The most common gas used for MIG welding is a 75% argon, 25% CO2 mixture. But it is not the only gas you may need. A few other gases are also important. For example, you may see Helium blends used to weld thick aluminum.

Your shielding gas choice significantly impacts the weld quality, arc behavior, productivity, and costs. So, it’s vital to pick the correct gas for the job at hand.

But, don’t worry. MIG welding shielding gases are straightforward, and our guide will answer all of your questions.

Related read: GMAW Process Overview

Most Common Gases Used in MIG Welding

MIG welding typically employs four shielding gases. Two are reactive, oxygen (O2) and carbon dioxide (CO2). Two are inert, argon (Ar) and helium (He). These gases have different characteristics, and even more differences are found when these gases are blended.

Argon in MIG Welding

Argon is denser than air and settles over the joint to protect the molten pool from atmospheric gas contamination. In addition, argon is easy to ionize, so it handles a long arc at low voltages well.

But it’s not ideal to use pure argon to weld steel (including stainless)…

The outer edges of the arc remain too cold, and you get narrow, reduced penetration with less fusion. Plus, the filler material remains on top of the steel, resulting in a “tall” bead. So instead, welders typically use a mixture of Ar and CO2 or a blend of Ar and O2, which we’ll cover soon.

On the other hand, a 100% argon gas creates favorable conditions in the weld pool for welding non-ferrous metals like aluminum, magnesium, titanium, copper, and nickel. Argon’s cathodic cleaning action removes surface oxides with DCEP polarity making it indispensable for welding aluminum.

CO2 in MIG Welding

Carbon dioxide is the only reactive gas that can be used purely without adding inert gas.

However, 100% CO2 creates a less stable arc and more spatter. But, it’s the most affordable gas and often the hobbyists’ choice.

It is impossible to weld non-ferrous metal with CO2 or mixtures with CO2, so only use it with steel. Pure carbon dioxide is a perfect choice for welding thick sections because it improves penetration.

However, working with 100% CO2 is limited to the short circuit, metal-transfer welding mode.

Oxygen in MIG Welding

Depending on the welded metal, oxygen may be blended into CO2 or Ar. A small addition of oxygen dramatically affects the weld, and the maximum oxygen content is 9% of the shielding gas mixture.

Since iron oxide attracts the arc when using 100% Ar, arc irregularities can occur when welding steel with pure argon. So, a small addition of oxygen significantly improves arc stability.

Oxygen also improves penetration, weld pool fluidity, and arc stability when welding low alloy, mild steel, and stainless steel. But, since oxygen causes metal oxidation, it should never be used with aluminum, copper, and magnesium.

Helium in MIG Welding

Helium is an inert gas like argon, but it’s much lighter and has a higher ionization potential. Due to its low weight, it floats away from the weld pool easily.

That’s why it’s necessary to double the shielding gas flow rate when using it. It’s not the most economical since helium is expensive, and you must crank up the flow.

Related read: What Should the Gas Pressure Be When MIG Welding?

However, thanks to better ionization, helium produces a significantly hotter arc. This improves weld penetration, and it’s beneficial for welding thick aluminum or magnesium.

Blending helium with argon can make welding more affordable with this light, inert gas.

While typically used to weld non-ferrous metal, helium is also sometimes added to argon and CO2 to weld stainless steel.

Blends

While a complete list of blends used in MIG welding would be very long, there are a few you should know.

- 75% Ar + 25% CO2 – Provides the best balance of arc stability, spatter reduction, weld puddle control, and penetration for welding carbon and stainless steel.

- Ar + 1%, 2%, or 3% O2 – Optimal arc control, but less common than the 75/25 Ar/CO2. Generally, 2-3% oxygen stabilizes the arc when welding carbon and low alloy steel, while 0.5-1% is necessary for stainless steel to prevent the refractory scale of chromium oxide.

- 10% Ar + 85-90% He + 2-5% CO2 – Often the best tri-mix shielding gas blend for stainless steel MIG welding.

- Ar + 25%, 50%, or 75% He – The best blend for welding thick aluminum, magnesium, copper, and nickel. The higher the helium content, the hotter the arc and the thicker you can weld.

- Ar + CO2 + O2 – Used to weld low alloy steel and some stainless steel in all-metal transfer modes.

