What size generator do I need to run a welder?

I get asked that a lot.

There are good reasons why it makes sense.

- You need to repair a gate that’s not close enough to household power

- A friend’s truck is broken down out on the trail

- You want to build a greenhouse in your garden

But if it’s too small, you could damage or kill your expensive welder.

Too big, and it may cost too much to run, be hard to move, and take up too much room.

How to Figure Out What Size Generator For Your Welder

This question usually takes one of these forms, for example:

- What size ggenerator do I need for a 180 amp welder?

- Will a 7,000-watt generator run a welder?

- How big of a welder can you run with a generator of X size?

These are actually all the same questions. You’re just asking it from different viewpoints.

This Is How You Do It

Generators, like welders, come in lots of different sizes. There are a lot of features and options available. And you’ll need to decide if you want 120-volt output, 240 volts, or both.

The trickiest thing to watch out for is that generators are rated in total WATTS of power output, but welders are rated for output AMPERAGE.

That means you need to figure out how many watts a welder needs to produce its rated amps.

How Many Watts Does Your Welder Use?

There’s a very basic math equation to move back and forth between volts, amps, and watts:

Volts x Amps = Watts

Volts: The technical definition is “a measurement of the difference in electrical potential between two points.”

Think of volts in the same way you think of water pressure. It’s the available “push” that gets the electricity going.

Amps: Amperes are a way to measure the flow of electrical current.

Keeping with our water supply analogy, think of amps as the rate of flow in the pipes, fast or slow.

Watts: A watt measures heat energy. As electrons flow through the circuit, friction makes heat, measured in watts.

So what you need is the voltage the welder uses, multiplied by the input amps of the welder.

Find Your Welder’s Input Power

Step 1: Find the power & current levels

First, you need to know what power and current levels your welder needs to run. A commonplace to find this info is in the manual.

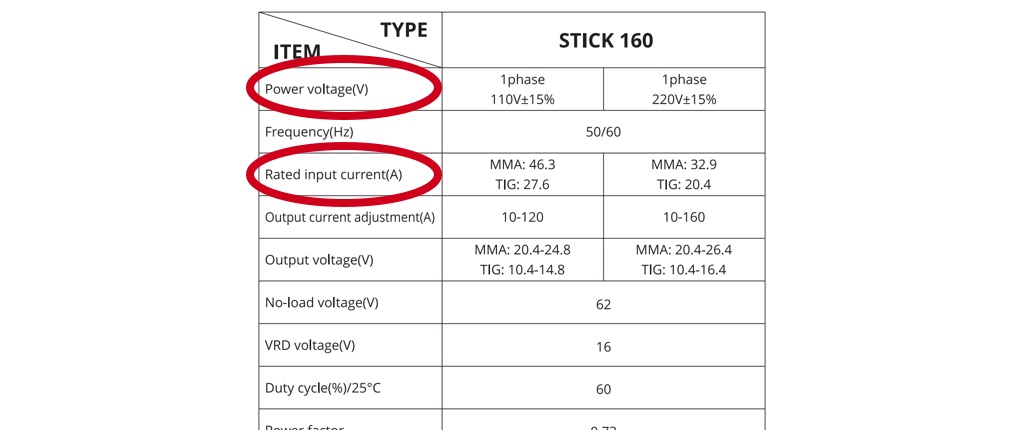

Here’s an example from the manual for the PrimeWeld Stick 160.

Look at “Power voltage(V)”. That’s your input voltage.

It’s important to go with the “plus 15 percent” for calculations to be certain your portable generator is large enough to fit your needs.

110 volts + 15% = 126.5 volts

220 volts + 15% = 253 volts

Step 2: Calculate the input current

Second, you want the “Input current (A)”.

The highest input current on the 110-volt side is 46.3 amps.

Now you can do your math:

126.5 volts x 46.3 amps = 5,856.95 watts, a “running watts” number. But you still need to add a good safety margin for “starting watts.” An extra 30 percent is recommended.

Let’s check the 220-volt numbers.

Input current on the 220 side is 32.9 amps.

253 volts x 32.9 amps = 8323.7 watts for your operating load on the 220 side. As always, add a 30 percent safety margin to provide enough starting power for your machine. I’ll talk more about this 30 percent in a minute.

