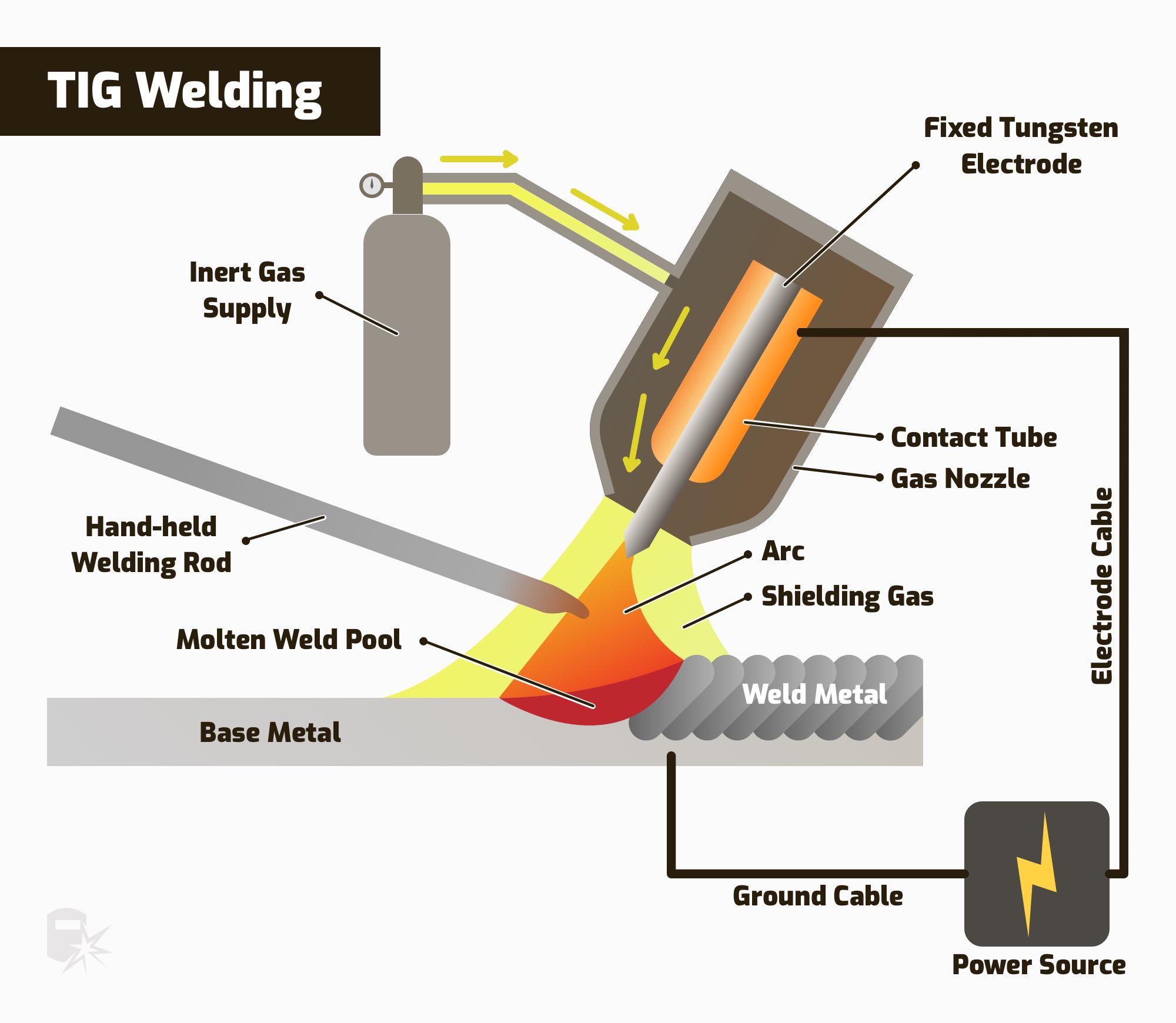

Gas tungsten arc welding (GTAW), or TIG welding, is an arc welding process that uses a non-consumable tungsten electrode to create an arc and join metal. It requires shielding gas, mostly pure argon or argon mixed with helium.

