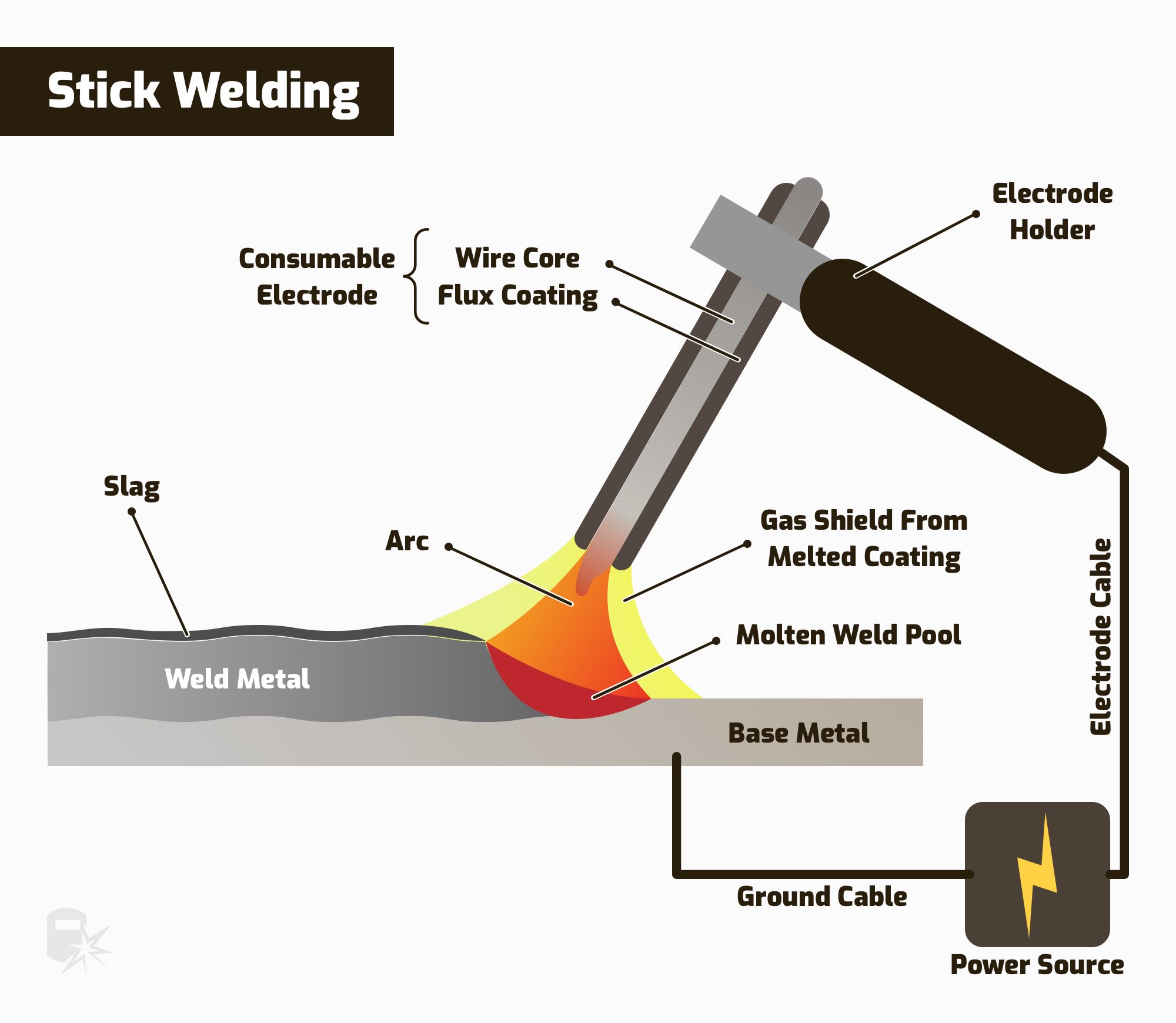

Shielded Metal Arc Welding (SMAW), also known as stick welding, is a welding process that uses an electric current to form an arc at the end of a consumable electrode.

The arc melts the base and electrode metals to create the weld puddle and form the weld bead.

