Metal inert gas (MIG) welding is commonly used in the automotive, construction, high-production manufacturing, aerospace, railroad, and shipping industries. It is also used in many niche markets, and most welding hobbyists and DIYers own a MIG machine thanks to its ease of use.

Whether it be lightweight aluminum household items, car frames, or heavy steel construction, you will find that MIG welding is employed.

It is a versatile form of welding used with numerous metals. But MIG welding shines when you need high-volume welding that must be completed in a short time frame.

So, let’s first look at the different types of metal that can be MIG welded.

What Metals is MIG Welding Used For?

You MIG weld with various common metals, including steel, aluminum, stainless, cast iron, and magnesium. Let’s take a look at each one.

Steels

© weldguru.com – Image usage rights

There are different types of steel: carbon, alloy, stainless, and tool steel, to name a few. Carbon steel is the easiest metal to MIG weld; it’s also used more often than any other metal.

At some point, you’ll probably work with carbon steel. It’s the least expensive metal, and it’s very versatile. MIG welding can be used to prefab building parts, such as stairs and rails, and even to repair car frames.

You can also MIG weld more delicate steel projects like lighting fixtures and furniture.

Steel is an excellent metal for learning the MIG welding ropes. Depending on the metal’s thickness, you’ll have to adjust your welding machine’s wire speed and voltage.

Steel is a straightforward metal to MIG weld with and is ideal for beginners to learn.

Aluminum

© weldguru.com – Image usage rights

Like steel, there are different types of aluminum. However, there are major differences when MIG welding aluminum. It’s much lighter than steel, so it can’t take extreme heat as long as steel.

It takes a quick and delicate hand to weld it properly, and your wire speed must be faster than it is with steel. Also, pushing the weld is the best choice to avoid contaminated welds.

All this means it’s easier to produce a bad weld. To avoid that, you’ll have to consider several variables before starting MIG welding with aluminum. It is crucial to know its thickness and alloy type when taking on a project.

Always start with clean metal, using a stainless steel or aluminum wire brush to remove the oxide from the surface. It’s critical to remove this oxide layer to prevent contaminating the bead. Also, wipe the joint down after brushing to remove debris.

© weldguru.com – Image usage rights

The most common shielding gas choice is 100% argon, and a 4043 or 5356 wire is typical when MIG welding aluminum.

Speaking of wire, aluminum is softer and more malleable than steel. That makes it harder to push through the lead, and it can get clogged or form “nests” of wire at the wire feeder.

To avoid this, you can use different liners with less friction with the wire, making it easier to push it to the torch. Or, you can use a spool gun which eliminates the need to push the wire through the lead.

Read more: MIG Welding Aluminum (with settings)

Stainless Steel

© weldguru.com – Image usage rights

While there are numerous different alloys, in general, stainless steel shares some things in common with steel and aluminum. It’s a form of steel, so it’s not light like aluminum.

But it does need to be cleaned up the same way before welding since the welds could easily become contaminated, like aluminum.

The type of wire and gas are details you’ll definitely want to confirm before you start MIG welding with stainless steel. The most critical factor regarding gas is that you need to have less than 5% carbon dioxide in your shielding gas.

Read more: Best Gas To Use When MIG Welding

The most commonly used wires are 308, 309, and 316, but you must make sure the wire used is designed for the particular alloy of stainless you are welding. It’s worth double-checking this as there are many alloys of stainless steel.

You want to push your weld with stainless steel to maintain proper gas coverage. As with any type of welding, maintain a consistent speed that’s not too fast or too slow.

It may take some practice since stainless steel tends to show inconsistent welding techniques more clearly than regular steel.

Read more: MIG Welding Stainless Steel

Magnesium

It would be easy to assume that MIG welding magnesium is identical to aluminum, given how similar they look and feel. They both require the same steady hand, use pure argon gas, and require a high wire feed speed.

Most of the settings on your machine can be the same as with aluminum. Most welders use the MIG process to weld magnesium that’s on the thicker side. Magnesium requires even more finesse when thin, making TIG welding the better option with thinner gauges.

But there is also a critical difference when MIG welding magnesium. The required wire is different.

If you weld magnesium with a wire that’s made for aluminum, it will break. The proper wire is both hard to find and very expensive. If you’re up for the hunt, look for AZ61A wire, It’s what you want.

Cast Iron

I’m not including cast iron because it’s a great metal for MIG welding. It’s not a great welding material in general. But it can be welded if you’re familiar with its unique qualities.

I mistakenly ruined cast iron parts in the past because I didn’t know enough about their properties. It was winter, and the cast iron needed to be preheated before it was welded.

You can use a torch to get the metal hot slowly. Hold the torch further from the cast iron to start, moving it closer as the piece heats up. It should be a slow process.

