The Tungsten Inert Gas (“TIG”) welding process makes precision joints with almost all metals.

Nearly every industry uses TIG, but this welding method is not without some shortcomings. So, it’s not always the preferred choice.

This article will teach you about TIG welding applications, why each material benefits from TIG welding, and the pros and cons of this welding process.

Materials You Can TIG Weld

You can TIG weld almost any metal. But generally, the more unusual, exotic metals are TIG welded.

Speed can be a critical factor in process selection, so faster welding methods are employed with the more commonly used metals when production is needed.

However, if you want the best weld quality, TIG welding is irreplaceable.

Aluminum

AC TIG welding is the best method to weld aluminum. This metal is challenging to weld because it forms surface oxides almost immediately when exposed to air, even if you first clean the surface with a brush.

Aluminum oxide melts at a significantly higher temperature than the base metal underneath. So, the pure aluminum melts before the oxide layer. This results in oxide layer inclusions in the weld, significantly reducing joint strength.

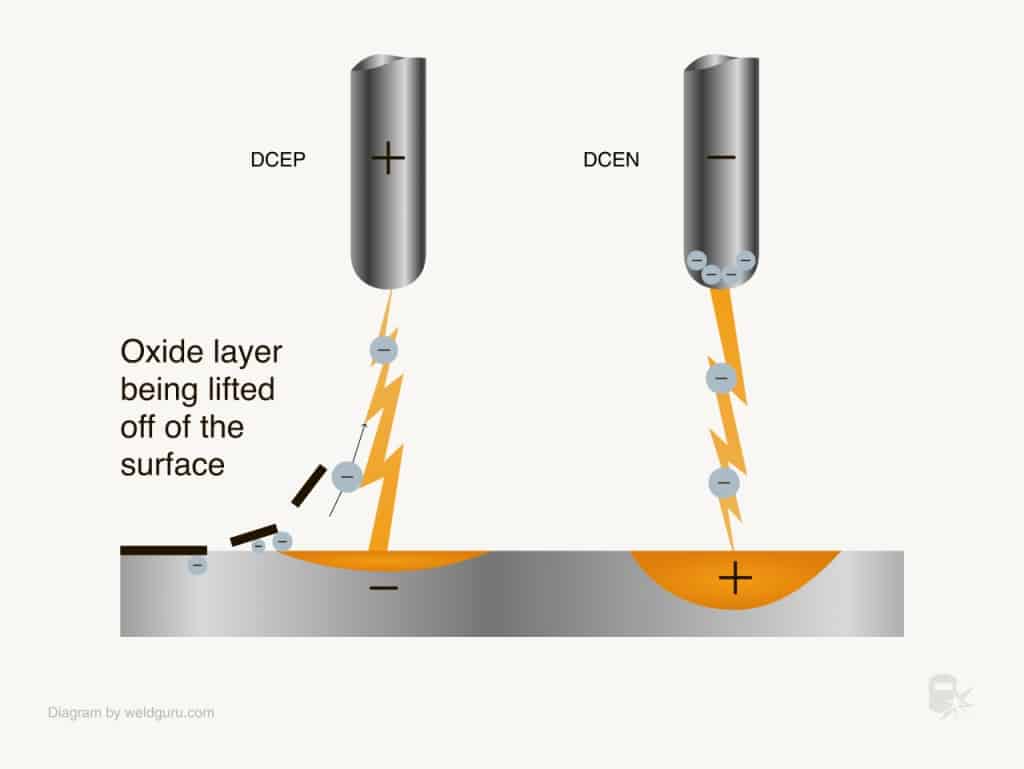

TIG welding was invented to solve the aluminum oxide issue, and AC TIG perfected the process. The AC TIG output consists of alternating EN and EP portions that switch many times per second. The EP phase breaks the oxides, while the EN phase penetrates and joins the aluminum.

© weldguru.com – Image usage rights

This dual action of EP and EN allows perfect aluminum welding. While MIG welding aluminum also works well, the TIG welding method is unsurpassed.

