Every welder has pondered it at one point, inverter or transformer-based welders?

The main difference is that an inverter welding machine is significantly more efficient and lighter. But, transformer welding machines are more reliable in the long run and better suited to harsher conditions.

So, the answer is not as easy as you might think. Some welders swear by a transformer welder, and others would never give up the convenience of an inverter welder no matter what.

There are many more differences beyond that brief introduction, and this article dissects each technology thoroughly to help you decide which suits your needs the best.

Inverter vs. Transformer Welder: A Quick Overview

| Inverters | Transformers | |

|---|---|---|

| Weight | Low | High |

| Size | Compact | Huge |

| Efficiency | High | Low |

| Duty Cycle | Longer | Shorter |

| Generator Support | Worse | Better |

| Current Output | AC and DC | AC and DC (only with rectifier) |

| Advanced Digital Arc Control | Yes | No |

| Multiple Processes In One Welder | Yes | No |

| Arc Stability | Better | Worse |

| Cost | $$ | $$$$ |

| Technology age | Relatively new | Old |

| Lifespan | Shorter | Longer |

Transformer Welders

In truth, every welder has a transformer inside—even inverter-based welders. However, transformer welders don’t use advanced technology to reduce the core size.

So, when we say transformer-based or transformer-core welder, we are referring to the old technology of bulky, heavy machines.

What is a Transformer Welder

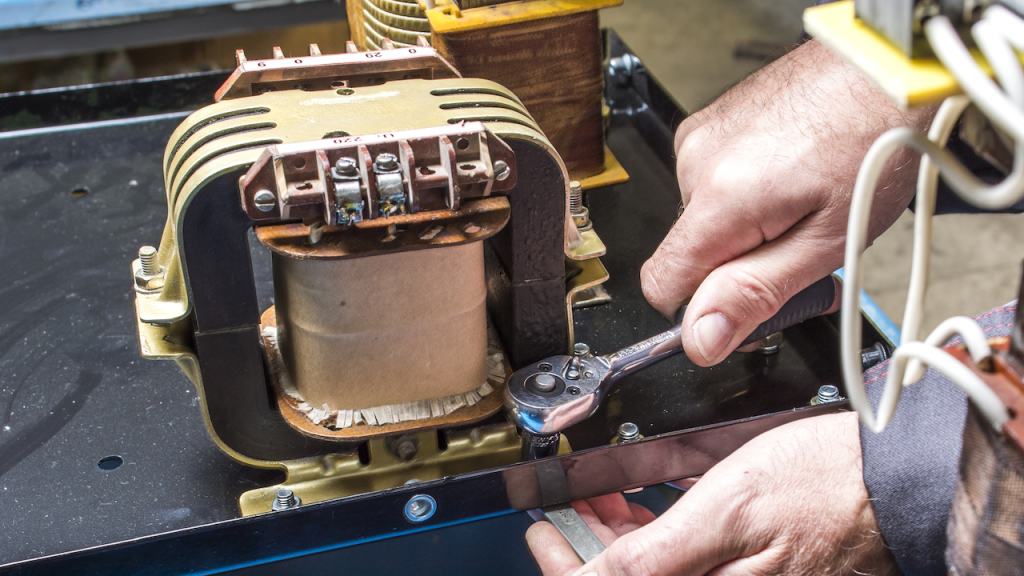

A traditional transformer welder is a robust piece of technology with limited arc control and substantial weight. So today, transformer welders are primarily used in heavy industry or as stationary workhorses in welding shops.

Thanks to the transformer’s longevity, these machines can live to see your grandkids. Many welding shops still use such gear that’s over 50 years old.

However, since their transformer core is gigantic and heavy, they are difficult to move and nearly impossible to transport.

Quick History of the Transformer

The first transformer-based welders appeared in the early 1900s, but these early models were mainly experimental. It was many years until engineers managed to design machines with a relatively stable arc.

It wasn’t until the 1920s and 1930s that transformer welders saw actual adoption. At the time, joining steel was mostly performed with rivets, gas welding, and forging.

Arc welding started significantly taking over near the end of WWII. By the 1980s, almost all manufactured arc welding machines were transformer-based.

So, transformer-core welders have nearly a hundred years of research and development, which explains much of why they are so reliable.