Choosing the Perfect MIG Shielding Gas for the Job

Now that we’ve covered the basics let’s see how the metal type, thickness, and costs impact the choice of shielding gas.

Welded Metal

Let’s dive deep into best practices of shielding gas use and discuss the pitfalls to avoid with commonly welded metals.

Carbon Steel

Earlier, I noted that you shouldn’t use 100% Ar gas for carbon steel. That’s because the cathodic action of argon gas causes iron oxide present in the steel to attract the arc. The iron oxide emits electrons causing the arc to follow them.

But, since iron oxides are distributed unevenly on the steel surface, the arc follows an irregular path, which results in uneven weld deposits.

Adding a small amount of oxygen or carbon dioxide improves arc stability. These argon blends produce an even iron oxide film on the steel joint’s surface and provide an easy path for the arc to follow.

Oxygen requires small additions since it’s a more potent oxidizer than carbon dioxide. But you must also use a MIG welding wire with more deoxidizers to pick up the free oxygen and prevent porosity.

Using a mixture of carbon dioxide and argon provides for deeper penetration. The best combination is 75% Ar and 25% CO2. Since CO2 has high thermal conductivity, it requires more voltage to keep a stable arc, improving penetration.

But if you need less penetration, you should reduce the CO2 content in the blend. A minimum of 5% CO2 is required for a stable arc.

A 100% CO2 shielding gas doesn’t offer good arc stability. But, it provides maximum penetration and allows high welding speeds. For some, that makes it a good choice.

However, you shouldn’t use pure carbon dioxide as a shielding gas for MIG welding thin metal. It’s easy to burn through a light gauge and distort the sheet.

To weld thick steel sections, you can use 100% carbon dioxide. If your MIG welder has an induction setting, it’s good to crank it up. A higher inductance with pure CO2 makes for a softer arc and improves wetting at the weld toes.

Aluminum

To MIG weld aluminum, you must use a 100% argon gas or an Ar/He mixture. Don’t use any blends with CO2 or O2. it’s devastating for aluminum and creates a disastrous joint. Any reactive gas is a big “don’t” for welding aluminum.

Helium creates a similar effect for aluminum as carbon dioxide does for steel. Adding helium improves penetration and welding speed.

But, helium slightly reduces arc stability. If you weld aluminum thicker than 1/4 in., consider an Ar/He blends to improve penetration. Otherwise, stick to straight argon.

It’s also good to add some helium to argon if your welding machine doesn’t have high amperage. You can maximize the penetration potential of your MIG welder by using a He/Ar blend.

But remember that the MIG welding process becomes increasingly globular as you increase the helium content. So, keep helium below 50% unless you want a globular arc transfer.

However, most people don’t need anything other than a pure argon gas bottle to MIG weld aluminum. If the aluminum piece is thick, you can preheat it to a maximum of 250F° to avoid buying a helium mixture for just one job.

But, professionals benefit from Ar/He mixtures to create the best aluminum welds on thicker parts.

Read more: How to MIG Weld Aluminum

Wire Feeding And Shielding Gas

There are three ways to feed aluminum wire for MIG welding:

- The machine’s wire feed system and a standard MIG gun (most likely to cause wire nesting)

- A spool gun

- A push-pull gun

Regardless of the wire feed method, you need pure argon or an Ar/He mixture as a shielding gas.

But keep in mind that the spool guns are typically rated for hobbyist application and have limited duty cycles for high amperage output. So, by increasing the arc’s heat with a helium addition, you may overheat the spool gun more quickly.

For heavy-duty use, it’s best to get a spool gun with a high rating like the one that comes with Hobart Ironman 240 or a push-pull gun.

Stainless Steel

Stainless steel is a complex metal to weld, and shielding gas choice is not straightforward. But, to make this as simple as possible, let’s discuss the gas selection that gets the job done for most people, especially home hobbyists.

Two Gas Blend

You can weld SS (“stainless steel”) with a typical 75/25 Ar/CO2 gas, and it works well for most people. However, it’s far from a perfect shielding gas for SS. Using 25% carbon dioxide in the mix provides too much carbon in the joint. As a result, the SS may lose some corrosion resistance.

If you wish to stick to the Ar/CO2 mix, keep the CO2 content below 5% to maintain the stainless steel’s corrosion resistance. But, if you are working on a hobbyist working on a noncritical joint, the 75/25 mix is acceptable.