If you want to run this welder in 110-volt mode only, you’ll need a generator that puts out 6,000 watts (6 KW), PLUS 30 percent for starting and demand spikes (another 2 KW), meaning you need a welder generator rated for 6,000 watts running and 8,000 peak watts.

To run the welder unfettered with full power on the 220-volt side, you’ll need 8,500 running watts and 11,000 peak wattage.

Maybe you don’t have access to the manual. What then?

Every power tool and appliance has an information label that lists its electrical information. It’s usually on the rear of your welder or the inside of the case.

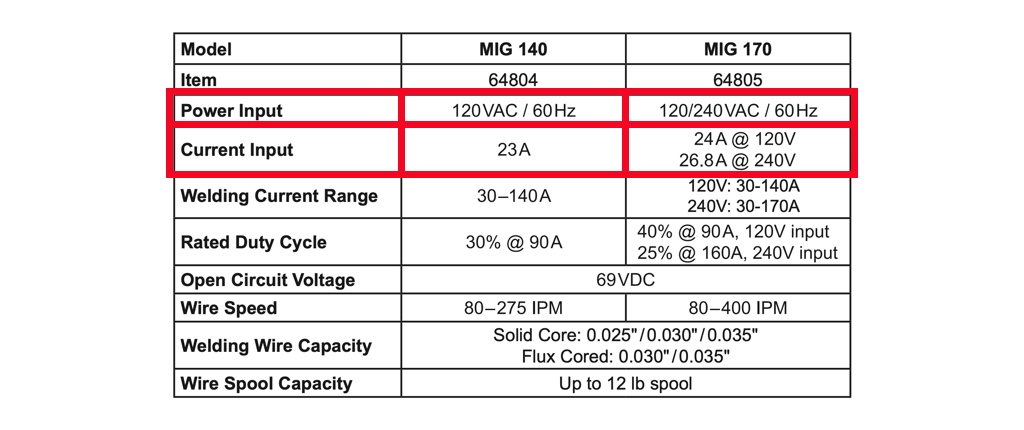

Your welder’s input power will be listed on this label. Here’s an example from the Titanium MIG 140, a machine that takes 120-volt power. Notice the label also has information on the MIG 170 from the same series, a machine that takes either 120- or 240-volt power.

Checking the specifications, once again, there are numbers here for “Current Input”. This label is easier to work with than some because it gives both input voltage and the input current needed by the welder.

It’s easy to figure out how much power you need in watts from a generator for your welder. For the 140-amp version, multiply:

120 volts input x 23 amps = 2,760 watts

That’s only the BASIC number, however. It’s characteristic of power tools to use much more power to start than it takes to keep them running.

Generator makers advise adding up to 30 percent to the running watts to account for starting devices.

2,760 watts x .30 = 828 watts

Add this 30 percent safety margin to the basic running figure of 2,760 watts:

2,760 + 828 = 3,588

This amounts to 3,600 watts. This welder will need a generator rated at 2,800 operating watts, with a peak rating of 3,600 watts.

Take away notes:

- DON’T FORGET to add specified tolerance, like our example was plus or minus 15 percent. ALWAYS ADD THE TOLERANCE IN.

- REMEMBER TO ADD 30 percent to your total wattage to cover the starting surge. The exception to this rule is if you’re using a value known as “I1max“. See the next section for more information.

Input Values Can Have Other Names too

Sometimes there are several different types of electrical ratings. You may not have a rating on the label that’s specifically called “input voltage” or “input current,” but there are other names for them.

No need to be confused, however. Check for values with these names instead:

Input Voltage

- Max Power

- Max Voltage

- V max or Vmax

- U max or Umax

- U1max

Input Current

- Max Amperage

- Max Current

- A max

- I max

- I1max

Note that choice 5 in both cases has a notation of 1max. This name specifically indicates main input power.

I2 or I2max means output power.

The I1max rating is already adjusted for surge or starting watts. If you calculate with I1max, you already have your maximum starting watts rating WITHOUT a need to add 30 percent.

Another unit you sometimes see on a generator for welders is the Kilovolt Amp or KVA.

For this unit 1,000 volts x 1 Amp = 1 KVA, the same as 1 Kilowatt (Kw).

