Blends of carbon dioxide (CO2) and Argon are the most common shielding gas for MIG welders. So, why use straight CO2 instead of a mixture of Argon and CO2?

Well, for the home welding enthusiast, using pure CO2 saves you money.

But 100% CO2 will affect your welds, with pros and cons. So, understanding the benefits and drawbacks is a must.

Without this knowledge, you are gambling with your weld quality when using pure CO2.

Why Use Pure CO2?

Yes, CO2 is more cost-efficient. But that is a general, bold statement, and you may have asked, how cost-efficient is it?

Glad you asked. Let’s break it down…

C100 vs. C25

| 20# of Pure CO2 | 80CF of C25 | |

|---|---|---|

| Height x Width | 26 in. x 8 in. | 35 in. x 7 in. |

| Full Weight | 45 lbs | 56 lbs |

| Volume | 175 cf | 80 cf |

| Operating Time @ 20cfh | 8.8 hrs. | 4.0 hrs. |

| Initial $ | $150 (empty) | $311(full) |

| Initial $/hr | $21 (includes initial refill) | $78 |

| Refill $ | $35 | $75 |

| Refill $/hr | $4 | $19 |

To make a fair cost comparison, we added the initial filling of the CO2 tank to the initial cost to calculate the initial $/hr operating costs (the C25 tanks ship full).

This breakdown attests to the savings of using pure CO2.

Based on the refill costs, the operating cost is less than ¼ of the C25 $/hr. And the upfront investment is ½ the initial $/hr cost.

That means; Significant savings are real when you use C100 as a shielding gas.

Related read: GMAW Welding – What Is It?

Pros & Cons

CO2 tanks ship empty. That is because CO2 exists as a liquid at high pressure inside the tank, which cannot be shipped full safely.

So, be aware of the first con when using CO2; you will need to fill a new tank to use it.

Portability

In the tank, C25 is a compressed gas and can be shipped full. This complicated our initial $/hr calculation a bit. But it also means C25 needs bigger tanks to hold less.

We included the dimensions precisely to show the C25 tank is bigger, with less CF of gas. What this means for welders; C100 takes less storage space.

So, CO2 is more portable with smaller tanks. But you can also take that to an extreme since CO2 is available in sizes smaller than 20 lbs.

In fact, you can find real small CO2 tanks used for paintball guns (like these) and home soda makers. You sacrifice operating time, but you can keep things compact and light for mobile jobs that don’t require a lot of welding time.

Related read: Welding Cylinder Sizes and Welding Time

Refills

Since CO2 is used for more than just welding, you have more options to refill CO2 tanks. Plus, some refill options are more “consumer” friendly. You may even find some open on weekends and after hours.

Some places other than welding centers where you might fill a CO2 tank include:

- Homebrew Shops

- Sports Stores (that sell paintball gear, e.g. Dick’s Sporting Goods)

- Fire Extinguisher Service Centers

- Aquarium Supplies

Related Read: How Much Does Welding Gas Cost?

Equipment Considerations

CO2 Gas

Of course, your tanks must be filled. But keep in mind when you go to fill a carbon dioxide bottle, you will find industrial and food grades of CO2.

Food-grade is slightly purer, but it is not necessary for welding. The industrial grade is usually a little cheaper and will work fine if that is what you can get.

MIG Welder

One question always comes up… Do I need a special machine to use CO2?

No, decent MIG welders, with adequate controls, work with CO2.

However, the more adjustments you have, the better. Better units provide supplementary controls and can help dial in your optimum settings when using pure CO2.

For instance, slope control may help smooth out the arc. (it may also be called inductance control). An example is the Lincoln 210, offering a hobbyist a lot of control when using C100 gas.

You pay more for a welder with improved control. But they are more versatile.

If you plan on using 100% CO2, it might be worth paying a little more for the welder.

Regulator

The regulator used for Argon/CO2 blends has different threads than a CO2 regulator.

Also, most CO2 regulators usually only display pressure.

