The wrong TIG shielding gas selection leads to pores, cracks, irregular-shaped beads, and uneven penetration. On the other hand, you can make flawless, gorgeous TIG welds by using the correct shielding gas for the task.

Luckily, choosing a shielding gas for TIG welding is not rocket science, even if the gas tank looks like a rocket.

In this article, you’ll learn which gas to choose for different applications and, most importantly, the pitfalls to avoid.

What Gas is Best for TIG Welding?

The most commonly used shielding gases for TIG welding are argon and helium or a mixture of the two.

Occasionally, other gases like hydrogen, nitrogen, oxygen, and carbon dioxide are added.

But, these additions are rarely justified and can impair the weld quality if not properly used.

TIG Welding with Argon

Argon is a noble inert shielding gas, so it doesn’t chemically interact with the welded metal, tungsten electrode, or filler wire.

An “inert” gas means it doesn’t react with the metal or negatively affects the completed joint properties.

Since it’s denser than air, argon settles over the weld pool and protects the molten metal from air contaminants.

But, it only works well in a flat welding position where gravity helps keeps the heavy argon in place.

The high argon density hinders the coverage if you make out-of-position welds (overhead). A simple way to solve the overhead issue is to use a higher gas flow rate, increasing costs.

Argon is easy to ionize, which helps arc starting characteristics and keeping a stable arc, even if you use an extended arc length.

Additionally, argon permits cathodic cleaning action, making welding aluminum possible with alternating current.

Using 100% argon gets the job done 90% of the time. Argon is a suitable shielding gas choice for TIG welding mild steel, stainless steel, aluminum, magnesium, etc.

It’s also cheaper than other gases and more readily available. So, unless you benefit from helium or other gases listed below, a pure argon gas bottle will be your best friend for TIG welds.

TIG Welding with Helium

Helium, like argon, is an inert gas. But, it impacts the weld differently than argon since helium has a higher thermal conductivity. Thus, it increases heat input into the joint.

As a result, penetration and welding speed improves, and the resulting bead has a higher depth-to-width ratio.

However, welding with a 100% helium shielding gas is usually employed with automated TIG operations rather than manual welds. Helium has a lower ionization potential, making a long arc challenging to keep.

Therefore, it’s difficult to manually dab the filler wire into the molten weld pool because the tungsten tip is too close to the liquid puddle. Pure helium is not the best choice for manual TIG welding.

Also, helium is more expensive than argon and lighter than air. To keep the weld protected in the flat welding position, you must use twice the gas flow as compared to argon.

On the other hand, overhead welding is easier with helium because it floats upwards. Still, there aren’t many reasons to use pure helium in manual TIG applications.

However, it is often used as an additive to argon, and we’ll discuss blends in more detail later.

Related read: What is a TIG Welder Used For?

TIG Welding with Hydrogen

Hydrogen is a reactive gas that chemically affects hot metals. It’s used as an additive to argon when high welding speed and deep penetration are needed.

But, it’s limited to austenitic stainless steel and nickel alloy welding.

When welding austenitic stainless steel, adding hydrogen to argon helps clean surface oxides, stabilize the arc, and create deep, broad penetration.

If you need to weld duplex or super-duplex stainless steel, use nitrogen instead of hydrogen as an additive in the argon blend.

In exceptional cases, oxygen and carbon dioxide may be added in tiny quantities to achieve desired weld properties.

For example, a minuscule amount of 0.4% oxygen with 99.6% helium solves the problem of surface-active oxygen on some stainless steel by adjusting the oxygen content in the weld pool.

However, oxygen and CO2 are severely problematic for TIG welding unless used in specialized cases because these reactive gases destroy the tungsten electrode.

TIG Welding Shielding Gas Blends

- Helium + Argon – The most commonly used mixture is 75% He and 25% Ar. Using less helium provides a more stable arc but lower penetration. Adding more helium helps you maximize the available amperage of your welder and allows welding of metal thicker than the machine’s rating. Additionally, it helps in cold climates. For example, TIG welding pipes in Alaska with an Ar/He shielding gas helps alleviate your arc’s heat loss to the environment. You can use this mixture to work on all metals.

