Welders can struggle with thin sheet metal because the hot arc warps or burns through the metal easily. Even professional welders flounder with welding thin stock at times.

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes.

But MIG and TIG provide the best results.

This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make.

While welding thin metal will test even the best welders, you can achieve great results with some know-how and practice.

Welding Processes for Thin or Sheet Metal

Each welding process requires specific precautions and equipment setup for a successful sheet metal weld.

So, let’s discuss the preparation needed for each arc welding process before proceeding to the common problems with thin gauge welds.

MIG Welding (GMAW)

MIG welding works fine for thin materials. But you must use a small diameter wire since it requires less heat to melt, minimizing your heat input.

Never use wire thicker than the base metal because the stock will warp or burn before the wire melts. Using 0.023, 0.024, and 0.030 in MIG solid wires for sheet metal is best.

Also, avoid a 100% CO2 shielding gas because it amplifies penetration, which leads to burn-through. The best shielding gas for MIG welding thin mild steel sheets is the 75% argon and 25% carbon dioxide mixture.

You also want to push your weld instead of pulling. Pulling your weld will give you more penetration that is not needed on thinner materials.

If possible, buy or refill a shielding gas tank with even less CO2. You can even go as low as 5% CO2 when welding very thin gauges.

Don’t use straight argon unless you’re welding aluminum. You must have at least 5% CO2 for steel to stabilize the arc.

Avoid flux-cored wires because they input far more heat into the metal. The flux-cored wires are hollow.

The cross-sectional area of the steel wire is small, which increases the current (heat) concentration flow into the welding pool.

The design of these wires is for welding thick sections and improving penetration, so they’re a poor choice for welding sheet metal.

TIG Welding (GTAW)

TIG welding works well for welding thin sheet metal, especially if your welder supports a pulsed TIG mode.

Pulsed TIG provides an arc that fluctuates amperage output between two set values up to 500 times per second, allowing the best heat control with practice.

But, even if you don’t have the pulse TIG option, foot pedal control works well to time the high and low amperage input into the weld pool.

If you have a basic TIG setup, the level of heat control is on par with MIG welding or a bit worse. It depends on your skills.

Still, skilled TIG welders achieve outstanding results because the TIG welding process has a narrower heat-affected zone (“HAZ”) than any other arc welding process.

