Weld spatter is an all-too-common issue that can lead to unsightly results and potential safety hazards. As a serious welder, understanding how to minimize this problem is crucial for high-quality, visually appealing welds.

So, what exactly is weld spatter, what causes it, and how can you prevent it?

In this article, I’ll delve into the intricacies of weld spatter and its various causes.

I will also offer tips on proper equipment maintenance and welding techniques to ensure you get a spatter-free experience and a pristine final product.

What Is Weld Spatter?

Weld spatter occurs when small, molten droplets form and scatter during welding, settling on the surrounding work area, base material, or welding tools. Once cooled, these droplets impact the appearance of the weld.

© weldguru.com – Image usage rights

Spatter is a common issue in welding, often leading to unsightly imperfections and potential safety hazards, like burns. If it lands on you, expect your skin to scorch; these tiny metal globules can burn through clothing. Ouch!

© weldguru.com – Image usage rights

Most of these issues occur predominantly when MIG welding (GMAW), though they’re also common in flux-cored (FCAW) and stick welding (SMAW). And because spatter ejects metal from the weld, it may even compromise the integrity of the weld and the parent metal in severe cases.

While spatter may seem unavoidable, understanding its causes and employing effective techniques can significantly reduce it.

What Causes Weld Spatter?

The main cause of weld spatter is an unstable welding arc. This can result from wrong voltage and amperage settings, leading to an arc that’s too cool to keep the wire and pool molten—causing a stubbing effect that leads to spatter.

© weldguru.com – Image usage rights

Additional factors that cause spatter include incorrect shielding gas selection and low-quality materials. For example, while cost-effective, CO2 shielding gases can generate more spatter than argon, which tends to counterbalance the spatter caused by CO2.

However, the instability of the welding arc can have various underlying causes, such as disturbance in the weld pool during wire transfer or the use of low-quality welding wire or base material.

Other contributing factors include metal composition, contaminated metals, and your welding technique.

Is Weld Spatter Considered a Defect?

Whether weld spatter is considered a defect depends on the project specifications or relevant welding standards. If spatter exceeds the allowed limits, it can compromise the integrity and appearance of the final product.

While minor spatter is often an inevitable part of the welding process, excessive amounts can become problematic, especially when strict surface quality and finish requirements are in place.

Therefore, welders should be keenly aware of project requirements and take necessary measures to minimize spatter, ensuring that the final product meets desired quality standards.

5 Tips To Prevent Spatter

Reducing spatter is essential for achieving high-quality welds and ensuring safety.

Let’s take a look at each of the factors to help reduce weld spatter.

1. Use the Right Welding Settings

The wrong settings can disrupt the welding pool and lead to increased spatter. Correct wire feed speed, amperage, and voltage are key for MIG and stick welding.

With a MIG welder, consider the type of gas and its flow rate to minimize spatter.

Note: Dialing in your settings may take some experimentation. Try practicing on scrap metal first. If you make major changes, you risk skipping over the optimal settings. Investing this time not only improves your welds but also minimizes spatter.

MIG Welder (GMAW) Settings

- Remember to flip your polarity when switching from flux-cored (FCAW) wire to solid.

- Check your current and voltage to ensure good penetration and proper heat.

- Wire speed matters: too slow and you risk vaporizing the wire before it gets to the weld, causing spatter. Too fast, and you’ll disturb the molten pool, resulting in spatter.

- Lastly, ensure your gas blanket is evenly distributed; otherwise, you risk contamination and more spatter.

Related read: MIG Welding Settings Explained with Chart

Stick Welder (SMAW) Settings

With a stick welder, the speed of your work correlates with your current and voltage settings. If it’s too hot and you have to move fast, you’ll create spatter.

On the flip side, if it’s too cold, your welding may fluctuate between welding and sticking, also resulting in spatter.

2. Clean off Dirt & Contamination

The key to reducing spatter lies not just in the right welding settings but also in maintaining a clean workspace and materials.

Dirt, rust, and other forms of contamination can lead to increased spatter, compromising the quality of your welds.

Why Cleanliness Matters

© weldguru.com – Image usage rights

Just like adding water to hot oil causes it to spit and splatter, dirt and contamination have the same effect on molten metal.

These impurities can result in spatter that requires additional cleaning, thereby extending your work time.

Common Contaminants

Manufacturers often apply protective coatings to metals; although it’s possible to weld through these treatments, it usually results in more spatter. So, think of these coatings as potential contaminants.

Also, remember that your filler materials can be contaminated, too. Neglected welding wire or rods, especially dirty or rusted ones, can also be a significant source of spatter.

Tips for Maintaining Cleanliness

- Remove any protective coatings or oils from the base material before you begin welding.

- Check your filler materials; make sure they’re free from dirt, rust, and oil. Store them properly to prevent contamination.

