Stainless steel looks great and resists corrosion. Plus, it’s durable and strong. So, stainless has a lot going for it…

But when it comes to welding it, things can get complicated. Some even think it is too hard to weld stainless unless you have decades of experience.

But is it?

Spoiler, you can learn to weld it if you have the right knowledge and enough practice. So, let’s dive into the facts regarding how to weld stainless steel and hopefully clear up the misconceptions along the way.

FAQs About Welding Stainless Steel

Since it is why you are here, let’s clear up the most commonly asked questions first.

Can You Weld Stainless Steel?

Yes! Stainless steel can be welded using any arc welding process such as MIG, TIG, Stick & Flux-cored. Each process will yield a slightly different result and will require some learning and skill to accomplish.

Is Welding Stainless Difficult?

While not as easy as welding mild steel, it is doable with a little knowledge and practice for just about everyone with the right equipment.

Welding stainless steel presents a challenge for inexperienced welders as it retains heat efficiently. If you apply excess heat, stainless steel can warp, or it may even distort as it cools.

Stainless steel also clearly shows every imperfection in the weld. For this reason alone, some will say welding stainless is a more complicated, unforgiving job best suited for advanced users. But like all welding, anyone can learn with enough practice.

Another issue with welding stainless, there are a lot of different alloys. You MUST use the right filler material, shielding gas, settings, etc., for each alloy.

This level of detail can be a pain and adds to the perception that welding stainless is difficult. But normally, you will focus only on the particular alloys you use, not all of them. So, the learning curve is not as bad as some make it.

What Kind of Welder is Best for Stainless Steel?

