New MIG and TIG welders have to guess how much welding they will do.

That means they also do not understand how much gas they should plan on using, which greatly complicates the purchase of gas tanks for a novice.

No one wants to run out of gas every other day. But those enormous tanks are hard to move and store. So, understanding how long certain size gas tanks last helps rookie welders zero on the right size for their particular needs.

You can use some guidelines and calculations to determine the expected duration times for popular-sized tanks. So, we have compiled the data into this handy reference article. Hopefully, it will help those new to welding select a properly sized tank.

Size and weight always matter, and we have also included the dimensions and weight of the various tanks too. You need to know if a certain gas tank can fit in your truck, welding cart, shop, etc.

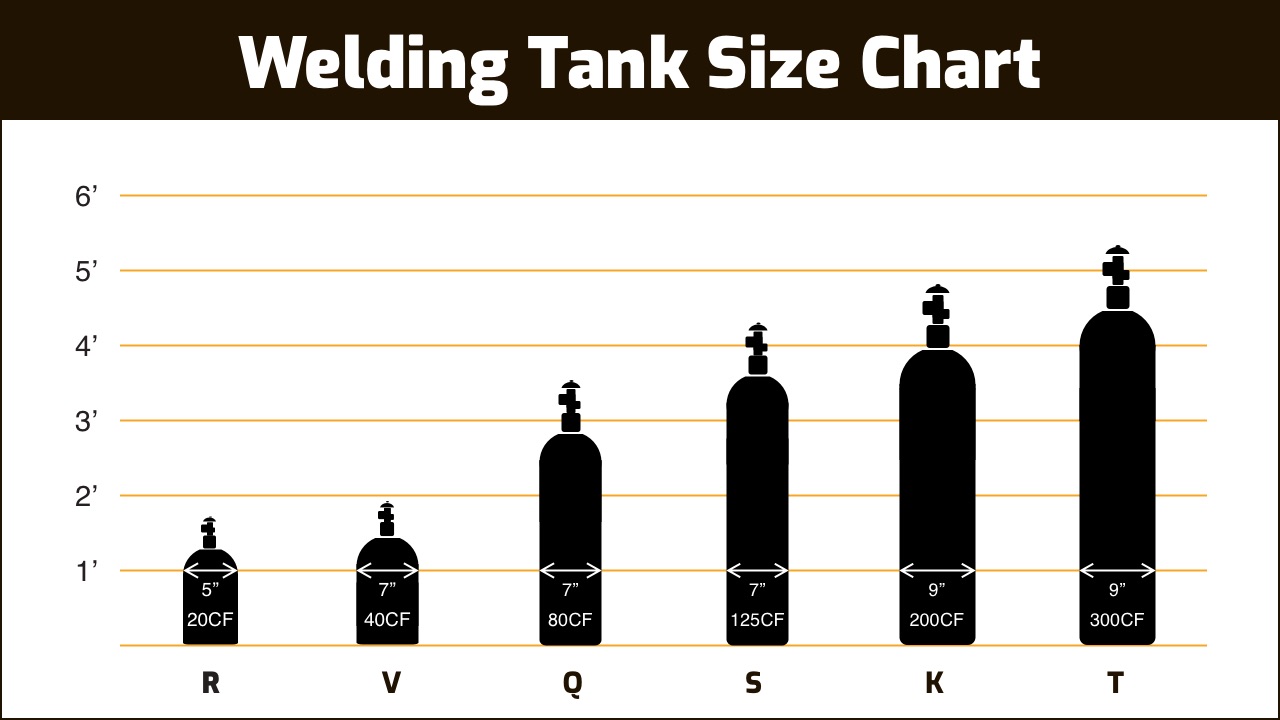

Popular Welding Gas Bottle Sizes for MIG and TIG

There are many size gas MIG/TIG tanks on the market. But the three main sizes a homeowner, or hobby welder will most likely use is the 40, 80, or 125 cubic feet (“cf”) tanks of Argon or MIG gas mixture (75% Argon, 25% CO2).