This process can use an optional hand-fed filler metal that fills the space between two close-fitting materials.

TIG welding can use a direct current (“DC”) or alternating current (“AC”) depending on the metal the welder joins, making it a sophisticated, precise, and versatile arc welding method that joins almost all metals.

The TIG welding process was initially named “heliarc,” as helium was the primary shielding gas, but barely anyone uses that term today.

This article will explain how TIG welding works, its applications, and how to start. Plus, it’ll compare it to MIG welding (GMAW), discuss TIG welding careers, and share this process’s pros and cons.

How TIG Welding Works

© weldguru.com – Image usage rights

TIG welding works by melting the base metal with an electrical arc formed between the tungsten electrode and the grounded metal (the work clamp closes the circuit).

Time to break it down.

The Tungsten Electrode

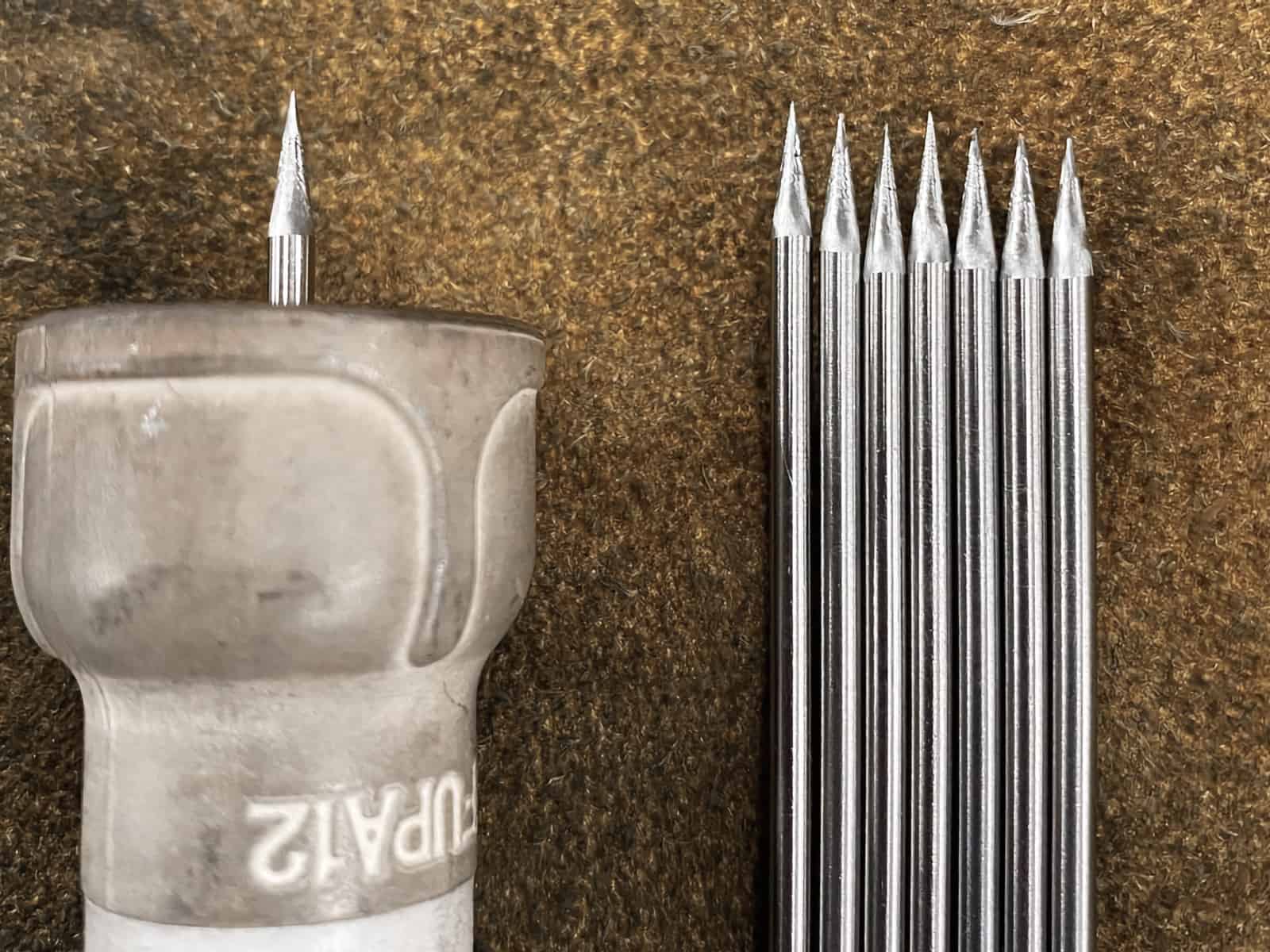

The unique aspects of TIG welding are the absence of physical contact between the tungsten electrode and the welded metal pieces and the fact that the process doesn’t consume the tungsten.

© weldguru.com – Image usage rights

As a result, the arc is stable and clean, producing aesthetically pleasing welds.

Electrodes used in other arc welding processes physically interact with the metal and may involve various fluxing agents, which results in spatter and less control over the welding arc.

Tungsten metal melts at far higher temperatures (3422°C) than metals like steel (1371-1540°C) and aluminum (660°C). So, the tungsten electrode tolerates the high heat as it directs the electrical arc into the weld puddle.

Plus, as the tungsten gets hotter, the electron emission improves, creating an even more stable, clean arc.