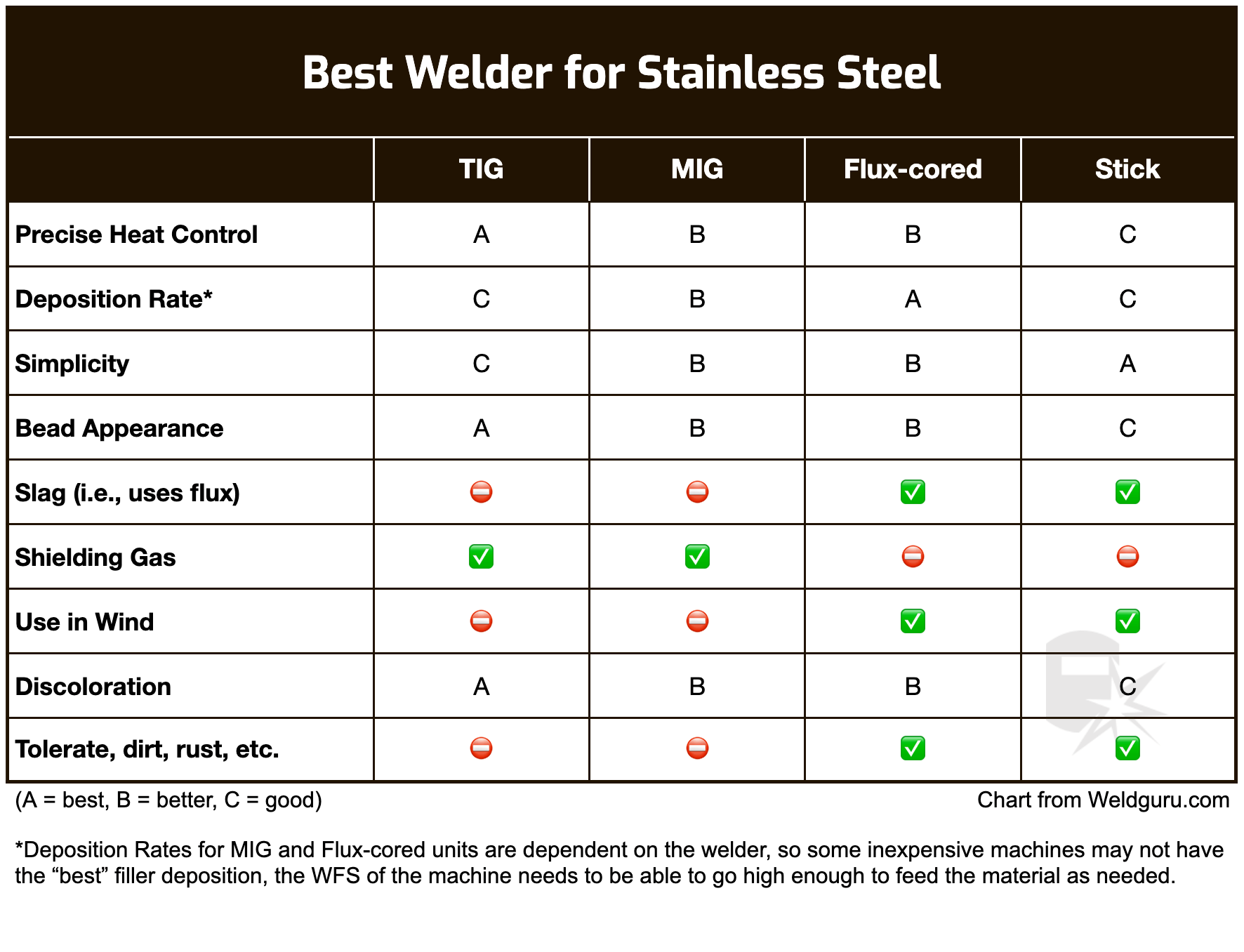

Many new welders are surprised to learn that you can use several different welding processes to join stainless steel (“SS”), including TIG, MIG, flux-cored, and stick.

TIG Welders

If you want those sleek, professional-looking beads, a TIG welder should be your first choice. TIG welders make clean, attractive welds on SS. So, they are usually the right tool when the finished piece must be aesthetically pleasing.

Also, TIG welders with a foot pedal (or finger control) give you precise control over how much heat you apply. In other words, you can make micro-adjustments on the fly as you lay the bead. Fine heat control helps to minimize warping in a stainless steel piece.

There are drawbacks to TIG welding SS, though. You need to replace the filler rod now and then, meaning long welds will have stops and starts. Plus, you do need to use an expensive shielding gas.

MIG Welders

Too many assume TIG welding is the only process that welds SS. But MIG, flux-cored, and stick welders can all weld it, too. You may even be surprised to learn that they are a better choice for some jobs.

© weldguru.com – Image usage rights

For example, MIG welding stainless steel is better on long welds. You don’t have to constantly swap in new electrodes/filler rods as you must with TIG and stick welders.

However, you will need a different, more expensive shielding gas since the oxygen levels SS can tolerate are lower than mild steel.

Flux-Cored Welders

If the added cost of MIG welding SS is an issue, flux-cored welding allows you to use less expensive CO2 or even no shielding gas.

© weldguru.com – Image usage rights

But since the wire’s core mixture contains flux, you will have to deal with the slag, especially when doing multiple passes.

It’s possible to flux core weld stainless steel without gas (FCAW-S) using a specialized wire. However, it doesn’t provide the cleanest weld. So unless you don’t care about the appearance of the finished weld, you should use a shielding gas.

The main advantage of flux-core welding without gas is that you can use it in windy conditions using a specialized self-shielded wire.

Stick Welders

In industrial or construction applications, appearance may not be a high priority. So, the portability and ease of a SMAW welder to weld stainless may be just what you need on a large job site.

Plus, since there is no shielding gas, which allows you can weld in windy conditions.

© weldguru.com – Image usage rights

Stick electrodes have an external coating that contains flux. Flux means these electrodes produce slag that you must deal with, and controlling the heat in the metal can be a challenge. Plus, you must replace the consumable electrode often.

What Metals Can You Weld To Stainless Steel?

Dissimilar metals can be welded together, including stainless steel. But for several reasons, this is a tricky challenge with special considerations. You need to assess the risks and decide if they are acceptable for the intended application.

In many cases, the melting point of the two metals will be far apart, creating a challenge. For this reason, a filler material becomes quite important, and the choice of what filler you use is critical.

The bottom line, welding dissimilar metals is a risk. You need to understand the two metals you are welding and use the correct filler material.