Welding the entire piece at once can also cause a crack. So, stop welding every inch or so to let the temperature even out. The joint must also cool down slowly, or it will crack.

Again using your torch, you can apply an incrementally lower heat every 30 seconds for a few minutes, providing a gradual cool down.

Read more: Cast Iron Welding

Applications That Work Well With MIG Welding

MIG welding is a versatile process used by DIY enthusiasts but is also used in industrial settings where high-volume or automated welding is required.

High Volume

My favorite thing about MIG is the work speed. When stick welding, you can only go so fast. On the other hand, MIG uses a shielding gas, not flux, and you can adjust the wire feed speed to keep up with your movements.

This enables the deposition of more filler, and more bonding occurs with each torch pass.

Whether you’re working with large parts that require long welds or small parts that only need one-inch welds, using MIG is probably faster than stick.

So, as long as your settings are dialed in and your technique is proper, you can fly through jobs. The more comfortable you get, the more ambitious you can get with your settings.

On one job, I welded small parts that would have taken much longer using a stick welder. It became obvious that you don’t have to aim the end of a long stick into small spaces with a MIG gun.

Unlike stick welding, you can put the gun down anywhere without the electrode trying to weld itself to the table or any other nearby metal. This is helpful when moving parts on and off your table at a high rate.

Automated Welds

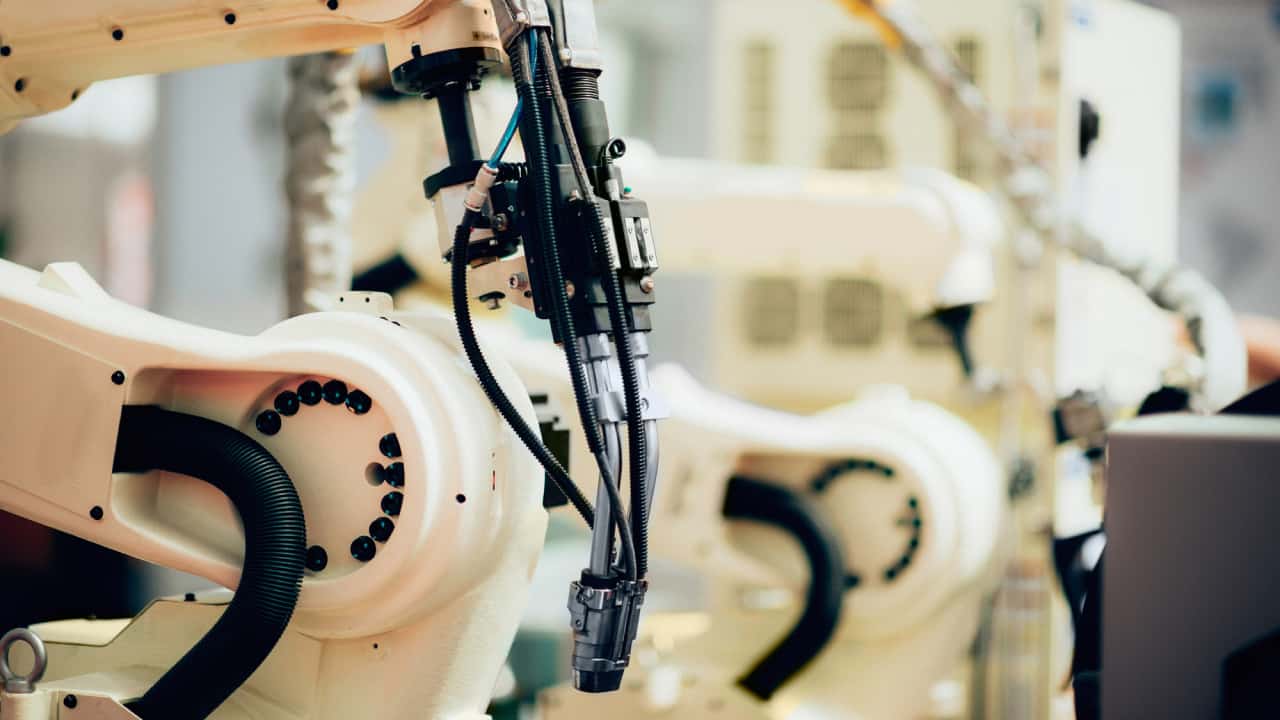

Automated MIG welding is what you get when you cross a MIG welder with programming and machinery (e.g., robots). There is an ever-increasing number of computerized machines that MIG weld today.

Some do simple spot welds, while others can run long, beautiful beads. When you combine the basic premise of MIG welding with other machines, amazing things can happen. Later, we’ll talk about robotics and MIG welding.

Automated MIG welding systems work with various metal types, ranging from mild carbon steel to stainless steel, aluminum, and other non-ferrous metals. They can weld everything from very thin gauge metals to large structural pieces, such as beams and bar joists.

