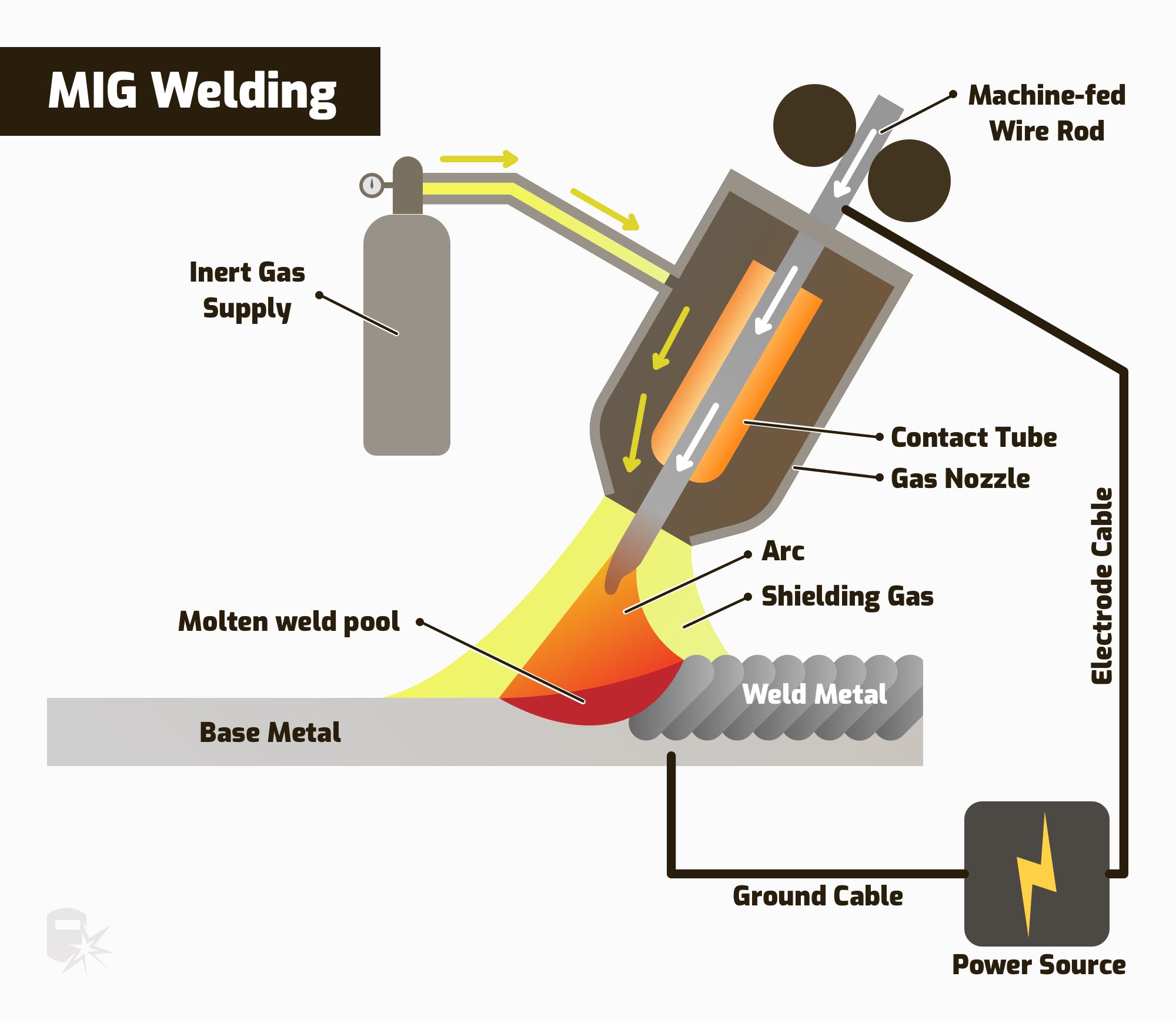

Gas metal arc welding (“GMAW”) is an arc welding process that uses a consumable wire electrode and shielding gas, which a welding gun feeds to the joint.

An electrical arc between the wire and base metal generates heat that melts. Shielding gas protects the molten weld pool from harmful atmospheric gasses.

GMAW most commonly uses a constant voltage, direct current power source, but constant current systems and alternating current are usable.

This article explains the basics of the MIG welding process, when to apply it, the necessary equipment, GMAW career opportunities, and the pros and cons of MIG welding.

How Does MIG Welding Work?

A MIG welder automatically feeds an electrically charged, solid wire into the weld joint at a set speed, and the supplied gas shields the molten pool.