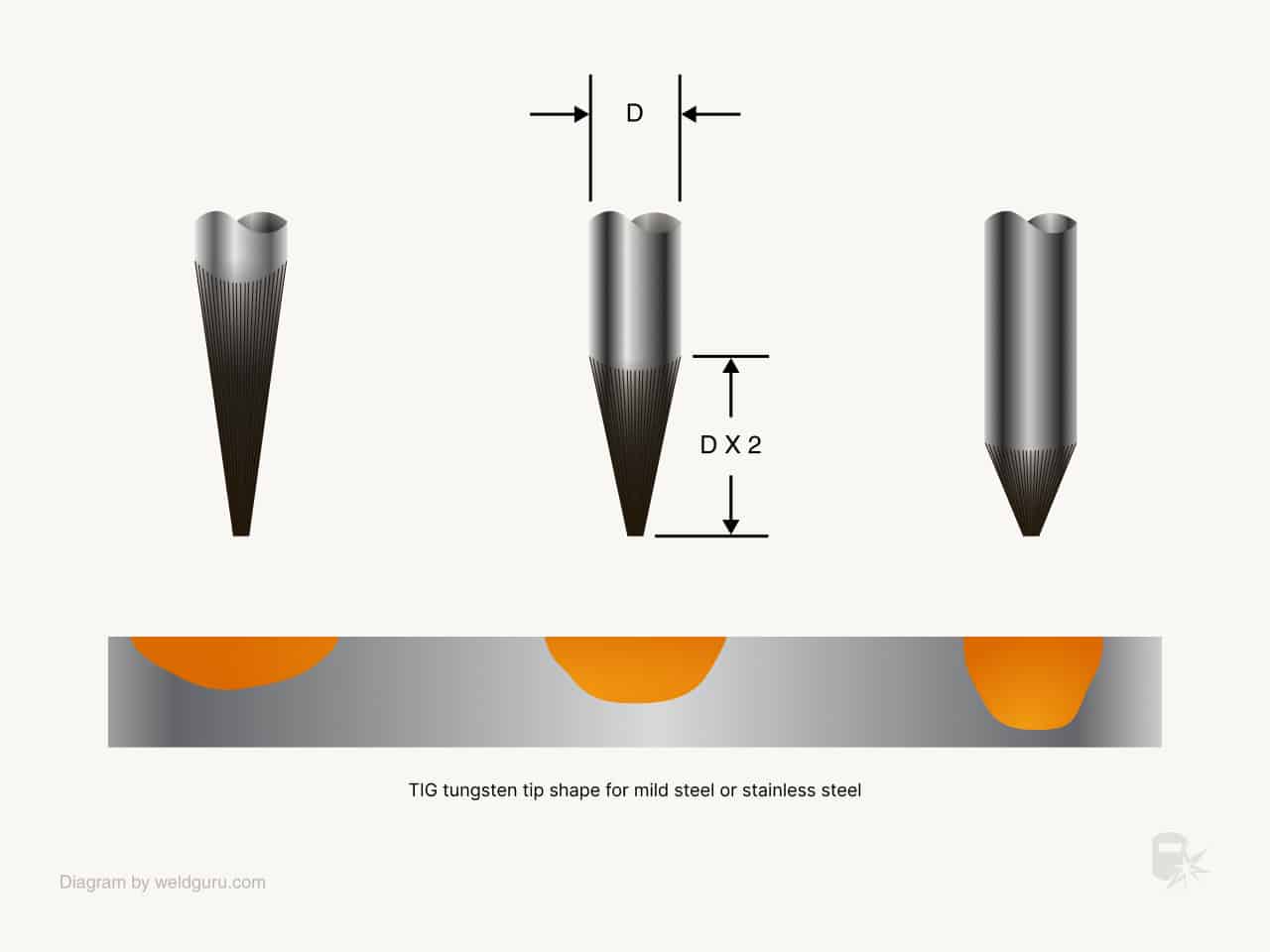

To weld thin stock successfully, use a small diameter tungsten electrode like 0.020, 0.040, and 1/16 in. Large-diameter tungsten electrodes require higher amperage to start the arc, leading to warping or burning of the material.

Grind the tungsten tip to a sharp point to weld steel, and use either ER70S-2 filler metal or a silicon bronze rod. You need little heat to melt silicon bronze, making it one of the most popular filler metals for fragile, thin steel sheets.

Avoid helium-argon shielding gas mixtures because helium improves the heat input. It’s best to stick to pure argon shielding gas when TIG welding thin gauges.

Give yourself the best chance of success by using a gas lens to improve gas coverage and pushing your weld to avoid unnecessary penetration.

Stick Welding (SMAW)

Most welders avoid welding thin metal with the stick welding process. It’s difficult to control your heat input and very easy to burn through the material.

Stick welding is not a delicate process but with a proper setup and rod size, you can weld sheet metal with the SMAW.

Unlike MIG and TIG, stick welding doesn’t require a shielding gas. Instead, the flux covering on the consumable electrode protects the weld pool but also influences the arc’s characteristics.

So, some stick electrodes like E6013 offer very shallow penetration, which you need to weld thin metal.

Additionally, using a DCEN polarity reduces heat input and metal deposition rate. As a result, it’s easier to control warping and prevent burning through thin stock.

Finally, keep the amperage output as low as possible when welding, but this goes for all arc welding processes when joining thin materials.

Avoiding or Fixing Problems When Welding Thin Metal

Now that we’ve covered the essential considerations for different arc welding processes, let’s discuss how to prevent and fix common issues when welding sheet metal.

