Can You MIG Weld Steel Using 100% Argon Gas?

It’s a question every welder will face at some point, and yes, you can MIG weld steel if all you have is pure Argon.

But it is not ideal. And stainless is not recommended. Welding with pure argon is unstable.

And… There always seems to be a but, or two, or three.

However, in this case, you need to know the hows and whys behind those buts to properly answer this seemingly simple question.

Why Would You Use Pure Argon?

Most people reading this article will already know why someone would consider using 100% Argon to MIG weld steel.

Necessity.

Running out of gas happens to every welder. But no one wants to waste valuable time running around to get more gas in the middle of a workday. Or maybe your gas supplier is closed.

But, if you keep a tank of 100% Argon in the shop for other types of welding, you can use that and keep working. No interruption to dart out for a refill of your MIG gas mixture bottle.

Using pure Argon is simply a matter of being resourceful and productive in a pinch.

But, the steel weld may not be of high enough quality depending on what you are welding.

Why is 100% Argon so Different?

The MIG shielding gas does more than just shield the weld from harmful atmospheric gases. Yes, it is important to keep those gases out and not make the weld porous.

But its composition also affects the arc quality and thermal conduction. These properties also have significant impacts on the resulting weld.

So, you need to know what to expect when using 100% Argon to MIG weld steel.

Some of the characteristics you will experience when using it include:

- Argon has a lower ionization potential, which reduces the arc voltage and power.

- The arc tends to be less stable.

- Combining an unstable arc with reduced power prevents the formation of a fluid, workable puddle. In other words, the molten pool will be of higher viscosity and harder to manipulate and control.

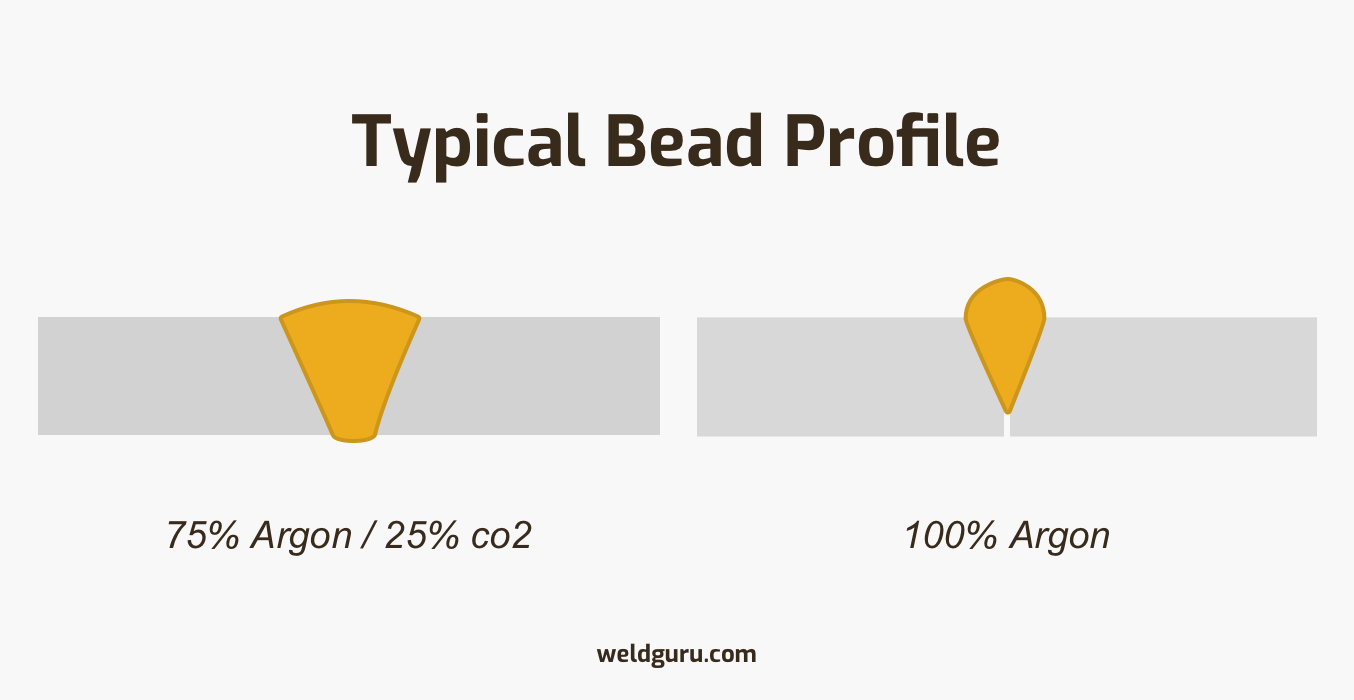

- Argon has lower thermal conduction, and the outer edges of the arc remain cool. This means you get narrow, reduced penetration with less fusion.