The power source inside the welder energizes the wire, creating and driving the arc.

GMAW always uses a direct current electrode positive (“DCEP”) polarity. That means the ground clamp attaches to the negative terminal, and the MIG torch attaches to the positive terminal.

Attaching the ground clamp to the welded piece and pulling the MIG torch trigger to feed the wire into the joint creates an arc. The arc happens as the wire contacts the grounded metal, which closes and shorts the electrical circuit.

The arc quickly generates heat, and the wire at the tip melts, as does a thin part of the base metal. But the wire feeder continually pushes a solid wire into the joint, which creates another short circuit.

Shorting the circuit and melting the tip occurs many times per second, and it’s responsible for spatter, sparks, and the well-known, unique MIG sizzling sound. It sounds like bacon frying in a pan.

Note that the wire acts as an electrode and filler metal material with the MIG process. It’s required to create an arc and deposit metal into the joint. So, it’s impossible to MIG weld without filler material.

The short circuit transfer method is the most commonly used. But there are four primary methods of metal transfer possible with GMAW:

- Short-circuiting

- Globular

- Spray

- Pulsed-spray

The metal transfer mode depends on the wire feed speed, the voltage setting, and the shielding gas.

Read more on transfer modes here.

MIG Equipment

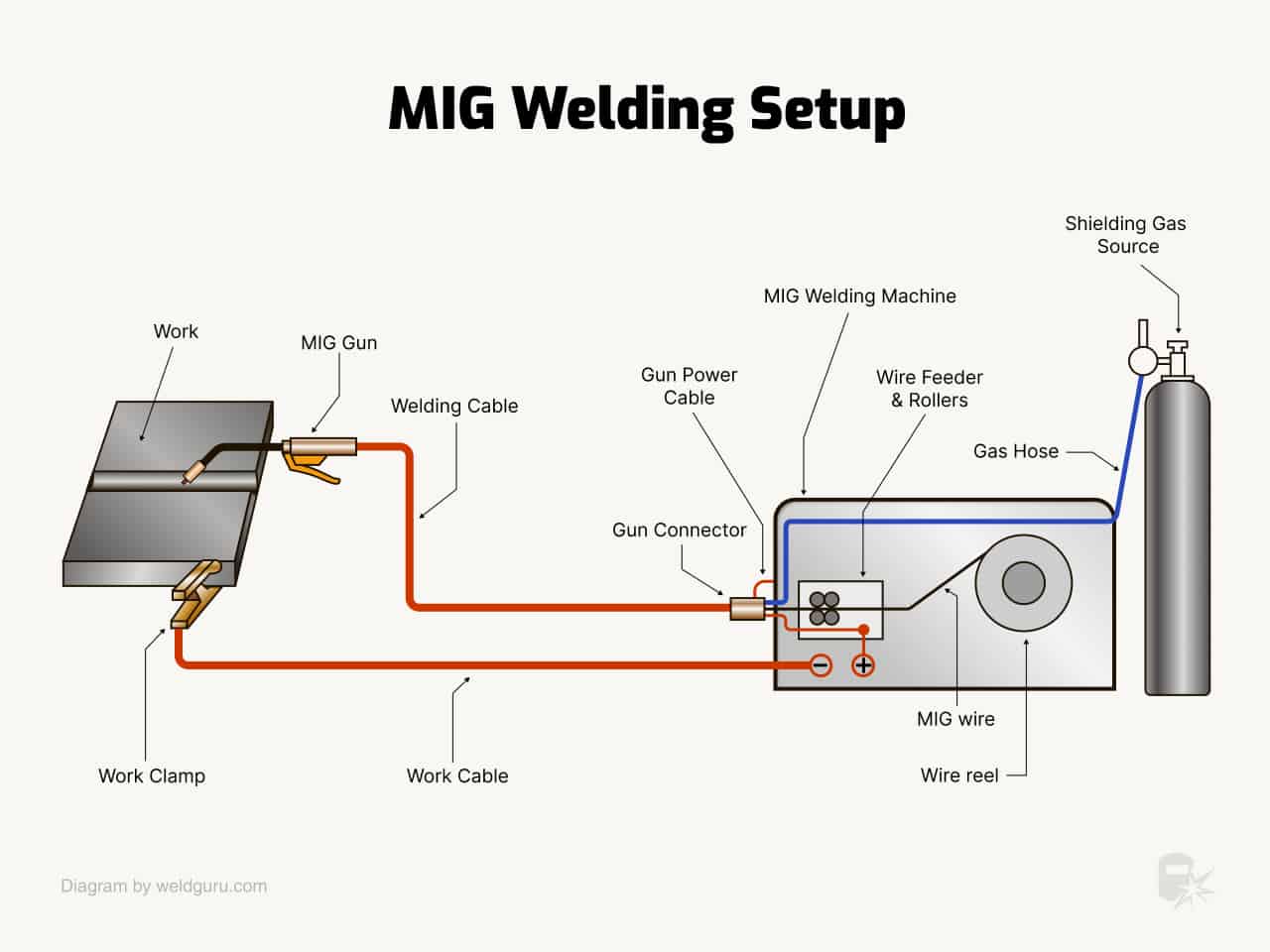

The minimum equipment needed for a typical GMAW setup includes a MIG welding machine, a power source, a shielding gas cylinder, a consumable MIG wire, a welding gun, and a ground clamp, also known as the work clamp.

Wear basic safety equipment such as a welding helmet to protect the eyes and face and welding gloves to protect hands from hot weld spatter.

The Shielding Gas

While the shielding gas protects the weld pool from atmospheric contamination, it’s imperative to understand how different shielding gasses affect the resulting weld.

There are two classifications for shielding gasses:

- Active gasses like carbon dioxide (“CO2”) and oxygen (“O2”)

- Inert gasses like argon (“Ar”) and helium (“He”)

Technically, MIG welding requires the use of inert gas only. That’s why people call the process “metal inert gas” welding.

If the shielding gas mixture contains active gasses, the name switches to “metal active gas” welding, or MAG for short. But most people call both approaches MIG welding because there isn’t a distinctive difference.

Read more: MIG vs. MAG Welding

Active gasses influence the weld pool, spatter amount, and penetration depth. Inert gasses don’t interact with the welded metal.

However, inert gasses also modify the welding characteristics to an extent. For example, helium is inert but improves heat input, penetration, and travel speed.

Usually, MIG welding carbon steel requires a mix of 75% argon and 25% CO2. It’s also possible to MIG weld mild steel with 100% CO2 to achieve better penetration. But welding aluminum requires 100% argon or an Ar/He mixture.

You can learn more about MIG welding shielding gasses here.

Where is MIG Welding Used?

Various industries use MIG welding, from vehicle manufacturing to construction and general fabrication.