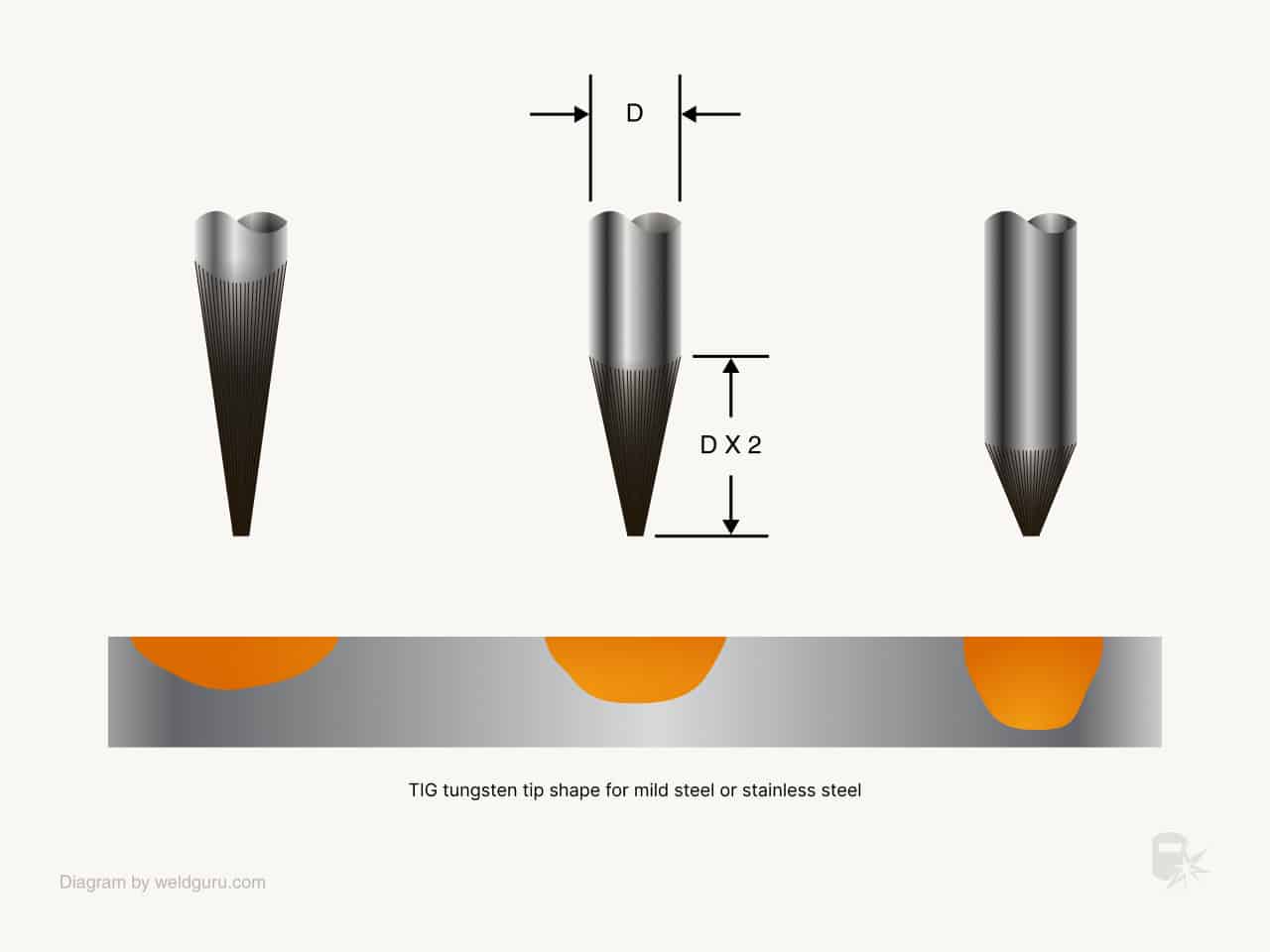

It’s possible to shape the welding arc and cone width by grinding the tungsten electrode tip to a point. This metal is easy to shape and retains the desired configuration.

Heat input and concentration alter by tailoring the tungsten tip shape, which is a highly beneficial aspect of TIG welding.

© weldguru.com – Image usage rights

Filler Metal

The TIG welding process can join metals with or without filler metal. The welding arc from the tungsten electrode melts the two base metals and fuses them.

However, welders can use filler metal to achieve strong joints and avoid cracking.

Adding filler metal is one of the challenging aspects of GTAW. A welder must add the filler metal by dabbing a filler wire into the weld pool with one hand while controlling the TIG torch with the other.

Touching the tungsten with the filler metal contaminates the electrode, requiring the welder to stop and regrind the tungsten tip.

So, adding the filler metal is tricky because the tungsten tip and the filler wire tip have to be close and move in the same direction without touching.

Shielding Gas

As the name implies, the “tungsten inert gas” welding process requires using an inert shielding gas to protect the tungsten electrode and the molten metal from oxidation.

Inert gasses don’t react with the materials used to weld. This protection is essential because it ensures a clean, stable environment for the arc and the molten metal puddle in the joint.

The two most commonly used shielding gasses for TIG welding are argon and helium.

Argon is almost perfect and does the job in 99% of the cases. However, a helium argon blend can improve penetration and travel speed with some tasks. Just know it sacrifices some arc stability.

Where is TIG Welding Used?

GTAW is typically used for precision welds and joining exotic metals like stainless steel, aluminum, Chromoly, nickel alloys, and magnesium.

However, it’s also employed for welding regular mild steel if the joint quality must be absolute. Otherwise, MIG welding is more suitable for mild steel because it’s faster and easier.

TIG welding allows total control over the heat input and welding arc.

