MIG welding safety should be taken seriously as the welder needs to be protected against the forces of heat, gas, electricity and light that MIG welders produce.

The principles of safety are fairly straight forward and focus on:

- Cleanliness and organization, locate welding machine in a dry location on floor of a welding booth

- Adequate lighting

- Checking for gas leaks

- Ventilation per OSHA standards (also check MSDS for each metal being welded). Use a respirator when required by the MSDS.

- Safe storage of flammable gases and liquids such as in a specially designed storage locker

- Check integrity of electrical cords

- Protect against burns caused by metal heating, electrodes and from ultraviolet light

- Regular equipment maintenance and proper installation

- Keep a first aid kit on hand

- Use proper welding gear that includes eye protection and protective clothing (shoes/boots, gloves, long sleeve shirt, pants over tops of shoes with optional shoe covers (called spats), hat or welder beanie, leather jacket or apron.

- Keep a fire extinguisher on hand

When thinking about safety also think about those around you. A welding arc should not be seen by the naked eye closer than 20 feet away.

Precautions

Ventilation, Fumes and Gases

Can harm you, keep your head out of the fumes. Use general ventilation, respiratory protective equipment or local exhaust ventilation as recommended in the MSDS for the material being welded.

Do not weld on a dirty plate or plates contaminated with unknown material. Remove all paint and galvanized coatings before welding.

Be careful when working with carbon dioxide shielding since it can be hazardous. Use appropriate ventilation.

Use a higher percentage or argon gas along with the pulse-spray transfer method to reduce gas-related hazards.

Be especially cautious when welding with the following metals since they have toxic vapors:

- lead

- cadmium

- copper

- zinc

- beryllium

Keep Degreasing Away From Welding Area

Keep any degreasing away from welding area. Degreasers are made with carbon tetrachloride, perchloroethylene and trichlorethylene can break down into phosgene when exposed to arc rays.

Shown: Eagle 1932 Safety Cabinet for Flammable Liquids, 2 Door Manual Close, 30 gallon, 44″Height, 43″Width, 18″Depth, Steel, Yellow

Arc Rays and Spatter

Beware of arc rays and mig spatter when reviewing MIG welding safety plans.

Arc rays and spatter can injure eyes and burn skin. Wear eye, ear, and body protection to prevent this.

Electric arc radiation can burn eyes and skin the same way as strong sunlight. Electric arcs emit both ultraviolet and infrared rays. Use the correct filter.

Electrical Shock

ELECTRIC SHOCK can kill you. Do not touch live electrical parts. Turn off the machine when doing any repair work on the gun. Unplug the machine when doing any repair work inside the machine. Shock can occur if you touch the electrode and work or ground at the same time.

- When you pull the trigger the coil can shock

- Never touch the metal parts of the electrode holder and the electrode with wet clothing or skin

- Keep insulation between the metal being welded or ground

Wire Feeder Safety

When adjusting or aligning drive rolls turn off the power. There are also multiple points where fingers can get pinched.

Do not point wire at the body.

Protective Equipment

The following welding protective equipment is called for when Mig welding process:

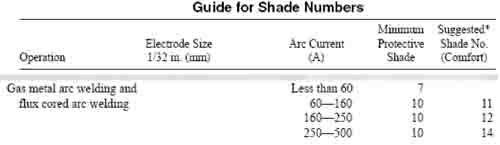

- Welding mask: as a general guideline a top-rated MIG welding helmet with a lens rated number 6 is for work up to 30 amperes. Number 14 should be used when using more than 400 amperes (see table below). As a rule of thumb, close your eyes immediately after welding, if you still see the arc then you need to go to a darker lens shade.

- Steel capped boots or other appropriate footwear

- Eye protection and safety glasses – protects against a condition called welders flash that can permanently damage eyesight. GMAW typically uses shade numbers 11 – 12.

- Long hair covered

- Protect the back of the head and neck from problems caused by reflected radiation

- Protective clothing or leather apron

- Leather gloves

- Welding sleeves or long sleeve dark color shirt: the dark color reduces reflection.