You won’t be forced into getting another gas tank just to reduce the carbon dioxide percentage in the mix. But the risk of corrosion will be higher.

Use a blend of Ar with 2% a maximum of 2% oxygen to maintain the SS corrosion resistance. This blend also improves travel speed, allowing you to weld faster than with the 5% CO2 we mentioned above.

Tri-Mix Blends

Finally, the tri-mix gas blend of He/Ar/CO2 is the best shielding gas for welding stainless steel. Using 10% argon with 85-90% helium and 2-5% carbon dioxide provides significantly faster travel speeds than any two-part blends.

With this tri-mix, you can achieve excellent penetration, bead shape, arc stability, and control over the thin metal distortion. However, this gas blend may not always be the best choice.

As we mentioned earlier, choosing a shielding gas for SS is tricky. There are many SS grades and numerous types (austenitic, ferritic, martensitic, and duplex).

Different alloys require different shielding gases and your gas selection influences the resulting joint characteristics. So, for professional applications, you may need a different tri-mix formula.

Read more: How To MIG Weld Stainless Steel

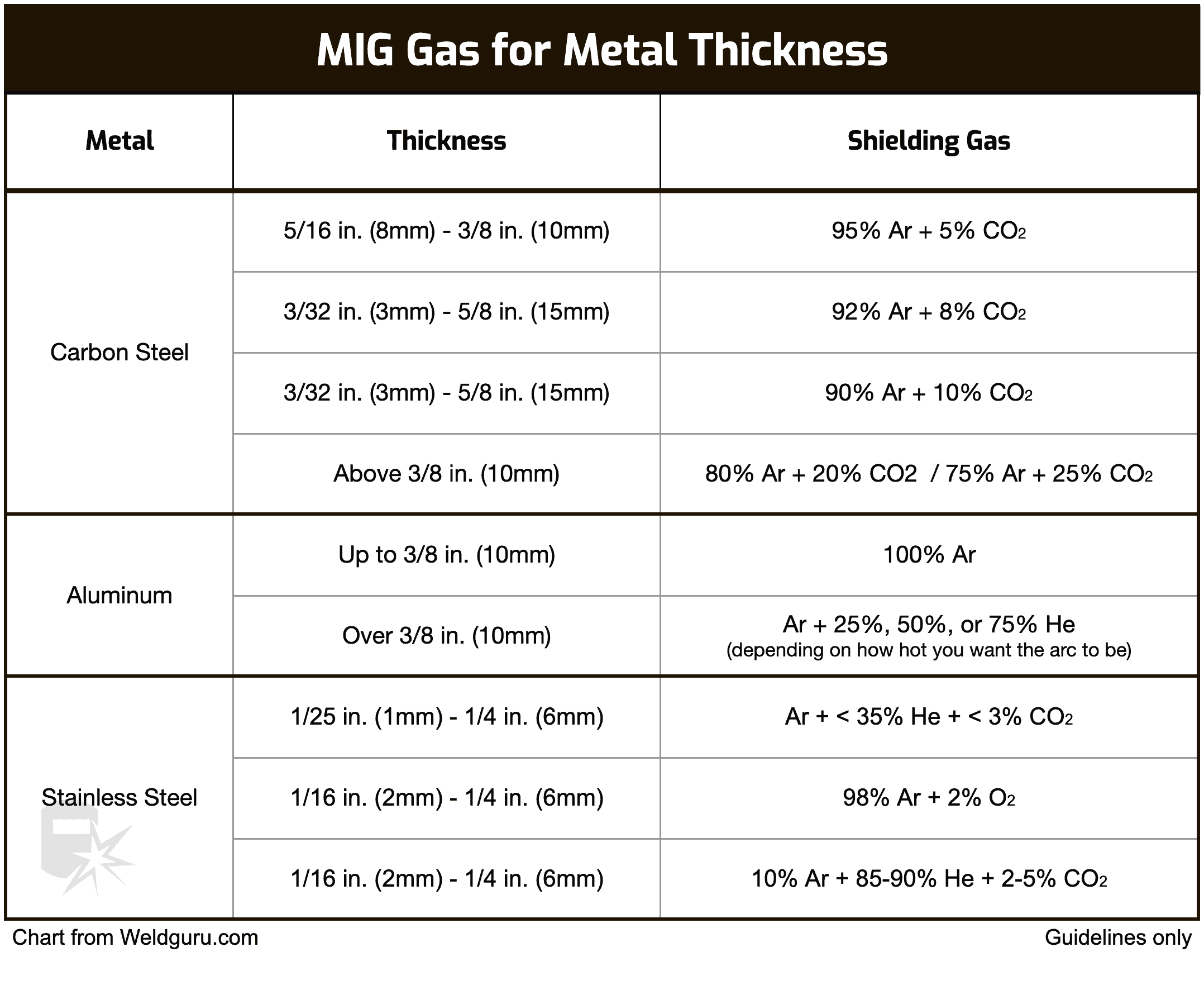

Metal Thickness

The thickness of the metal can also play a role in shielding gas selection. However, it is often the most cost-effective to get a shielding gas that works for many thicknesses.

For example, you can use 75/25 Ar/CO2 to weld almost all mild steel thicknesses.

Getting a specialized mixture is only economical if you often weld a specific thickness or require the best possible weld.

Budget

Shielding gas selection impacts welding shop efficiency and costs. But, DIYers also shouldn’t spend more money than necessary on shielding gas and the tank.

There are two ways to acquire gas tanks: buying or renting a gas bottle. When buying the tank, you can choose between disposable and refillable bottles. So, let’s see which is the best option for you.

Buying Disposable or Refillable Tanks

Disposable gas tanks are more prevalent in the UK but can also be bought in the USA. However, we would not recommend disposable shielding gas tanks unless you need to make a few minor welds or weld on the go.

It’s much more economical to buy a refillable gas tank.