3. Use the Correct Filler Composition

Selecting quality materials is not just about durability or appearance; it’s a critical factor in reducing spatter during the welding process.

Both your base metal and filler materials should be of high quality to minimize the occurrence of weld spatter.

Why Material Quality Matters

Using cheaper metals often means dealing with “filler” substances that make the metal more challenging to weld cleanly. Spatter is almost inevitable when you use such low-grade materials.

The same principle applies to your filler materials like rods and welding wire. Lower quality often contains substances that are prone to cause spatter.

How to Choose Quality Materials

- Know Your Metal: Always research and understand the type of metal you’re working with. Quality metals that are well-suited for welding will naturally produce less spatter.

- Choose the Right Filler: It’s not just about the base metal; your filler materials must also be quality. Investing in the best filler wire and rods you can find will reduce spatter and contribute to the overall quality of your weld.

4. Use the Proper Welding Technique

No amount of high-quality materials or perfectly dialed-in equipment settings can make up for poor technique when it comes to reducing spatter.

Your welding technique, be it with a MIG or stick welder, plays a crucial role in minimizing the incidence of spatter.

Why Technique Matters

© weldguru.com – Image usage rights

The angle of your MIG gun, the speed of your movements, and the length of your arc in stick welding are all technique-related factors that can lead to increased spatter.

Ignoring these could undo all your preparation and set you back to square one in your fight against spatter.

Guidelines to Minimize Spatter

MIG Welding (GMAW)