But you need a regulator that tells you the gas flow rate. So you have two options.

- Use an adapter to attach your existing Argon/CO2 regulator, or

- Buy a quality CO2 regulator with a flow rate indicator (like this one).

Keep in mind, if you do use your existing Argon regulator for pure CO2, make sure it is rated to do so. Not all Argon regulators can run CO2. The cold and frost from CO2 can damage some regulators.

The linked Argon regulator above (i.e. CGA580 thread) comes with flow rate scales for both Argon and CO2. So, you can use it either way, if you have a CO2 tank adapter (i.e. CGA320 to CGA580 thread).

Consumables

Standard MIG consumables work with pure CO2 shielding gas.

However, increased oxidation from the CO2 can increase weld porosity. So, choose a MIG welding wire with powerful deoxidizers like some solid ER70S-6 wire products.

While a little hard to find, you can also find flux-core, gas-shielded wires (like this one).

This means you can shield the welding pool from atmospheric gases, and provide protection against the oxidation from CO2 which causes a porous weld.

Welding with 100% CO2 Shielding Gas

There are noticeable differences when welding with 100% CO2, since at high welding temperatures, CO2 changes from an inert to reactive gas.

This means better bite compared to Argon blends and in general pure CO2 has:

- Better joint penetration.

- Higher welding speeds.

- Aggressive cleaning action.

These properties mean you can weld thicker metal with your MIG welder, have faster travel speeds, and cut through rust and mill scale more easily when using pure carbon dioxide.

But it also means thin metal will be hard to weld. Increasing your welding travel speed helps, but on very thin metal, it will be difficult.

Related: Welding Gases: Different Types & Uses

Impact on The Arc

Undoubtedly, poor arc quality is the biggest drawback to using 100% CO2.

Carbon dioxide’s electrical conductivity is lower than Argon. When it is added to added argon, up to 25%, it helps to stabilize the arc.

But pure CO2 produces a rough, inconsistent arc and you see more spatter. However, it is possible to find a sweet spot, and when you do, the arc is only “slightly” more fickle.

Getting that sweet spot with your settings, though, is difficult to hit. But when you do, good welds are possible. Plus, you can keep the arc length short to reduce spatter.

You can expect a short-circuit transfer with low currents and globular transfer at higher currents. When you use pure CO2, spray transfer is not possible.

All this means you will need to experiment a little. But with time, you should be able to determine what settings your welder needs for a stable arc.

If you recall, we mentioned a welder with more controls does make a difference with C100. And getting a stable arc is where this can really help. With practice, you will find the settings for quality, consistent welds.

Related read: Weld spatter causes & how to reduce it

Welder Setup

It is common for welder manufacturers to recommend settings for straight CO2. In general, for a given wire speed setting (”WFS”) the voltage will be higher.

So, you can lower the wire feed to match your preferred gas flow rate. Or, you can bump up the voltage to work with your preferred wire speed.

But keep in mind, the sweet spot is narrow. It will take some time to find it for your setup.

Also, if you have the ability to adjust the inductance (or slope control), increasing it will help to stabilize the arc.

[welder101]