How Does a Transformer Welder Work?

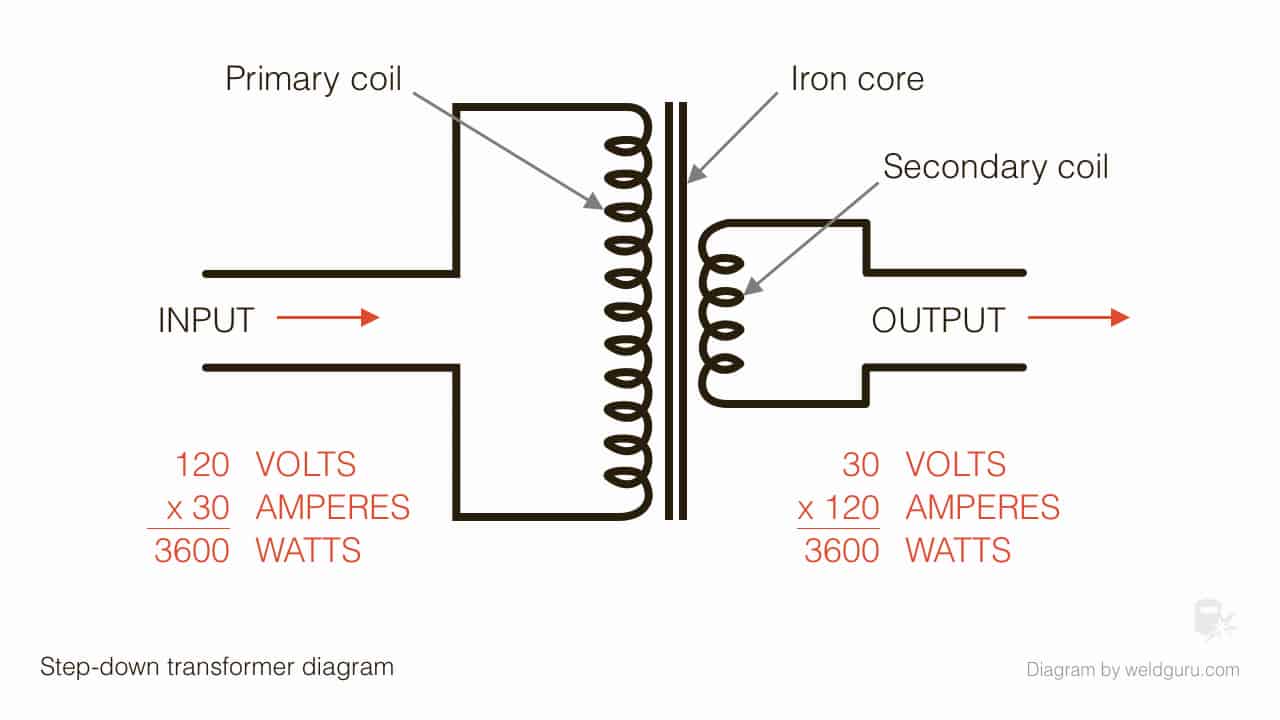

Transformer welders use a “step-down transformer.” This simple technology takes a high-voltage, low-amperage current and reverses it into a low-voltage, high-amperage current.

So, an AC high voltage input (110V, 220V, 380V, etc.) with a low amperage current (30A, 40A, 60A, etc.) becomes 17V-45V at 200A-600A.

© weldguru.com – Image usage rights

The transformer “core” encompasses three parts:

- Primary coil – Copper wire winding connected to the main input voltage from the power supply.

- Secondary coil – Winding connected to the welding leads. This coil has less wire than the primary coil. So, when the magnetic field from the primary coil induces electricity to the secondary coil, the voltage and amps reverse. This is the essence of a step-down transformer system.

- Core – It concentrates the magnetic field produced in the primary coil into the secondary coil.