- The filler material sits on top of the steel in a narrow, tall bead.

- MIG welds using pure Argon are prone to undercutting.

- Experience shows that MIG welds on steel with pure Argon gas lose ductility. As a result, bending or twisting can crack or break the rigid weld.

© weldguru.com – Image usage rights

In summary, it is possible to weld steel together using a good MIG welder with 100% Argon shielding gas. But you end up with a shoddy-looking, weak, brittle weld that is not structurally safe.

If you need a strong, quality weld, 100% Argon is NOT a good choice for MIG welding steel.

These problems are even more pronounced with stainless steel, and using pure Argon to MIG weld stainless is never recommended.

The YouTube video below presents some useful information and visuals regarding MIG welding steel with 100% Argon.

Related: What is GMAW?

Using 100% Argon to MIG Weld Steel

If you find yourself in the unenviable position of having to MIG weld steel with pure Argon shielding gas, there are a couple of tips that may help.

- Bevel the edges of the joint. It will help fuse the base metal and make for a stronger welded joint.

- Turn up the heat, but be careful not to burn through thinner steel. Getting the bead to sit flat will likely be hard or impossible.

Also, Argon does produce good welds when using a different weld method (i.e. TIG) or different base metals.

Some base metals where you might want to use 100% Argon with a MIG welder include:

- Aluminum

- Titanium

- Magnesium

- Nickel (under ⅛ in.)

- Copper (under ⅛ in.)

One last note of interest, for some, the lower penetration makes MIG welding with 100% Argon advantageous when welding steel sheet.

In this case, pure Argon can reduce the likelihood of melting through the thin base metal. But you will probably still get a tall, narrow bead.

Related read: TIG Welding Gases (with Chart)

CO2 / Argon Blends Work Better to MIG Weld Steel

Blending some carbon dioxide (“CO2“) into the Argon is a common gas blend for MIG welding and solves the problems associated with 100% Argon. A 5 to 25% amount of CO2 is usually added to improve the results with a MIG welder.

This gas blend provides a fluid, workable puddle and better penetration. Plus, it eliminates the undercutting, and there is less spatter. Importantly, the heating and cooling are better controlled, improving the resistance of the weld to bending and twisting.

When buying an Argon/CO2 blend, the gas is labeled to indicate the amount of CO2 added to the Argon.

For example, “C25” is a 25% CO2, 75% Argon shielding gas. Welding with 100% Co2 would be labeled C100.

Taking the concept of blending gases to another level, using a trimix shielding gas (e.g. 90% Helium, 7.5 % Argon, and 2.5% CO2) produces the best welds on stainless steel.

This gas can be expensive and is not always available to the hobbyist welder. But for quality welds on stainless, it may be worth the cost and trouble to find a trimix blend.

Related read: What size gas tank for MIG / TIG

Why Does 100% Argon Work to TIG Weld Steel?

MIG welding and TIG welding differ in applying the filler material and the type of electrode used. This does affect the arc and characteristics of the weld.

MIG welding uses the filler as the electrode, and hence the need to continuously feed wire to the tip as it is consumed.

In contrast, TIG welding uses a non-consumable tungsten electrode, and the filler is fed into the arc separately. This electrode produces a stable and strong arc, but the tungsten tip must remain clean and undamaged.

Related: MIG vs. TIG Welding

So, TIG welding demands a gas that remains inert, even at high welding temperatures. Argon does stay inert, even at elevated temperatures. It also produces easy starts, maintains a stable arc, and helps to keep the tungsten electrode clean.

So, TIG welding of steel with Argon can work, whereas MIG welding of steel benefits by using an Argon/CO2 blend.

Also Read:

Argon Gas Cost – How Much & Where to Buy

I’m not a welder however i do like playing with the 20yr old Clarke weld ive got….came into a load of free argon and wondered why my bad amateur weld’s we’re even worse than normal..now I know…thanks for clearing that up!