Weld Bead Appearance

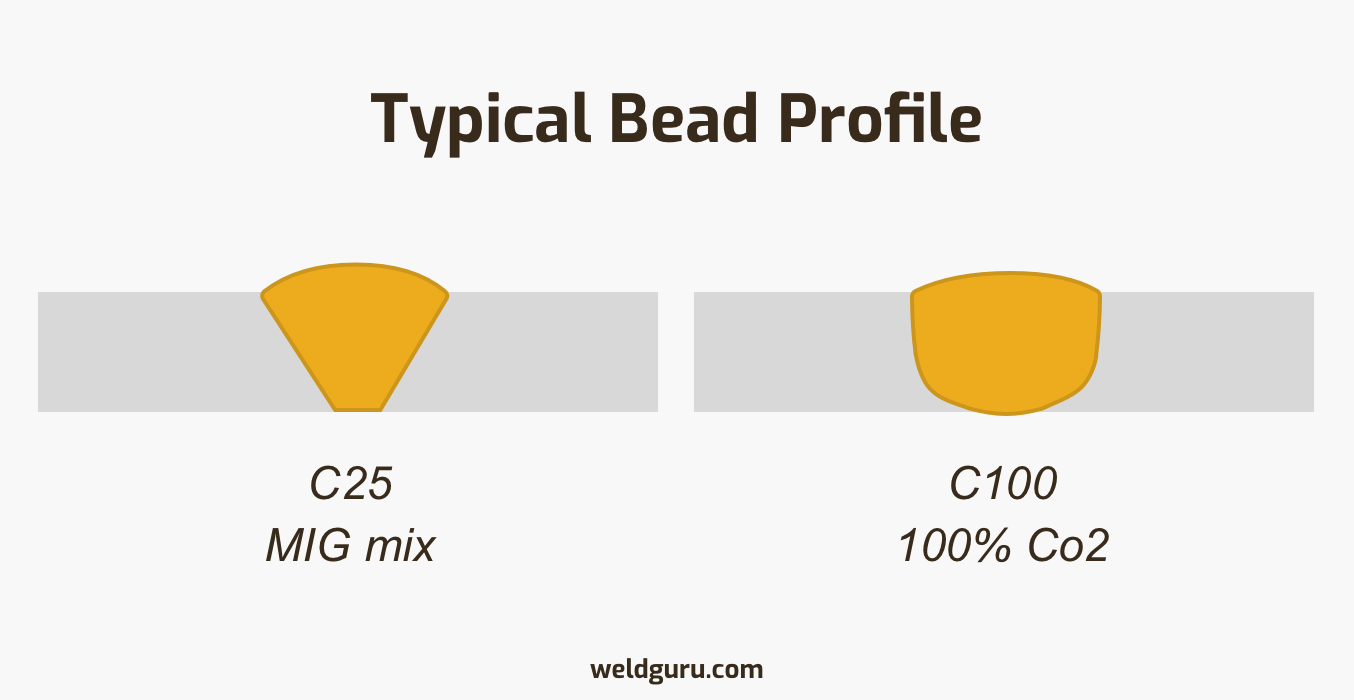

100% CO2 gas does penetrate better and it produces a broad bead with deep penetration. So, you get a wide, flatter bead.

This does mean smaller machines can weld thicker metal, but thinner metal becomes a challenge.

Related read: How to weld thin sheet metal

Also, you may get more spatter.

So, if you need a clean, presentable finish, you will likely need to do some cleanup when the weld is done.

FAQs

When is my CO2 tank empty?

Because CO2 is a liquid in the tank, the pressure drop is not a good indicator of how much gas is left. Weight is a better indicator. However, when the PSI falls to around 200 psi, you need to get a refill.

Running a bottle to 0 psi can create problems. It allows water and contaminant gases inside the tank.

Why does CO2 frost up the regulator?

CO2 expands and goes through a phase change as it flows from the tank. This means it draws large amounts of heat from its surroundings. In humid conditions, this leads to frost formation. You should not be surprised if this happens at flow rates above 25 CFM.

Does 100% CO2 shielding gas add carbon?

Carbon dioxide is composed of carbon and oxygen. So, it is possible to add a small amount of carbon to a weld. But it is fine for mild steel. However, low alloy metals are impacted by low amounts of additives, and using CO2 shielding gas could create a problem.

Summary

Using pure CO2 saves you money on gas. But it produces a more erratic arc, and you need to determine what MIG welder settings work best. For many, this is well worth the effort to realize the savings over Argon blends.

You gain penetration, which lets you work on thicker metal. Plus, your speed picks up, and CO2 cuts rust, mill scale, and contamination better. But it does produce more spatter, and working on thin material is hard, if not impossible.

The bottom line is, if CO2 gets you more welding time, use it. Improving your skills only happens through experience. The more time you weld, the better you get. So, you sacrifice very little using pure CO2 to earn more welding knowledge.