© weldguru.com – Image usage rights

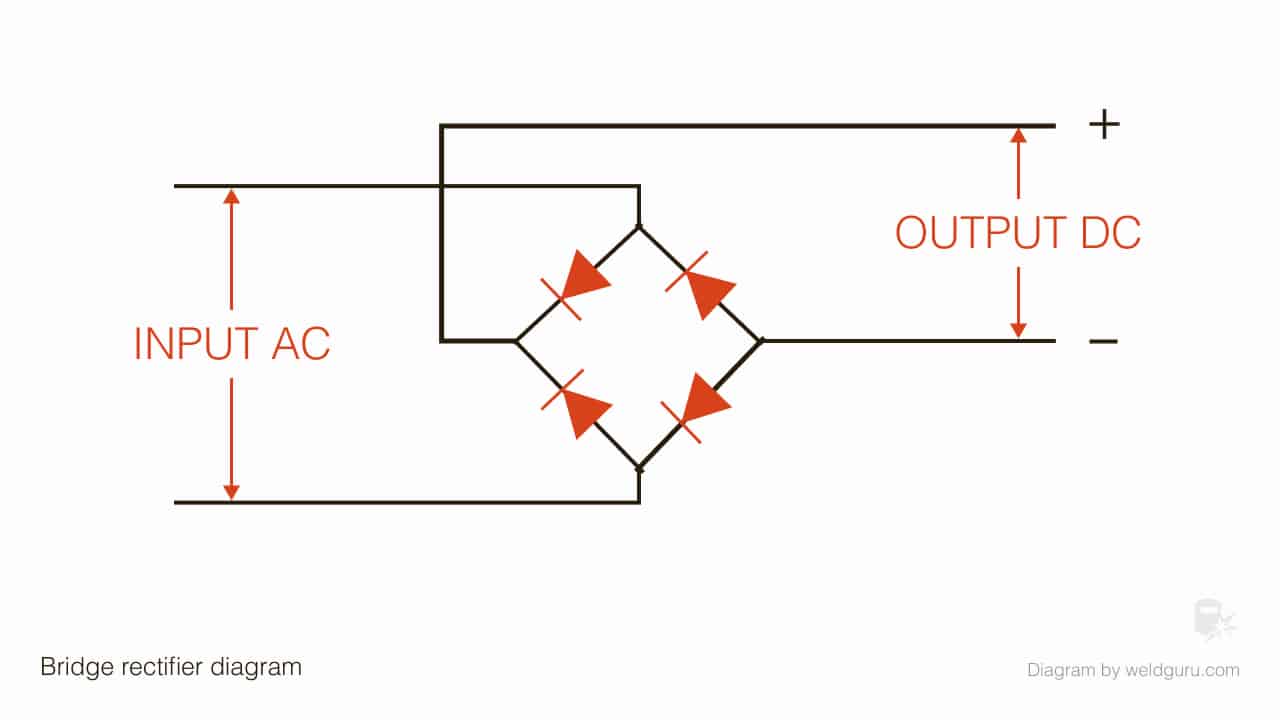

Transformer-based welders output AC power only, unless they have a bridge of rectifiers. The added rectifiers block one of two polarities in the AC, leaving a clean direct current (DC) output preferred for most welding types.

Related read: AC vs DC Welding Differences

Advantages & Disadvantages of Transformer Welders

Pros

- Time-tested technology developed over a century

- Simple, redundant design without digital elements

- Reliable

- Easier to repair and maintain than inverter-based machines

Cons

- Heavy

- Bulky

- Sometimes welding leads must be very long because the machine is difficult to move around, which can lead to a drop in DC current

- Less stable arc compared to inverters

- Low-duty cycle in portable transformer-based welders

- A limited number of functions for arc control

- Expensive

Inverter Welders

Inverter-based welders use modern technology to improve efficiency and reduce the machine’s weight drastically.

Additionally, inverter welders can enhance the arc quality and provide valuable functions that were impossible with the old transformer welders.

What is an Inverter Welder

An inverter welder is a welding machine that uses solid-state electronic parts to improve efficiency in the electric current conversion. Inverter welding machines are light, portable, and often no bigger than your lunchbox.

Also, inverter-based welders often include many digital functions for arc control. They use hardware and software to control arc stability, frequency, arc cone width, bead profile, starting and ending amperage, AC balance, shielding gas flow, wire burnback, inductance, and settings for many other welding variables.

Often, inverter-based welders include a digital display to help you with all the settings, but so do some modern transformer-based units. So, digital controls don’t necessarily mean that the welder uses inverter technology.