SMAW is commonly called “stick welding” because the electrodes are flux-coated rods of metal resembling sticks.

How Does SMAW Work?

© weldguru.com – Image usage rights

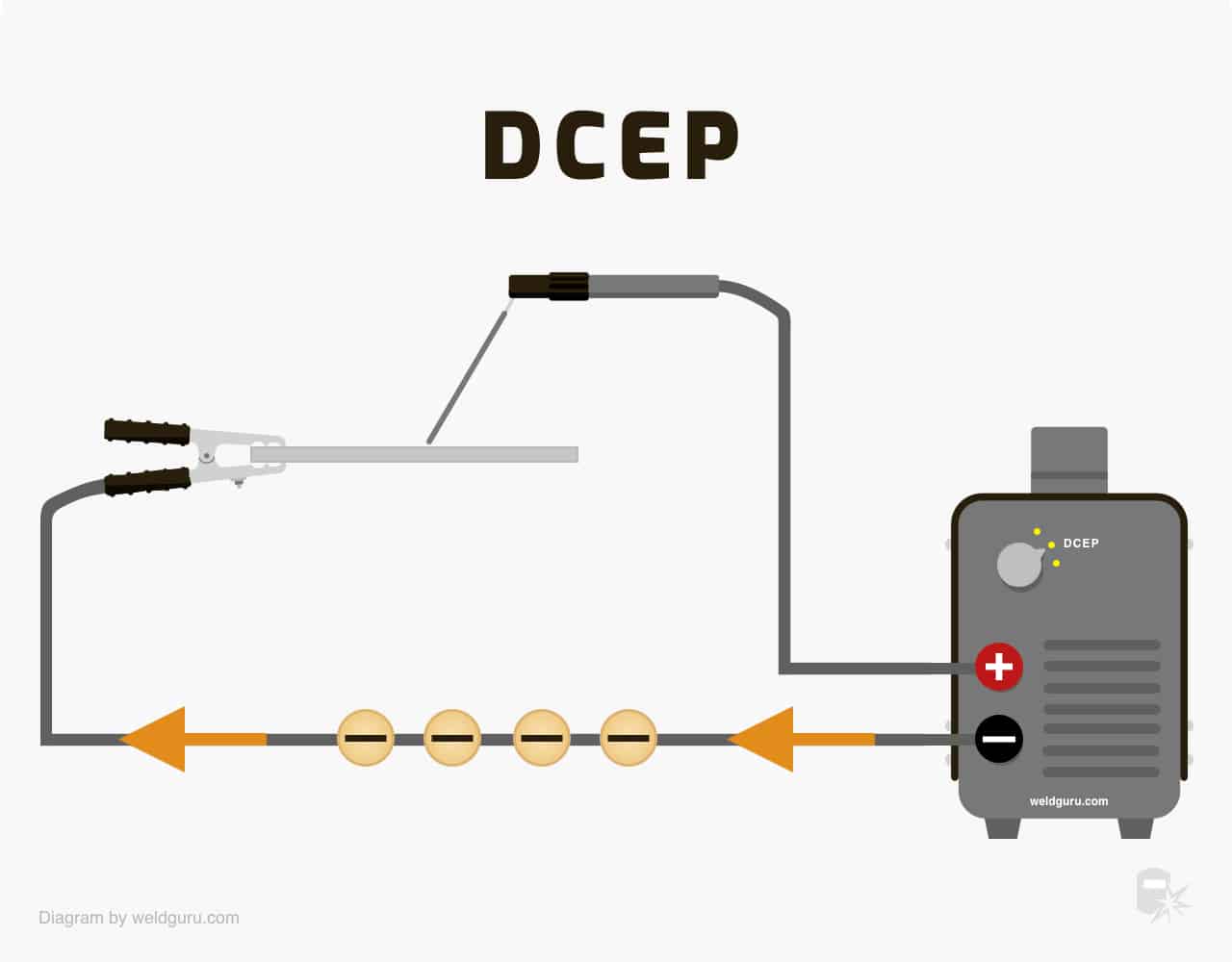

The SMAW welding machine produces a constant amperage in alternating current (AC) or direct current (DC).