- 95% Argon + 5% Hydrogen – Using up to 5% hydrogen (H2) with argon stabilizes the arc, improves penetration and welding speed, and cleans surface oxides. Use with austenitic stainless steel and nickel alloys only.

- 98% Argon + 2% Nitrogen – Used to weld duplex, super duplex, austenitic stainless steels, and copper.

Can You Use The Same Gas for MIG and TIG?

You cannot use the same shielding gas for MIG and TIG welding. Most MIG welding applications require a 75% argon and 25% carbon dioxide mixture or a 100% CO2 shielding gas.

However, MIG welding aluminum does require a pure argon shielding gas. So, if you have a 100% Ar gas bottle for MIG welding aluminum, you can also use it to TIG weld.

If you are new to TIG welding, you may wonder why you can’t just use a 75/25 MIG gas since it has 75% argon. What’s the worst that can happen since the gas is 3/4 argon?

Because it is also 25% CO2, Using a 75/25 MIG gas to TIG weld will produce sparks like it’s the 4th of July. That’s not what TIG welding is supposed to look like. CO2 is an active gas, not inert. Therefore, it conducts electricity, breaks surface tension on the molten metal, and quickly burns the tungsten electrode.

Due to the CO2 presence, the arc becomes highly erratic, and the tungsten electrode is contaminated and burns. Your weld expels sparks, and fumes obscure your view.

Even worse, the weld will burn holes uncontrollably, be porous, develop cracks, and look horrible. So, to successfully TIG weld, use plain argon gas or a mixture with helium.

Choosing the Best TIG Shielding Gas for the Right Job

Now that we’ve covered the basics of the TIG shielding gases, let’s discuss how to select the best shielding gas depending on the welded metal and budget.

Some mixtures are more expensive but necessary for certain metals.

But of course, it’s best if you can save some money and use inexpensive argon when possible.

Welded Metal

Pure argon gets the job done regardless of the metal you weld. So, you can use it to weld anything from mild steel (DC TIG) to aluminum (AC TIG).

However, if you wish to improve penetration, welding speed, or other variables, you can use certain mixtures.

Steel

Straight argon or Ar/He mixtures work best for welding carbon steel. However, introducing helium is rarely necessary, and most people never use Ar/He blends for mild steel.

So, if all you ever weld is regular mild steel, get yourself a 100% Ar bottle, and don’t worry about other TIG shielding gases.

Stainless Steel

Welding stainless steel (SS) is far more complex than mild steel because there are many grades and types.

So, unless you know the type of SS you are working with, it’s safest to stick to Ar/He mixtures or pure argon.

Avoid helium additions if welding thin SS because it makes heat management difficult. Helium increases heat input, leading to the SS losing corrosion resistance, warping, burn-through, and surface discoloration.

Welding thick austenitic SS benefits with argon blended with up to 5% hydrogen. Hydrogen provides a similar effect as helium but offers stronger penetration.

Read more: TIG Welding Stainless Steel – A Beginners Guide

Alternatively, welding duplex and super duplex SS requires a nitrogen additive instead of hydrogen in the argon.

So, it is imperative first to know what stainless steel alloy you are welding to choose an appropriate shielding gas.

Related: Recommend TIG welders for Stainless Steel

Aluminum

To TIG weld aluminum, you need straight argon or an Ar/He mixture. Adding helium works great when welding thick aluminum because aluminum dissipates heat quickly and requires a very hot arc.

But remember that you cannot weld aluminum with 100% helium with AC TIG because the cathodic cleaning action does not occur.

Aluminum oxides are only removed if argon is present in the shielding gas.

However, it is possible to DC TIG weld aluminum with 100% helium. This is a trade secret not known by many. But, DC TIG welding aluminum is not recommended for beginners.

The arc is more difficult to control, and as mentioned earlier, 100% helium reduces the arc length, making it more challenging to weld.

Exotic Metals

If you are unsure about the exact alloy of exotic metal or how the welded element will be treated, it’s probably best to stick to 100% Ar.