How Does an Inverter Welder Work?

Inverter welders works by increasing the power input frequency from 50Hz to 20,000 – 100,000Hz. This high-frequency current requires a drastically smaller transformer core than old, transformer-based welders.

The old technology sized the transformer to use the standard 50-60Hz AC frequency available from the wall outlet.

Since the inverter-based welders use electronic switches, which turn the power on and off up to 1 million times a second, this technology allows the inverter to increase the AC frequency significantly.

So, by using the higher frequency, inverter-based welders “energize” the core much faster, 100,000 times a second instead of 60 times a second. This allows a smaller core without a loss in power output, making inverter welders far more efficient.

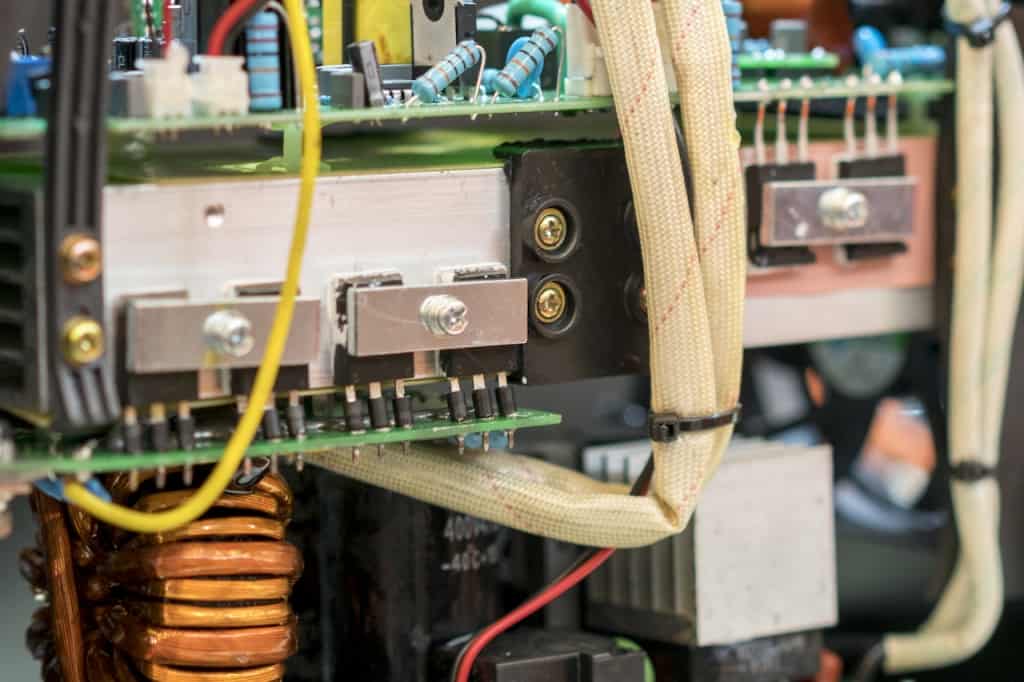

What is IGBT Technology?

Insulated Gate Bipolar Transistors, or IGBTs, are a three-terminal, semiconductor-based technology used for high-efficiency electrical power switching. IGBTs were designed to meet the demand for synthesizing complex waveforms and are used for more than just welding machines.

You can find IGBT systems in electric vehicles, trains, refrigerators, air conditioners, etc. It’s the second most widely used power transistor in the world.

IGBTs have a significant advantage over previous MOSFET systems, especially in high voltage, high current systems found in welding machines. So, inverter-based welders with IGBT technology are more durable than MOSFET-based inverter welders.

Advantages & Disadvantages of Inverter Welders

Pros

- Low weight and small size

- High efficiency

- Lower power draw

- Requires lower-rated circuit breaker

- Less expensive equipment

- Better arc stability

- A significant number of digital functions for arc control

- Longer duty cycle

- Allows a machine to perform multi-process welds

Cons

- Lower life expectancy

- Challenging to repair

- Less robust and easier to damage due to sensitive electronics

- Only specialized inverter welders can efficiently run the E6010 electrode

Inverter vs. Transformer Welders – Which is better?

While the technology choice is subjective, it seems like more welders are joining the inverter technology club daily.