Remember: Volts x Amps = Watts

Because 1 KVA = 1 Kw, a generator that makes 6 KVA of peak power is also rated at 6 kW.

Power Supply Differences Between Inverters & Transformers

One important choice is whether your welding machine is powered by a transformer or is an inverter welder. This matters because with generators for welders, there is a quality called “dirty power.”

“Dirty Power” means small and repeated fluctuations in the power level as the engine runs.

These fluctuations in power are called “harmonic distortion” and measured in units of Total Harmonic Distortion, or THD. It’s presented as a percentage, for instance, “5 percent THD.”

Transformer-powered welders are quite forgiving of dirty power from a generator. Nearly any modern generator can run a transformer-powered welder.

The problem is with inverter-powered machines. Commonly called IGBT and MOSFET welders, they have problems with dirty power because their control circuits are easily damaged by harmonic distortions in the power supply.

Without getting too technical, these designs use capacitors to filter out distortion, smoothing the power supply. Another benefit of inverter power is the welder itself can be lighter.

A lot of modern generators are designed with inverter filters, making them safe for inverter-powered welders.

If you have a transformer-powered welder, THD isn’t a problem, but if you want to run a computer, anything digital, or an IGBT or MOSFET welder, you need to be below 6 percent THD.

Read more about inverter and transformers welders here.

Other Factors Affecting Your Choice

High Altitude Issues

At high altitudes, there’s less oxygen. Gasoline, diesel, and propane engines run less efficiently, making less power. Your welding generator will make less wattage at high altitudes than it would at sea level. Generator makers advise planning on a 3.5 percent power loss for every 1,000 feet of elevation.

Depending on the elevation, it could be barely noticeable, or it could be a lot less power. Generator makers offer high-altitude kits to help.

Extra Tools and Equipment

If you need to run extra tools like saws, grinders, drills and the like, you need to add at least another 2,000 watts to the capacity because many grinders and reciprocating saws take as much as 1,800 watts to operate.

Also, consider fans, heaters, and lighting. It may actually be cheaper to buy a smaller generator for these accessories than one large one to run both your welder and extra tools.

Here’s a partial list of common devices and their power demands:

| Appliance | Running Watts | Starting Watts |

|---|---|---|

| Coffee Maker | 1750 | 0 |

| 625W Microwave | 625 | 800 |

| Single 60W equivalent CFL bulb | 15 | 0 |

| Radio | 50-200 | 0 |

| Room Air Conditioner: 10,000 BTU | 1500 | 2200 |

| Small Appliance | 200 | 1700 |

| 8in. Bench Grinder | 1400 | 2500 |

| Pressure Washer: 1 HP | 1200 | 3600 |

| 7-1/4in. Circular Saw | 1400 | 2300 |

| Electric Chain Saw: 14in. Bar, 2 HP | 1100 | 0 |

| 10in. Table Saw | 1800 | 4500 |

| Drill: 3/8in., 4 Amps | 440 | 600 |

| Drill: 1/2in., 5.4 Amps | 600 | 900 |

| Portable Heater (Kerosene, Diesel Fuel): 90,000 BTU | 500 | 725 |

| Battery Charger: 60 Amp with 250 Amp Boost | 1500/5750 | 0 |

| Laptop | 65 | 0 |

| LCD Computer Monitor | 25 | 0 |

| Inkjet Printer | 15 | 0 |

| Tablet | 12 | 0 |

| Cell Phone Charger | 10 | 0 |

How Long Is the Run Time?

This is how long a generator can run at full demand, with a full tank of fuel. Some can run as long as 8-10 hours, while some big generators might only last a couple of hours between refills if they’re working hard.

Noise

Generators are loud, although generally not as loud as some tools and vehicles are. There are also exhaust fumes to consider, with the danger of carbon monoxide. You can’t put a generator inside safely, and they all have labels telling you not to do this.

You need to make sure it’s ventilated well, protected from collisions or dropped items, cords can reach your work area safely, and noise won’t be a problem where it’s sitting.

Check its dB rating to see how loud it is. Anything over 90 dB is damaging to hearing. 120-decibel ratings and above are equivalent to literally deafening sounds like drag racers, artillery, jet aircraft, and hunting rifles.

Placement

This chart gives some National Electrical Manufacturers (NEMA) recommendations on extension cord length. Whenever possible, plug devices directly into the generator.