But there are also many techniques and special materials you may need depending on what you are welding. Do your research ahead of time.

| Alloy/Metal | Yes / No |

|---|---|

| Carbon Steel | Yes1 |

| Mild Steel (low carbon) | Yes2 |

| Galvanized Steel | Yes3 |

| Cast Iron | Yes4 |

| Aluminum | No5 |

1 Usually requires preheating the carbon steel.

2 Use the MIG process with the ER309L filler wire and a tri-mix shielding gas for most jobs.

3 Must remove zinc which produces a health hazard and can contaminate the weld bead

4 Use the “butter” method to keep the carbon from the SS with a NiFe-CI or Ni-CI filler.

5 There are workarounds like bi-metal transition inserts, But the bi-metal inserts are made using special processes usually not possible on site. Pre-made inserts are difficult to find if you are a small shop or hobbyist.

How to Weld Stainless Steel

Before you being to weld stainless steel, you need to make sure you have the right equipment and your welder and steel is prepared.

Let’s go over them.

What do You Need to Weld Stainless Steel?

The gear needed to weld SS will not be that different from welding other metals. In general, you will need:

- Welder (MIG, TIG, flux-cored, or stick)

- Electrodes (the wire or stick must be carefully selected for the weld)

- Shielding gas (for MIG and TIG, and possibly flux-cored)

- Grinder/wire brush/solvent to clean the metal

- Clamps

- Welding table (for smaller, in-shop work)

- Welding helmet

- Safety glasses (for grinding and other ancillary work)

- Leather apron, sleeves, and gloves

- Welding boots (25% of all welding accidents involve foot injuries)

- Ventilation (if indoors)

- MIG Pliers (handy to have for all welding processes)

Ventilation was included as required gear since stainless produces hexavalent chromium gas. This toxic gas means you must protect yourself and ensure you are not breathing the fumes when welding SS.

Preparing Your Welder

For all processes that weld SS, you must first choose the right electrode/filler material. It needs to be the right alloy for the weld you intend, no matter what type of welder you use. There are plenty of guides from manufacturers and internet sources to help you.

Then, there are particulars for the various welding processes, which we detail below.

TIG Welder Preparation

Amperage

On many TIG welders, you control the amperage as you weld (more on that in a bit). But you must first set your maximum amps on the machine. It will vary with the SS alloy and other variables like thickness. Charts are readily available to help you with this setting.

Finger or Foot Amperage Control

If your welder has it, the ability to tweak the heat, or amps, as you weld helps to minimize excess heat and the resulting warping in the SS. If you are on a ladder or other hard-to-reach areas, finger control may be necessary.

But for other jobs, the foot pedal may be a more comfortable setup. Be sure to set up the best amp control for the particular weld on your machine. Many TIG welders have the option to turn the foot pedal/finger control on or off, so be sure you set it correctly ahead of time.

Electrode Details

Electrode size makes a difference in a TIG welder. So, the electrode used must have the right diameter. It is commonly 3/32 but can go up to 1/4 inch. Which size you need depends on variables like polarity, amperage, joint size, base metal thickness.

You must also pay attention to the tungsten electrode type. You will see a thoriated red electrode used for most SS welding jobs. But some SS alloys may require a different “color” electrode.

Also, geometry matters. A taper of no more than 2.5 times the electrode diameter allows for a focused arc that produces deep, thin beads, and a small heat-affected zone (“HAZ”). If the electrode tapers more than 2.5 times its diameter, the arc starts to fan out, resulting in less penetration and a larger HAZ.

Polarity and Pulsing

For welding SS set your TIG welder polarity to DCEN (direct current electrode negative). Some people call this straight polarity, and you should never use electrode positive, as it will burn out your tungsten in a flash.

Also, if your welder has a pulse setting, use it. Experienced welders should set the pulse rate at 100 pulses per second (PPS) to start and go up as high as 500 PPS. Some TIG welders may not pulse that high, and inexperienced welders often count the pulses (from .5 to 2 PPS) to time the movement of the torch and the cold wire when the PPS is limited to 10.

TIG Shielding Gas

Not a minor detail; you must choose the right shielding gas and set the proper flow rates. The gas normally used for TIG welding is pure argon (Ar).

But helium (He) may be added to increase penetration and fluidity of the weld pool. In some cases, nitrogen (N2) and hydrogen (H2) are added to achieve special properties. For example, the inclusion of hydrogen gives a similar but stronger effect compared to adding helium. However, hydrogen should not be used when welding martensitic, ferritic, or duplex grades.

Flow rates are normally 35 to 50 cubic feet per hour but consult the recommendations for your machine and other commonly available charts and sources.