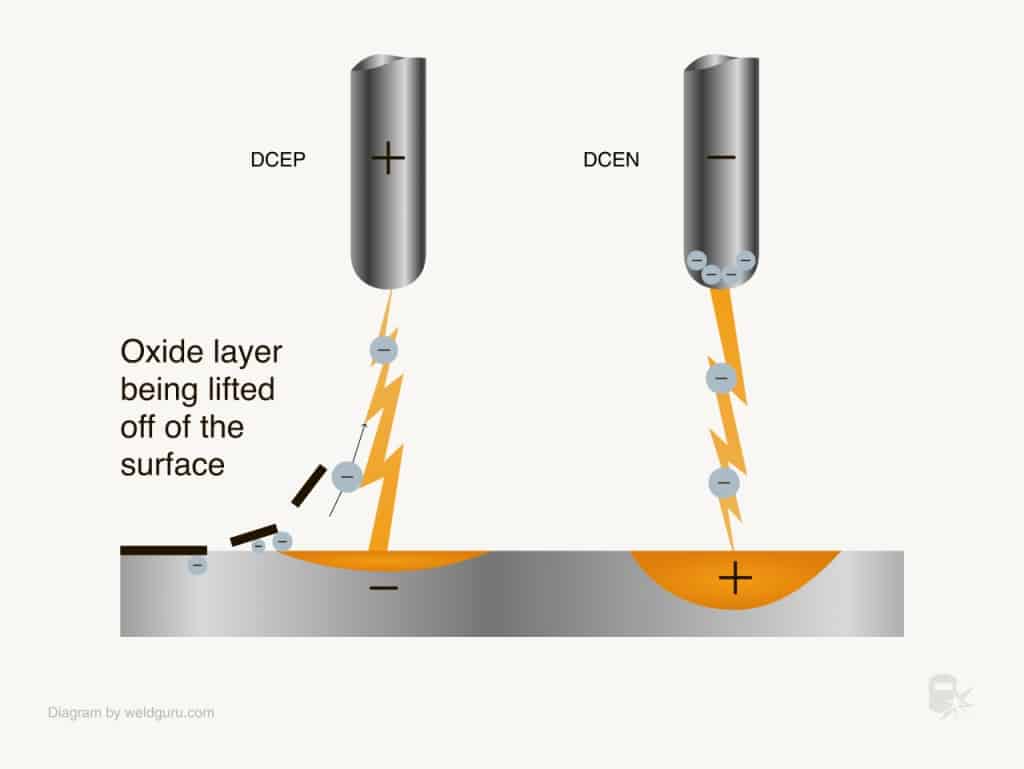

Modern TIG power sources support pulsed TIG and can modify the AC balance, frequency, waveforms, and individual amperage output for DCEN (electrode negative) and DCEP (electrode positive) portions of the AC current.

Plus, a foot pedal allows for moderate amperage output in real-time during welding.

Use precise heat control for professional thin stock welding, especially with exotic materials. For example, stainless steel retains heat, leading to carbon precipitation that quickly destroys its corrosion resistance.

But with pulsed TIG welding, the welder can control heat input and make perfect stainless steel welds.

Welding Aluminum and Magnesium

Some materials like aluminum or magnesium can only be TIG welded to achieve maximum joint quality. MIG welding aluminum also works well, but AC TIG welds are king.

That’s because the DCEP completely removes surface oxides while DCEN allows them to penetrate the material. MIG welding power sources can’t provide total control like TIG welders.

© weldguru.com – Image usage rights

The welder can tailor the arc for specific aluminum or magnesium pieces by using AC balance and amplitude control (individually modifying DCEN and DCEP amperage output).

Doing this takes experience because the extent of surface oxides needs evaluation, and the proper AC balance and amperage output for each polarity match the situation. No other arc welding process offers so much control.

Weld Looks

Finally, aesthetics play a significant role when deciding which welding process to use.

Stick and flux-cored welding are not an option for pretty welds. While MIG welds can look good, TIG welding achieves the best results.

Imagine using the stick welding process to make a bicycle frame. It would be a disaster and include extensive post-weld cleanup.

But, on the other hand, a skilled TIG welder can make the famous “stack of dimes” bead that requires little to no cleanup. The same goes for car body repairs, interior furniture, or anything else where aesthetics are essential.

How Is TIG Different From MIG Welding?