This current travels from the machine, through the electrode, across the welding arc, and back to the machine through the work clamp.

When the electrode touches the workpiece in a scratching motion, the current will jump the gap between the electrode tip and the base metals.

This jumping of the current forms a stable electric arc.

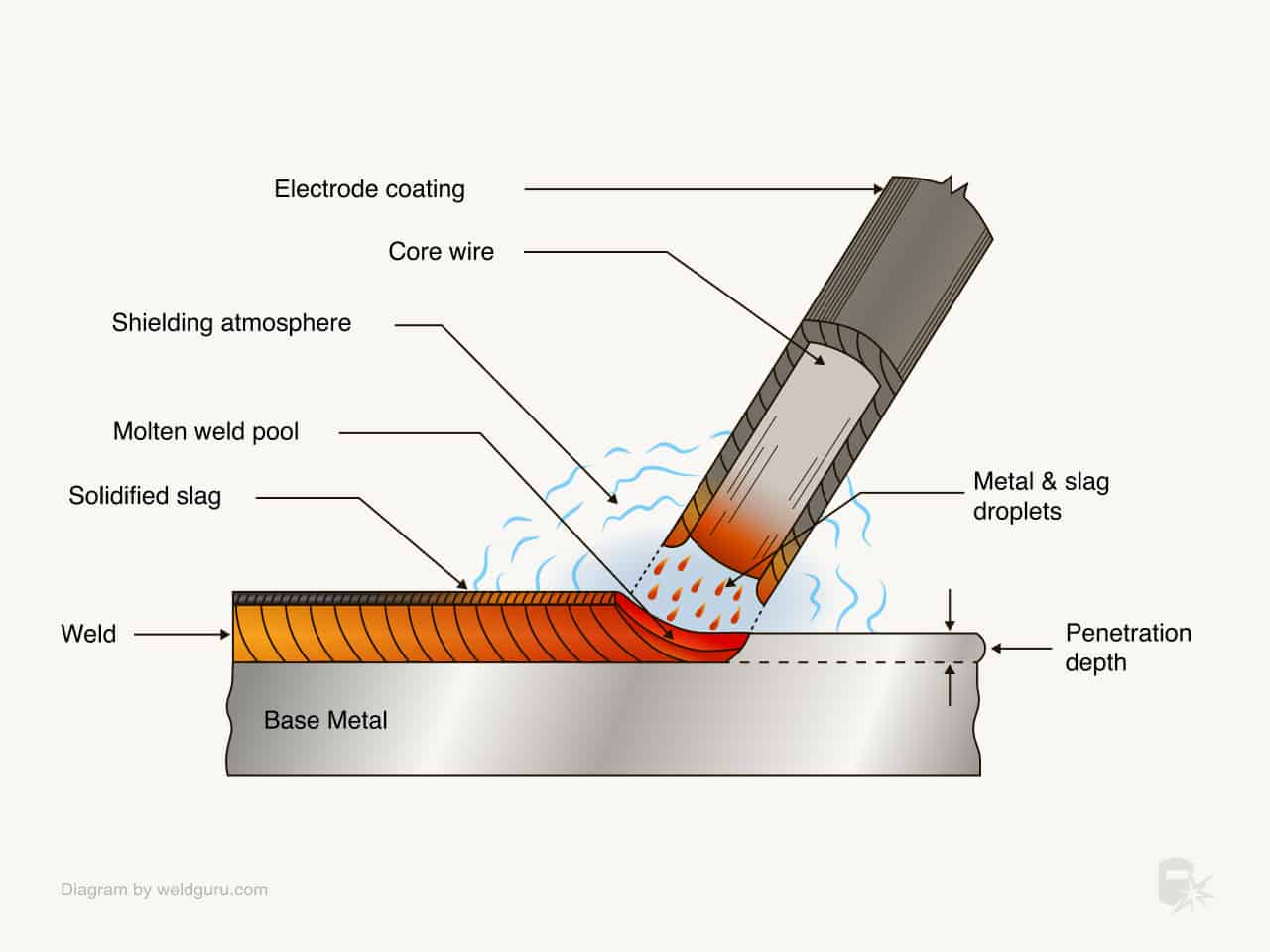

The heat from the arc melts the base metals along with the metal in the electrode. The electrode is then manipulated and moved along the joint to create a weld bead.