Refillable gas bottles come in many sizes, but the three most commonly sold are 40, 80, and 125 cubic feet (“CF”). If you are a hobbyist and only weld occasionally, it’s best to buy a 40 or 80CF gas tank. However, if you often weld or run a welding shop, the 125CF tanks are the norm.

To learn more, you can read our complete guide on welding gas cylinder sizes.

Keep in mind that it’s cheaper to refill a larger tank. Plus, if you buy a cylinder too small for your needs, you will make frequent trips to the gas supply center, further increasing costs and downtime.

If it’s too big, you will spend more money on the tank and waste more storage space. Plus, moving a large tank is a pain. While it sounds obvious, ideally, you should get a gas tank that’s not too small and not too large.

Leasing Refillable Tanks

Welding shops and demanding welders often lease large gas tanks. These bottles are typically above 125CF, but it’s also possible to rent smaller sizes.

Conditions of leasing refillable gas bottles vary a lot by region, and often it is not the most cost-effective way of acquiring a gas tank. I wouldn’t recommend it unless you need many bottles for a large-scale operation and trying to save money upfront. While buying a gas tank is a bit more expensive, it’s cheaper in the long run.

Cost

The shielding gas tank’s initial cost and refill price largely depend on your local gas supplier. However, we made the table below to provide some basic comparison.

Argon is typically more expensive than carbon dioxide, and the standard 75/25 Ar/CO2 mixture is similarly priced to 100% Ar.

As for 100% CO2, make sure you are getting an industrial-grade, not food-grade, carbon dioxide because it’s not necessary and costs more.

100% Argon Tank Costs

| Size | Initial Cost (full) | Refill |

|---|---|---|

| 40CF | $230 to $260 (example) | $45 to $60 |

| 80CF | $290 to $320 (example) | $55 to $65 |

| 125CF | $350 to $390 (example) | $70 to $85 |

75% Argon / 25% CO2 Tank Costs

| Size | Initial Cost (full) | Refill |

|---|---|---|

| 40CF | $240 to $280 (example) | $45 to $60 |

| 80CF | $290 to $330 (example) | $55 to $65 |

| 125CF | $350 to $390 (example) | $70 – $85 |

Related: Where to buy Welding Gas & What Does it Cost?