The largest of the three sizes provides plenty of use time without sacrificing too much portability. So, if you have the room, and can afford it, go with the larger 125 cf tank. Otherwise, select the 40 or 80 cf tank based on your available space and budget.

You should also keep refills in mind. A larger tank is cheaper to fill. To get “twice” as much gas during a refill is not that much more. So again, always get the largest tank you have room for and can afford.

One last thought, those really gigantic tanks you may have seen are usually leased. They are for high-volume users, and they usually have to be delivered by the gas supplier. They are not an option unless you operate a large operation that does a lot of work.

MIG/TIG Welding Gas Tank Specifications (Argon/MIG Blends)

| Size | 40 cf (#2/V) | 80 cf (#3/Q) | 125 cf (#4/D) |

|---|---|---|---|

| Height | 22 in. | 35 in. | 45 in. |

| Diameter | 6½ – 7¼ in. | 6½ – 7¼ in. | 6½ – 7¼ in. |

| Empty Weight | 24 lbs | 47 lbs | 58 lbs |

| Full Weight | 28 lbs | 56 lbs | 71 lbs |

| Full Pressure | 2015 PSI | 2015 PSI | 2265 PSI |

Please note that tanks can vary slightly depending on the manufacturer. Always double-check the dimensions on the actual tank you are considering if you are cutting it close with the fit.

Note that some tank sizes may be marked with a letter, and we have included that information in table headings just in case you do run into this.

Sometimes, the manufacturer identifies other tank sizes by weight, which is also included in the table.

You also may want to check in with the local gas supplier before purchasing a tank if you have one in your area. They can help you with what sizes are popular and why.

A local gas supplier can also confirm what tanks they can and cannot refill ahead of time to prevent a problem when you go for your first refill. Further, they can provide insight with certain details, like storage and handling in your climate.

There is a myth that you can only buy empty tanks online. But that is just wrong.

Full tanks are available, shipped to your door at a reasonable price. These online full cylinders are hydro-tested and refillable.

Recommended Argon/CO2 Tank Sizes for MIG

Recommended 100% Argon Tank Sizes for TIG

Related read: MIG Welding with 100% Argon Shielding Gas

How Long Will MIG/TIG Welding Gas Last?

One question new welders will have to ask, how long will my tanks of gas last?

Well, that will depend on your flow rate, which is typically 10 – 40 cubic feet per hour (“cfh”), depending on the work you are doing.

A higher flow rate maintains shielding gas in high winds. Many welders find at least 20 cfh is needed, even with very little wind. Plus, geometry comes into play, too, as flat is easier than vertical.

But to calculate the use time for a full tank of gas, you can a decent estimation using the equation:

Gas welding time (hours) = [cylinder volume (cf)] / [flow rate (cfh)]

For example, if we use an 80 cf tank, and run at 20 cfh, then:

Welding time = 80 cf / 20 cfh = 4 hours

Related read: MIG Welder Gas Regulator Settings

Calculated Welding Time for Tank Sizes at Different Flow Rates

| Flow rate | Tank Size | ||

|---|---|---|---|

| 40 cf | 80 cf | 125 cf | |

| 10 cfh | 4.0 hrs | 8.0 hrs | 12.5 hrs |

| 15 cfh | 2.7 hrs | 5.3 hrs | 8.3 hrs |

| 20 cfh | 2.0 hrs | 4.0 hrs | 6.3 hrs |

| 30 cfh | 1.3 hrs | 2.7 hrs | 4.2 hrs |

| 40 cfh | 1.0 hrs | 2.0 hrs | 3.1 hrs |

Keep in mind the calculations will vary from your actual use a little because of temperature changes and the number of starts and stops. This is especially true if you have pre/post flow settings.

Also, keep an eye on your regulator. As you use the gas, the pressure in the tank drops. This causes the flow rate to drop, and you have to adjust it.

Temperature changes can also change your flow rate. You should be prepared to adjust your regulator more often than you expect.