As the weld bead forms, the weld puddle consumes the metal in the electrode, adding it to the weld.

To protect the weld puddle from the atmosphere, SMAW electrodes have a flux coating, which burns and forms a protective shield. The flux coating also creates a layer of slag on the weld.

The Components of a Stick Welder

© weldguru.com – Image usage rights

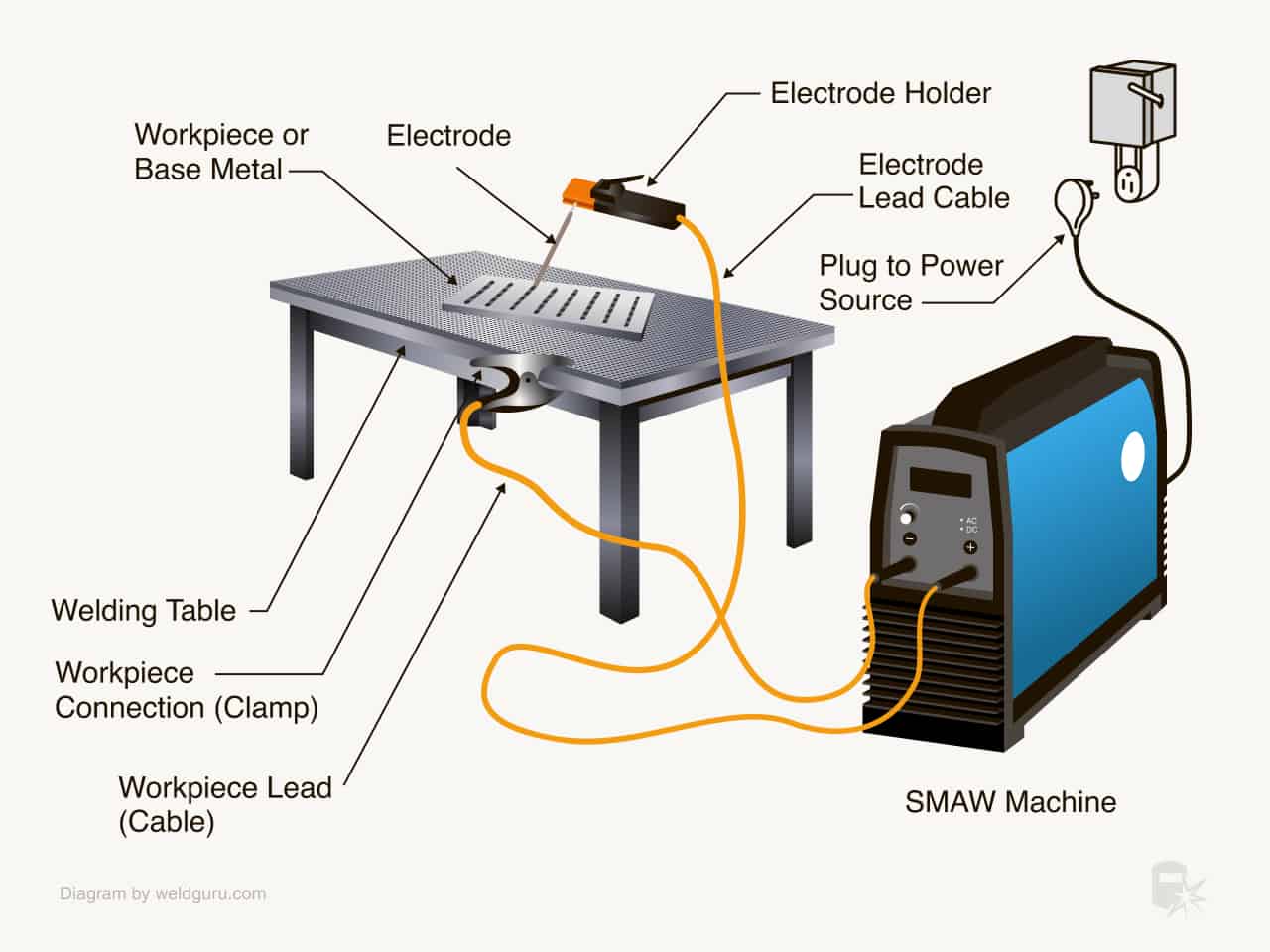

SMAW welding is the simplest of the electric arc welding processes. The only equipment required is a constant current power supply, work clamp, electrode holder, and electrodes.