It’s easy to master and provides one of the highest production rates of all manual arc welding methods. Therefore, professionals and hobbyists use MIG welding often.

MIG welding is the most common metal joining method in industrial applications since it’s easy to automate and has a high degree of flexibility. Most manufacturing plants use the MIG process to perform more than 50% of their welded joints.

The most common MIG welding applications include:

- Cars and other vehicles often use automated (”robotic”) MIG welds during assembly, but autobody repair happens manually. Most automotive shops use the MIG welding process.

- Manufacturing plants use MIG welding to join sheet metal and various metal sections.

- The construction industry depends on welding small and large load-bearing elements like steel beams and columns. MIG welding offers the necessary speed in quick-paced construction environments.

- Pipe welders often use the MIG welding process in the oil and gas industry and for infrastructure projects to join pipes.

- General repair is faster and more efficient with the GMAW. But, TIG welding is better suited for repair jobs if you need the highest weld quality.

Read more: What is MIG Welding Used For?

What matters most for weekend warriors and individual professionals is how portable and affordable manual MIG welding equipment has become.

MIG welders are easy to set up and often work with a 110V input, making this welding process accessible to anyone just about anywhere.

The ease of use and flexibility make GMAW the go-to choice for most welding applications.

Related: 4 Most Common Welding Processes (MIG, TIG, STICK FCAW)

Pros & Cons of MIG Welding

Advantages of MIG welding:

- Most straightforward arc welding process to master

- Inexpensive equipment

- High welding speed and productivity

- Excellent metal deposition rate

- Works with commonly welded metals

- Weld appearance is better than stick welding

- Supports numerous metal transfer modes, including pulsed MIG welding

- Can weld thin sheet metal

- Offers deep welding penetration for thick materials

- Lower spatter, spark, and smoke emission than stick welding

- Established welding process with lots of experience and information available

- No slag to remove, which minimizes post-weld cleaning

- Works great as a low hydrogen alternative to stick welding

Disadvantages of MIG welding:

- Produces more spatter, sparks, and smoke than TIG welding

- Not usable outdoors in windy conditions because the shielding gas blows away

- The resulting weld appearance isn’t as pleasing as TIG welds

- Requires numerous consumables, meaning replacement tips and gas nozzles need frequent replacement, which makes the process somewhat expensive

- Often requires additional, costly equipment like spool guns or push-pull systems (Note: the MIG welder must have a connection for these specialized guns)

- Fewer functions for arc control compared to TIG welding

- A spool gun to weld aluminum limits the welder to small spool diameters, increasing wire costs since it’s cheaper to buy large spools and requires more frequent reloading

- MIG gun is often challenging to use in hard-to-access corners because of its size

Related read: MIG Welding vs TIG welding

What Equipment Does MIG Welding Use?