Your coffee maker can brew until you take a break, then you can pour a cup once you walk over and shut off the generator.

| Total Wattage | 10 gauge cord | 12 gauge cord | 14 gauge cord | 16 gauge cord |

|---|---|---|---|---|

| 2,400 | 250 feet | 150 feet | 100 feet | 75 feet |

| 4,800 | 125 feet | 75 feet | 50 feet | 25 feet |

| 7,200 | 60 feet | 35 feet | 25 feet | 10 feet |

| 9,600 | 30 feet | 15 feet | 10 feet | 0 |

| 12,000 | 15 feet | 0 | 0 | 0 |

Generators with 4Kw or more running wattage can easily weigh over two hundred pounds. Wheel kits, wheelbarrow-style handles, and lifting bales for hooks are all items that make things a lot easier when positioning such a heavy piece of equipment.

Related: What Size Wire for Welder Extension Cords?

Generator Sizing Chart for Welders

Here’s a quick reference table I put together to give you an idea of what size generator you should be aiming for, depending on your welder’s current level.

| Welder Current Level | Minimum Generator Sizing | Recommended Generator Size |

|---|---|---|

| Up to 160A | 7kva 0r 7000 watts | 8000+ watts |

| 180–200A | 8kva or 8000 watts | 10,000+ watts |

| 210-250A | 13kva or 13,000 watts | 15,000+ wats |

Best Generators for Welders

I’m going with substantial portable generators here.

You don’t want your generator working too hard, running flat out. It’s easier on your new power plant if it’s not breathing hard to get the job done.

Cleaner and more consistent power, less wear, and longer life are the rewards of a small extra investment.

For that reason, I would not go below 7,000 running watts.

| Model | Champion 9375 | DuroMax XP12000EH | Powerhorse 9000ES |

|---|---|---|---|

| Running Watts | 7,500 | 9,500 | 7,250 |

| Starting Watts | 9,375 | 12,000 | 9,000 |

| Weight | 224 lbs | 224 lbs | 209 lbs |

| Engine | Champion 420cc | DuroMax 18 HP | DH420 12.2 HP |

| IGBT-Safe | No (8-16% THD) | No (12 % THD) | Yes |

| Outlets | – 120/240V 30A locking (L14-30R) – (2) GFCI 120V (5-20R), – 120/240V 50A (14-50R) |

– (2) 120V household GFCI outlets – (1) 120V 30A twist-lock outlet – (1) 240V 30A outlet – (1) 240V 50A outlet |

– (4) 5-20R 120V-20A, – (1) L5-30R 120V-30A locking, – (1) L14-30R 120/240V-30A locking – (1) 12V DC |

| Run Time | 8hrs at 1/2 load | 9hrs at 1/2 load 5hrs. at full load |

9.6hrs at 1/2 load 5.7hrs at full load |

| Noise Level | 74 dB | 74 dB | 98 dB |

| Extras | Electric start, wheel kit, hours meter | Electric start, dual fuel, wheel kit, 12v battery charger | Electric start, dual fuel, wheel kit, low oil shutoff |

| Where to buy | Northern Tool | Amazon | Northern Tool |

Best Inverter Generators for Welders

An inverter generator is specifically designed to power sensitive equipment like digital devices, computers, and IGBT/MOSFET welders.

If there’s anything in your shop you should never be cheap about; it’s your inverter generator. Be patient and save up for the next bigger size.

“I sure do wish I had less power. That would be great!”

Said nobody, ever.

| Model | Powerhorse 7500i | Champion Digital Hybrid 8750 | No products found. |

|---|---|---|---|

| Running Watts | 6,500 | 7,000 | 8,000 |

| Peak Watts | 7,500 | 8,750 | 10,000 |

| Weight | 333 lbs | 155.4 lbs | 224 lbs |

| Engine | Powerhorse 420cc | Champion 420cc | Briggs & Stratton 420cc |

| IGBT-Safe | Yes (1.5% THD) | Yes (≤ 3% THD) | Yes (3-6% THD) |

| Outlets | – (4) 20A 120V GFCI, – (1) 50A 120/240V 14-50R, – (1) 30A 120/240V L14-30R, – (1) 30A 120V L5-30R, – (2) USB |