The power supply used in SMAW welding is constant current, which means the power supply delivers a constant amperage.

In contrast, wire machines, such as MIG, FCAW, and MCAW, use a constant voltage power supply. These power supplies will output both AC and DC power.

Related: Stick vs. MIG welding

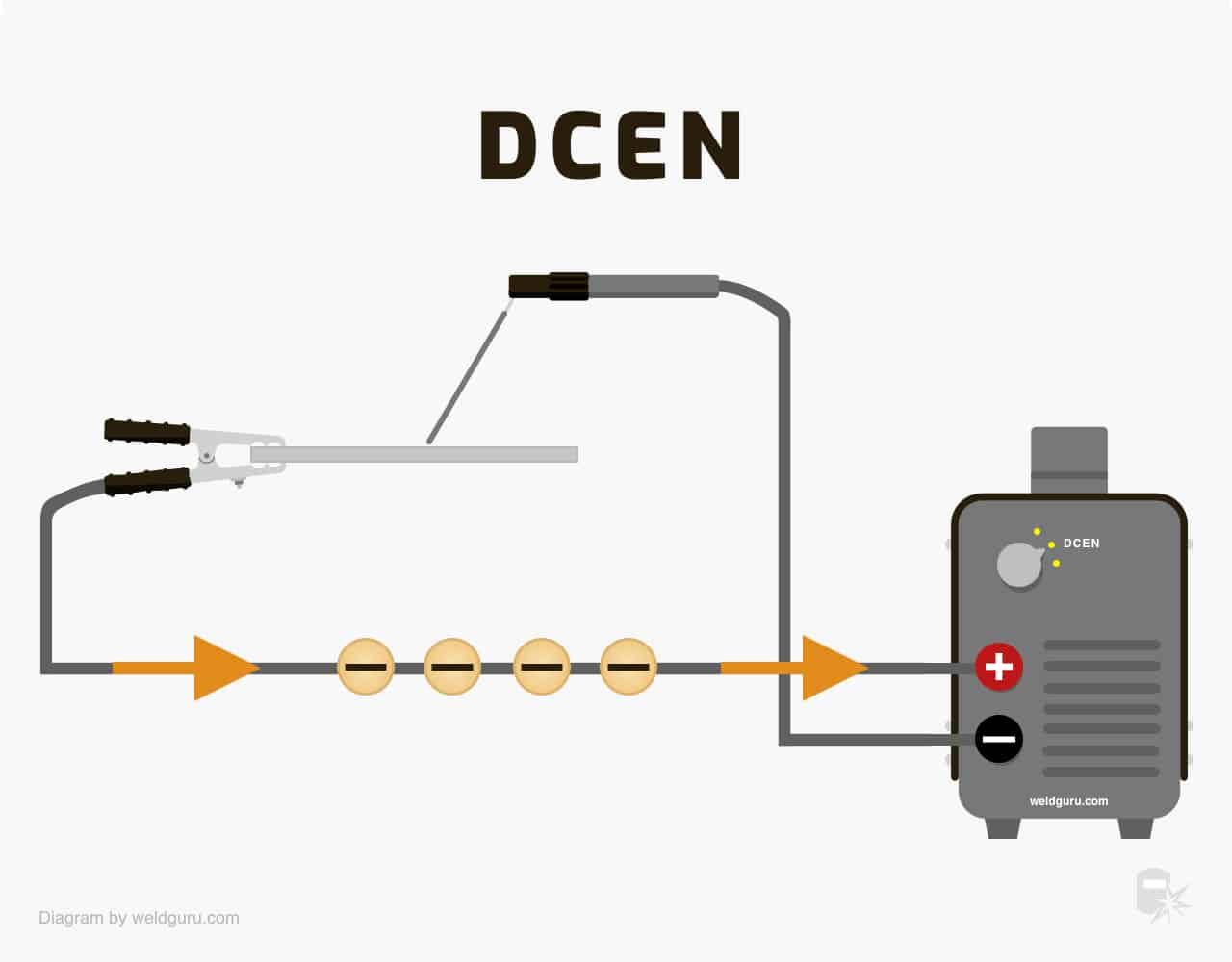

The DC polarity can be straight or reverse depending on the electrode choice and welding scenario.