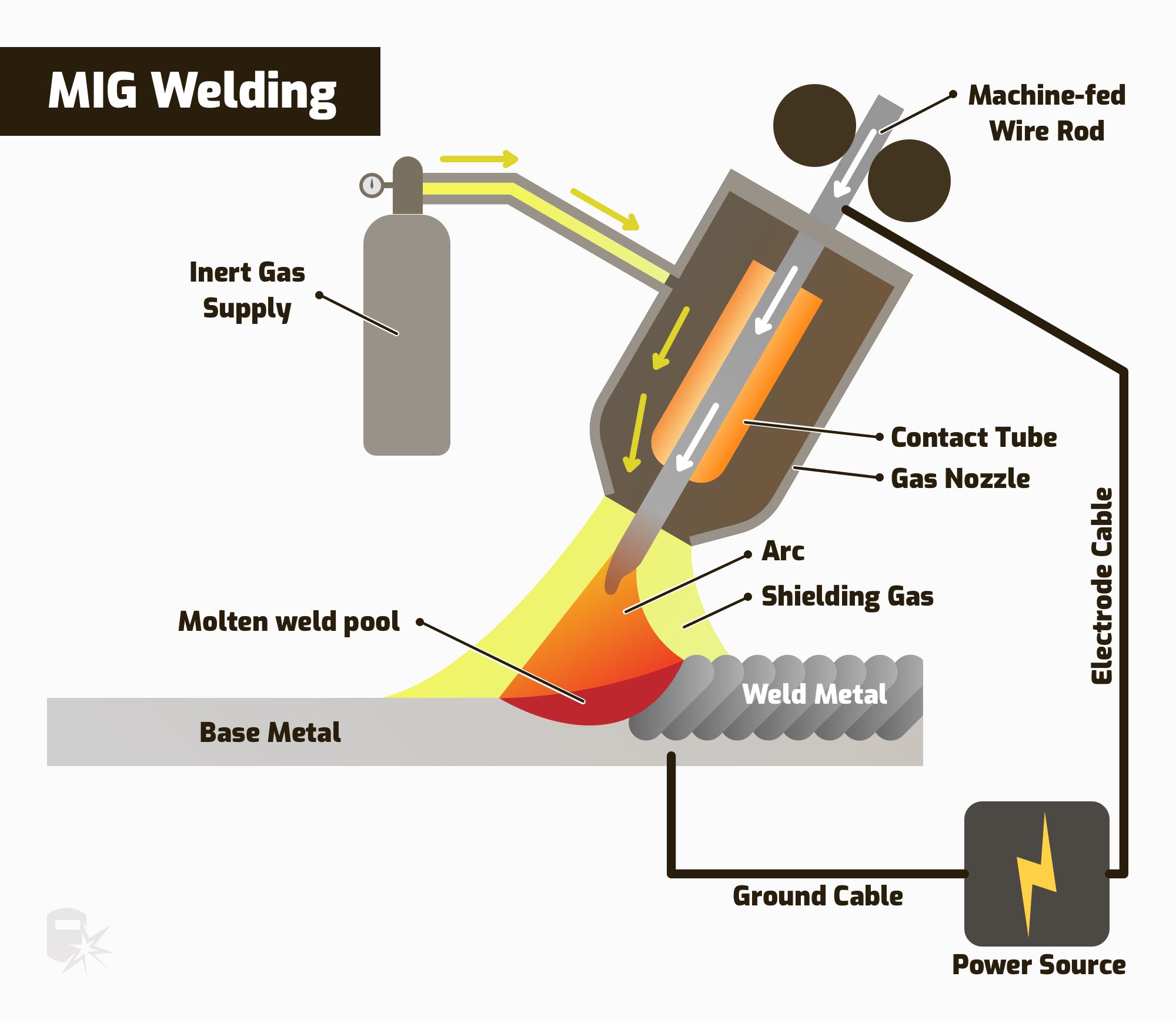

TIG welding is very different from MIG welding because the MIG welding process uses a consumable electrode that also acts as a filler metal.

© weldguru.com – Image usage rights

Unlike TIG, MIG welding relies on an automatic wire feeder that pushes the filler metal wire into the molten weld pool. But this filler wire is also energized, just like the tungsten electrode in TIG welding.

MIG wire exits from the wire feeder, through the lead, and into the MIG gun torch. Once the wire touches the metal, an arc forms, which melts the wire and base metal.

So, unlike TIG, the electrode becomes part of the joint, and welding without a filler metal is impossible.

MIG welding also creates spatter because the arc extinguishes and re-ignites whenever the wire touches the metal. This effect occurs many times in a second during a typical short-circuit MIG transfer.

