldering, and brazing machine setters, operators, and tenders follow specified layouts, work orders, or blueprints. Operators must load parts correctly and constantly monitor the machine to ensure that it produces the desired bond.

The work of arc, plasma, and oxy-gas cutters is closely related to that of welders. However, instead of joining metals, cutters use the heat from an electric arc, a stream of ionized gas (plasma), or burning gases to cut and trim metal objects to specific dimensions.

Cutters also dismantle large objects, such as ships, railroad cars, automobiles, buildings, or aircraft. Some operate and monitor cutting machines similar to those used by welding machine operators.

Plasma cutting has been increasing in popularity because, unlike other methods, it can cut a wide variety of metals, including stainless steel, aluminum, and titanium.

Working Conditions

Welding, soldering, and brazing workers often are exposed to a number of hazards, including the intense light created by the arc, poisonous fumes, and very hot materials.

They wear safety shoes, goggles, hoods with protective lenses, and other devices designed to prevent burns and eye injuries and to protect them from falling objects.

They normally work in well-ventilated areas to limit their exposure to fumes.

Automated welding, soldering, and brazing machine operators are not exposed to as many dangers, however, and a face shield or goggles usually provide adequate protection for these workers.

Welders and cutters may work outdoors, often in inclement weather, or indoors, sometimes in a confined area designed to contain sparks and glare.

Outdoors, they may work on a scaffold or platform high off the ground. In addition, they may be required to lift heavy objects and work in a variety of awkward positions, while bending, stooping, or standing to perform work overhead.

Although about 52 percent of welders, solderers, and brazers work a 40-hour week, overtime is common, and some welders work up to 70 hours per week.

Welders also may work in shifts as long as 12 hours. Some welders, solderers, brazers, and machine operators work in factories that operate around the clock, necessitating shift work.

Welding Career Training

Training for welding, soldering, and brazing workers can range from a few weeks of school or on-the-job training for low-skilled positions to several years of combined school and on-the-job training for highly skilled jobs.

Formal training is available in high schools, vocational schools, and post-secondary institutions, such as vocational-technical institutes, community colleges, and private welding schools. There are even basic online welding courses to help you get set up.

The Armed Forces operate welding schools as well.

While some employers provide basic training, they prefer to hire workers with experience or more formal training.

Courses in blueprint reading, shop mathematics, mechanical drawing, physics, chemistry, and metallurgy are helpful.

An understanding of electricity also is very helpful and knowledge of computers is gaining importance, especially for welding, soldering, and brazing machine operators, who are becoming more responsible for the programming of computer-controlled machines, including robots.

Welding Programs For Veterans

The Wounded Warriors Family Support program has partnered with UAW-Ford to offer a free six week welding training program for veterans. Everything is 100% paid for including room and board, plus course tuition.

Training includes a number of welding processes such as GTAW, GMAW and SMAW and a number or positions and joints. Successful completion qualifies participants to take the AWS Certified Welder Test in the 1G through 4G positions. To learn more visit the Wounded Warrior Website.

Welding Certification

Some welders become certified, a process whereby the employer sends a worker to an institution, such as an independent testing lab, equipment manufacturer, or technical school, to weld a test specimen according to specific codes and standards required by the employer.

Testing procedures are based on the standards and codes set by industry associations with which the employer may be affiliated.

If the welding inspector at the examining institution determines that the worker has performed according to the employer’s guidelines, the inspector will then certify that the welder being tested is able to work with a particular welding procedure.

To maximize earnings it pays to add a certification to your welding career plan.

Welding Certifications offered by the American Welding Society:

- Certified Welder

- Certified Associate Welding Inspector

- Certified Welding Engineer

- Certified Robotic Arc Welding Operator

- Certified Welding Supervisor

- Senior Certified Welding Inspector

Welding Certifications offered by the International Code Council:

- Structural Welding Special Inspector

Qualifications

To launch a welding career, welding, soldering, and brazing workers need good eyesight, hand-eye coordination, and manual dexterity.

They should be able to concentrate on detailed work for long periods and be able to bend, stoop, and work in awkward positions.

In addition, welders increasingly need to be willing to receive training and perform tasks in other production jobs.

Related: How To Get A Welding Job

Advancement

Welding career advancement to more skilled welding jobs require additional training and experience. For example, they may become:

- welding technicians

- supervisors

- inspectors

- instructors.

Some experienced welders open their own repair shops as their welding career choice.