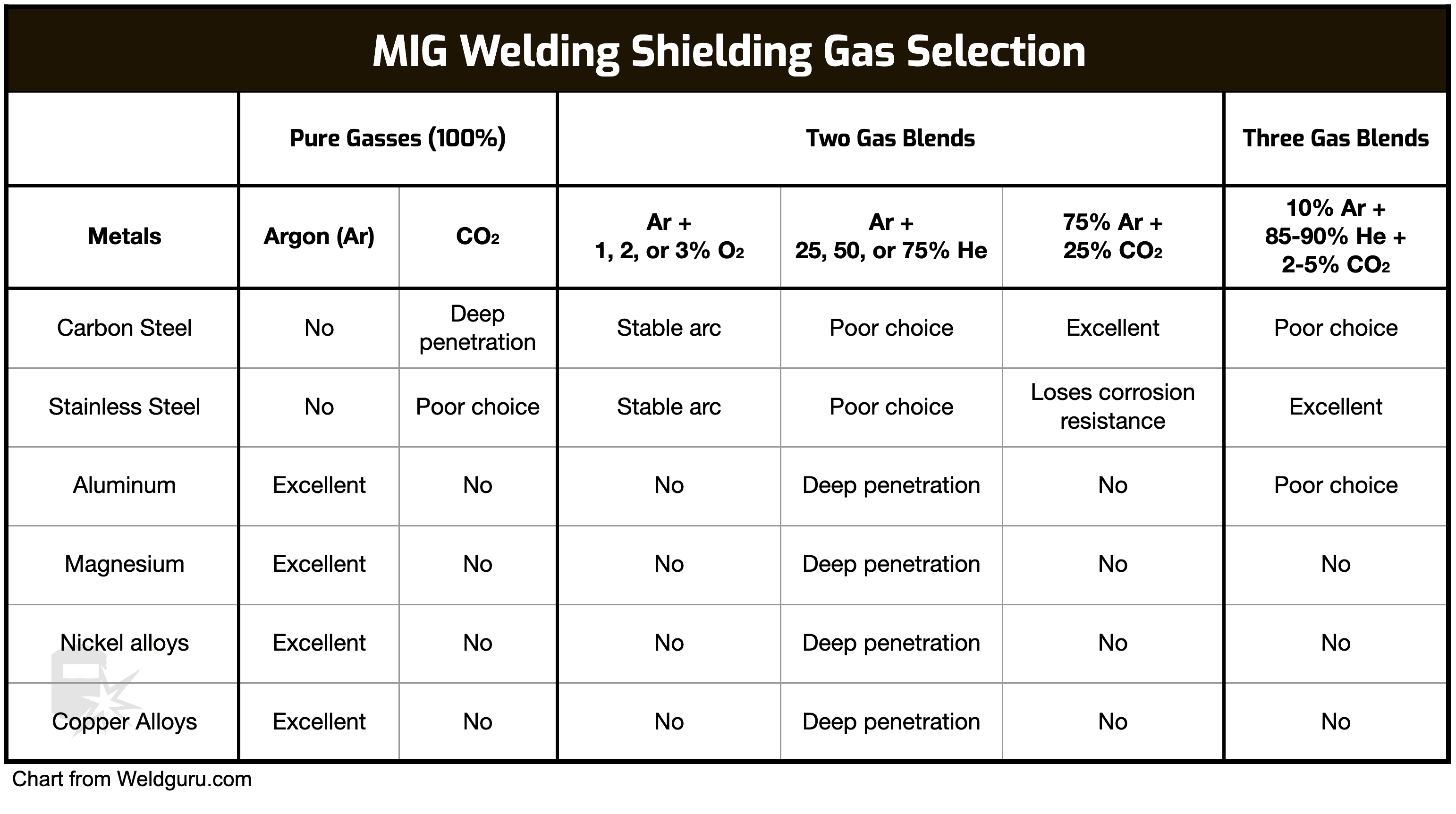

Summary Chart

Choosing your welding gas primarily depends on the metal you weld. But as already discussed, you can also tailor the mixture to improve penetration and arc characteristics.

To summarize what we presented in this article, we made a simple table to simplify your MIG shielding gas selection. Additionally, I invite you to read our guide on MIG welder settings.

You can get the most out of your welding setup by learning how to tweak everything correctly, including your shielding gas.

Wrapping It

One of the best things you can do is check with your local gas supplier before buying a tank.

Their refilling process varies, and some companies don’t refill the tanks sold by third parties, but most do. But confirm in advance that they will fill any tank you intend to buy.

Thanks for the feedback Petros – appreciated