- Knee pads – if you plan to be working low down for long periods

Materials that withstand radiant energy include wool, leather and aluminum-coated cloth.

As a rule of thumb, start with a shade that is too dark to see the weld zone. Then go to a lighter shade which gives a sufficient view of the weld zone without going below the minimum.

In oxy-fuel gas welding or cutting where the torch produces a high yellow light, it is desirable to use a filter lens that absorbs the yellow or sodium line in the visible light of the (spectrum) operation.

Experience has shown that lighter filters may be used when the arc is hidden by the workpiece. (Information taken from ANSI Z49.1.2005.)

Related: Tools Needed for Welding

Safe Welding Space

Fumes and sparks are two of the hazards that need to be accounted for when designing a space to weld. Consider the following:

- Lighting: to make sure that you can see your work.

- Flame Retardant Room: Check the walls and floors for flame retardant qualities. Floors should be concrete and cinder blocks for the walls are the types of materials that are needed. Plan out where each piece of equipment will be stored or kept.As a rule of thumb, anything flammable should be at least 35 feet from anything being welded.

- Electrical: Anticipate the types of equipment and number of machines that will be running to plan your power needs. Many types of welding equipment will run on 110 single phase service, which is the type found in U.S. homes backed up by 20 amp circuit breakers. You may also want access to 220 phase service (same as what is used for a home clothes dryer) to equipment that requires this type of service.

- Ventilation: The gasses and smoke created by welding can be harmful if not properly ventilated.

MIG Welding Safety Operations

Pre-Operation

Use this as a basic Mig welding safety checklist:

- Clean and organized work area

- Remove flammable liquids from area

- Check ventilation

- Remove any jewelry and loose clothing

- Inspect gas lines for leaks

Operating MIG Equipment

- Clear work area from unauthorized personnel

- Position the flash blind in order to protect any nearby personnel

- Check cable position to avoid any damage due to sparks or materials that can fall

- Check all equipment settings

- Much of the risk from welding fumes and smoke can be reduced by using a shielding gas with a higher percentage of argon and pulse-spray mode of transfer

- Remember that wire feeder pushes wire, no need to push gun into arc

- Keep nozzles free of spatter – MIG pliers can help with this. Spatter can build up and electrically connect the insulated nozzle to contact tube. A clean nozzle will have spatter fall off on its’ own. You can use an anti-spatter compound on nozzle and gun and contact tube end. Whatever you do, do not clean the nozzle by pounding it on a hard surface. It can break and become damaged.

Post Operation

- Turn off machine

- Firmly close gas cylinder

- Return the welding gun to storage

Gas Cylinder Safety

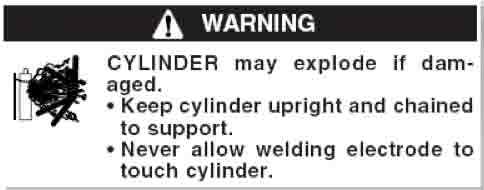

Gas is also a concern when planning for MIG welding safety. High-pressure bottles or cylinders are used in the MIG welding process.

Bottles must ALWAYS be chained. Bottles not being used must be capped.

Most cylinders need to be periodically tested and re-certified. Every cylinder should have markings that indicate its’ certification status. OSHA sets standards for acetylene, LPG, oxygen and hydrogen.

Store cylinders in a protected area away from hazards such as grease, cold and fire. They should be secured so that they will not be knocked over.

Be sure to use the correct flow-meter and regulator for the cylinder being used.

Empty cylinders are stored upright with a closed valve.

High-pressure bottles have double seated valves and should be ALL ON or ALL OFF.

Also read: Choosing The Right Size Gas Cylinder for MIG & TIG

Fire Safety

For MIG welding safety do not weld near flammable materials or fumes. For example, keep welds away from areas where materials are painted or dipped.

Also do not use flammable flooring or tables. Keep welding equipment away from flammable walls.

If welding a container. ensure that any flammable materials have been adequately removed.