Salaries

Industries with the highest levels of employment in this occupation:

| Industry | Employment (1) | Percent of industry employment | Hourly mean wage | Annual mean wage (2) |

|---|---|---|---|---|

| Fabricated Metal Product Manufacturing (3323 and 3324 only) | 71,030 | 14.46 | $20.47 | $42,570 |

| Machinery Manufacturing (3331, 3332, 3334, and 3339 only) | 59,520 | 7.91 | $20.76 | $43,180 |

| Fabricated Metal Product Manufacturing (3321, 3322, 3325, 3326, and 3329 only) | 24,370 | 5.02 | $20.15 | $41,910 |

| Motor Vehicle Body and Trailer Manufacturing | 22,520 | 13.70 | $19.16 | $39,860 |

| Employment Services | 16,880 | 0.46 | $20.49 | $42,610 |

Industries with the highest concentration of employment in this occupation:

| Industry | Employment (1) | Percent of industry employment | Hourly mean wage | Annual mean wage (2) |

|---|---|---|---|---|

| Railroad Rolling Stock Manufacturing | 3,590 | 15.45 | $20.66 | $42,980 |

| Fabricated Metal Product Manufacturing (3323 and 3324 only) | 71,030 | 14.46 | $20.47 | $42,570 |

| Motor Vehicle Body and Trailer Manufacturing | 22,520 | 13.70 | $19.16 | $39,860 |

| Ship and Boat Building | 12,890 | 9.16 | $24.54 | $51,050 |

| Machinery Manufacturing (3331, 3332, 3334, and 3339 only) | 59,520 | 7.91 | $20.76 | $43,180 |

Top paying industries for this occupation:

| Industry | Employment (1) | Percent of industry employment | Hourly mean wage | Annual mean wage (2) |

|---|---|---|---|---|

| Scheduled Air Transportation | 60 | 0.01 | $42.84 | $89,110 |

| Natural Gas Distribution | 670 | 0.61 | $38.76 | $80,620 |

| Electric Power Generation, Transmission and Distribution | 1,260 | 0.33 | $37.62 | $78,260 |

| Petroleum and Coal Products Manufacturing | 920 | 0.82 | $31.68 | $65,900 |

| Other Pipeline Transportation | 40 | 0.49 | $31.15 | $64,780 |

Top paying States for this occupation:

| State | Employment (1) | Employment per thousand jobs | Location quotient (9) | Hourly mean wage | Annual mean wage (2) |

|---|---|---|---|---|---|

| Alaska | 570 | 1.81 | 0.65 | $32.09 | $66,740 |

| District of Columbia | 80 | 0.11 | 0.04 | $30.76 | $63,980 |

| Hawaii | 530 | 0.83 | 0.30 | $29.73 | $61,830 |

| Wyoming | 2,040 | 7.48 | 2.67 | $29.64 | $61,650 |

| New Mexico | 2,080 | 2.53 | 0.90 | $27.28 | $56,740 |

(1) Estimates for detailed occupations do not sum to the totals because the totals include occupations not shown separately. Estimates do not include self-employed workers.

(2) Annual wages have been calculated by multiplying the hourly mean wage by a “year-round, full-time” hours figure of 2,080 hours; for those occupations where there is not an hourly wage published, the annual wage has been directly calculated from the reported survey data.

(9) The location quotient is the ratio of the area concentration of occupational employment to the national average concentration. A location quotient greater than one indicates the occupation has a higher share of employment than average, and a location quotient less than one indicates the occupation is less prevalent in the area than average.