To MIG weld, obtain the following equipment:

- MIG welder: A constant voltage power source with an integrated wire feeder. If the welder doesn’t include a wire feeder, have a dedicated machine. Most hobbyist-grade and portable professional welders integrate the wire feeder with the power source.

- MIG gun: Usually comes with the welding machine. But consider the duty cycle rating of the MIG gun. For example, a hobbyist-grade MIG torch rated for a 40% duty cycle at 150A will overheat when welding 1/2-inch thick steel with 250A output. Always aim for a minimum duty cycle of 60% for the amperage range.

- Shielding gas tank: Buy or rent a gas bottle, but buying is better. Read about shielding gas bottle sizes here.

- Shielding gas regulator: Dual-gauge dial regulators are “standard,” but flowmeter regulators offer better readability and reliability.

- MIG welding wire: Gas-shielded arc welding needs a solid MIG wire. Many MIG units can also use a flux-cored wire for FCAW, a different process that doesn’t require a shielding gas.

- Welding helmet: Wear an auto-darkening welding helmet because it makes work easier and more enjoyable than a passive hood.

- Welding gloves: Get a pair of robust and durable leather gloves. MIG welding spatter can cause injuries, so get heavy-duty gloves.

- Welding boots: Never use regular sneakers to weld because the molten slag can melt synthetic materials and burn cloth, creating severe burns. Instead, get a pair of boots certified for welding. Boots with metatarsal guards are the best because they offer additional protection from molten debris.

Careers in MIG Welding (GMAW)

Certified MIG welders can find work in almost every industry since the welding method is widely adopted. Plus, MIG welding is easy to learn, and it only takes a few weeks of training to pass the welding certification tests. So, this is an excellent career for people who love hands-on work.

Almost every manufacturing facility needs certified MIG welders. If bending, shaping, cutting, and MIG welding raw materials sound interesting, a welder fabricator job may sound right. The U.S. national median pay is $44,000, and the most dedicated fabrication welders earn above $75,000 yearly.

Construction ironworkers also need to know how to weld. While this job often relies on stick welding (SMAW), they prefer MIG welding when the welding area guards against wind drafts, and they need high deposition rates.

Creating a welding shop is a great way to build a career based on MIG welding. Shops can repair cars, farm equipment, tools, boilers, and more. Welding shops also contract to fabricate construction parts, or welders can work as a subcontractor for a larger manufacturing facility.

Whatever industry seems most interesting, the chances are high that it has a strong demand for certified MIG welders.

Learning to weld in a recognized welding school like the Tulsa Welding School or Lincoln Electric Welding School will help tremendously. These educational institutions will teach their students well and help them land excellent jobs after graduation.

Quick FAQs

What is MIG welding used for?

MIG welding is commonly used to join metals of various thicknesses, including steel, aluminum, and stainless steel.

It’s often used in automotive repairs, construction, manufacturing, and other industrial applications due to its efficiency, ease of use, and the strong, clean welds it produces.

Its ability to create continuous welds makes MIG welding particularly suitable for projects requiring extended seams or intricate patterns.

What is MIG welding not good for?

MIG welding is less suitable for very thin metals, as it may cause warping. It’s also challenging to use outdoors due to wind interference with the shielding gas.

Other limitations include a lack of precision for artistic welds and the complexity and cost of equipment, making it less practical for small-scale or occasional use.

Is MIG welding good for beginners?

Yes, MIG welding is often considered suitable for beginners due to its forgiving process and easy learning curve. The continuous wire feed and less required manual dexterity make it a popular choice for new welders.

Wrapping It

MIG welding is a widely adopted metal joining method. It’s the least challenging arc welding process to master and provides high welding speeds. As a result, the MIG welding process offers one of the most efficient and productive choices for many applications.

Because the welder feeds the electrode wire automatically, MIG welding equipment is simple to set up and use. Plus, MIG welding machines are more affordable than TIG welders. But GMAW offers fewer features for arc control.

Almost every industry depends on MIG welding. While there are innovative variations of MIG welding, like Fronius’s cold metal transfer (“CMT”), traditional MIG welding will remain the top metal joining method for the foreseeable future.