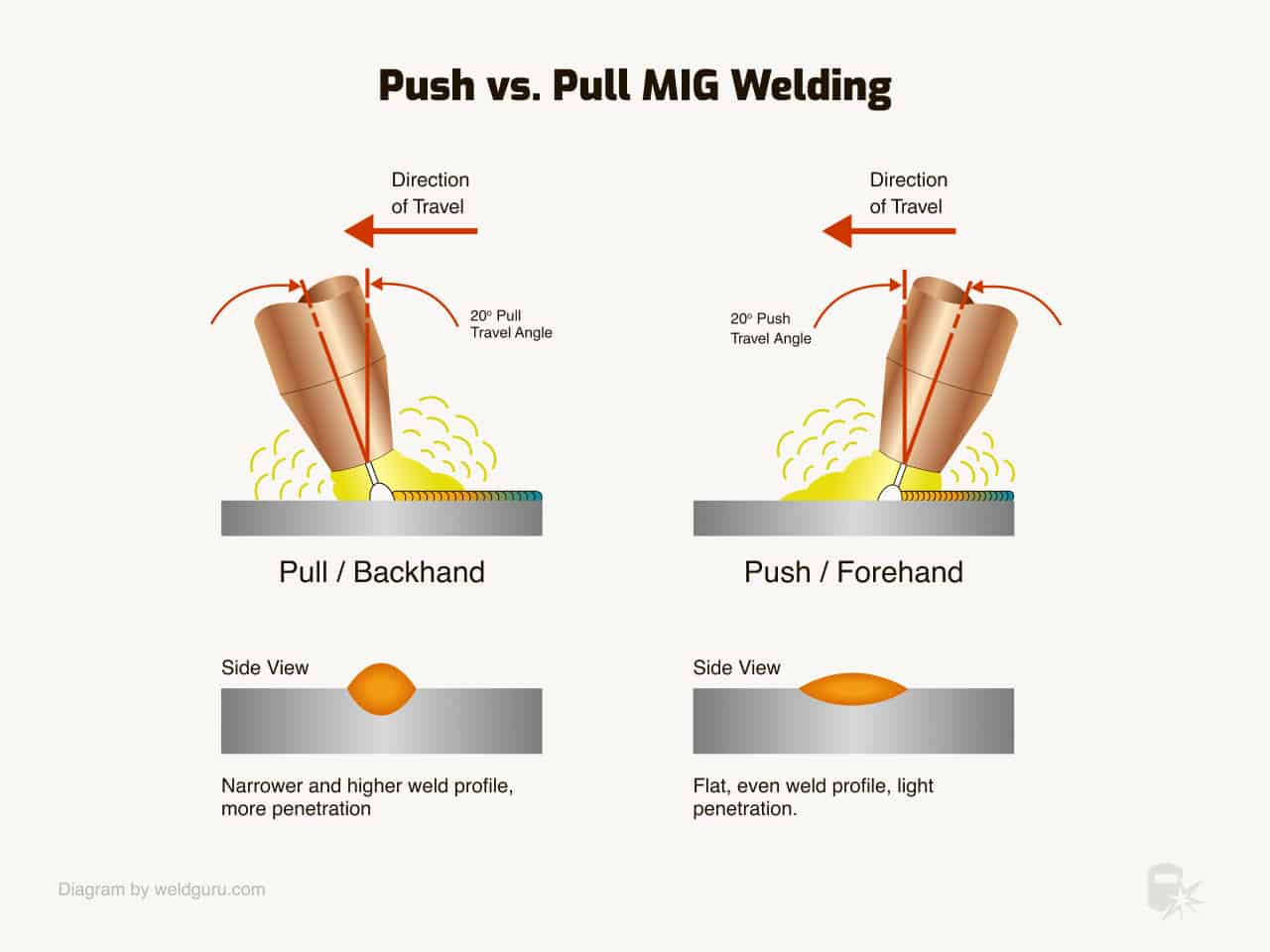

- Direction: Your movement direction during welding matters. Pulling is better for consistent heat, while pushing distributes heat more evenly. Get this wrong, and you’ll likely face more spatter. Read more: Is it better to push or pull when MIG welding?

- Angle: Maintain a 15° to 20° angle with your MIG gun to minimize spatter. Drifting over a 20° angle will produce more spatter than you’d like.

- Speed: Moving too quickly or too slowly can compromise your bead quality and, yes, cause additional spatter.

Stick Welder (SMAW)

- Speed: Just like with MIG welding, moving too quickly with a stick welder can lead to more spatter, especially if your voltage is set too high.

- Arc Length: The ideal arc length should be equivalent to the metallic core of the electrode you’re using. Longer arcs increase the voltage and, consequently, the spatter.

5. Use the Right Shielding Gas for MIG Welding

When it comes to MIG welding, the gas you use matters almost as much as the equipment you’re wielding.

Picking the right shielding gas can make a world of difference in your ongoing battle against spatter.

The Role of Shielding Gas in Spatter Reduction

Shielding gas serves as an invisible barrier that protects your weld pool from contaminants like oxygen and water vapor. But some gases are more prone to generating spatter than others.

Gas Types & Their Impact

- Carbon Dioxide (CO2): It’s cheap and readily available, but it has a downside. CO2 increases arc energy and spatter. Use it when you must, but know the trade-offs.

- Argon: Pricier but more refined, argon tends to reduce spatter. In some cases, it counterbalances the spatter-enhancing properties of CO2.

- Argon/CO2 Mix: Often, you’ll see this blend in MIG/MAG welding setups. It offers a middle ground between the cost-effectiveness of CO2 and the spatter-reducing properties of argon.

Experiment to Optimize

Experimenting with various gas mixtures and flow rates is essential to find the optimal combination for your specific welding application.

Remember that factors like material type, thickness, and welding position may require adjustments to the shielding gas mixture and flow rate to reduce the spatter and achieve the desired weld quality.

How to Fine-Tune Your Gas Settings

- Test Different Mixtures: Use scrap metal to experiment with various gas mixtures and observe the spatter levels.

- Adjust Flow Rates: Sometimes, it’s not just what gas you use but how much of it. Tweaking the flow rate can affect spatter.

- Consider the Material: The type and thickness of the material you’re welding can influence the optimal gas mixture and flow rate.

Related read: Choosing the right gas for MIG welding

How To Clean Spatter

After taking all the precautions you can, you may still get some spatter.

When spatter occurs, you usually need to clean it to make the weld look its best. Here’s a rundown of your options.

- Use a grinder: One method of cleaning spatter is breaking out the tried and true angle grinder. It works but takes time and effort. However, simultaneously hitting the spatter makes sense if you’re grinding as part of the finishing operation.

- Use a chipping hammer: For those times when you get a small amount of spatter, a chipping hammer works well. These hammers are designed and manufactured to remove the offending spatter quickly without damaging the base metal, leaving you with a cleaner-looking weld.

- Anti-Spatter Solutions: Sprays, Gels, and Tapes: Another strategy you can use is not letting the spatter stick in the first place. You can apply anti-spatter spray and nozzle gel to keep the spatter from adhering. Some welders also find tape works well to mask certain areas. But use aluminum tape. It holds up to the heat of the spatter and doesn’t melt like plastic tape.

Wrapping It Up

In conclusion, weld spatter may be an unwelcome guest in the world of welding, but with the right knowledge and techniques, you can minimize its impact.

By understanding the various causes of spatter and implementing effective strategies such as optimizing welder settings, maintaining cleanliness, using quality materials, perfecting your technique, and choosing the appropriate shielding gas, you can significantly reduce spatter and produce top-notch welds.

Remember that practice makes perfect; the more experience you gain, the better equipped you’ll be to address spatter-related issues. Don’t shy away from experimenting with different settings, materials, and techniques to find the perfect balance for your specific welding needs.

With persistence, attention to detail, and a commitment to continuous improvement, you’ll be well on your way to mastering the art of spatter-free welding and achieving exceptional results.

Keep the sparks flying, and happy welding!