- Copper – Since copper dissipates heat extremely quickly, it’s best to use a 100% helium shielding gas and DC TIG

- Chromoly – Use 100% Ar and DC TIG

- Nickel alloys – Adding up to 5% hydrogen helps avoid porosity when welding pure nickel. But you can also use pure argon or a mixture of Ar/He

- Magnesium – Welding magnesium is significantly more dangerous than other metals we discussed. Make sure you read all OSHA hazard prevention measures. Use argon or argon/helium mixtures to AC TIG weld magnesium or a 100% helium for DC TIG

Budget

Disposable gas tanks are a good choice if you weld on the go or need a small amount of shielding gas. However, buying a refillable tank is more cost-effective in the long run.

You can buy a full-sized shielding gas bottle and refill it at your local gas dealer. Gas is far cheaper than the bottle, so refills won’t be as expensive after the initial investment.

There are many gas tank sizes to choose from, and you can learn all about them in our article on shielding gas bottle sizes. However, a general rule is that hobbyists need a 40-80 cubic feet (“CF”) tank and more demanding welders require a larger 125 CF bottle.

Below is a table with the most readily available TIG welding gas, argon. Other gases are likely to cost more and you should check with your local gas supplier.

| Tank Size | Initial Cost (full) | Refill Cost |

|---|---|---|

| 40CF | $245 – $270 (example) | $45 – $60 |

| 80CF | $285 – $315 (example) | $55 – $75 |

| 125CF | $380 – $420 (example) | $70 – $90 |

Related: How Much is Welding Gas?

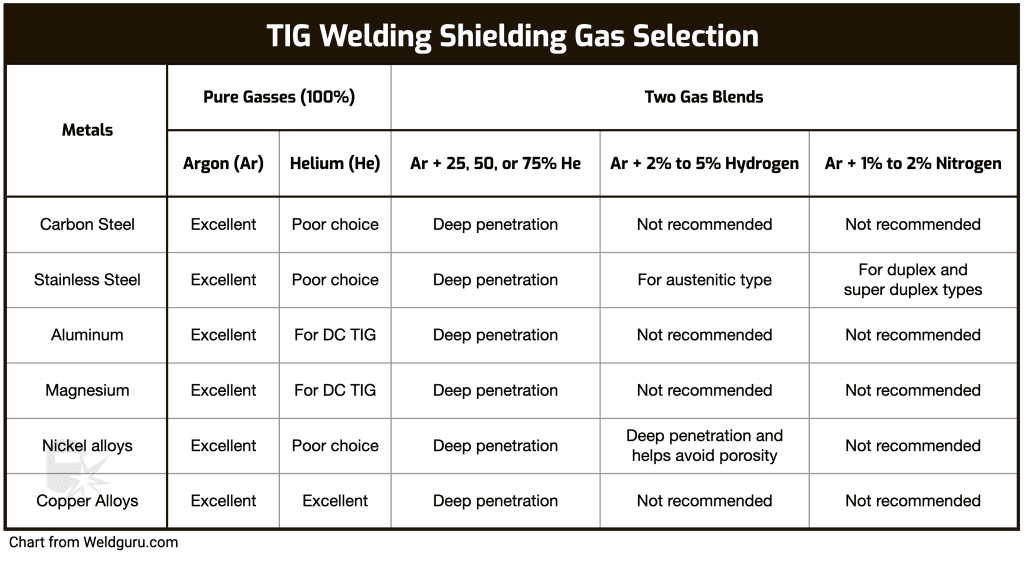

Summary Chart

We created the table below to summarize everything we have covered to provide you with a quick reference.

Use special shielding gas mixtures depending on what metal you are welding. If you have doubts, argon is the best universal solution.

Wrapping It

If you want a general shielding gas for TIG welding, most welders will use 100% Ar.

But, if you need to modify the arc characteristics to achieve better penetration or oxide removal, consider helium, nitrogen, and hydrogen additions, depending on the welded metal.

But whatever you do, never use oxygen and carbon dioxide in your gas mixture. The TIG welds will be horrible, weak, and porous.

While such gasses are added to argon, they are usually used in specialized, controlled welding situations and only in minuscule amounts.

Additional reads:

What Is TIG? – A Full Process Explanation for Beginners