© weldguru.com – Image usage rights

Straight polarity is when the electrode holder connects to the negative pole of the power supply output. Reverse polarity is when the electrode holder attaches to the positive output.

© weldguru.com – Image usage rights

The work clamp is at the end of a long heavy welding cable that connects to the power supply. Its design allows it to clamp onto the workpiece close to the weld joint.

The work clamp is an important part of the welding machine because it completes the electrical circuit, making welding possible.

The other end of the electrical circuit is the electrode holder, also known as a ‘stinger’. They hold the electrode while protecting the welder’s hands by keeping them safe from the arc and the electrical current.

Electrode holders come in many styles and are on the end of a long heavy welding cable.

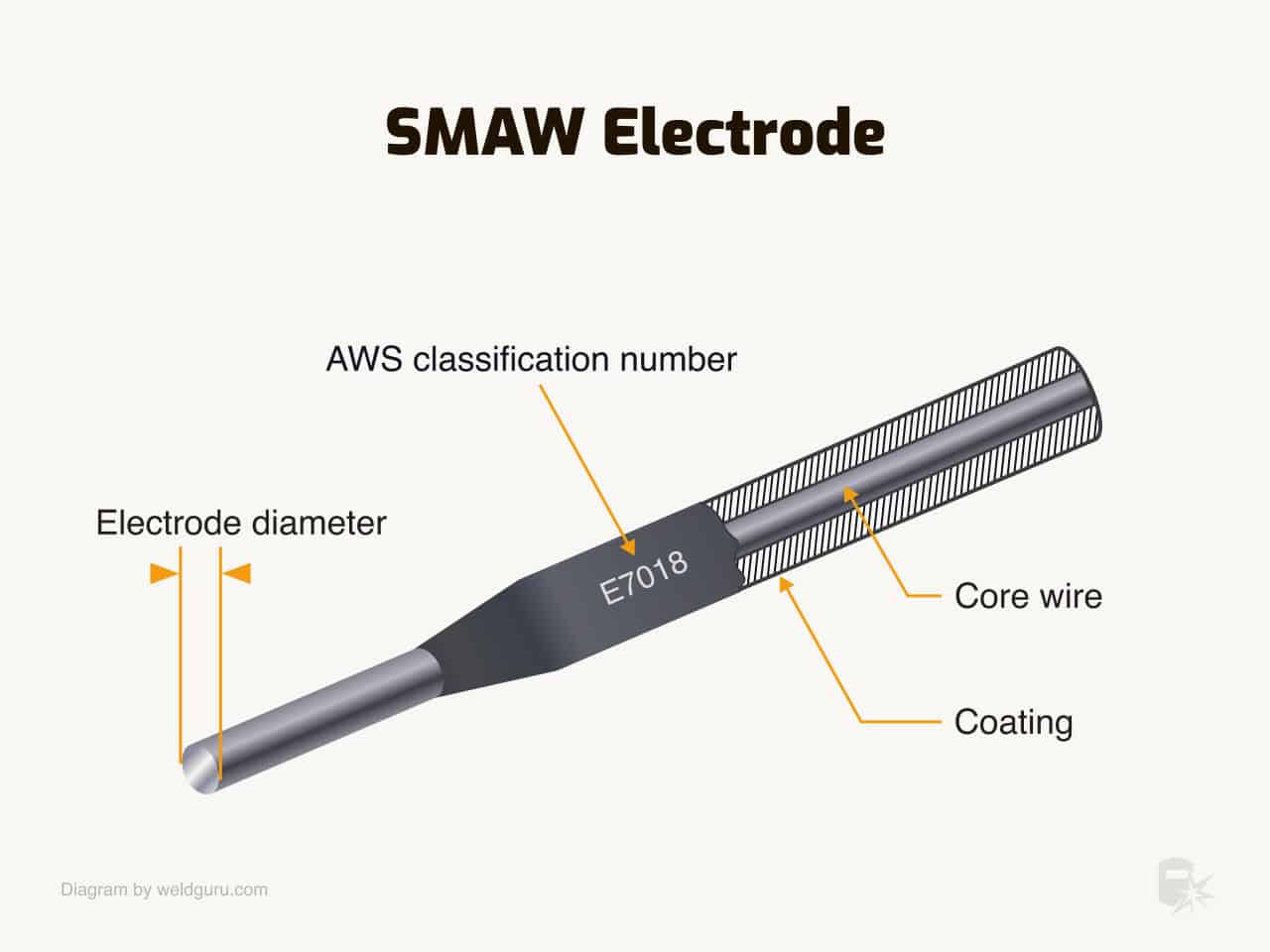

Electrodes add the metal into the weld puddle, forming the weld bead. They’re available in various diameters to suit different material thicknesses and weld sizes.

SMAW electrodes have a flux coating, which protects the weld area from the atmosphere as the arc melts it.

SMAW electrodes come in many different metals and alloys to suit various base metals and welding conditions.

The Role of the Electrode in SMAW Welding

The SMAW electrode serves three purposes.

- It conducts the electric current from the machine to the workpiece.

- It provides the filler material for the weld.

- A flux coating protects the weld from the atmosphere.

The center of the SMAW electrode is a bare metal rod selected to match the base metals of the weld joint. The numbers marked on the rod are a classification for the properties of the electrode.

This metal conducts the electric current from the welding machine to the workpiece.

© weldguru.com – Image usage rights

When the tip of the electrode scratches across the surface of the base metal, the current jumps the gap. The jumping of the current causes an electric arc to form.

The electric arc melts the base metal along with the electrode. The melting electrode mixes with the weld puddle, forming the weld bead.

This process consumes the electrode, and once the electrode becomes too short, the welder replaces it with a new one.

The flux coating affects several aspects of the weld, and each is critical to producing a good weld bead.