Stainless Steel

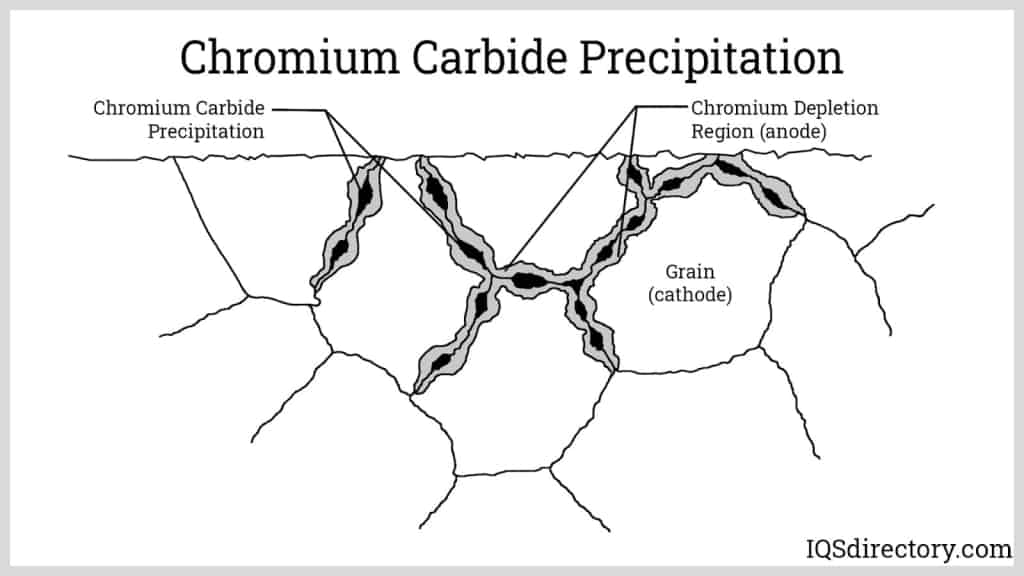

Stainless steel is highly susceptible to heat input and can warp, distort, discolor, and lose corrosion resistance in the heat-affected zone (“HAZ”). While it’s possible to MIG or stick weld stainless steel, the TIG welding process produces far superior results.

Image credit: iqsdirectory.com

The pulsed TIG function with a foot control pedal produces the best heat input control. The pulsed TIG alternates between high and low amperage output many times every second, which results in a narrow, focused arc and minimal heat input. The foot control allows you to back off the amperage output in real-time and prevent high heat concentration.

Since stainless steel retains heat, it gets increasingly hot as you weld. That’s why it’s necessary to reduce the amperage input as you go along the joint, making the TIG foot pedal an indispensable tool for welding stainless steel.

Also, stainless steel is often used for its appearance. The TIG welding process provides the most aesthetically pleasing welds and is known for its clean, professional beads when done correctly.

Learn more: Welding Stainless Using GTAW

Copper

Unlike stainless steel, copper conducts heat exceptionally well, even better than aluminum. As a result, you must input high amounts of heat into the joint to keep the weld puddle moving. Plus, copper oxidizes rapidly, so you need to weld quickly.

Thankfully, you can use 100% helium with the TIG welding process to dramatically increase your heat input (up to 70%) and achieve high welding speeds.

While copper and some of its alloys are MIG or stick weldable, you can focus heat into the joint and achieve the best arc stability using TIG.

Titanium

TIG welding is commonly used for welding titanium because this process allows the best aesthetics and joint quality. Plus, welding titanium under 1/8-inch thickness rarely requires filler metal.

GTAW is the only arc welding process to achieve weld fusion without filler material.

Additionally, titanium is susceptible to contamination and oxygen reaction.

A high frequency (“HF”) TIG arc start prevents tungsten contamination because the tungsten electrode never has to touch the metal.

Plus, the TIG torch cup provides excellent shielding gas coverage, protecting the titanium’s HAZ from oxidation reactions.

Magnesium

Like aluminum, magnesium forms an oxide layer that you must clean. So, you should use AC TIG because the EP phase of the arc cleans the surface, and the EN phase achieves joint fusion. Magnesium is only MIG welded if the sections are thick. Otherwise, TIG welding is the best choice.

Magnesium castings are often very expensive. For example, airplane engine parts can cost tens of thousands of dollars. So, the inherent precision of the TIG welding process easily makes it the best choice.

Other Non-ferrous Metals

The TIG welding method is the best way to join non-ferrous metals. Laser, friction, and other less accessible welding processes sometimes provide better results and higher productivity.

So, you may have to do your homework and some practice welds. But, TIG equipment, books, studies, and expert opinions are widely available since GTAW has been utilized for decades.

- Gold – Often joined with a micro-TIG welding process

- Nickel – TIG is used because of its joint appearance and low chance of impurity inclusions

- Bronze and brass – Benefit from the GTAW aesthetics

Steels

Besides stainless steel, other steel alloys benefit from TIG’s heat and arc control. Depending on the alloying elements like manganese, chromium, cobalt, silicon, molybdenum, and tungsten, different TIG techniques and machine settings are necessary.

Apart from alloy steels, welding standard carbon steel (low, medium, and high carbon) using DC TIG is common. This welding process is usually employed when maximum joint quality and weld aesthetics are necessary. Otherwise, MIG and stick welding processes are preferred for regular carbon steel.

Related read: Best TIG Welders for The Money

Applications Where TIG Welding Is Used

If you are welding a sensitive, thin, exotic, or expensive piece of metal, the chances are that you should use a TIG welding process.

Think of TIG as an all-around best solution.