Warping

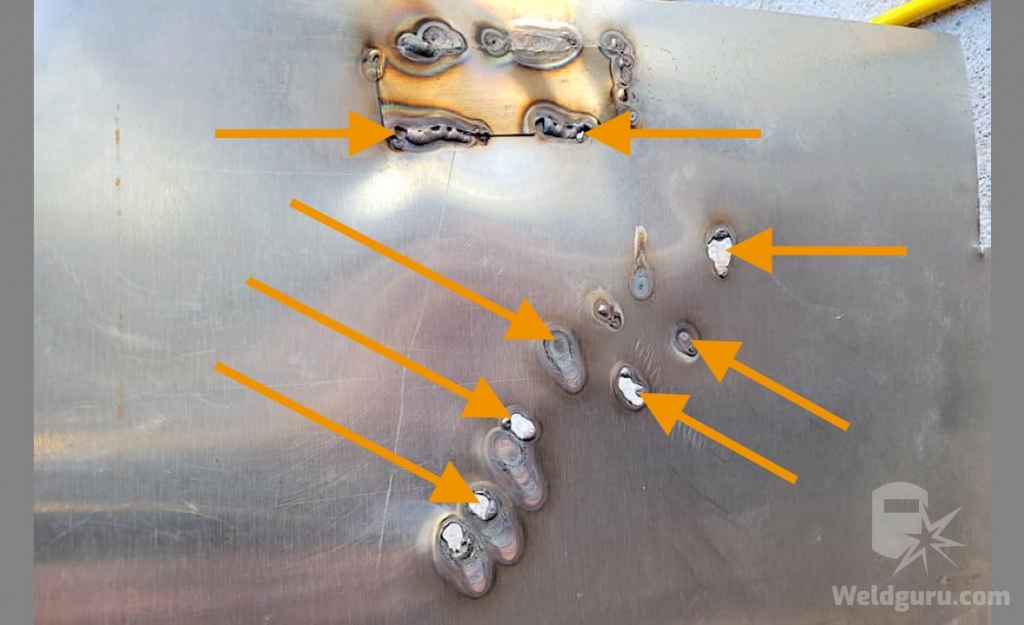

To avoid warping the metal, you must tack weld metal sheets in place and avoid significant gaps between the tacks.

After you tack everything, place intermittent welds. Avoid long, continuous welds that input high amounts of heat.

It’s best if your welder supports a tack weld timer. For example, Eastwood MIG 180 lets you create repeatable tack welds with the same amperage input and arc duration.

If your welder doesn’t support a tack timer, you may keep the arc lit for too long on some tack welds, which inputs too much heat compared to the other tacks, warping the material.

Also, try to increase your welding speed. Too much heat at one time in one place causes warpage.

If you weld too slowly, you’ll focus too much heat on one area. Therefore, increasing your travel speed eliminates one of those variables. Low welding speed is especially detrimental to stainless steel.

Pros often use heatsinks to help conduct excess heat away from the welded metal. So, placing aluminum or copper flat bars underneath the workpieces can help prevent heat build-up and warping.

Burn throughs

Everything we discussed to avoid warping applies to preventing burn through.

If you blow holes in the metal, you’ve gone further in the wrong direction. Some excessive heat warps the metal sheet, but too much burns it away.

© weldguru.com – Image usage rights

So, increase your welding speed and place short, intermittent welds. Try to weld the joint from multiple positions. For example, divide the joint’s length by four, mark the divisions, and fuse each separately.

Use a shop air compressor to cool the sheet metal between welds. This choice is also helpful in preventing warpage, but if the material is too thin and you keep blowing holes through it, you’ll need all the help you can get.

Significantly lower the amperage output. If your current amperage setting burns through the metal, try dropping it 30-50%. Also, reduce the tungsten, stick electrode, or MIG wire diameter to the lower amperage accordingly.

Appearance

Welding sheet metal often requires a beautiful, smooth weld line. You can only achieve that naturally with a TIG welder.

Short circuit MIG welding causes spatter and uneven beads, while stick welding creates the least appealing welds. Additionally, stick welding leaves slag that you must remove.

After chipping away the slag or brushing the silica remains from MIG welds, you must grind down the weld line to improve its appearance. Don’t press down too hard with an angle grinder; avoid smoothing one area for too long to prevent heat build-up.

Even heat generated from grinding friction can also distort the thin sheet metal.

Grinding stainless steel is a vast topic on its own. So, ensure you use an abrasive type and grit size that gives you the desired finish.