- Shields the arc – As the flux melts, it releases gasses that shield the arc from the atmosphere. The melting flux is similar to the shielding gasses used with MIG, flux-core, or TIG. The difference is that SMAW doesn’t need an external bottle of shielding gas.

- Forms slag – The flux also forms a protective layer of slag over the weld, protecting and slowly cooling the weld and shaping the weld bead.

- Controls hydrogen – One crucial job of flux in SMAW welding is to control the amount of hydrogen in the weld, reducing the chance of hydrogen cracking.

- Arc initiation – Flux also helps in making the arc initiation easier and maintained.

There are many types of flux but only three main classes: cellulose, rutile, and basic. Each class has different characteristics that affect the weld.

Electrodes are available in a variety of alloys and metals. It’s possible to weld mild steel, stainless steel, aluminum, and many steel alloys with SMAW welding.

Understanding the Welding Arc in SMAW

© weldguru.com – Image usage rights

The welding arc forms when a current of enough amperage can jump from the tip of the electrode to the base metal.

To start the arc, the welder will drag the end of the electrode across the base metal in a motion like striking a match.

The amperage must be set to the right level because the arc will not establish itself if it is set too low.

If the amperage is too high, the arc will be erratic, the weld puddle will be too fluid, and there will be a lot of spatter.

Proper arc length is critical once the arc is stable and the weld begins.

If the arc length is too short, the electrode will stick in the weld puddle and extinguish the arc.

If the arc length is too long, the voltage increases, the weld bead will become flatter, and there will be lots of spatter.

A good rule of thumb is to use an arc length similar to the electrode diameter. For example, a ⅛” electrode should have an arc length of ⅛”.

The welding arc melts the base metals on either side of the weld joint and the metal in the electrode. As the electrode melts, drops of molten metal will deposit themselves in the weld puddle. This added metal will form the weld bead.

The welding arc can be as hot as 10,000 degrees Fahrenheit and emit damaging UV rays. A SMAW welder must wear the appropriate protective clothing and a welding helmet with a shaded filter lens.