No other manual welding process offers the same level of heat management. So, welders often use TIG for joining thin stock. But, welding thick metal also benefits from GTAW because you can use a “pointy” arc, crank up the amperage output, use a helium shielding gas, and achieve exceptional heat concentration necessary for deep penetration.

With TIG, heat management goes both ways. You can carefully input low heat or concentrate as much energy as your machine allows. This makes GTAW a highly versatile welding process for nearly all metal thicknesses and heat conductivity levels.

The manual placement of filler material and a stable, predictable arc allow you to obtain any weld aesthetic you desire. So, architectural details, visible stainless steel elements, car body parts, pipes, railings, and similar components where appearance is vital, benefit significantly from GTAW.

Industries that Use TIG Welding

Almost every industry applies TIG welding thanks to its versatility and inherent advantages. But, some industries rely on this welding method more than others.

So, let’s examine how and why most prominent industries use TIG welding.

Welding Pipes

While “pipe welding” is not an industry, it is a prominent career for TIG welders. Pipes are used in the oil and gas, infrastructure, automotive, and construction industries.

The TIG welding process works wonderfully with thin-walled, small diameter pipes, especially if made from stainless steel.

Aerospace

The aerospace industry relies heavily on TIG welders to create solid joints with specialty alloys. Thanks to GTAW’s precision, joint quality, and versatility, we can construct and repair planes, helicopters, and space ships.

Non-arc welding methods like laser and friction welding also play a significant role in aerospace engineering. However, GTAW offers high precision, especially for manual welding jobs and repairs.

Transportation

TIG welding use has increased in vehicle manufacturing because of the increased use of aluminum. Since regulations are becoming stricter, manufacturers must reduce a vehicle’s weight to meet stringent fuel consumption and emission standards. So, cars, vans, trucks, and other vehicles now use aluminum instead of steel wherever possible.

However, TIG welding is not the only process that makes excellent aluminum welds. The cold metal transfer (“CMT”) process, a heavily modified MIG welding method developed by Fronius, is superior to standard TIG welding.

Nuclear and Power

It’s very challenging to weld irradiated metals. Not even the TIG welding process is “clean” enough, but it’s one of the most trusted welding processes to handle nuclear challenges.

The irradiated structural steel alloys in nuclear environments create helium out of “nothing” by transmuting boron and nickel. So, when welding structural elements, pressure vessels, or other irradiated parts in a nuclear environment, the helium forms and traps bubbles in the molten joint. That’s just one example of how unpredictable welding irradiated metals can be.

Welding in the nuclear industry requires extreme quality control and adherence to strict codes and standards. So, the TIG welding process plays a significant role in building and repairing nuclear power plants.

Food and Beverage

The food and beverage industry requires maximum weld cleanliness and precision. There can be no crevices, spatter traces, tiny cracks, or notches where bacteria and mold can grow. Plus, most food/beverage containers are made of stainless steel, thanks to its corrosion resistance and antibacterial properties.

So, the TIG welding process is the most frequently employed welding method in this industry because it offers smooth, clean, uniform welds on stainless steel.

Bicycle Industry

Bicycle frame construction is a highly specialized skill because it requires welding thin steel and aluminum tubes that need to meet exceptional weld aesthetic expectations.

GTAW is most commonly used to join tubes into a light, strong bike frame thanks to its precision and excellent weld appearance.

Advantages & Disadvantages of TIG Welding

The principal advantage of TIG welding is its exceptional control over the arc and heat input. As a result, this welding process provides maximum joint quality. Plus, TIG’s superior control enables the welding of all metals.

Since the tungsten electrode is non-consumable in the welding process, welding without a filler metal is possible. Also, there is no need for fluxes, which means no smoke or spatter.

But GTAW is not perfect. TIG is the slowest arc welding process and the most challenging to master. TIG welding requires significant time and effort to learn, and some even view it as almost impossible to master. It’s easily the most challenging welding process to conquer among the four commonly used processes (i.e., TIG, MIG, flux-cored, and stick).

Additionally, the needed equipment is expensive. So, MIG welding has an economic advantage over TIG because MIG is faster, and the equipment is less costly. When production is more important than appearance, MIG is usually the first choice.

Read more: TIG vs MIG – Pros & Cons

Wrapping It

TIG welding is a crucial metal joining process for numerous industries. It makes welding exotic metals relatively easy and produces excellent joint quality. It’s primarily used to join stainless steel and aluminum, but GTAW is the best choice for maximum weld quality regardless of the welded metal.

There isn’t a better arc welding process than TIG for welding thin sheet metal pieces. Thanks to the various arc and heat control methods, the TIG welding process offers you the best heat management to prevent warping, discoloration, and burn-through.

But, GTAW requires skilled operators with years of experience and doesn’t offer high welding speed. And since you need to feed the filler metal manually, you can only weld as fast as the filler rod melts and deposits into the joint, which is not even close to the MIG welding speed.