MIG Welder Preparation

MIG Wire

The first step is to obtain and install the right wire alloy and size for the weld you want to conduct. Depending on the specific alloy you are welding, some research may be needed, but the ER309L wire is popular. Be sure to use the right diameter wire, too.

Shielding Gas

You must pick the right gas. Stainless steel is sensitive to atmospheric gasses, and a tri-mix of 90% helium, 7.5% argon, and 2.5% carbon dioxide is popular. This mix produces a nice bead contour, and the CO2 levels are low enough not to harm the corrosion resistance of the SS.

You do not want to use a pure inert shielding gas, such as helium or argon, for SS MIG welding. The arc characteristics of the MIG process are markedly different from the TIG process, and pure Ar or He would negatively impact the efficiency of the MIG arc.

Also, be sure to set your flow rate properly. As already stated, SS is sensitive to reactive gasses, and that means it requires a good blanket to prevent weld contamination. Consult your welder’s manual or settings chart for a good starting point.

Polarity

Your welder should be set up for a direct current electrode positive (“DCEP”) arrangement.

Wire Feed Speed

The manual and setting chart for your unit should provide the necessary wire feed speeds for SS alloys at various thicknesses. But if not, most SS welds use a slightly higher wire feed speed (“WFS”) than what you would use with mild steel.

Amperage and Voltage Settings

Consult your welders manual and/or welding settings chart to set your amperage and voltage levels. If you do not have those, experienced welders or the internet can also provide charts and recommendations for starting settings.

SS normally requires a lower amperage setting due to a higher WFS. Additionally, higher voltage settings need to be used, which wets out the puddle that allows a flatter face and feathers in the toes of the weld.

Flux-cored Welder Preparation

Wire Selection

As with the other SS welding processes, the filler material is important. But with flux-cored welding, the consumable electrode wire is the filler material, and it carries the flux in the core of the wire to shield the weld.

That means the composition of the wire is more complex than a solid MIG wire. So, you need to be careful when selecting/buying wire. The SS alloy and thickness will be two important variables when selecting a flux-cored wire, but the flux core composition can also vary.

Also, a true gasless wire will work in windy conditions. But it will likely be limited to flat and horizontal work.

So, another important factor to consider is shielding gas. Many SS flux-cored wires do require gas. While wind can be a problem, these wires handle out-of-position welds better. These are often called dual-shielded wires and are widely available (obtaining true “gasless” flux-cored SS wire is harder).

Polarity

The polarity can get confusing with flux-cored (or FCAW) welding, as the setting changes depending on what wire you use. So, be sure to note what polarity you need for the flux-cored wire you have, and ensure your machine is set appropriately.

Shielding Gas

Yes, with FCAW, shielding gas is unnecessary for many welds. But SS is different than carbon steel, and it is necessary for many jobs. If using a double-shielded wire (flux and shielding gas together), be sure to have shielding gas on hand.

Welders often use a 100% CO2 or 75% argon 25% CO2 mixture. The slag encapsulation of the weld limits the absorption of carbon, making using shielding gas with high CO2 content possible.

Stick Welder Preparation

Stick Electrode

You might be seeing a pattern here, but the selection of your filler material matters in every welding process.

Stick electrodes are sold in various SS alloys with various flux coatings. Do your research and select the right size and alloy for your particular weld.

The manufacturers usually apply the correct flux coating to the SS alloy used to make the stick. So, you typically do not need to check on it.

But if you are welding dissimilar metals or other unusual joints, you may want to note the flux mixture on the electrode, too.

Amperage

The amperage settings should be listed in the welder manual or a chart printed on the welder, or you can find recommendations pretty easily if they aren’t. But in general, set the amps on the low end, as “cool” as possible.

With a stick welder, you will find the stick gets hotter as you get a couple of inches into the weld, and the arc and bead characteristics will change. So, you need to allow for this on any joint over one or two inches long.

Anti-Spatter Product

Stick is simple and easy to use, but it does produce a lot of spatter. On stainless work, that can be a problem. So, you may want to have some anti-spatter gel or spray on hand to prep the workpiece before welding.

Preparing stainless steel for welding

After setting up your welder for stainless steel, you now need to prepare the metal before welding. Here are some things you should prepare…

Cleanliness

Stainless steel does not tolerate contamination well. Even trace amounts can create an issue. So, the metal needs to be free of all paint, rust, oil, etc., and cleaned before welding. No exceptions, so be meticulous.

