It includes iron (cast, pig, wrought) and steel.

The differences between cast iron and steel are the amount of carbon in the constituency of the metal.

Types of ferrous metals include iron, steel and tungsten carbide.

One simple test to see if the metal has iron content is if it attracts a magnet.

If it does then the metal has some iron content and is ferrous.

Processes

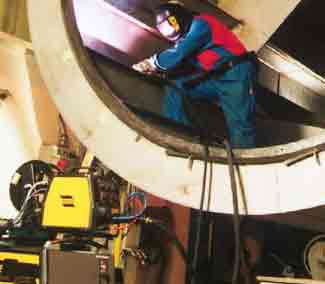

Several welding processes are used when welding ferrous metals. These include:

- Oxyacetylene gas welding

- Resistance welding

- Spot welding

- Arc welding (tungsten-arc/GTA, metal-inert gas-Mig)

- Induction welding

Welding Sheet Metal

For welding purposes, the term “sheet metal” is restricted to thicknesses of metals up to and including 1/8 in. (3.2 mm).

Welds in sheet metal up to 1/16 in. (1.6 mm) thick can be made satisfactorily by flanging the edges at the joint. The flanges must be at least equal to the thickness of the metal. The edges should be aligned with the flanges and then tack welded every 5 or 6 in. (127.0 to 152.4 mm).

Heavy angles or bars should be clamped on each side of the joint to prevent distortion or buckling. The raised edges are equally melted by the welding flare. This produces a weld nearly flush with the sheet metal surface. By controlling the welding speed and the flame motion, good fusion to the underside of the sheet can be obtained without burning through. A plain square butt joint can also be made on sheet metal up to 1/16 in. (1.6 mm) thick by using a rust-resisting, copper-coated low carbon filler rod 1/16 in. (1.6 mm) in diameter. The method of aligning the joint and tacking the edges is the same as that used for welding flanged edge joints.

Where it is necessary to make an inside edge or corner weld, there is danger of burning through the sheet unless special care is taken to control the welding heat. Such welds can be made satisfactorily in sheet metal up to 1/16 in. (1.6 mm) thick by following the procedures below:

Heat the end of a 1/8 in. (3.2 mm) low carbon welding rod until approximately 1/2 in. (12.7 mm) of the rod is molten.

Hold the rod so that the molten end is above the joint to be welded.

By sweeping the flame across the molten end of the rod, the metal can be removed and deposited on the seam. The quantity of molten weld metal is relatively large as compared with the light gauge sheet. Its heat is sufficient to preheat the sheet metal. By passing the flame quickly back and forth, the filler metal is distributed along the joint. The additional heat supplied by the flame will produce complete fusion. This method of welding can be used for making difficult repairs on automobile bodies, metal containers, and similar applications. Consideration should be given to expansion and contraction of sheet metal before welding is stated.

For sheet metal 1/16 to 1/8 in. (1.6 to 3.2 mm) thick, a butt joint, with a space of approximately 1/8 in. (3.2 mm) between the edges, should be prepared. A 1/8 in. (3.2 mm) diameter copper-coated low carbon filler rod should be used. Sheet metal welding with a filler rod on butt joints should be done by the forehand method of welding.

Related read: How to weld sheet metal (for beginners)

Welding Ferrous Metals: Steel

The term “steel” may be applied to many ferrous metals which differ greatly in both chemical and physical properties.

In general, they may be divided into plain carbon and alloy groups. B

y following the proper procedures, most steels can be successfully welded. However, parts fabricated by welding generally contain less than 0.30 percent carbon.

Heat increases the carbon combining power of steel.

Care must be taken during all welding processes to avoid carbon pickup.

Welding Process

Steel heated with an oxyacetylene flame becomes fluid between 2450 and 2750ºF (1343 and 1510ºC), depending on its composition.

It passes through a soft range between the solid and liquid states. This soft range enables the operator to control the weld.

To produce a weld with good fusion, the welding rod should be placed in the molten puddle. The rod and base metal should be melted together so that they will solidify to form a solid joint. Care should be taken to avoid heating a large portion of the joint.

This will dissipate the heat and may cause some of the weld metal to adhere to but not fuse with the sides of the welded joint. The flare should be directed against the sides and bottom of the welded joint. This will allow penetration of the lower section of the joint.

Weld metal should be added in sufficient quantities to fill the joint without leaving any undercut or overlap.

Do not overheat. Overheating will burn the weld metal and weaken the finished joint.

Impurities

Oxygen, carbon, and nitrogen impurities produce defective weld metal because they tend to increase porosity, blowholes, oxides, and slag inclusions.

When oxygen combines with steel to form iron oxides at high temperatures, care should be taken to ensure that all the oxides formed are removed by proper manipulation of the rod and torch flame.

An oxidizing flame causes the steel to foam and give off sparks. The oxides formed are distributed through the metal and cause a brittle, porous weld. Oxides that form on the surface of the finished weld can be removed by wire brushing after cooling.

A carburizing flame adds carbon to the molten steel and causes boiling of the metal. Steel welds made with strongly carburizing flames are hard and brittle.

Nitrogen from the atmosphere will combine with molten steel to form nitrides of iron. These will impair its strength and ductility if included in sufficient quantities.

By controlling the melting rate of the base metal and welding rod, the size of the puddle, the speed of welding, and the flame adjustment, the inclusion of impurities from the above sources may be held to a minimum.

Welding Steel Plates

In plates up to 3/16 in. (4.8 mm) in thickness, joints are prepared with a space between the edges equal to the plate thickness. This allows the flame and welding rod to penetrate to the root of the joint. Proper allowance should be made for expansion and contraction in order to eliminate warping of the plates or cracking of the weld.

The edges of heavy section steel plates (more than 3/16 in. (4.8 mm) thick) should be beveled to obtain full penetration of the weld metal and good fusion at the joint. Use the forehand method of welding.

Plates 1/2 to 3/4 in. (12.7 to 19.1 mm) thick should be prepared for a U type joint in all cases. The root face is provided at the base of the joint to cushion the first bead or layer of weld metal. The backhand method is generally used in welding these plates.

NOTE

Welding of plates 1/2 to 3/4 in. (12.7 to 19.1 mm) thick is not recommended for oxyacetylene welding.

The edges of plates 3/4 in. (19.1 mm) or thicker are usually prepared by using the double V or double U type joint when welding can be done from both sides of the plate. A single V or single U joint is used for all plate thicknesses when welding is done from one side of the plate.

General Principles in Welding Steel

A well balanced neutral flame is used for welding most steels. To be sure that the flame is not oxidizing, it is sometimes used with a slight acetylene feather. A very slight excess of acetylene may be used for welding alloys with a high carbon, chromium, or nickel content. However, increased welding speeds are possible by using a slightly reducing flame. Avoid excessive gas pressure because it gives a harsh flame. This often results in cold shuts or laps, and makes molten metal control difficult.

The tip size and volume of flame used should be sufficient to reduce the metal to a fully molten state and to produce complete joint penetration. Care should be taken to avoid the formation of molten metal drip heads from the bottom of the joint. The flame should bring the joint edges to the fusion point ahead of the puddle as the weld progresses.

The pool of the molten metal should progress evenly down the seam as the weld is being made.

The inner cone tip of the flame should not be permitted to come in contact with the welding rod, molten puddle, or base metal. The flame should be manipulated so that the molten metal is protected from the atmosphere by the envelope or outer flame.

The end of the welding rod should be melted by placing it in the puddle under the protection of the enveloping flame. The rod should not be melted above the puddle and allowed to drip into it.