Automated MIG welding is becoming more accessible. As technology evolves, more companies will be offering automatic welding machines online.

What Industries is MIG Welding Used in?

Manufacturing

MIG welding is used in all types of manufacturing jobs. Lightweight and heavy-duty MIG machines are used across many manufacturing sectors, from small parts for home decor to large construction prefab parts.

A MIG machine typically makes things in high volumes on an assembly line. If it’s mass-produced by hand, there’s a good chance it was MIG welded.

Construction

Most of the more prominent buildings you see use steel. Typically, you won’t find MIG machines on job sites. But MIG welds are often used to create the parts used while constructing new buildings.

Drawing from experience, I have built various types of construction parts with a MIG machine in the shop, such as stairs, handrails, and ladders. Heavy-duty MIG machines are also used to create bar joists of all sizes.

Any pieces welded in the shop typically get installed on-site using a stick welder. MIG welder leads are not long enough to weld bar joists and beams over multiple stories in the air.

Automotive

As technology evolves, welding in the automotive industry is becoming more automated. Over the last few decades, developments could eventually eliminate manual welding in manufacturing new vehicles.

However, MIG is often the best route to take when it comes to repairs. You can repair most auto-body damage using manual MIG welds. It can also repair exhaust system damage.

There are times when MIG isn’t the best choice for repairing vehicles. Aluminum alloy wheels are a good example; it’s best to use a TIG machine in that case.

Robotics

With technological advances, the automation of MIG welding also moves forward. When you introduce robotics into automated welding systems, you achieve a new, improved level of productivity.

There are several types of welding used in robotics. MIG is best utilized with simple jobs that need to be done quickly. Automation takes the speed offered by MIG welding and kicks it up a notch.

Robotic arms do require maintenance, but they don’t tire out like human arms. They are also much more consistent, providing perfect, uniform welds. This is because they can only do what they are programmed to do, and mistakes are essentially impossible.

Read more: Robotic Welding

Advantages & Disadvantages of MIG Welding

The versatility and speed of MIG welding are serious perks, especially if you’re in a shop and need to make high quantities of parts in a short amount of time.

MIG has unparalleled ease of use, flexibility, and speed. These make up for the fact that TIG produces prettier welds and TIG’s inability to be used freely on job sites.

Advantages

- High welding volumes can be completed in a short amount of time

- Easy to learn

- Works with a wide range of metals

- Strong and clean welds

- Efficiently transfers more filler metal with fewer passes

Disadvantages

- Less mobile than stick welding

- Limited positions can be used

- Potentially high set-up costs

- Welds are not quite as pretty as TIG

You can find more details about how MIG welding works in our article What is GMAW (MIG Welding) & How Does it Work?

FAQs

What’s The Difference Between MIG And TIG Welding?

Both MIG and TIG use an electric arc to make a weld, but they do it differently.

Where a MIG gun contains everything you need to weld, TIG uses a non-consumable tungsten electrode in one hand and a filler rod in the other.

TIG is known for creating extremely precise and clean welds that MIG isn’t capable of. But MIG is easier to use and faster.

What Is Gasless MIG Welding?

Gasless MIG welding uses a flux core wire instead of a tank of inert gas to shield the weld.

The flux melts and provides the gas needed to shield the weld. Gasless is not as smooth, and it produces slag, which needs to be cleaned from the surface of the weld.

It’s harder to achieve a clean and defect-free weld when you’re using flux-cored wire. They tend to spatter much more than using solid wire and gas MIG welds.

Is MIG Welding Expensive?

You can find cheap MIG machines starting at around $200. Quality and price go hand in hand with welding equipment, so keep that in mind when shopping for welding equipment. Be careful when purchasing; many flux core welders will say they are MIG welders. But they do not use inert gas.

Spools of MIG wire start around $20. Again, the price rises with the quality. As for the gas, it’s similar to buying propane, less expensive once you have the tank. The tank will run you between $100 and $200, dropping to well under $100 for a refill.

Wrapping It Up

It may seem like a lot to take in, especially if you’re starting your welding journey. But it’s not so overwhelming after you’ve welded a few times. MIG is the easiest type of welding to get the hang of in the shortest amount of time.

If you are someone who’s thinking about getting into welding, MIG is where I would recommend starting. It allows you to try out multiple types of materials, and it’s flexible enough to take in many directions. You can build a lot of things with a MIG machine.

Related: Top Rated List of MIG Welders To Buy Today

That’s why you find it used by DIYers and professional welders in industries like automotive, construction, high-production manufacturing, aerospace, railroad, and shipping.

All you need is enough interest to get started and the willingness to learn something new. Just remember that welding has a few inherent safety risks, so be sure to take the required steps to protect yourself.