As a result, MIG welding inherently can’t make aesthetically pleasing welds like the TIG welding process.

However, the MIG welding process is far easier to learn since it automatically adds filler metal to the weld pool. Plus, welding speed and productivity are higher compared to TIG welding.

If the MIG welding process is an option, use it because it’s more productive and less expensive. Use TIG welding when the joint quality is paramount, when welding exotic materials, or if weld aesthetics are essential.

Related: TIG vs MIG Welding – Main Differences

What Do I Need to TIG Weld?

TIG welding equipment is more expensive than MIG or stick welding gear. There are affordable TIG welders on the market, but they don’t offer all of the previously discussed functions for arc control.

The necessary equipment for TIG welding includes:

- TIG welder: The most expensive piece of the setup. The TIG welding machine must support AC TIG output to weld aluminum.

- Tungsten electrode: Welders commonly use lanthanum, cerium, thorium, and pure tungsten rods. Thoriated tungsten is radioactive, but lanthanum is an excellent, safer substitute.

- Filler rods: Use ER70S-6 for general mild steel, ER308 for standard 200 and 300-series stainless steels, and ER4043 for most aluminum applications.

- Shielding gas tank: Buy and refill; don’t rent. It’s cheaper that way. Read about shielding gas tank sizes here, or get an 80CF argon gas bottle that’ll work for most jobs and workloads.

- Welding helmet: The welding hood should be for low TIG amperage if thin materials require a low amp start.

- Gloves: Don’t use heavy-duty gloves for MIG or stick welding. Use light, flexible goatskin gloves designed for TIG.

- Foot pedal: It allows for control of the amperage output in real time, but not all welding machines support foot pedal connection.

Welders also must arm themselves with patience. Learning to TIG weld takes practice, time, and hands-on experience. Don’t feel discouragement when failing to recreate those pristine welds posted by popular social media welders.

No one ever truly masters TIG welding. Everyone is just along for the ride. Ask any professional, and they’ll say they are still learning.

But, with some practice, anyone can make beautiful, consistent welds in a flat, horizontal position. With more experience, welding more complex joints and working on exotic materials becomes possible.

Related read: 18 Essential TIG Welding Tips For Beginners

Advantages & Disadvantages of TIG Welding

TIG welding has a lot of benefits. However, it’s not without some drawbacks.

Pros

- Maximum joint quality

- Welds almost all materials

- Perfect for thin stock

- Low chance of weld contamination

- Weld with or without filler metal

- No spatter or smoke

- Doesn’t require flux or slag

- Allows welding in all positions

- Maximum control over the arc and heat input

- Provides excellent visibility of arc and weld pool

- Makes the best-looking welds

Cons

- Challenging to learn

- A slow process, which reduces productivity

- Small mistakes in travel speed, amperage output, pulse settings, or tungsten preparation can significantly impair weld quality

- Welding outdoors blows away the shielding gas

- Expensive equipment

Careers in TIG Welding

The aerospace and pipeline industries provide the best jobs for skilled TIG welders. However, pipeline workers often perform in harsh environments.

So, when repairing airplanes, the working conditions will be better.

Source: nasaspaceflight.com

Other industries include fabrication, structural welding, art, food and beverage, and oil and gas. All require skilled TIG operators to join exotic alloys and make complex joints.

Being a certified TIG welder is necessary to get a high-paying TIG welding job.

Those interested can join a welding school like Tulsa, Lincoln Electric, or Hobart. Students will learn from the best, and welding instructors and career counselors can help land a good job as soon as a graduate gets their papers.

Wrapping It Up

TIG welding is the best arc welding method for achieving high-quality, beautiful welds. Thanks to a non-consumable electrode that directs the arc and the numerous functions modern TIG equipment offers, the welder can tailor the arc and heat input exactly as needed.

However, TIG welding is slow and extremely hard to learn.

For that reason, MIG welding is the most widely used arc welding process.

But GTAW is the reigning king in aesthetics and cleanliness, making it irreplaceable for many welding applications.

Also Read: 4 Main Types of Welding Processes