Yes, first-generation inverter-based machines weren’t very reliable. But, today, most inverter welders use up-to-date technology.

So, if you get a welder from a reputable brand, you can reap the benefits of modern technology without many drawbacks.

Performance

Transformer-based welders provide a reasonably decent arc, but the inverter-based machines output a more stable arc with better consistency. Since transformer machines can’t modify the arc in real-time, they are prone to arc voltage fluctuations, arc blow, and other arc-related issues.

An internal microcontroller controls the IGBTs in inverter-based welders, allowing real-time control over the arc. This provides a reliable constant voltage, more stable arc and allows for significantly more functions, which we’ll cover later.

So, inverter-based machines offer better performance. Professionals benefit from a less post-welding clean-up, uniform penetration, and consistent bead profile. Beginners benefit from an easier-to-control arc.

Reliability & Life Expectancy

While inverter-based welders have experienced significant improvements in the last 30 years, transformer-based machines are still more reliable. There isn’t an inverter welder currently operational over 30 years old, except in a museum.

However, thousands of 50-year-old transformer-core units are in use all over the US, and they are still in good condition.

But, this doesn’t mean that inverter-based welders are not reliable. Quality inverter welders have extended warranties (3-years or more), and most outlive the warranty period. But, transformer-based welders have a longer life expectancy.

Costs

Inverter welders were pricey when they first appeared. But today, IGBT machines are significantly less expensive than transformer-based welders unless you buy second-hand equipment.

Inverters have made welding equipment accessible to anyone. What used to cost several thousands of dollars is now priced at just a few hundred dollars or less.

Of course, the cost depends on multiple factors like the machine’s brand and build quality. But, there is no denying the impact of inverters on the market.

So, manufacturers are phasing out transformer-based welders, and many brands no longer manufacture the commercial market.

Welding Environments

Transformer-based machines handle dusty and humid environments better than inverter-based welders. They have earned their robust reputation.

However, you should abide by the safety rating of your device and the instruction manual. Many inverter welders are better rated for questionable conditions than transformer units.

Additionally, many older transformer-based machines don’t include a voltage reduction device (“VRD”), while quality inverter-based MMA welders do.

The VRD is a crucial safety feature for stick welding. It reduces the open-circuit voltage (“OCV”) to safe levels to prevent accidental operator electrocution. So, you can weld in adverse conditions like cramped spaces, high humidity, and wet areas without the risk of an electrical shock.

Unfortunately, many welders were injured or killed using non-VRD equipment, and old transformer systems usually don’t support this safety measure.

Energy

Inverter welders are drastically more efficient than the old transformer units. They can output the same amount of energy while requiring up to 50% less input power. That’s why many inverter machines support a standard 110V home outlet.

For example, the Hobart Ironman 240, a transformer-based welder, requires an input of 50A and 240V to output 200A. In contrast, the Eastwood MIG 250, an inverter-based unit, requires an input of 46A and 240V to output 250A.

But, the same Eastwood unit outputs 140A if plugged into a 120V outlet with a 20A circuit. So, inverters are far superior in energy efficiency, providing more power and often allowing you to use a 110/115/120V.

Portability & Weight

Due to their immense weight, transformer welders are best used as stationary machines in welding shops and fabrication facilities. It’s impractical to use heavy, bulky machines for work that demands portability.

Inverter-based machines are mobile, light, and portable. Plus, the portability of inverters allows you to move to a new worksite quickly. You can weld in your garage or load the machine into the back of your truck to work somewhere else.

Duty Cycle

Conventional transformer welders have a massive core that accumulates heat due to electrical resistance. Small transformers in inverter-based machines also heat up from resistance, but they can dissipate this heat quickly thanks to a significantly lower mass. That’s why inverter welders often have longer duty cycles than old transformer units.

Additionally, small electrical components like PCB boards in inverter-based welders tend to heat up fast, but they are easy to cool. So, you’ll often see inverter machines with fan systems and grates for airflow.

Their mechanical parts are easy to cool, thanks to their low mass. So, if you want a long-duty cycle, inverter technology is a good choice. However, this varies a lot between specific models. There are transformer welders with better duty cycles than some inverters.