To remove stainless steel discoloration from welding, you can use stainless steel wire wheels and a 360-grit or coarser abrasive.

You should perform bead blending and flattening with a 40-80 grit abrasive disc, belt, or flap disc.

Grinding the mild steel and aluminum is less complex. But aluminum requires unique, wax-based grinding wheels. Aluminum loads up the regular wheels quickly, which may cause wheel explosion.

Whichever metal you grind to finish, be careful not to remove too much material. Light stock is easy to over-grind and thin out, jeopardizing joint strength.

Proud (Above the Surface) Welds

If the weld bead is too high above the metal’s surface, this is a weld defect called overfill or excessive reinforcement.

It doesn’t necessarily call for rework, but it makes for a poor appearance, places the toes of the weld under stress, and increases the chances of slag entrapment and cracking along the edges of the weld.

If you keep making proud welds, try increasing your weld speed and reducing the MIG wire feed speed or amperage output when stick welding.

You can grind off the excess metal, but grinding causes pinholes and cracking if done too aggressively. Remember that since the top of these beads is proud, the toes of the weld are under higher stress as the grinding wheel exerts force from above.

Also, the pressure at the weld toes is higher than when grinding lower-height beads. So, use a gentle touch.

Different Metals have different characteristics

Commonly welded metals like mild steel, stainless steel, and aluminum have different precautions to consider when welding thin gauges.

Mild steel is the easiest to work with if you keep the amperage down, weld quickly, and space out your welds. With these precautions, you should achieve good results.

Stainless steel is much less forgiving. It doesn’t conduct heat as effectively as mild steel, so heat concentrates in the heat-affected zone (HAZ). This concentration leads to discoloration at best.

At worst, stainless steel loses corrosion resistance. Additionally, the heat retention in the HAZ encourages warping and burn-through. Using heat sinks is less effective with stainless steel than mild steel.

Unlike steel, aluminum conducts heat rapidly but also melts at a low temperature (compared to steel). To make things worse, the protective oxide on the aluminum’s surface melts at a significantly higher temperature than the aluminum underneath.

This combination of factors makes aluminum, especially thin sheets, very challenging to weld.

To weld thin aluminum, you must move even faster than with steel. Additionally, use stringer, straight beads. This way, you’ll minimize the heat input and prevent burning through this sensitive material.

Since aluminum conducts heat exceptionally well, using heat sinks significantly reduces heat concentration in the HAZ.

Summary Video

This video by Everlast demonstrates many concepts we’ve discussed in this article. So, it can help you visualize what blow-through and warping look like and how to prevent them.

Frequently Asked Questions

What Is The Thinnest Sheet Metal You Can Weld?

The thinnest sheet metal that can be arc welded is 26 ga thick mild steel. If you’re a skilled welder, you may be able to weld even thinner with some distortion and metal burning.

I have seen experienced TIG welders weld pop cans together with the right setup.

What Is The Best Welding Process For Thin Metal Or Sheet Metal?

The best welding process for thin metal is TIG because of its heat control and narrow HAZ. TIG requires a very high skill level, so many welders argue that the MIG welding process has an advantage because of its high travel speed.

What Is The 1 For 1 Rule When Welding Thin Metal?

The 1-for-1 rule states you should use 1 amp per 1 thousandth (0.001) inch of thickness for thin carbon steel. Stainless steel requires 1/3 fewer amps, and aluminum requires about 1/3 more.

What Is The Thickest Metal You Can Spot Weld?

The thickest metal you can spot weld is 1.25 inches.

Wrapping It

Welding thin metal is challenging. There is no denying that. But, if you practice and use the tips we shared in this article, you’ll get the best chance for success.

After you inevitably burn through some scrap sheets of metal and warp others, you’ll gain more experience and learn how fast you need to weld, depending on the material and its thickness. It’s faster than you’re comfortable with at the beginning.

Many welding jobs require an understanding of how to weld thin gauges. Even hobbyist-level projects involve thin sections.

Welded sheet metal improves everyday items, construction elements, or machine parts that benefit from reduced weight. So, every welder should master welding thin stock.