One habit you may want to adopt is setting the gas regulator back to “0” when you finish for the day. Manufacturers do recommend removing pressure on the spring and valve diaphragm when in storage. This also forces you to adjust the gas flow when you weld the next time.

100% CO2 Gas Cylinders for MIG Welding

While it is not for everyone, you can use pure CO2 to shield MIG welds from contamination. CO2 is plain-old carbon dioxide. It’s the same stuff used to put out fires and add that fizz to your beer or soda.

The most common reason people MIG weld with CO2, lower operating costs. There are some advantages and a few downsides, but a deeper discussion of these is for another article.

As for sizing the cylinder, you need to know two things if you opt to purchase a CO2 tank.

- Tanks are not rated by volume like other TIG and MIG welding gas cylinders. The industry sizes CO2 tanks by weight.

- The threads are different, and you must use a different regulator when MIG welding with CO2. You cannot just use the regulator from your Argon or MIG gas mixture tank.

Some of the more common sizes you may want to consider are tabulated below.

Also read: What is the Best Gas for MIG Welding?

CO2 Tank Specs and Use Time

| SIZE (lb) | H x W (in.) | Cubic Feet | Use Time |

|---|---|---|---|

| 1 ¼ (lbs) | 10.5 x 3 | 11 | ½ hr |

| 5 (lb) | 18.25 x 5.5 | 44 | 2 ¼ hrs |

| 10 (lbs) | 20.5 x 7 | 87 | 4 ½ hrs |

| 20 (lbs) | 27.5 x 8 | 175 | 8 ¾ hrs |

| 50 (lbs) | 47 x 8 | 437 | 22 hrs |

Knowing How Much Gas Is Left in the Cylinder

To keep your shop running, you need to know when you are running low on gas.

Fortunately, with the Argon and Argon/CO2 mixtures, you can use the pressure gauge on your regulator to estimate how much gas you have left in the tank.

With 100% CO2, you cannot use the pressure drop as reliably since it is a more sudden drop near the end. To get an accurate reading on a pure CO2 tank, you need to use the weight to monitor the contents.

But when an Argon of Argon/CO2 tank is full, it should read near the maximum pressure (which is 2015 psi most times). As you use gas, the pressure will drop accordingly.

Some examples, as you use gas to weld, you will have ¾ of a tank left when the pressure reads about 1500 psi. At ½ full, it will read around 1000 psi. And so on.

Keep in mind, as the pressure changes, you need to adjust your flow rate to keep a constant CFH. So, you need to keep an eye on the gauges for multiple reasons as you weld.

Also, remember that temperature changes can change the pressure in the tank. For example, if there is a drastic drop in temperature, the pressure will also drop. Try to gauge your “full” reading at a consistent temperature as possible.

Also, regulator quality varies, and invariably, your regulator needle will seem to be stuck. Don’t worry too much about this, as the indicator will move again if you give it a little time.

That means you may see some sudden drops now and then. But these are normal and nothing to worry about.

Related:

What gas is used for welding? – Different types & Uses

Welding Gas Prices – How Much & Where to Buy

Hello Jef, Greeting from Costa Rica!

I am new in MIG soldering and I want to use 100% CO2 tank from a extinguisher to welding. The tank is KIDDE model 15KS, I want to know what kind of care do I need to take to use the CO2 straight direct from the extinguisher.

I see un you tube some people connecting the extinguisher direct to the welding machine and weld.

Please let me know your comments…

I wouldn’t even try what you’re suggesting. First of all why do you even want to use gas with your MIG welder. I’ve probably used miles of wire in my MIG and probably only used gas about 25% of the time and that was when when I was welding in new panels on vehicles I was restoring. You really only need gas while welding thin material where you’re concerned about too much heat and want to reduce the splatter. Gas will only work indoors where there is no wind. For everything else, use the appropriate size of flux core wire. Flux core wire doesn’t require gas because the flux inside protects the weld from oxidation.