Fit-Up

Be sure that the pieces are aligned properly and that there are no gaps or variations in the joint. Gaps of variations in the joint width require excess filler material, which adds more heat to the weld. Plus, the weld looks better if the bead width is consistent.

Edge Prep

With thicker pieces, the edges will need to be beveled or chamfered. This profile helps with the fit-up, but it also allows you to make stronger, better-looking welds, too.

10 Tips for Welding Stainless Steel Successfully

1. Keep the Heat Down

Stainless steel warps when exposed to excess heat. Remember? We mentioned that near the beginning of this article. So, it makes sense, set your amps, a.k.a. your heat input, on the low side to keep the problem at bay.

2. Avoid Large Filler Diameter

The thicker the filler rod/wire, the more heat you need. But with SS, you need to keep the amps down. So, avoid big filler rods/wires as another way to keep your heat down.

3. Fine Tune The Fit-Up

Proper fit-up allows you to use the proper amount of filler material and eliminates the need to fill gaps. That means you will not need to add excessive heat to the metal. So, take the time to fine-tune the fit-up of the workpieces to avoid warping and poor appearance.

4. Use a Filler Material/Electrode Designed for the SS Alloy

Yes, you can weld stainless steel with the same mild steel filler you use regularly. The problem is that the weld can corrode, and you need to coat the bead to keep it from rusting. Switching to a stainless steel filler alloy that matches the base metal avoids the problem. Also, you avoid contaminating the SS with carbon in the HAZ, which can cause rust in the SS pieces.

5. Use the Right Torch Angle (Stick and Flux-Cored)

With slag, you drag. This advice works, in general, all FCAW or stick welding. By dragging the electrode, you’re allowing the flux to rise to the top of the weld pool and properly cover the bead.

Otherwise, you can have issues with slag inclusions in your weld.

For FCAW stainless, a 10-degree drag angle should generally work fine as a starting point. But with SMAW, you may want to try a much steeper angle.

Read more: Push or Pull When MIG Welding?

6. Have the Right Wire Stick Out

With MIG and flux-cored welding, you need to have the right stick out when you start a weld for a smooth arc. Plus, you need to avoid varying this distance between the nozzle and metal as you weld.

Also, when flux-core welding, trim the wire tip every time you lay a bead. If you don’t trim every time, you can get a silicon blob at the tip of your wire that can mess up your start. Trimming your wire is probably a good tip for your MIG welds, too, to ensure proper stick out and a clean tip.

7. Control The TIG Weld Puddle

The weld puddle diameter should equal the base metal thickness. If the puddle gets too big, use your fingertip or foot pedal to reduce the heat.

At the end of the weld, eliminate craters by tapering the current down and adding filler metal until the puddle hardens.

8. Use A Higher Deposition Rate

The various welding processes have varying deposition rates, and there is no substitute for experience to learn how it varies with your welders.

But in general, if you need a high deposition rate, use a flux-cored welder with a dual-shielded wire. This setup will usually give you the best deposition rates.

9. Watch Your Travel Speed

In general, you don’t want to move too slowly. That will create excess heat in the stainless steel. So, keep your travel speeds up.

Also, with stick and flux-cored welding, you can tell if your speed is off by the resulting bead. Signs you can look for are:

- Slow weld travel: Your bead will crown high, and the slag won’t cover the weld well. It’ll tend to leave the weld exposed near the crown, and the metal will turn gray. You’ll probably have porosity issues, and the weld might be prone to rust.

- Fast weld travel: The weld will turn out extra ropey, and the weld bead will be too narrow.

10. Rust Prevention

It is a nuisance, but SS welds can rust. To prevent this from happening, you can do a few things.

First, be sure to provide a good blanket of shielding gas. Reactive gasses in the air can cause all kinds of problems, including rust.

The second thing to do is clean your finished weld completely, including discoloration. Cleaning is usually done with pickling pastes, grinders/wire brushes/abrasives, or electrochemical cleaning. Also, do not use a steel wire brush. It can contaminate the weld, and yep rust.

Third, this will sound repetitive by now, but keep your heat down. Excess heat can cause stainless steel to lose its corrosion resistance.