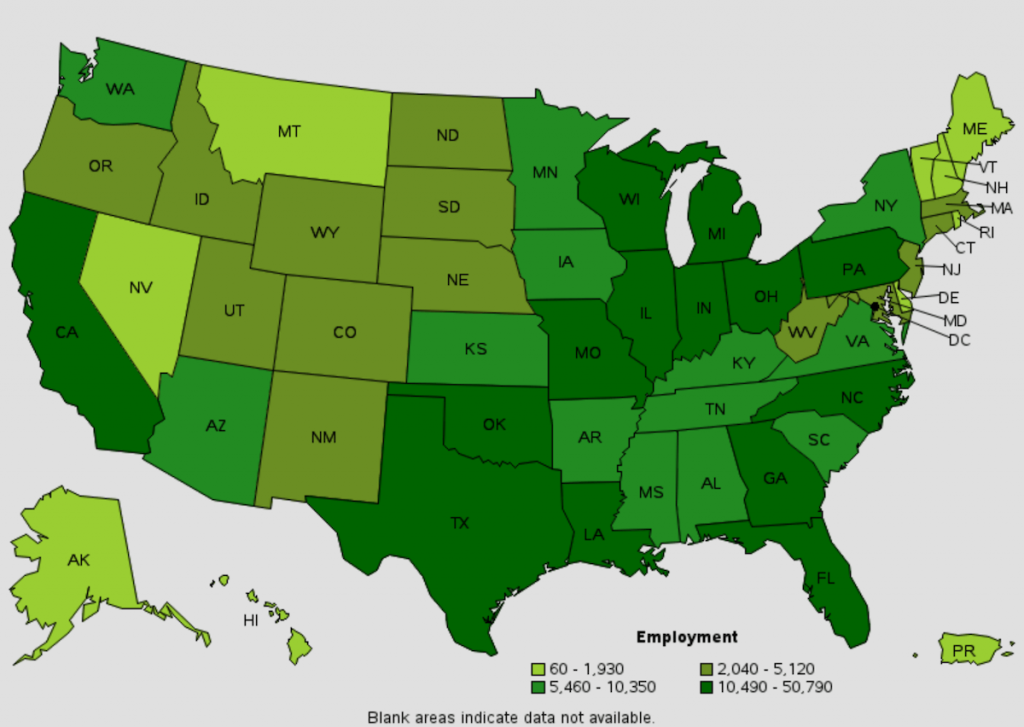

Welding Employment Opportunities by State

Every state is different when launching a welding career in terms of demand for skilled professionals. See the map below for employment by state.

States with the highest employment level in this occupation:

| State | Employment (1) | Employment per thousand jobs | Location quotient (9) | Hourly mean wage | Annual mean wage (2) |

|---|---|---|---|---|---|

| Texas | 50,790 | 4.09 | 1.46 | $22.57 | $46,940 |

| California | 28,980 | 1.67 | 0.60 | $23.03 | $47,910 |

| Ohio | 18,500 | 3.40 | 1.21 | $20.22 | $42,060 |

| Pennsylvania | 17,430 | 2.95 | 1.06 | $21.38 | $44,480 |

| Indiana | 16,550 | 5.38 | 1.93 | $20.27 | $42,160 |

(1) Estimates for detailed occupations do not sum to the totals because the totals include occupations not shown separately. Estimates do not include self-employed workers.

(2) Annual wages have been calculated by multiplying the hourly mean wage by a “year-round, full-time” hours figure of 2,080 hours; for those occupations where there is not an hourly wage published, the annual wage has been directly calculated from the reported survey data.

(9) The location quotient is the ratio of the area concentration of occupational employment to the national average concentration. A location quotient greater than one indicates the occupation has a higher share of employment than average, and a location quotient less than one indicates the occupation is less prevalent in the area than average.

Welding Unions

Many welders belong to unions or receive training through a union. The union is also a source of safety information and updates on welding technology.

Among these are the:

- International Association of Bridge, Structural, Ornamental and Reinforcing Iron Workers Union

- The International Brotherhood of Boilermakers

- United Automobile, Aerospace and Agricultural Implement Workers of America

- The United Electrical, Radio, and Machine Workers of America

- International Brotherhood of Electrical Workers (IBEW)

- International Union of Elevator Constructors (IUEC)

- International Union of Operating Engineers (IUOE)

- Sheet Metal Workers’ International Association (SMWIA)

- United Brotherhood of Carpenters (UBC)

Welding, soldering and brazing workers are skilled metalworkers. Other metal workers include:

- Machinists

- Machine setters

- Operators

- Tenders—metal and plastic

- Computer control programmers and operators

- Tool and die makers

- Sheet metal workers

- Boilermakers

Assemblers and fabricators of electrical and electronic equipment often assemble parts using soldering.

Information on careers and educational opportunities in welding is available from:

For information on training opportunities and jobs for welding, soldering, and brazing workers, contact local employers, the local office of the State employment service, or schools providing welding, soldering, or brazing training.

See our guide to U.S. and International welding scholarships.

American Welding Society, 550 N.W. Lejeune Rd., Miami, FL 33126.

References

(1) Estimates for detailed occupations do not sum to the totals because the totals include occupations not shown separately. Estimates do not include self-employed workers.

(2) Annual wages have been calculated by multiplying the hourly mean wage by a “year-round, full-time” hours figure of 2,080 hours; for those occupations where there is not an hourly mean wage published, the annual wage has been directly calculated from the reported survey data.

(3) The relative standard error (RSE) is a measure of the reliability of a survey statistic. The smaller the relative standard error, the more precise the estimate.

My boyfriend is a mig welder. He gets treated like absolute crud. Businesses who do more than just welding treat mig welders as second class citizens. They also get paid like crud starting out at $13/h and have to work 10-11 hours breathing in nasty smoke and metal dust. If you’re going to get into welding, do tig welding. You get treated real well and the pay is starting out at $22-$25/h.