– (1) 120/240V 30A locking outlet (L14-30R) – (4) 120V 20A GFCI protected household outlets (5-20R) – 12V DC automotive |

– (4) GFCI 120V household outlets, – (1) 120/240V 30A locking outlet |

| Run Time | 16 hrs. at 1/4 load | 10.5 hrs | 9 hrs. at 1/2 load |

| Noise Level | 55 dB | 72 dB | No rating |

| Extras | Electric start, wheel kit, low oil shutoff, digital monitoring system, USB charging, connects to another generator | Electric start, wheel kit, light and compact | Electric start, wheel kit, hours meter, Bluetooth InfoHub,CO monitor/shutdown |

| Where to Buy | Northern Tool (free delivery) |

Amazon | No products found. |

Common FAQs About Generators for Welders

Will a 3000 watt generator run a welder?

In the Titanium example, we found it could run 140 amps running at 2,800 watts. So if the machine is rated to run at 3,000 watts (not peak at 3,000), it could run most small 120-volt welders under 120 amps. However, it would be running full blast the whole time.

Will a 5000 watt generator run a welder?

You can run up to 180-200 amps on a 240-volt generator rated for 5,000 running watts and 6,000 starting watts, but it will spend a lot of time at high rpm. A generator rated at 5,000 peak watts would be restricted to a 120-volt welder at 140 amps while running full blast.

What Size Generator For a 220v Welder?

There is not enough information to answer this question. You need to know the input wattage for the 220v welder to work out the size generator you need.

Input Volts x Input Amps = Input Watts

Besides the fact it plugs into 220 volts, you also need to know the input CURRENT for this welder.

For example, if the manual or label says the welder needs 32 amps input current, you need a generator rated at 7,040 running watts and 9,100 peak watts.

Can you run a stick welder on a generator?

The short answer is yes as long as the generator has the output wattage to match the needs of your arc welder.

Wrapping it up: Free Yourself and Weld Outside

Every craftsman and welder reaches a point where skills need dramatic, new challenges to continue improving. Outdoor or isolated welding might be just the thing your skillset needs.

It’s time to get out of your shop and into the fresh air with your welder. These generators offer ways to expand your ability to repair and fabricate in a way that’s just not possible otherwise.

Related read: Best Engine Driven Welder

Resources

https://www.northerntool.com/shop/tools/buyers-guides_generators

http://blog.hondalawnparts.com/modifying-your-honda-engine-for-high-altitude-use/

http://help.championpowerequipment.com/article/dgn7qk3fzz-total-harmonic-distortion

Hi,

I appreciate all your information. It helps me get started and have a clue to where I need to start and have. But I still need confirmation from someone who actually knows like yourself. I have a Unlimited 200™ Professional Multiprocess Welder With 120/240V Input. That I want to buy a welder for.

I believe I figured it out but not sure?

To run my welder at 120V I will need a generator with 8,400 running watts plus 30% at 10,920 starting watts ???

To run my welder at 240V I will need 8,640 running watts? And 11,232 starting watts?

I am no math expert so if these numbers make no sense I apologize.

I want to buy a campion generator with 9,500 running watts and 12,000 starting. Will this be enough? Or should I just go with a 12,000 running watts and 15,000 starting watts. (Also campion generator)

Any feed back will be much appreciated

Thanks

Hi Sal, thanks for you comment. I’ll try and break your example down for you. Let’s start with some facts…

The Unlimited 200™ runs on 240v.

The max current input on 240v is 36A.

240v + 15% = 276v

276v x 36A = 9,936 running watts required.

For the starting watts we add around 30% safety margin to the running watts.

9936 + 2980 = 12,916 starting watts

The champion generator you mention should be enough to cover this with the safety margins built in to the calculation.

Question- I use a 220v 30-amp breaker on my welder, Titanium welder. I have never popped the breaker. So, these calculations are based on max input and max output. So, in this case could I actually use 30-amp input for calculations and use a lower wattage generator. I realize I only use 1/8-inch welding rod so the wattage I need is less then say a 5/32 rod would need. I also use a 3/32 rod when I use 120-volt 20-amp house plug or 21.3-amp twist lock. Just putting this out as another way to see what I need for different applications. Smaller generator and/or smaller lighter welder when by myself and lifting lighter things when possible. Thank you.