On a Generator

Some generators tend to output “dirty” power, which is a fancy way of saying that their output voltage may fluctuate. Sometimes, the generator’s output voltage may be high enough to damage the inverter-based welders’ sensitive parts.

However, you have nothing to worry about if you use a quality generator. Look for a generator with a total harmonic distortion (“THD”) rating below 6%. The lower the THD, the lower the occurrence of unpredictable voltage surges from the generator.

So, transformer-based welders are more forgiving and won’t sustain any damage on most modern generators. But, many inverter-based welders have protection systems ensuring their safety.

For example, power factor correction (“PFC”) automatically compensates voltage surges and provides adequate voltage to the inverter. Additionally, many manufacturers use high-voltage capacitors to prevent damage, and they market these inverters as generator-friendly.

Features

Transformer-based models can’t match the numerous features available on inverter welders. So, while old transformer welders have their ways of providing essential useful functions via mechanical methods, they can’t compare to the versatility of digitally controlled inverters.

For example, AC TIG inverter machines can output different waveforms like square, triangular, and soft waves. Transformer welders are limited to a simple sine wave.

This change alone can significantly improve your work. Additionally, inverters introduced the ability to perform pulsed TIG, drastically improving results when welding thin metal.

But, MIG, FCAW, and stick welding are not without improvements either. Inverter technology allows pulsed MIG welding, which reduces heat input and spatter while achieving high deposition rates and visually stunning welds.

Many inverter welders include a “Synergic” or “Auto” mode that automatically updates wire feeding speed and voltage in real-time, making it easier for beginners.

Inverter technology has also made it possible to combine multiple welding processes into one machine. So, you can carry a suitcase-sized welder without breaking a sweat and have AC/DC TIG, MIG, Flux-cored, and MMA available with dual voltage inputs.

Plus, each process has numerous functions to fine-tune, like arc pulse frequency and width, AC balance, EN/EP amplitude, arc force, hot start, inductance, burnback control, and others.

A great example of this is the Yeswelder MP200 5-in-1 welder and plasma cutter machine.

Known Problems

Not all inverter-based welders can handle the E6010 stick electrode. This cellulosic electrode is used for pipe welding, out-of-position welding, and joining rusty steel.

Transformer welders don’t struggle with the E6010 electrode because they have a high OCV, providing sufficient voltage pressure to keep the arc established.

However, most inverter welders don’t have a high enough OCV or the necessary algorithms for efficient arc control with the E6010 electrode.

So, if you need to use this electrode, look for inverter welders where the manufacturer specifically states the welder supports it. This information is usually included in the sales brochure or the specification sheet.

Transformer-based welders also have one lesser-known caveat. Since these are primarily stationary machines, it is necessary to use very long cables to maneuver around the work.

This is not an issue if you use AC output. But since most welding processes use DC power output (except AC TIG), the voltage will drop in long leads and impair welding results.

Wrapping It

Inverter-based welders are far easier to weld with, thanks to numerous helpful features. Plus, they are lightweight and portable.

Thanks to their low cost and better arc stability, DIYers and hobby welders benefit the most from inverter-based units.

But, professionals also benefit greatly from more expensive, high-end inverter machines.

So, inverter welders have a significant edge over the old transformer units. But the old transformer technology has earned its reputation for longevity.

Transformer-based machines can last for decades since they use a simple, robust design without any digital elements.

Only you can decide which is best for you based on your needs. Hopefully, the information in this article provided you with insightful information to help you with the choice. Thanks for reading!

- https://edisontechcenter.org/Transformers.html

- https://www.allaboutcircuits.com/textbook/alternating-current/chpt-9/step-up-and-step-down-transformers/

- Welding: Principles and Applications, 8th ed., by Larry Jeffus.

- https://www.e-education.psu.edu/eme812/node/711

I’ve got both inverter and transformer welders for hobby use. My “go to” mode is MMA (stick) because I’ve had 55 years of familiarity with it. I still prefer the transformer welder with high frequency for TIG and use a Synergic multi mode for wirefeed on thin steel. All that being said I still keep the oxy-propane for brazing, silver soldering and cutting. I have a plasma cutter but seldom use it, the angle grinder or gas cutting torch is quicker to set up.

Thanks for pointing that out Peter – Yes it was a typo mistake. I have now updated it.