The welding arc will cause hazardous smoke and fumes as it burns the flux and melts the metal. Proper ventilation and/or respiratory protection are also vital to welder safety.

What Is SMAW Typically Used For?

Even though SMAW has been in use for about a century, it remains a preferred choice for many welding applications.

- DIY Applications: SMAW welding machines are inexpensive and available for sale at many big box hardware stores. Since it doesn’t need bottles of shielding gas, tips, liners, or welding guns, SMAW is cost-effective for anyone doing DIY projects.

- Construction Industry: Most welding processes need the welder to be within a dozen feet of the welding machine. Stick welding machines can have welding cables over 100 feet long. SMAW is also a less costly process because not moving a heavy welding machine around the construction site saves time.

- Shipbuilding: Shipbuilders use SMAW for similar reasons as in construction. Ships have a lot of areas where it’s not practical or safe to move welding machines into. Instead, the welder can run lengths of welding cable for the work clamp and electrode holder to where the welding needs to occur.

- Pipe Welding: Pipe welding often happens in locations and environments where MIG, TIG, and flux core welding make it more difficult to operate. On the other hand, SMAW is more practical in most places where pipe welding takes place. Since SMAW requires little equipment, bringing it to a work site in the back of a truck is easy. Many stick welding machines are also generators, which are useful when out in the bush welding pipeline as a power source for a grinder and other power tools

- Industrial Repair and Maintenance: Many industrial sites have staff that repair equipment by welding. In these cases, bringing a small stick welder to the equipment or running some cables is easier than dragging a MIG welder to the site. Also, industrial repairs usually happen in tight spaces and on dirty materials. These are cases that SMAW can handle without too many issues.

- Manufacturing: SMAW welding is not widely used in manufacturing because it has one of the slowest deposition rates. Even so, there are many instances where SMAW would be a good option. Sometimes, tight spaces in weldments are best suited for using a SMAW electrode to reach. In other cases, weldments made from specialized alloys may be welded with SMAW more cost-effectively than MIG or flux core.

Advantages and Disadvantages of SMAW (Stick) Welding

Like all welding processes, SMAW has advantages and disadvantages. These benefits and drawbacks need consideration before choosing SMAW for a welding job.

Benefits of SMAW

SMAW has many advantages, making it a great option for many welding situations.

- SMAW is practical for the outdoors, while MIG, TIG, or flux core are not good choices for an outdoor environment, as they use a shielding gas, and the wind will be an issue.

- Long runs of cables make doing SMAW welding at greater distances from the power supply much easier than other welding processes.

- The base material doesn’t have to be as clean as it would be for other processes like TIG. This quality makes SMAW great for field repairs.

- Equipment costs are lower than MIG, TIG, or flux core.

Limitations of SMAW Welding

While SMAW has many advantages, there are several disadvantages as well.

- Compared to MIG or flux core, SMAW is a much slower process, as weld deposition rates are very low in comparison.

- Once the electrode becomes too short, it needs replacing. Constant replacing means that the weld bead will have many starts and stops. Most weld faults originate from stops and starts.

- The slag left on the weld needs chipping off and the weld underneath cleaned, again making this process slower.

Related: Differences Between Stick & Flux Core Welding

Quick FAQs

Does Stick Welding Require Gas?

SMAW doesn’t require a shielding gas. The flux on the outside of the electrode provides the necessary shielding from the atmosphere.

Is Stick Welding Hard?

SMAW can be tricky to learn at first, but it becomes second nature with practice and some muscle memory.

Compared to MIG, it’s not as easy to learn or use, but it’s a good process to start with for anyone looking to learn how to weld as it’s very cost-effective.

Is stick welding as strong as MIG?

The welds produced by SMAW will be stronger than welds made by MIG welding.

The difference between the two processes is that MIG doesn’t have the penetration that SMAW has.

SMAW also has the advantage of handling dirty base metals, whereas MIG welding doesn’t react well to the same contaminations.

Wrapping it Up

SMAW has been around for a century – and for many good reasons. It’s an effective process that has a place in many industries and situations.

From DIY projects in the garage to underwater welding on an offshore oil rig, SMAW will remain an integral part of the welding industry for decades.

Related read